Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PT BM 183 DC 00008 Preheat Procedure

Caricato da

eldobie3Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PT BM 183 DC 00008 Preheat Procedure

Caricato da

eldobie3Copyright:

Formati disponibili

Code

I.E.M.S.A

PREHEAT

PROCEDURE

UAN (for QMHA)

Page

11-3090

1 of 5

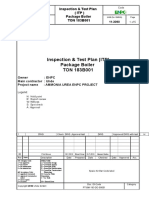

PREHEAT PROCEDURE

Owner

: ENPC

Main contractor : Uhde

Project name

: AMMONIA UREA PROJECT

00

Rev

Status

CC Category Code:

1 = for approval

2 = for review

3 = for information

4 = for internal use

AC Acceptance Code:

1 = approved / reviewed

2 = approved / reviewed as

noted

3 = not accepted

4 = received

First Issue

11/6/2010

Emad Omar

11/6/2010

Hassan Basha

Description

Date

Prepared

Date

Checked

Date

Approved

Acc.

Status Code:

A = Issued for Design

D = Issued for Inquiry

E = Issued for Order

F = Issued for Prefabrication

G = Issued for Construction /

Fabrication

H = Issue for Work

Preparation

I = As- built

M = General Issue

Copyright 2007 Uhde GmbH

Doc. ID-Code

PT-BM-183-DC-00008

Category

1

Code

PREHEAT

PROCEDURE

I.E.M.S.A

CONTENTS

1

2

3

4

5

6

ENPC

UAN (for QMHA)

Page

11-3090

2 of 5

PAGE

3

3

3

3

4

5

Purpose

Scope

Reference

Method & Equipment

Preheat preparation

Documentation

1- Purpose:

Copyright 2007 Uhde GmbH

Doc. ID-Code

PT-BM-183-DC-00008

Rev.

00

Code

I.E.M.S.A

PREHEAT

PROCEDURE

ENPC

UAN (for QMHA)

Page

11-3090

3 of 5

The purpose of this procedure is to define the practices and controls to adopt the

Preheating activities for piping .

2- Scope:

This procedure provides requirements for local preheat before and while welding

joints in piping. The preheating shall be performed when required by the Welding

Procedure Specification (depending on the material type, thickness, and service

conditions)

3- References:

UD-BM-G00-EC-00016 . ESD-Y4 Pipe Welding on site and the applicable WPS.

Welding & weld examination of metallic piping (UN 9253-06 Part 1)

List of fluids scope & post weld heat treatment (PWHT) ESD Y5

Preheating before cutting by flame (Oxypropane or Oxyacetylene)

4- Method & Equipment

Preheating is carried out using soft flame torches or gas burners or electrical

resistances with automatic or manually operated calibrated machines rated 45

or higher kVA, 3 phase 380V at 50 Hz with 3 to 6 channels. (according to joint

dimensions and type of base metals)

The heating elements shall be flexible ceramic pad heaters capable to with

stand 1000C with multi-stranded Ni-Cr electrically insulated element wire rated

at 30 to 80V. The cold wire shall be Ni or Ni-Cu wire.

Calibrated recorders shall have a range of 0 to 1000C minimum, inlets for 6

minimum type K thermocouples (TC), capable to accommodate charts at least

150 mm wide and with variable chart speed regulator.

Insulation shall be provided by ceramic fiber mats (stainless steel or Nickel alloy

wire mesh cover) 25 mm thick approximately and with minimum density of 64

Kg/m. When mineral wool is used, thickness shall be approximately doubled.

Measuring thermocouple TC type "K", NI-CHR/NI-AL

Copyright 2007 Uhde GmbH

Doc. ID-Code

PT-BM-183-DC-00008

Rev.

00

Code

PREHEAT

PROCEDURE

I.E.M.S.A

ENPC

UAN (for QMHA)

Page

11-3090

4 of 5

5- Preheat preparation

Heating of the material before and after welding shall be performed by means of

adjustable electric heating elements or by flame torches or gas burners (according

to joint dimensions and type of base metals)

The heating elements shall be arranged on both sides of the weld according to Figure 1.

In order to allow for the required grinding work, the spacing "A" should be approximately

100 mm.

The heat loss which depends on the wall thickness and the spacing of the heating

elements may be controlled by applying or removing insulation material in the area of the

weld.

The outer surfaces of the heating elements shall be provided with heat insulation to avoid

heat losses, and to protect the welder from excessive heat radiation during preheating.

The area between the heating elements shall be covered with ceramic fiber fabric.

The power supply of the heating elements must not be covered with the insulation to

avoid damage of the power cables.

Insulation

Insulation

M1

Thermocouple wire

50mm

Joint gap

Heat elements

Power cable

M2

50mm

Heat affected zone

Figure 1: Arrangement of heating elements

Preheating of the material up to the welding temperature shall be controlled by a number

of measuring points (See table no. 1) by suitable measuring instruments. Thermal stick,

Contact thermometers, infrared measuring instruments, or thermocouples are permitted

for this purpose. Measured temperatures shall be recorded.

If thermocouples have to be used, the thermocouple wires shall be tack welded at both

sides (MI, M2) of the joint by means of a spot-welding device, in each case in the 6

o'clock and 12 o'clock position. Prior to tack welding, the measuring points shall be locally

preheated according to table 1, The measuring points MI and M2 shall be arranged

according to Figure 1

The specified temperature shall be maintained during welding and checked with the aid of

thermochrome crayons, surface thermometers or thermocouples.

Copyright 2007 Uhde GmbH

Doc. ID-Code

PT-BM-183-DC-00008

Rev.

00

Code

PREHEAT

PROCEDURE

I.E.M.S.A

Material

Dim

(DN)

< 50

X10 Cr Mo VNb

9-1

>50<3

00

>300

< 50

X20 Cr Mo V

12-1

>50<3

00

>300

Preheating

temp.

Interpass temp.

(Max.)

180OC200OC

180OC200OC

180OC200OC

230OC250OC

230OC250OC

230OC250OC

300-320OC

<100

>100<

200

13 Cr Mo 4-5

>200<

900

>900

< 30 mm

thk. =

150OC

> 30 mm

thk. =

200OC

ENPC

11-3090

5 of 5

2 TC

4 TC

300-320 C

6 TC

250-300OC

2 TC

4 TC

250-300 C

6 TC

300 OC

NA

300 OC

NA

300 OC

NA

300 OC

NA

250-300 C

Page

No. Of thermocouple

Location

Preheat

300-320 C

UAN (for QMHA)

See Figure 1

6- DOCUMENTATION:

Preheating Chart in the case of using adjustable electric heating elements

Copyright 2007 Uhde GmbH

Doc. ID-Code

PT-BM-183-DC-00008

Rev.

00

Potrebbero piacerti anche

- PT BM 183 DC 00007 PWHT ProcedureDocumento7 paginePT BM 183 DC 00007 PWHT Procedureeldobie3100% (1)

- Jpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Documento9 pagineJpghrsghrb-905 (PWHT Procedure, Asme) Rev.0Anoop N Kutty100% (1)

- PWHT Procedure A2Documento15 paginePWHT Procedure A2Raja Thakur100% (4)

- MIZAT PWHT Procedure Ensures Welded Joints Meet StandardsDocumento9 pagineMIZAT PWHT Procedure Ensures Welded Joints Meet StandardsM. R. Shahnawaz KhanNessuna valutazione finora

- PWHT ProcedureDocumento10 paginePWHT ProcedureSang Nguyen QuangNessuna valutazione finora

- Pro PWHT 006 Rev 1 - Procedure For PWHTDocumento6 paginePro PWHT 006 Rev 1 - Procedure For PWHTsugumar100% (1)

- Amigos Technical PWHT ProcedureDocumento12 pagineAmigos Technical PWHT Procedurevsnaiduqc50% (2)

- PWHT Procedure PDFDocumento9 paginePWHT Procedure PDFAbhishek AnandNessuna valutazione finora

- PWHT Procedure for Boiler OverhaulDocumento10 paginePWHT Procedure for Boiler OverhaulDedy Trianda100% (1)

- PWHT Procedure For Petrol Steel - CoreDocumento9 paginePWHT Procedure For Petrol Steel - CoreSuleyman HaliciogluNessuna valutazione finora

- Sahid PWHT ProcedureDocumento16 pagineSahid PWHT ProcedurebaNessuna valutazione finora

- PT NDT ProcedureDocumento5 paginePT NDT ProcedureMohamed AbubackerNessuna valutazione finora

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Documento2 pagineLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNessuna valutazione finora

- Welder Performace Qualification Report 2014..Documento132 pagineWelder Performace Qualification Report 2014..Kayra Riri ChirulNessuna valutazione finora

- 10 Procedure For PWHT PDFDocumento5 pagine10 Procedure For PWHT PDFeghashangzadeh100% (1)

- Welder IdentificationDocumento9 pagineWelder Identificationdandiar1Nessuna valutazione finora

- Welder Qualification Test Record for NDBDocumento1 paginaWelder Qualification Test Record for NDBAli HammoudaNessuna valutazione finora

- Iqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlDocumento1 paginaIqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlAjayNessuna valutazione finora

- UT Report FormDocumento1 paginaUT Report FormElisha NguyenNessuna valutazione finora

- Wps Model 2 PDFDocumento17 pagineWps Model 2 PDFbeyNessuna valutazione finora

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Documento2 pagineWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangNessuna valutazione finora

- Welding Procecure SpecificationDocumento9 pagineWelding Procecure SpecificationNwoha PeterNessuna valutazione finora

- Welding Procedure Specification: Page 1 of 1Documento2 pagineWelding Procedure Specification: Page 1 of 1Anderson Perez MartinezNessuna valutazione finora

- JIMT Visual Inspection ReportDocumento1.913 pagineJIMT Visual Inspection Reportgomathyselvi100% (1)

- Post Weld Heat Treatment ProcedureDocumento15 paginePost Weld Heat Treatment ProcedureSamer Bayati100% (1)

- Asme PQR DemoDocumento3 pagineAsme PQR DemoMuthusamy AyyanapillaiNessuna valutazione finora

- Welder Visual Inspection ReportsDocumento24 pagineWelder Visual Inspection ReportsKyNessuna valutazione finora

- Dep 30.10.60.32 - Welding of Metals, Based On Iso StandardsDocumento76 pagineDep 30.10.60.32 - Welding of Metals, Based On Iso StandardsPablo PazNessuna valutazione finora

- Differences between Welding Procedure Specification and Welder Performance QualificationDocumento1 paginaDifferences between Welding Procedure Specification and Welder Performance QualificationFazeel Rick MohammedNessuna valutazione finora

- Welding Inspector Job and ResponsilbilitiesDocumento5 pagineWelding Inspector Job and ResponsilbilitiesFelix GomintongNessuna valutazione finora

- WFP 2-01 ASME B31 Piping Welding ProcedureDocumento8 pagineWFP 2-01 ASME B31 Piping Welding Procedureleodavid87Nessuna valutazione finora

- 4) RT-EQ-P-03 - Control of NDT Equipments and ConsumablesDocumento6 pagine4) RT-EQ-P-03 - Control of NDT Equipments and ConsumablesMOHD AZMIL AMIN BIN MOHAMAD STUDENT100% (1)

- Qualified Welder List Valid Until - 03-12-2019Documento2 pagineQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- Weld ShrinkageDocumento16 pagineWeld ShrinkageWeff JingNessuna valutazione finora

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocumento31 pagineALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNessuna valutazione finora

- Exhibit No.34 - Welding Consumables Receiving Inspection RecordDocumento1 paginaExhibit No.34 - Welding Consumables Receiving Inspection RecordMohammed KamalNessuna valutazione finora

- Piping WpsDocumento37 paginePiping WpsZulfokar FahdawiNessuna valutazione finora

- Sample Wps-Carbon Steel GTAW+SMAWDocumento2 pagineSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- MEENA Internation NDT TrainingDocumento45 pagineMEENA Internation NDT Trainingahmzahid100% (1)

- Hot Tap ReportDocumento2 pagineHot Tap ReportCak NhassNessuna valutazione finora

- 10 Procedure For PWHTDocumento5 pagine10 Procedure For PWHTSachin S. SalunkheNessuna valutazione finora

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Documento3 pagineHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNessuna valutazione finora

- Welding Report For Tank 1Documento1 paginaWelding Report For Tank 1Rifki HasyaNessuna valutazione finora

- Welding Procedure SpecificationDocumento3 pagineWelding Procedure SpecificationAhmed saber100% (1)

- Welding Proposed Pwps For Our Jubail WorkDocumento2 pagineWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Fit Up Welding Visual Inspection ReportDocumento2 pagineFit Up Welding Visual Inspection Reportmohd as shahiddin jafriNessuna valutazione finora

- Welder qualification test recordDocumento3 pagineWelder qualification test recordTuTuy AnNessuna valutazione finora

- Dye Penetrant ProcedureDocumento7 pagineDye Penetrant Procedurezaki fadl100% (1)

- Madina Group W.L.L. Procedure Qualification Record 152Documento38 pagineMadina Group W.L.L. Procedure Qualification Record 152MAT-LIONNessuna valutazione finora

- PT Kuwera Karya Me: PanduDocumento2 paginePT Kuwera Karya Me: PanduGalang Pratama PutraNessuna valutazione finora

- Method Statement For Welding RepairDocumento7 pagineMethod Statement For Welding RepairHarun AkkayaNessuna valutazione finora

- Electrode Handling Procedure - Simple - SMAWDocumento7 pagineElectrode Handling Procedure - Simple - SMAWGalih Suksmono Adi0% (1)

- Fit Up Welding Visual Inspection ReportDocumento2 pagineFit Up Welding Visual Inspection Reportgst ajah100% (1)

- Magnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiDocumento1 paginaMagnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiMurugan RajaNessuna valutazione finora

- Fit Up ReportDocumento5 pagineFit Up ReportAkash Singh Tomar100% (1)

- Industrial radiography A Complete Guide - 2019 EditionDa EverandIndustrial radiography A Complete Guide - 2019 EditionNessuna valutazione finora

- 3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFDocumento11 pagine3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFManoj Balla100% (1)

- POST WELD HEAT TREATMENT PROCEDUREDocumento8 paginePOST WELD HEAT TREATMENT PROCEDUREM. R. Shahnawaz KhanNessuna valutazione finora

- PWHT ProcedureDocumento8 paginePWHT ProcedureTuesou MachereNessuna valutazione finora

- PWHT ProcedureDocumento10 paginePWHT ProcedureMohammed Kamal100% (11)

- Method of Statement For Hydro Test ProcedureDocumento11 pagineMethod of Statement For Hydro Test Procedureeldobie3Nessuna valutazione finora

- Pene Trant Removal ProcessDocumento3 paginePene Trant Removal Processeldobie3Nessuna valutazione finora

- NDE PROCESS CONTROL Rev 1Documento15 pagineNDE PROCESS CONTROL Rev 1eldobie3Nessuna valutazione finora

- Ogpd-Lrf-Tr-00336 Tie-In Procedure ApproveDocumento2 pagineOgpd-Lrf-Tr-00336 Tie-In Procedure Approveeldobie3Nessuna valutazione finora

- Pene Trant Testing MaterialsDocumento3 paginePene Trant Testing Materialseldobie3Nessuna valutazione finora

- Emulsifier SDocumento2 pagineEmulsifier Seldobie3Nessuna valutazione finora

- Preparing Parts for Penetrant InspectionDocumento2 paginePreparing Parts for Penetrant Inspectioneldobie3Nessuna valutazione finora

- Nature of The DefectDocumento3 pagineNature of The Defecteldobie3Nessuna valutazione finora

- Process Control of TemperatureDocumento1 paginaProcess Control of Temperatureeldobie3Nessuna valutazione finora

- Density or Specific GravityDocumento1 paginaDensity or Specific Gravityeldobie3Nessuna valutazione finora

- Pen Et RantsDocumento1 paginaPen Et Rantseldobie3Nessuna valutazione finora

- Introduction and History of Penetrant Inspection: Capillary ActionDocumento1 paginaIntroduction and History of Penetrant Inspection: Capillary Actioneldobie3Nessuna valutazione finora

- PT BM 183 DC 00006 Ut ProcedureDocumento6 paginePT BM 183 DC 00006 Ut Procedureeldobie3Nessuna valutazione finora

- Developers: Developer FormsDocumento3 pagineDevelopers: Developer Formseldobie3Nessuna valutazione finora

- Common Uses of Liquid Pene Trant InspectionDocumento2 pagineCommon Uses of Liquid Pene Trant Inspectioneldobie3Nessuna valutazione finora

- PT BM 183 DC 00005 VT ProcedureDocumento6 paginePT BM 183 DC 00005 VT Procedureeldobie3Nessuna valutazione finora

- Dimensional Threshold of FluorescenceDocumento2 pagineDimensional Threshold of Fluorescenceeldobie3Nessuna valutazione finora

- Pt-bm-183-Dc-00009 Welding Consumable Handling & StorageDocumento6 paginePt-bm-183-Dc-00009 Welding Consumable Handling & Storageeldobie3Nessuna valutazione finora

- Common Uses of Liquid Pene Trant InspectionDocumento2 pagineCommon Uses of Liquid Pene Trant Inspectioneldobie3Nessuna valutazione finora

- Color and Fluorescent BrightnessDocumento2 pagineColor and Fluorescent Brightnesseldobie3Nessuna valutazione finora

- PT BM 183 DC 00004 RT ProcedureDocumento6 paginePT BM 183 DC 00004 RT Procedureeldobie3Nessuna valutazione finora

- PT BM 183 DC 00001 Itp BoilerDocumento5 paginePT BM 183 DC 00001 Itp Boilereldobie30% (1)

- PT BM 183 DC 00002 MT ProcedureDocumento7 paginePT BM 183 DC 00002 MT Procedureeldobie3Nessuna valutazione finora

- PT BM 183 DC 00003 PT ProcedureDocumento6 paginePT BM 183 DC 00003 PT Procedureeldobie3Nessuna valutazione finora

- API 510 PC Mid Session Exam Open Book Attempt SheetDocumento1 paginaAPI 510 PC Mid Session Exam Open Book Attempt Sheeteldobie3Nessuna valutazione finora

- API 510 PC Final Exam Closed Book Attempt SheetDocumento1 paginaAPI 510 PC Final Exam Closed Book Attempt Sheeteldobie3Nessuna valutazione finora

- API 510 PC 20 31 Aug05 Final Open AnswerDocumento1 paginaAPI 510 PC 20 31 Aug05 Final Open Answereldobie3Nessuna valutazione finora

- API 510 PC Final Exam ClosedDocumento12 pagineAPI 510 PC Final Exam ClosedAbdel-Rahman Taha Merdan100% (1)

- PT. NURMAN MITRA SENTOSA HSE REPORTDocumento4 paginePT. NURMAN MITRA SENTOSA HSE REPORTSigit WiyonoNessuna valutazione finora

- History UNIT 2 Class NotesDocumento15 pagineHistory UNIT 2 Class NotesVANSHIKA CHAUDHARYNessuna valutazione finora

- Ecg EkgDocumento3 pagineEcg EkgrochimNessuna valutazione finora

- Cummins 6cta8.3 Engine Spare Parts CatalogDocumento11 pagineCummins 6cta8.3 Engine Spare Parts CatalogChen CarolineNessuna valutazione finora

- Career Interest Inventory HandoutDocumento2 pagineCareer Interest Inventory HandoutfernangogetitNessuna valutazione finora

- Electric Bike ReportDocumento33 pagineElectric Bike ReportGautham M A100% (1)

- Cultural Impacts of Tourism in VietnamDocumento4 pagineCultural Impacts of Tourism in VietnamBùi Thanh Ngọc BíchNessuna valutazione finora

- Manila Bay accretion disputeDocumento24 pagineManila Bay accretion disputeRoman KushpatrovNessuna valutazione finora

- CePSWaM Training Report FormatDocumento11 pagineCePSWaM Training Report FormatKelvin29% (7)

- Citizen PTR Receipt (2023-2024)Documento1 paginaCitizen PTR Receipt (2023-2024)AnmolBansalNessuna valutazione finora

- Defect Life Cycle or A Bug Lifecycle in Software TestingDocumento6 pagineDefect Life Cycle or A Bug Lifecycle in Software TestingKrish KumarNessuna valutazione finora

- Unit 2 - Professional Ethics & Code of ConductDocumento97 pagineUnit 2 - Professional Ethics & Code of ConductPradiba Raajkumaar25% (4)

- DAU Program Managers ToolkitDocumento157 pagineDAU Program Managers ToolkitMuzafar Shah Mosam ShahNessuna valutazione finora

- LM - Top Voicemail HacksDocumento5 pagineLM - Top Voicemail HacksMaksi UnairNessuna valutazione finora

- Division 8 Doors and Windows: Group 3Documento22 pagineDivision 8 Doors and Windows: Group 3Alen Ybanez100% (2)

- Deposit SlipDocumento1 paginaDeposit SlipMansoor RaoNessuna valutazione finora

- Magnetic Separator GuideDocumento31 pagineMagnetic Separator GuideMNButt100% (1)

- Items in The Classroom: Words)Documento2 pagineItems in The Classroom: Words)Alan MartínezNessuna valutazione finora

- Cybercrime Prevention Act of 2012Documento1 paginaCybercrime Prevention Act of 2012Jerwin LadioNessuna valutazione finora

- Cambridge English For The Media Intermediate Students Book With Audio CD Frontmatter PDFDocumento5 pagineCambridge English For The Media Intermediate Students Book With Audio CD Frontmatter PDFBrenda Funes67% (3)

- UAE HealthcareDocumento15 pagineUAE HealthcareUmaira UsmanNessuna valutazione finora

- R 245Documento2 pagineR 245Ravi RanjanNessuna valutazione finora

- EUA 105 Pfizer Paxlovid FS For HCPs 05242023 - 0Documento41 pagineEUA 105 Pfizer Paxlovid FS For HCPs 05242023 - 0bachillerataNessuna valutazione finora

- Joint Operations Doctrine Core PublicationDocumento182 pagineJoint Operations Doctrine Core Publicationfredscout76100% (2)

- Prospectus Ph.D. July 2021 SessionDocumento5 pagineProspectus Ph.D. July 2021 SessiondamadolNessuna valutazione finora

- Eco System and Green Logistics BasicsDocumento32 pagineEco System and Green Logistics BasicsBudmed GanbaatarNessuna valutazione finora

- Model MRP: Samsung B7620Documento19 pagineModel MRP: Samsung B7620Rajni MenonNessuna valutazione finora

- The Evolution of B2B Sales: Trends and TransformationsDocumento14 pagineThe Evolution of B2B Sales: Trends and TransformationsSayed Faraz Ali ShahNessuna valutazione finora

- Vlan Irtual: V LANDocumento35 pagineVlan Irtual: V LANHansa JhaNessuna valutazione finora