Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Orrosion: Notes Post Fabrication Cleaning

Caricato da

ippon_osoto0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

25 visualizzazioni1 paginaPost fabrication cleaning is essential for stainless steel to perform well in its intended environment. Fabrication defects like arc strikes, weld spatter, scratches and gouges must be completely removed from all surfaces after fabrication through heavy cleaning methods like blasting, power brushing, pickling or electropolishing. Pickling for cleaning stainless steel is covered by ASTM standard A380.

Descrizione originale:

Info on post-fab cleaning

Titolo originale

Post Fabrication Cleaning

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoPost fabrication cleaning is essential for stainless steel to perform well in its intended environment. Fabrication defects like arc strikes, weld spatter, scratches and gouges must be completely removed from all surfaces after fabrication through heavy cleaning methods like blasting, power brushing, pickling or electropolishing. Pickling for cleaning stainless steel is covered by ASTM standard A380.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

25 visualizzazioni1 paginaOrrosion: Notes Post Fabrication Cleaning

Caricato da

ippon_osotoPost fabrication cleaning is essential for stainless steel to perform well in its intended environment. Fabrication defects like arc strikes, weld spatter, scratches and gouges must be completely removed from all surfaces after fabrication through heavy cleaning methods like blasting, power brushing, pickling or electropolishing. Pickling for cleaning stainless steel is covered by ASTM standard A380.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

20.

CORROSION

20.4

NOTES

POST FABRICATION CLEANING

Most of the commonly encountered corrosion problems, in environments

where that grade of stainless steel normally performs well, can be traced

to incomplete or inadequate cleaning of the surface following fabrication.

For best performance, it is essential to prevent or remove all fabrication

related defects, such as arc strikes, weld spatter, scratches, gouges, heat tint

scale, and embedded iron from all wetted surfaces after fabrication.The

heavy cleaning required after fabrication may be done by blasting with

various abrasives, by power brushing with aluminum oxide discs or

flapper wheels, by pickling or by electropolishing.

Pickling is covered in ASTM A380, Standard Practice for Cleaning,

Descaling and Passivation of Stainless Steel Parts, Equipment and

SystemsTable A2.1 Part 1.

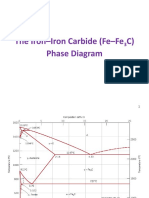

Figure 20-1 Effect of Carbon on Carbide Precipitation

F

C

900

1600

0.080

0.062

800

0.052

1400

700

1200

0.042

0.030

600

0.019%

Carbon

1000

500

800

10 sec. 1 min.

10 min.

1 hr.

10 hrs.

100 hrs.

1000 hrs.

10,000 hrs

Time-Temperature-Sensitization Curves

Time required for formation of carbide precipitation in stainless steels with various carbon contents.

Carbide precipitation forms in the areas to the right of the various carbon-content curves. Within

time-periods applicable to welding, chromium-nickel stainless steels with 0.05% carbon would be

quite free from grain boundary precipitation.

Stainless Steels and Specialty Alloys for Pulp and Paper

136

Potrebbero piacerti anche

- Advances in Solid Oxide Fuel Cells XDa EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNessuna valutazione finora

- AAA Passivation MethodsDocumento7 pagineAAA Passivation Methodsdianita nurnandaNessuna valutazione finora

- How To Passivate Stainless Steel PartsDocumento11 pagineHow To Passivate Stainless Steel Partsnqh2009Nessuna valutazione finora

- SS PassivationDocumento47 pagineSS PassivationSaid Alauddeen FaiszNessuna valutazione finora

- 05a - Appendix1-Tech Spec3 - Ts - Mech & PipingDocumento4 pagine05a - Appendix1-Tech Spec3 - Ts - Mech & PipingMuthazhagan SaravananNessuna valutazione finora

- FabricationDocumento9 pagineFabricationAnilkumar HatkarNessuna valutazione finora

- Process Specification For Pickling, Etching, and Descaling of MetalsDocumento10 pagineProcess Specification For Pickling, Etching, and Descaling of MetalsGys100% (1)

- PassivationDocumento8 paginePassivationhrsreenath100% (1)

- Alloy 625 Spec SheetDocumento3 pagineAlloy 625 Spec SheetLinnie McleodNessuna valutazione finora

- Pickling HandbookDocumento20 paginePickling HandbookRhona100% (1)

- Zero Defect Strategy Download 17-11-09Documento9 pagineZero Defect Strategy Download 17-11-09Jagadeesh NandamNessuna valutazione finora

- Astm-B600-2011-Reapproved-2017 (Standard Guide For Descaling and Cleaning Titanium and Titanium Alloy Surfaces)Documento5 pagineAstm-B600-2011-Reapproved-2017 (Standard Guide For Descaling and Cleaning Titanium and Titanium Alloy Surfaces)adamos.georgiosNessuna valutazione finora

- Suggested Fabrication Procedures For 20Cb-3® (Alloy 20) Stainless UNS N08020 PDFDocumento55 pagineSuggested Fabrication Procedures For 20Cb-3® (Alloy 20) Stainless UNS N08020 PDFWhoNessuna valutazione finora

- Summer Training ReportDocumento8 pagineSummer Training ReportshivamcanNessuna valutazione finora

- Providing High-Quality Zinc Coatings (Hot-Dip) : Standard Practice ForDocumento8 pagineProviding High-Quality Zinc Coatings (Hot-Dip) : Standard Practice ForIsraelNessuna valutazione finora

- Pickling and PassivationDocumento2 paginePickling and PassivationKalpesh JainNessuna valutazione finora

- Metal Sun ShadesDocumento7 pagineMetal Sun ShadesDanaya AstreroNessuna valutazione finora

- How To Passivate Stainless Steel PartsDocumento8 pagineHow To Passivate Stainless Steel PartsAFLAC ............Nessuna valutazione finora

- ALLOY-20 - FI - US - EN Very Good All AboutDocumento55 pagineALLOY-20 - FI - US - EN Very Good All Aboutmahmoud_allam3Nessuna valutazione finora

- Surface Preparation For Coating (Blasting)Documento11 pagineSurface Preparation For Coating (Blasting)Prabath MadusankaNessuna valutazione finora

- 2 Aluminium Fusion Welding 2015Documento21 pagine2 Aluminium Fusion Welding 2015Tuyen Nguyen100% (1)

- Introduction To Brazing of Aluminium Alloys: TALAT Lecture 4601Documento24 pagineIntroduction To Brazing of Aluminium Alloys: TALAT Lecture 4601fedeloquiNessuna valutazione finora

- Ab0cd: Sub-Sectoral Environmental and Social Guidelines: Ferrous Metal ProcessingDocumento13 pagineAb0cd: Sub-Sectoral Environmental and Social Guidelines: Ferrous Metal Processinganpuselvi125Nessuna valutazione finora

- Pickling HandbookDocumento20 paginePickling HandbookCuteAssadNessuna valutazione finora

- BS 4568Documento7 pagineBS 4568minjutNessuna valutazione finora

- 304 Chromic Acid AnodizingDocumento6 pagine304 Chromic Acid AnodizingPuguh Cahpordjo BaeNessuna valutazione finora

- Ma KemDocumento20 pagineMa KemVan Hien LeNessuna valutazione finora

- ASSDA - Pickling and PassivationDocumento2 pagineASSDA - Pickling and Passivationippon_osotoNessuna valutazione finora

- En 24Documento1 paginaEn 24V. A. TripathiNessuna valutazione finora

- Corus - A Corrosion Protection GuideDocumento6 pagineCorus - A Corrosion Protection GuideBellana SirishNessuna valutazione finora

- Cold Rolled 2010 DUNAFER HungriaDocumento12 pagineCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNessuna valutazione finora

- JazeeraDocumento38 pagineJazeeraaegon1510Nessuna valutazione finora

- Hard Chrome PlatingDocumento1 paginaHard Chrome PlatingKishora BhatNessuna valutazione finora

- Surface PreparationDocumento15 pagineSurface PreparationsawwahwahNessuna valutazione finora

- Material PropertiesDocumento16 pagineMaterial PropertiesMadan Kulkarni100% (1)

- Polythionic Acid CorrosionDocumento4 paginePolythionic Acid Corrosion최승원Nessuna valutazione finora

- Alloy Steel Astm A217 Grade Wc6 1Documento1 paginaAlloy Steel Astm A217 Grade Wc6 1didi sudiNessuna valutazione finora

- Investigation of Refractory Concrete Failure in Furnaces of Metals IndustryDocumento8 pagineInvestigation of Refractory Concrete Failure in Furnaces of Metals IndustryAditya PrajasNessuna valutazione finora

- Chapter4 PDFDocumento20 pagineChapter4 PDFshaik jaheerNessuna valutazione finora

- Userguide For SSDocumento26 pagineUserguide For SSehsan4uNessuna valutazione finora

- Zinc Nickel Plating: Platings & Coatings For IndustryDocumento1 paginaZinc Nickel Plating: Platings & Coatings For IndustryyağmurNessuna valutazione finora

- Application Notes Titanium EnglishDocumento6 pagineApplication Notes Titanium EnglishXEFTAXNessuna valutazione finora

- HDG DefectDocumento45 pagineHDG DefectjasminneeNessuna valutazione finora

- Presented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaDocumento6 paginePresented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaRahul MoottolikandyNessuna valutazione finora

- Standards R M Salem - UserguideDocumento49 pagineStandards R M Salem - Userguidearunas1081Nessuna valutazione finora

- AMS 2418 H Copper PlatingDocumento8 pagineAMS 2418 H Copper PlatingJesse Krebs67% (3)

- EN24 Steel PropertiesDocumento1 paginaEN24 Steel Propertieskanha15102003100% (1)

- Sae Ams 4345C-2018Documento8 pagineSae Ams 4345C-2018Hani YilmazNessuna valutazione finora

- Manufacture of Lead Processing KettlesDocumento7 pagineManufacture of Lead Processing Kettlesdanny2kNessuna valutazione finora

- 1 SS PP 042Documento16 pagine1 SS PP 042SURAJ PRSADNessuna valutazione finora

- Standard Practice For Preparation of Cold-Rolled Steel Panels For Testing Paint, Varnish, Conversion Coatings, and Related Coating ProductsDocumento3 pagineStandard Practice For Preparation of Cold-Rolled Steel Panels For Testing Paint, Varnish, Conversion Coatings, and Related Coating Productsjgómez_510704Nessuna valutazione finora

- Aluminum Alloy Sand Casting Edition 7Documento2 pagineAluminum Alloy Sand Casting Edition 7Ganesh SonawaneNessuna valutazione finora

- Inspection of The Hot Dipped Galvanizing ProcessDocumento5 pagineInspection of The Hot Dipped Galvanizing ProcessIrinaNessuna valutazione finora

- Advances in Ceramic Armor XDa EverandAdvances in Ceramic Armor XJerry C. LaSalviaNessuna valutazione finora

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkDa EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNessuna valutazione finora

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDa EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNessuna valutazione finora

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDa EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNessuna valutazione finora

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- Spot Welding Interview Success: An Introduction to Spot WeldingDa EverandSpot Welding Interview Success: An Introduction to Spot WeldingNessuna valutazione finora

- Wi Application FormDocumento2 pagineWi Application Formippon_osotoNessuna valutazione finora

- Cqi Certificate in Quality Management: Frequently Asked Questions (Faqs) ForDocumento4 pagineCqi Certificate in Quality Management: Frequently Asked Questions (Faqs) Forippon_osotoNessuna valutazione finora

- Continuing Professional Development: Steps of CPDDocumento1 paginaContinuing Professional Development: Steps of CPDippon_osoto100% (1)

- Sample Arc StrikeDocumento1 paginaSample Arc Strikeippon_osotoNessuna valutazione finora

- BSI Diploma in Quality Management Systems BSI Training Sales Flyer UK enDocumento2 pagineBSI Diploma in Quality Management Systems BSI Training Sales Flyer UK enippon_osotoNessuna valutazione finora

- CQE Fact SheetDocumento2 pagineCQE Fact Sheetippon_osotoNessuna valutazione finora

- Purgeye Api100 LFT A3-Web-PDocumento4 paginePurgeye Api100 LFT A3-Web-Pippon_osotoNessuna valutazione finora

- Pages From SAES W 012Documento1 paginaPages From SAES W 012ippon_osotoNessuna valutazione finora

- FibersparDocumento2 pagineFibersparippon_osotoNessuna valutazione finora

- CQI Training Certificates in QMSDocumento2 pagineCQI Training Certificates in QMSippon_osotoNessuna valutazione finora

- Sample API 1104 WpsDocumento1 paginaSample API 1104 Wpsippon_osoto100% (1)

- AIA Philam Life Request For Extension of Grace PeriodDocumento1 paginaAIA Philam Life Request For Extension of Grace Periodippon_osotoNessuna valutazione finora

- AIA Philam Life Policy Fund Withdrawal FormDocumento2 pagineAIA Philam Life Policy Fund Withdrawal Formippon_osotoNessuna valutazione finora

- WI ComparisonDocumento1 paginaWI Comparisonippon_osotoNessuna valutazione finora

- Surfacing: Plasma Transferred Arc (PTA) PTADocumento1 paginaSurfacing: Plasma Transferred Arc (PTA) PTAippon_osotoNessuna valutazione finora

- PEMI - Redemption Order Form (ROF)Documento1 paginaPEMI - Redemption Order Form (ROF)ippon_osotoNessuna valutazione finora

- Rev 4 January 2013 General Introduction To Welding 1-2Documento1 paginaRev 4 January 2013 General Introduction To Welding 1-2ippon_osotoNessuna valutazione finora

- Single Phase Power SourceDocumento1 paginaSingle Phase Power Sourceippon_osotoNessuna valutazione finora

- Completed WeldDocumento1 paginaCompleted Weldippon_osotoNessuna valutazione finora

- Soldering: Prepared by The Welding Handbook Chapter Committee On Soldering: F. M. Hosking, ChairDocumento1 paginaSoldering: Prepared by The Welding Handbook Chapter Committee On Soldering: F. M. Hosking, Chairippon_osotoNessuna valutazione finora

- Soldering: Prepared by The Welding Handbook Chapter Committee On Soldering: F. M. Hosking, ChairDocumento1 paginaSoldering: Prepared by The Welding Handbook Chapter Committee On Soldering: F. M. Hosking, Chairippon_osotoNessuna valutazione finora

- Transformer Power SourceDocumento1 paginaTransformer Power Sourceippon_osotoNessuna valutazione finora

- SS DiodesDocumento1 paginaSS Diodesippon_osotoNessuna valutazione finora

- 2002 Chem 22002Documento17 pagine2002 Chem 22002SomaNessuna valutazione finora

- Properties of Engineering MaterialsDocumento20 pagineProperties of Engineering MaterialsCHARMAINE DIANNE GRACE CABATA�A FUNA0% (1)

- Chapter 9Documento18 pagineChapter 9roxy8marie8chanNessuna valutazione finora

- 2021 January (1C) QPDocumento36 pagine2021 January (1C) QPKevin MattNessuna valutazione finora

- TalcDocumento2 pagineTalcJoão AndréNessuna valutazione finora

- Precious Metals Refining PracticeDocumento16 paginePrecious Metals Refining Practicerichipc100% (1)

- Integrated Chemistry Problems AnswersDocumento3 pagineIntegrated Chemistry Problems Answersapi-284934591Nessuna valutazione finora

- Fun With Chemistry WorksheetDocumento23 pagineFun With Chemistry WorksheetSaroj ManSingh BasnyatNessuna valutazione finora

- Chapter 3 Assertion-Reason QuestionsDocumento2 pagineChapter 3 Assertion-Reason Questionsteresa tsoiNessuna valutazione finora

- Chemistry Chapter 8.ABakshDocumento10 pagineChemistry Chapter 8.ABakshNaomi JohnsonNessuna valutazione finora

- 1st QTR Review Sparrow ProgramDocumento28 pagine1st QTR Review Sparrow ProgramBernadette PeñaroyoNessuna valutazione finora

- The Iron-Iron Carbide (Fe-Fe C) Phase DiagramDocumento32 pagineThe Iron-Iron Carbide (Fe-Fe C) Phase DiagramNisaNessuna valutazione finora

- Chemistry Investigatory Project On Analysis of AlloyDocumento16 pagineChemistry Investigatory Project On Analysis of AlloyMia Scarlet80% (5)

- Resources: Rare Earth Element Deposits of Alkaline Igneous RocksDocumento12 pagineResources: Rare Earth Element Deposits of Alkaline Igneous RocksAlfin RifkiNessuna valutazione finora

- Paper 2 November 1999Documento4 paginePaper 2 November 1999MSHNessuna valutazione finora

- Chemistry Project Qualitative Analysis of Different Coins PDFDocumento26 pagineChemistry Project Qualitative Analysis of Different Coins PDFvasnhNessuna valutazione finora

- BalcoDocumento14 pagineBalcoManoj KumarNessuna valutazione finora

- N (A) Science (Chem) CHP 13b Preparation of SaltsDocumento4 pagineN (A) Science (Chem) CHP 13b Preparation of SaltshamsterishNessuna valutazione finora

- ArgonDocumento12 pagineArgonjosevitorromualdoNessuna valutazione finora

- Molybdenum DisulfideDocumento55 pagineMolybdenum DisulfideAnonymous gUjimJKNessuna valutazione finora

- Nadir Metal Rafineri Catalogue 2022Documento19 pagineNadir Metal Rafineri Catalogue 2022PieNessuna valutazione finora

- Aldehydes and KetonesDocumento2 pagineAldehydes and Ketones嘉雯吳Nessuna valutazione finora

- 8.6 - Acid-Base Properties of Salt Solutions - Student HandoutDocumento3 pagine8.6 - Acid-Base Properties of Salt Solutions - Student HandoutTresnawaty NurpertiwiNessuna valutazione finora

- Alloy ReportDocumento6 pagineAlloy ReportJanuszUlpindoNessuna valutazione finora

- Year 10 Chemistry Term 3 2024 Schemes of WorkDocumento12 pagineYear 10 Chemistry Term 3 2024 Schemes of WorkbrianomacheNessuna valutazione finora

- Preparation of SaltsDocumento6 paginePreparation of Saltssakibsultan_308Nessuna valutazione finora

- ANSYSd BListDocumento114 pagineANSYSd BListAnonymous nfHBPXz178Nessuna valutazione finora

- Polyatomic IonsDocumento2 paginePolyatomic IonsJuan KorNessuna valutazione finora

- Welding Handbook v68Documento390 pagineWelding Handbook v68Bryan Brito100% (1)