Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Brushless DC Motor

Caricato da

Ankitdarkopti0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

59 visualizzazioni11 paginedc machines

Titolo originale

Brushless Dc Motor

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentodc machines

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

59 visualizzazioni11 pagineBrushless DC Motor

Caricato da

Ankitdarkoptidc machines

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 11

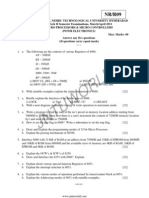

Brushless DC Motors Part I: Construction

and Operating Principles

Electrical equipment often has at least one motor used to

rotate or displace an object from its initial position. There

are a variety of motor types available in the market,

including induction motors, servomotors, DC motors

(brushed and brushless), etc. Depending upon the

application requirements, a particular motor can be

selected. However, a current trend is that most new

designs are moving towards Brushless DC motors,

popularly known as BLDC motors.

This article will concentrate on the following aspects of

BLDC motor design:

Construction of the BLDC motor

Operation of the BLDC motor

Torque and Efficiency requirements

Comparison with Induction and Brushed DC motors

Selection criteria for a BLDC motor

Motor control Speed, Position and Torque, to be

covered in Part II of this article.

Construction

BLDC motors have many similarities to AC induction

motors and brushed DC motors in terms of construction

and working principles respectively. Like all other motors,

BLDC motors also have a rotor and a stator.

Stator

Similar to an Induction AC motor, the BLDC motor stator

is made out of laminated steel stacked up to carry the

windings. Windings in a stator can be arranged in two

patterns; i.e. a star pattern (Y) or delta pattern (). The

major difference between the two patterns is that the Y

pattern gives high torque at low RPM and the pattern

gives low torque at low RPM. This is because in the

configuration, half of the voltage is applied across the

winding that is not driven, thus increasing losses and, in

turn, efficiency and torque.

Steel laminations in the stator can be slotted or slotless

as shown in Figure 2. A slotless core has lower

inductance, thus it can run at very high speeds.

Because of the absence of teeth in the lamination stack,

requirements for the cogging torque also go down, thus

making them an ideal fit for low speeds too (when

permanent magnets on rotor and tooth on the stator

align with each other then, because of the interaction

between the two, an undesirable cogging torque

develops and causes ripples in speed). The main

disadvantage of a slotless core is higher cost because it

requires more winding to compensate for the larger air

gap.

Proper selection of the laminated steel and windings for

the construction of stator are crucial to motor

performance. An improper selection may lead to multiple

problems during production, resulting in market delays

and increased design costs.

Rotor

The rotor of a typical BLDC motor is made out of

permanent magnets. Depending upon the application

requirements, the number of poles in the rotor may vary.

Increasing the number of poles does give better torque

but at the cost of reducing the maximum possible speed.

Another rotor parameter that impacts the maximum

torque is the material used for the construction of

permanent magnet; the higher the flux density of the

material, the higher the torque.

Working Principles and Operation

The underlying principles for the working of a BLDC

motor are the same as for a brushed DC motor; i.e.,

internal shaft position feedback. In case of a brushed DC

motor, feedback is implemented using a mechanical

commutator and brushes. With a in BLDC motor, it is

achieved using multiple feedback sensors. The most

commonly used sensors are hall sensors and optical

encoders.

Note: Hall sensors work on the hall-effect principle that

when a current-carrying conductor is exposed to the

magnetic field, charge carriers experience a force based

on the voltage developed across the two sides of the

conductor.

If the direction of the magnetic field is reversed, the

voltage developed will reverse as well. For Hall-effect

sensors used in BLDC motors, whenever rotor magnetic

poles (N or S) pass near the hall sensor, they generate a

HIGH or LOW level signal, which can be used to

determine the position of the shaft.

In a commutation system one that is based on the

position of the motor identified using feedback sensors

two of the three electrical windings are energized at a

time as shown in figure 4.

In figure 4 (A), the GREEN winding labeled 001 is

energized as the NORTH pole and the BLUE winding

labeled as 010 is energized as the SOUTH pole.

Because of this excitation, the SOUTH pole of the rotor

aligns with the GREEN winding and the NORTH pole

aligns with the RED winding labeled 100. In order to

move the rotor, the RED and BLUE windings are

energized in the direction shown in figure 4(B). This

causes the RED winding to become the NORTH pole

and the BLUE winding to become the SOUTH pole. This

shifting of the magnetic field in the stator produces

torque because of the development of repulsion (Red

winding NORTH-NORTH alignment) and attraction

forces (BLUE winding NORTH-SOUTH alignment),

which moves the rotor in the clockwise direction.

This torque is at its maximum when the rotor starts to

move, but it reduces as the two fields align to each other.

Thus, to preserve the torque or to build up the rotation,

the magnetic field generated by stator should keep

switching. To catch up with the field generated by the

stator, the rotor will keep rotating. Since the magnetic

field of the stator and rotor both rotate at the same

frequency, they come under the category of synchronous

motor.

This switching of the stator to build up the rotation is

known as commutation. For 3-phase windings, there are

6 steps in the commutation; i.e., 6 unique combinations

in which motor windings will be energized.

Driving circuitry and waveforms for the implementation of

a BLDC motor will be discussed in the second part of this

article.

Torque and Efficiency

For the study of electric motors, torque is a very

important term. By definition, torque is the tendency of

force to rotate an object about its axis.

Thus, to increase the torque, either force has to be

increased which requires stronger magnets or more

current or distance must be increased for which

bigger magnets will be required. Efficiency is critical for

motor design because it determines the amount of power

consumed. A higher efficiency motor will also require less

material to generate the required torque.

Where,

Having understood the above provided equations, it

becomes important to understand the speed vs. torque

curve.

Following are the takeaways from the graph shown in Figure 5:

With an increase in speed, the torque reduces

(considering the input power is constant).

Maximum power can be delivered when the speed is

half of the no load speed and torque is half of the stall

torque.

Applications

Single-speed For single-speed applications, induction

motors are more suitable, but if the speed has to be

maintained with the variation in load, then because of the

flat speed-torque curve of BLDC motor, BLDC motors

are a good fit for such applications.

BLDC motors become a more suitable fit

for such applications because variable speed induction

motors will also need an additional controller, thus

adding to system cost. Brushed DC motors will also be a

more expensive solution because of regular

maintenance.

Adjustable speed

Precise control is not required applications

like an induction cooker and because of low

maintenance; BLDC motors are a winner here too.

However, for such applications, BLDC motors use optical

encoders, and complex controllers are required to

monitor torque, speed, and position.

Position control

Brushed DC motors are known for

generating more EMI noise, so BLDC is a better fit but

controlling requirements for BLDC motors also generate

EMI and audible noise. This can, however, be addressed

using Field-Oriented Control (FOC) sinusoidal BLDC

motor control.

Low-noise applications

bout the Author

Pushek Madaan is currently working with Cypress

Semiconductor India Pvt. Ltd. as a Senior Application

Engineer. His interests lie in designing Embedded

system applications in C and assembly languages,

working with analog and digital circuits, developing GUIs

in C# and, above all, enjoying adventure sports. Pushek

can be reached at pmad@cypress.com.

Potrebbero piacerti anche

- Electrical Machines: Lecture Notes for Electrical Machines CourseDa EverandElectrical Machines: Lecture Notes for Electrical Machines CourseNessuna valutazione finora

- Project Electric BikeDocumento28 pagineProject Electric Bikeachint9100% (1)

- Motors and DrivesDocumento27 pagineMotors and DrivessifuszNessuna valutazione finora

- A New System of Alternating Current Motors and Transformers and Other EssaysDa EverandA New System of Alternating Current Motors and Transformers and Other EssaysValutazione: 5 su 5 stelle5/5 (1)

- Ebook - C Programming 4 Embedded Systems - Kirk ZurellDocumento191 pagineEbook - C Programming 4 Embedded Systems - Kirk Zurellmanojiitd2363100% (1)

- Electric Motor Control: DC, AC, and BLDC MotorsDa EverandElectric Motor Control: DC, AC, and BLDC MotorsValutazione: 4.5 su 5 stelle4.5/5 (19)

- Pspice TutorialDocumento56 paginePspice TutorialCutie0% (1)

- Pspice TutorialDocumento56 paginePspice TutorialCutie0% (1)

- An Introduction To Brushless DC Motor ControlDocumento33 pagineAn Introduction To Brushless DC Motor ControlIgor TrimcevskiNessuna valutazione finora

- DC MotorsDocumento12 pagineDC MotorsJamie Ray DalisayNessuna valutazione finora

- Brushless DC (BLDC) Motor FundamentalsDocumento20 pagineBrushless DC (BLDC) Motor FundamentalsEdo007100% (1)

- Study of a reluctance magnetic gearbox for energy storage system applicationDa EverandStudy of a reluctance magnetic gearbox for energy storage system applicationValutazione: 1 su 5 stelle1/5 (1)

- Brushless DC Motors - Part I: Construction and Operating PrinciplesDocumento14 pagineBrushless DC Motors - Part I: Construction and Operating PrinciplesHung Nguyen HuyNessuna valutazione finora

- Brushless DC Motors: An Introduction to Their Construction, Working Principles and AdvantagesDocumento21 pagineBrushless DC Motors: An Introduction to Their Construction, Working Principles and AdvantagesSRL MECHNessuna valutazione finora

- BLDC Motor : Brush Less DC MotorDocumento11 pagineBLDC Motor : Brush Less DC MotorVARSHAN MOHAN0% (1)

- Control of BLDC Motor Using dsPIC30F2010 Final Year ProjectDocumento54 pagineControl of BLDC Motor Using dsPIC30F2010 Final Year ProjectShreyankh Krishy50% (2)

- Eee-233 R1Documento14 pagineEee-233 R1ArifNessuna valutazione finora

- Ishaq Final Year Project Report PDFDocumento28 pagineIshaq Final Year Project Report PDFAmazon fbaNessuna valutazione finora

- Motors and DrivesDocumento23 pagineMotors and DrivesharishkumarsinghNessuna valutazione finora

- BDLC MotorDocumento8 pagineBDLC MotorArun VijayNessuna valutazione finora

- Brushless DC Electric Motor - Wikipedia, The Free EncyclopediaDocumento14 pagineBrushless DC Electric Motor - Wikipedia, The Free EncyclopediaSailesh ReddyNessuna valutazione finora

- Brushless DC MotorDocumento22 pagineBrushless DC MotorPhilip I. Ay-AdNessuna valutazione finora

- Appendix5 VSDDocumento21 pagineAppendix5 VSDChandraSekaranBmNessuna valutazione finora

- Construction and Working of Brushless DC PDFDocumento12 pagineConstruction and Working of Brushless DC PDFaswardi8756Nessuna valutazione finora

- Permanent Magnet Motor GuideDocumento36 paginePermanent Magnet Motor GuidekkarthiksNessuna valutazione finora

- Induction Motor: AC Motor GuideDocumento7 pagineInduction Motor: AC Motor GuideAbhishek ChibNessuna valutazione finora

- Implementing Embedded Speed Control For Brushless DC Motors Part1Documento8 pagineImplementing Embedded Speed Control For Brushless DC Motors Part1charliesteven100% (2)

- What Is DC MotorDocumento38 pagineWhat Is DC Motoralvin dalumpinesNessuna valutazione finora

- Fuzzy Logic Controller For Four Quadrant Operation of Three Phase BLDC MotorDocumento5 pagineFuzzy Logic Controller For Four Quadrant Operation of Three Phase BLDC MotorijtetjournalNessuna valutazione finora

- DW TechTip Brushless Servo SystemsDocumento14 pagineDW TechTip Brushless Servo SystemsgubiliNessuna valutazione finora

- Double Acting Hacksaw Machine Using Scotch Yoke MechanismDocumento32 pagineDouble Acting Hacksaw Machine Using Scotch Yoke Mechanismbalaji67% (12)

- BLDC MotorDocumento8 pagineBLDC MotorMahlet MelesseNessuna valutazione finora

- Everything About BLDC MotorsDocumento22 pagineEverything About BLDC MotorsNyn SoniNessuna valutazione finora

- Assignment # 6Documento7 pagineAssignment # 6Jay Ey100% (1)

- Lab Rep 2Documento5 pagineLab Rep 2Kent Orriele FadriquelNessuna valutazione finora

- A Project Report On: M. S. B. T. E. (Mumbai)Documento42 pagineA Project Report On: M. S. B. T. E. (Mumbai)YogeshNessuna valutazione finora

- Multipurpose Machines Using Scotch Yoke MechanismDocumento36 pagineMultipurpose Machines Using Scotch Yoke Mechanismnithinkenator88% (16)

- The Basic DC MotorDocumento22 pagineThe Basic DC MotortamilselviNessuna valutazione finora

- A Brushless DC MotorDocumento12 pagineA Brushless DC MotormitalipmNessuna valutazione finora

- Presentation 8QUIJANO FLORI AN PAQUERODocumento5 paginePresentation 8QUIJANO FLORI AN PAQUEROQUIJANO, FLORI-AN P.Nessuna valutazione finora

- Discovery of BLDC Motor: Brushless vs. Brushed DC MotorDocumento9 pagineDiscovery of BLDC Motor: Brushless vs. Brushed DC MotorNoni MaheshwariNessuna valutazione finora

- Permanent Magnet BLDC MotorsDocumento25 paginePermanent Magnet BLDC MotorsYash DeoliaNessuna valutazione finora

- Scotch Yoke MechanismDocumento37 pagineScotch Yoke MechanismSaravanan Viswakarma100% (1)

- Fadriquel 2208 Laboratory Report 2Documento7 pagineFadriquel 2208 Laboratory Report 2Kent Orriele FadriquelNessuna valutazione finora

- Construction and Working of BLDC MotorsDocumento6 pagineConstruction and Working of BLDC MotorsAnonymous MAit3mlYm100% (1)

- Brushless MotorDocumento44 pagineBrushless MotorabduljasNessuna valutazione finora

- Brushless DC MotorsDocumento7 pagineBrushless DC MotorsRonald LugwireNessuna valutazione finora

- BLDC Motor Guide: Brushless DC Motor Technology ExplainedDocumento8 pagineBLDC Motor Guide: Brushless DC Motor Technology ExplainedSondur LohithNessuna valutazione finora

- Lab Rep 2qweqretetDocumento7 pagineLab Rep 2qweqretetKent Orriele FadriquelNessuna valutazione finora

- Fabrication of Overhead CraneDocumento45 pagineFabrication of Overhead CraneWORLD360Nessuna valutazione finora

- AC Induction Motor SlipDocumento6 pagineAC Induction Motor SlipnotastudentNessuna valutazione finora

- Brushless DC MotorDocumento17 pagineBrushless DC Motorkrishna015100% (1)

- New Microsoft Word DocumentDocumento5 pagineNew Microsoft Word DocumentraviNessuna valutazione finora

- Speed Control of 3 Phase Ac Induction Motor Using Micro 2407Documento58 pagineSpeed Control of 3 Phase Ac Induction Motor Using Micro 2407sundarspace100% (2)

- Embedded BLCDDocumento24 pagineEmbedded BLCDDhananjay PatilNessuna valutazione finora

- Sequence Prediction of Firing Angle BLDC Motor Drive Using Lookup TableDocumento8 pagineSequence Prediction of Firing Angle BLDC Motor Drive Using Lookup TableEditor IJTSRDNessuna valutazione finora

- Robotic Trolley DesignDocumento46 pagineRobotic Trolley DesignSaggy ChhataniNessuna valutazione finora

- Servo MechanismDocumento24 pagineServo Mechanismmushahid980Nessuna valutazione finora

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkDa EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNessuna valutazione finora

- Ijert Ijert: Control of Three Phase BLDC Motor Using Fuzzy Logic ControllerDocumento5 pagineIjert Ijert: Control of Three Phase BLDC Motor Using Fuzzy Logic ControllergbksnNessuna valutazione finora

- With and With Out SnubberDocumento10 pagineWith and With Out SnubbergbksnNessuna valutazione finora

- Ee 2009Documento29 pagineEe 2009swapule36Nessuna valutazione finora

- GATE Electrical Engineering Solved Paper 2010Documento16 pagineGATE Electrical Engineering Solved Paper 2010safdarrrrrNessuna valutazione finora

- Journal Specific Instructions: How To Publish Your PaperDocumento4 pagineJournal Specific Instructions: How To Publish Your PapergbksnNessuna valutazione finora

- Unit-VIII Logic Programming Languages: Principles of Programming LanguageDocumento10 pagineUnit-VIII Logic Programming Languages: Principles of Programming LanguagegbksnNessuna valutazione finora

- Variable Reluctance MotorDocumento14 pagineVariable Reluctance MotorgbksnNessuna valutazione finora

- 5.speed Control OfPMBLDC Motor Using MATLABSimulink and Effects of LoadDocumento6 pagine5.speed Control OfPMBLDC Motor Using MATLABSimulink and Effects of LoadgbksnNessuna valutazione finora

- LPC2148Documento40 pagineLPC2148Bhulakshmi BoppanaNessuna valutazione finora

- GATE Electrical Engineering Solved Paper 2011Documento23 pagineGATE Electrical Engineering Solved Paper 2011Kishan KumarNessuna valutazione finora

- BR1202 FDocumento48 pagineBR1202 FpravnkumarNessuna valutazione finora

- 24 Pulse Auto TransformerDocumento8 pagine24 Pulse Auto TransformergbksnNessuna valutazione finora

- Nr-r09-Micro Processors & Micro ControllersDocumento1 paginaNr-r09-Micro Processors & Micro ControllersgbksnNessuna valutazione finora

- Viva QuestionsDocumento4 pagineViva QuestionsgbksnNessuna valutazione finora

- NR r09 Digital Control SystemsDocumento2 pagineNR r09 Digital Control SystemsgbksnNessuna valutazione finora

- MB9B500 AN706 00036 1v0 EDocumento16 pagineMB9B500 AN706 00036 1v0 Esanthi_manoj_204Nessuna valutazione finora

- Universal Serial Bus (USB) Is A Serial Bus Standard To ConnectDocumento22 pagineUniversal Serial Bus (USB) Is A Serial Bus Standard To ConnectMahesh Supekar100% (1)

- Outline: Lyapunov's Linearization MethodDocumento8 pagineOutline: Lyapunov's Linearization MethodPraveen DubeyNessuna valutazione finora

- Zig BeeDocumento16 pagineZig BeegbksnNessuna valutazione finora

- How Solar Inverters Work With Solar PanelsDocumento13 pagineHow Solar Inverters Work With Solar Panelsglobalrevolution100% (2)

- Dynamic Model of Induction Motors for Vector ControlDocumento10 pagineDynamic Model of Induction Motors for Vector ControlMarica RalucaNessuna valutazione finora