Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

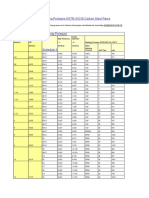

ASTM A572 Tensile Requirements

Caricato da

Dave MulvihillDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ASTM A572 Tensile Requirements

Caricato da

Dave MulvihillCopyright:

Formati disponibili

A572/A572M 12a

TABLE 1 Maximum Product Thickness or Size

Yield Point, min

Grade

Maximum Thickness or Size

ksi

[MPa]

42

50

55

60

65

[290]

[345]

[380]

[415]

[450]

in.

42

50

55

60

65

[290]A

[345]A

[380]

[415]A

[450]

Structural Shape

Flange or Leg

Thickness

Plates and Bars

6

4B

2

114 C

114

[mm]

in.

[mm]

[150]

[100]B

[50]

[32]C

[32]

all

all

all

2

2

all

all

all

[50]

[50]

Sheet Piling

Zees and Rolled

Tees

all

all

all

all

not available

all

all

all

all

all

A

In the above tabulation, Grades 42, 50, and 60 [290, 345, and 415], are the yield point levels most closely approximating a geometric progression pattern between 36

ksi [250 MPa], min, yield point steels covered by Specification A36/A36M and 100 ksi [690 MPa], min, yield strength steels covered by Specification A514/A514M.

B

Round bars up to and including 11 in. [275 mm] in diameter are permitted.

C

Round bars up to and including 312 in. [90 mm] in diameter are permitted.

TABLE 2 Chemical RequirementsA

(Heat Analysis)

Silicon

Diameter, Thickness,

or Distance

Between Parallel

Faces, in. [mm]

Plates and Bars

6 [150]

4 [100]E

2 [50]F

114 [32]F

>12 114 [1332]

#12 [13]H

Structural

Shape

Flange or

Leg

Thickness,

in. [mm]

all

all

all

#2 [50]

>1-2 [25-50]

# 1H

Grade

42

50

55

60

65

65

[290]

[345]

[380]

[415]

[450]

[450]

Carbon,

max, %

0.21

0.23

0.25

0.26

0.23

0.26

Manganese,B

max, %

Phosphorus,

max, %

1.35D

1.35D

1.35D

1.35D

1.65

1.35

Sulfur,

max,

%

0.04

0.04

0.04

0.04

0.04

0.04

Plates to 112 in. [40

mm] Thick,

Shapes with

Flange or Leg

Thickness to 3 in.

[75 mm] inclusive,

Sheet Piling,

Bars, Zees, and

Rolled TeesC

Plates Over 112 in.

[40 mm] Thick and

Shapes with Flange

Thickness

Over 3 in.

[75 mm]

max, %

range, %

0.40

0.40

0.40

0.40

0.40

0.40

0.150.40

0.150.40

0.15-0.40

0.05

0.05

0.05

0.05

0.05

0.05

G

G

G

Copper when specified shall have a minimum content of 0.20 % by heat analysis (0.18 % by product analysis).

Manganese, minimum, by heat analysis of 0.80 % (0.75 % by product analysis) shall be required for all plates over 38 in. [10 mm] in thickness; a minimum of 0.50 %

(0.45 % by product analysis) shall be required for plates 38 in. [10 mm] and less in thickness, and for all other products. The manganese to carbon ratio shall not be less

than 2 to 1.

C

Bars over 112 in. [40 mm] in diameter, thickness, or distance between parallel faces shall be made by a killed steel practice.

D

For each reduction of 0.01 percentage point below the specified carbon maximum, an increase of 0.06 percentage point manganese above the specified maximum is

permitted, up to a maximum of 1.60 %.

E

Round bars up to and including 11 in. [275 mm] in diameter are permitted.

F

Round bars up to and including 312 in. [90 mm] in diameter are permitted.

G

The size and grade is not described in this specification.

H

An alternative chemical requirement with a maximum carbon of 0.21 % and a maximum manganese of 1.65 % is permitted, with the balance of the elements as shown

in Table 2.

B

TABLE 4 Tensile RequirementsA

TABLE 3 Alloy Content

TypeA

1

2

3

Elements

Columbium

Vanadium

Columbium

Vanadium

Columbium plus vanadium

Titanium

Nitrogen

Vanadium

Heat

Analysis, %

Yield Point, min

Tensile Strength, min

Grade

0.0050.05B

0.010.15

0.005-0.05B

0.010.15

0.020.15C

42

50

55

60

65

0.006-0.04

0.0030.015

0.06 max

[290]

[345]

[380]

[415]

[450]

Minimum Elongation, % B,C,D

ksi

[MPa]

ksi

[MPa]

in 8 in.

[200 mm]

in 2 in.

[50 mm]

42

50

55

60

65

[290]

[345]

[380]

[415]

[450]

60

65

70

75

80

[415]

[450]

[485]

[520]

[550]

20

18

17

16

15

24

21

20

18

17

See specimen Orientation under the Tension Tests section of Specification

A6/A6M.

B

Elongation not required to be determined for floor plate.

C

For wide flange shapes over 426 lb/ft [634 kg/m], elongation in 2 in. [50 mm] of

19 % minimum applies.

D

For plates wider than 24 in. [600 mm], the elongation requirement is reduced two

percentage points for Grades 42, 50, and 55 [290, 345, and 380], and three

percentage points for Grades 60 and 65 [415 and 450]. See elongation requirement adjustments in the Tension Tests section of Specification A6/A6M.

Alloy content shall be in accordance with Type 1, 2, 3, or 5 and the contents of

the applicable elements shall be reported on the test report.

B

Product analysis limits = 0.004 to 0.06 %.

C

Product analysis limits = 0.01 to 0.16 %.

processor directly controls, or is responsible for, the operations

involved in the processing of a coil into a finished structural

2

Potrebbero piacerti anche

- Steel Fabrication Kickoff Prefabrication Meeting AgendaDocumento3 pagineSteel Fabrication Kickoff Prefabrication Meeting AgendaDave Mulvihill100% (2)

- Astm A500Documento6 pagineAstm A500notsofar100% (4)

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- 2006 ICC Concrete ManualDocumento364 pagine2006 ICC Concrete ManualDave Mulvihill78% (9)

- API 2H50 Data Sheet 2012 04 02Documento2 pagineAPI 2H50 Data Sheet 2012 04 02alvaedison00Nessuna valutazione finora

- Plate Asme Sa516 Grade 70Documento10 paginePlate Asme Sa516 Grade 70Deaz AmbrsNessuna valutazione finora

- ASTM A514 GR B Data Sheet 2012 04 01 PDFDocumento2 pagineASTM A514 GR B Data Sheet 2012 04 01 PDFMarco BacianNessuna valutazione finora

- API 2hgr50Documento3 pagineAPI 2hgr50Jym GensonNessuna valutazione finora

- Astm A 515Documento5 pagineAstm A 515rameshdatta100% (1)

- Pressure Vessel Steels - Astm A516Documento6 paginePressure Vessel Steels - Astm A516septo982Nessuna valutazione finora

- Material Properties and Chemical CompositionDocumento20 pagineMaterial Properties and Chemical CompositionMani Maran89% (9)

- Caracteristicas API 2HGr50 PDFDocumento3 pagineCaracteristicas API 2HGr50 PDFFernandoBarreraDominguezNessuna valutazione finora

- Extras ASTM A131 Naval Steel GradesDocumento1 paginaExtras ASTM A131 Naval Steel GradesAnonymous zOJdnwGjBNessuna valutazione finora

- Jis G4051Documento7 pagineJis G4051tnchsgNessuna valutazione finora

- TABLE 3 Alloy ContentDocumento1 paginaTABLE 3 Alloy ContentLaurence SarmientoNessuna valutazione finora

- Indian Standard Steel SectionsDocumento9 pagineIndian Standard Steel SectionsAmitava SilNessuna valutazione finora

- A 709/A 709M - 01b: N 1 - Where ". - ." Appears in This Table, There Is No RequirementDocumento1 paginaA 709/A 709M - 01b: N 1 - Where ". - ." Appears in This Table, There Is No Requirementle hoang vietNessuna valutazione finora

- Astm A709 - A709m (2009)Documento7 pagineAstm A709 - A709m (2009)Hà Việt Đức100% (1)

- High Strength Fine Grained Structural Steel, Quenched and TemperedDocumento6 pagineHigh Strength Fine Grained Structural Steel, Quenched and TemperedkazdanoNessuna valutazione finora

- ASTM A633 GR E Data Sheet 2012 04 01Documento2 pagineASTM A633 GR E Data Sheet 2012 04 01FrancescoGuglielmo100% (1)

- Preheat Ions For A 514 Grade B MaterialDocumento2 paginePreheat Ions For A 514 Grade B Materialjrod64Nessuna valutazione finora

- A 414 - A 414M - 00 Qtqxnc0wma - PDFDocumento3 pagineA 414 - A 414M - 00 Qtqxnc0wma - PDFTiến Lượng NguyễnNessuna valutazione finora

- Astm A572 - 04Documento1 paginaAstm A572 - 04Hai TranNessuna valutazione finora

- SteelDocumento38 pagineSteelArdeela IlezNessuna valutazione finora

- Pressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceDocumento3 paginePressure Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceStanley HallNessuna valutazione finora

- Asme Sa-738-Press - Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel For Modera&Lower TempDocumento6 pagineAsme Sa-738-Press - Vessel Plates, Heat-Treated, Carbon-Manganese-Silicon Steel For Modera&Lower Tempgst ajahNessuna valutazione finora

- High Strength Fine Grained Structural Steel Quenched and TemperedDocumento6 pagineHigh Strength Fine Grained Structural Steel Quenched and TemperedAugusto BerdetteNessuna valutazione finora

- GP20110327Documento36 pagineGP20110327Artem KuznetsovNessuna valutazione finora

- Maximum Working Pressure-ASTM A53 B Carbon Steel PipesDocumento2 pagineMaximum Working Pressure-ASTM A53 B Carbon Steel PipesBFEVietnamNessuna valutazione finora

- API 2W50 Data Sheet 2012 04 01Documento2 pagineAPI 2W50 Data Sheet 2012 04 01Alfon TampubolonNessuna valutazione finora

- Asme Section II A-2 Sa-455 Sa-455mDocumento4 pagineAsme Section II A-2 Sa-455 Sa-455mAnonymous GhPzn1xNessuna valutazione finora

- A516 NormalizedDocumento3 pagineA516 Normalizediran1362Nessuna valutazione finora

- Astm A 500Documento3 pagineAstm A 500LuckySingh100% (2)

- Bar STDDocumento8 pagineBar STDtushk20100% (1)

- Fire Piping-Astm A106Documento4 pagineFire Piping-Astm A106sinahimsNessuna valutazione finora

- High Strength Fine Grained Structural Steel, Quenched and TemperedDocumento6 pagineHigh Strength Fine Grained Structural Steel, Quenched and TemperedXQNessuna valutazione finora

- Plate Boiler A516 Grade 70 Datasheet PDF Beyond-SteelDocumento2 paginePlate Boiler A516 Grade 70 Datasheet PDF Beyond-SteelMugiyonoNessuna valutazione finora

- Astm A514 GR SDocumento9 pagineAstm A514 GR SMario GaytanNessuna valutazione finora

- Hot Rolled China SteelDocumento43 pagineHot Rolled China Steeledgarc999Nessuna valutazione finora

- Astm A557 A557mDocumento3 pagineAstm A557 A557mارفع راسك فوق انت يمنيNessuna valutazione finora

- Gray Iron Castings For Pressure-Containing Parts For Temperatures Up To 650°F (350°C)Documento4 pagineGray Iron Castings For Pressure-Containing Parts For Temperatures Up To 650°F (350°C)quiensabe0077Nessuna valutazione finora

- ASTM A709-04aDocumento1 paginaASTM A709-04aSoowhan JungNessuna valutazione finora

- Astm A387 A387m 1992Documento6 pagineAstm A387 A387m 1992Alberto Alexander RodriguezNessuna valutazione finora

- ASME-B31-4 CalcDocumento9 pagineASME-B31-4 Calcshafeeqm3086100% (1)

- Calculator ASME B31 4Documento9 pagineCalculator ASME B31 4jleonos100% (3)

- Tension Properties For Materials Used in ShipbuildingDocumento10 pagineTension Properties For Materials Used in ShipbuildingKarla JuárezNessuna valutazione finora

- ASTM A312 2014 Specification For Seamless and Welded Austenitic Stainless Steel Pipe PDFDocumento4 pagineASTM A312 2014 Specification For Seamless and Welded Austenitic Stainless Steel Pipe PDFanon_295291420Nessuna valutazione finora

- Norma China de Palanquillas de Acero PDFDocumento5 pagineNorma China de Palanquillas de Acero PDFrickhuezoNessuna valutazione finora

- 03.ASTM A572-15 - Eqv. A709Gr50Documento4 pagine03.ASTM A572-15 - Eqv. A709Gr50Mauricio_Vera_525950% (2)

- A 808 - A 808M - 00 Qtgwoc9boda4ts1sruqDocumento3 pagineA 808 - A 808M - 00 Qtgwoc9boda4ts1sruqdelta lab sangliNessuna valutazione finora

- Rebar CalidadDocumento12 pagineRebar CalidadrickhuezoNessuna valutazione finora

- Steel UserguideDocumento50 pagineSteel UserguideBhanu Pratap ChoudhuryNessuna valutazione finora

- Material SpecificationDocumento50 pagineMaterial SpecificationSangyt Karna0% (2)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeDa EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNessuna valutazione finora

- How to prepare Welding Procedures for Oil & Gas PipelinesDa EverandHow to prepare Welding Procedures for Oil & Gas PipelinesValutazione: 5 su 5 stelle5/5 (1)

- Saw Storage HandlingDocumento1 paginaSaw Storage HandlingDave MulvihillNessuna valutazione finora

- State of Idaho Public Works Statutes Rules 2021Documento55 pagineState of Idaho Public Works Statutes Rules 2021Dave MulvihillNessuna valutazione finora

- Rental Inspection Checklist: Entry Way & HallDocumento7 pagineRental Inspection Checklist: Entry Way & HallDave MulvihillNessuna valutazione finora

- Tech AlloyDocumento2 pagineTech AlloyDave MulvihillNessuna valutazione finora

- Wsdot 6-03.3Documento3 pagineWsdot 6-03.3Dave MulvihillNessuna valutazione finora

- 1-07 Legal Relations and Responsibilities To The Public: 1-07.1 Laws To Be ObservedDocumento3 pagine1-07 Legal Relations and Responsibilities To The Public: 1-07.1 Laws To Be ObservedDave MulvihillNessuna valutazione finora

- WSDOT Standard Spec2012Documento974 pagineWSDOT Standard Spec2012initiative1972Nessuna valutazione finora

- Degree and Course InformationDocumento2 pagineDegree and Course InformationDave MulvihillNessuna valutazione finora

- WABO Approved Fabricator Renewal: David MulvihillDocumento1 paginaWABO Approved Fabricator Renewal: David MulvihillDave MulvihillNessuna valutazione finora

- Alaska Standard Specifications For Construction 2004Documento438 pagineAlaska Standard Specifications For Construction 2004Dave MulvihillNessuna valutazione finora

- Nucor Steel ASTM A709 Plate Rolling ProcessDocumento54 pagineNucor Steel ASTM A709 Plate Rolling ProcessDave MulvihillNessuna valutazione finora

- American Structural ShapesDocumento56 pagineAmerican Structural Shapesioan92100% (1)

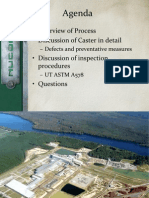

- Steel Bridge Prefabrication Meeting Agenda For SFSRBDocumento4 pagineSteel Bridge Prefabrication Meeting Agenda For SFSRBDave Mulvihill100% (1)

- Engineering Economics Module 8Documento12 pagineEngineering Economics Module 8Dave Mulvihill100% (1)

- Solution Guide Upload HW 3Documento4 pagineSolution Guide Upload HW 3Dave MulvihillNessuna valutazione finora

- Gem Bearing Pegmatites A Review PDFDocumento14 pagineGem Bearing Pegmatites A Review PDFJotagrcNessuna valutazione finora

- A Study On Employee Satisfaction in Avatar Gold and Diamonds, EdappalDocumento74 pagineA Study On Employee Satisfaction in Avatar Gold and Diamonds, Edappalripper0% (1)

- Notes On "ORGANIC CHEMISTRY" CBSE Class XIIDocumento52 pagineNotes On "ORGANIC CHEMISTRY" CBSE Class XIIMahesh AdhikariNessuna valutazione finora

- Sco Copper OreDocumento5 pagineSco Copper OreCarlos MartinezNessuna valutazione finora

- Analytical Chemistry PDFDocumento9 pagineAnalytical Chemistry PDFSagar AnawadeNessuna valutazione finora

- Reebol: Chemical Mould Release AgentDocumento3 pagineReebol: Chemical Mould Release Agentyoga pratamaNessuna valutazione finora

- Titration ConceptDocumento10 pagineTitration Conceptbasant kumar singh0% (1)

- En 1074-3 Eurocheck Non-Return ValveDocumento2 pagineEn 1074-3 Eurocheck Non-Return ValvegeorgecisNessuna valutazione finora

- Icm ScienceDocumento2 pagineIcm Scienceapi-345381848Nessuna valutazione finora

- A 744Documento5 pagineA 744Carlos JuárezNessuna valutazione finora

- 0653 w16 QP 32Documento20 pagine0653 w16 QP 32yuke kristinaNessuna valutazione finora

- List of ChemicalsDocumento2 pagineList of ChemicalsShahzaibUsman100% (1)

- 910-14 (Military MedJHHGical) SBGDocumento15 pagine910-14 (Military MedJHHGical) SBGSamsam Dequito AlthalathiniNessuna valutazione finora

- Steel Investment Castings General Requirements, For Pressure-Containing PartsDocumento12 pagineSteel Investment Castings General Requirements, For Pressure-Containing PartsManivannanMudhaliarNessuna valutazione finora

- June 2013 (v1) QP - Paper 1 CIE Chemistry IGCSEDocumento16 pagineJune 2013 (v1) QP - Paper 1 CIE Chemistry IGCSEmikayla bryanNessuna valutazione finora

- HSEDocumento7 pagineHSEElah PalaganasNessuna valutazione finora

- Welding of Nickel AlloysDocumento12 pagineWelding of Nickel AlloysErick HoganNessuna valutazione finora

- PANER, CM - Structure and Material Composition of A PaintingDocumento47 paginePANER, CM - Structure and Material Composition of A PaintingCrisencio M. PanerNessuna valutazione finora

- Compatibilidad Química Materiales - FTI PDFDocumento15 pagineCompatibilidad Química Materiales - FTI PDFmpicaNessuna valutazione finora

- Steel MetallurgyDocumento3 pagineSteel MetallurgyshubhgroNessuna valutazione finora

- New Methods of Al Recyc PDFDocumento6 pagineNew Methods of Al Recyc PDFSrinivasa Rao PulivartiNessuna valutazione finora

- Minara District A, Stage 2: Badrah DevelopmentDocumento4 pagineMinara District A, Stage 2: Badrah DevelopmentCody TillmanNessuna valutazione finora

- Physical ChemistryDocumento225 paginePhysical ChemistryAkash75% (4)

- Schunk Sealing RingsDocumento20 pagineSchunk Sealing Ringspeach5Nessuna valutazione finora

- EP2414464B1Documento48 pagineEP2414464B1vipin1222Nessuna valutazione finora

- Brochure JacoviDocumento5 pagineBrochure JacovimenriquepcNessuna valutazione finora

- National Report On Mining: ContentDocumento11 pagineNational Report On Mining: Contentkrishnakant1100% (1)

- Introduction To The ASTM Designation SystemDocumento6 pagineIntroduction To The ASTM Designation Systemmajor_duanNessuna valutazione finora

- A144 PDFDocumento2 pagineA144 PDFAbraham MallisaNessuna valutazione finora

- Material and Processes-Question - AnsDocumento15 pagineMaterial and Processes-Question - Ansprashanth_anNessuna valutazione finora