Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Contoh Proteksi Katodik Perhitungan

Caricato da

Deo HaritaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Contoh Proteksi Katodik Perhitungan

Caricato da

Deo HaritaCopyright:

Formati disponibili

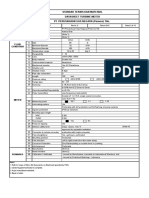

CATHODIC PROTECTION DESIGN FOR BRACELET ANODE

This spreadsheet determines the anode requirements for the main line.

The output represents the anode requirements to satisfy the mean and final current demand of the pipelines.

Mthodology is in accordance with DNV-RP-B401 (2010).

1.0 INPUT DATA

Definition of Units for MATHCAD :

CK

years 8760 hr

A amp

1.1 Pipeline Data

Pipeline Length

Lp := 16000 m

Outside Diameter

D := 273.1mm

Joint Length

Lj := 12.2m

Corrosion Coating thickness

t c := 3.5 mm

Design Life

t f := 15 years

Operating Temperature

Top := 55 C

Mean Current Density (Depth > 30-100 m

i cm := 0.06 A m

and surface water temperature >20

(Assume that the temperature for the

anodes is the same as the

temperature of the pipeline)

-2

(Table 10-2, DNV-RP-B401, 2010)

oC)

Final Current Density (Depth > 30-100 m and

surface water temperature >20

(3LPE coating)

-2

(Table 10-1, DNV-RP-B401, 2010)

i cf := 0.08 A m

oC)

-2

-1

Temperature correction (>25 deg C)

Tc := 0.001 A m

Constant in Coating Breakdown Factor

(Coating Category III)

a := 0.02

(Table 10-4 DNV-RP-B401, 2010)

Constant in Coating Breakdown Factor

(Coating Category III)

b := 0.008

(Table 10-4 DNV-RP-B401, 2010)

Mean Coating Breakdown Factor

fcm := a + b

Final coating brakdown factor

fcf := a + b

Design Protective Potential vs Ag/AgCl

tf

2 years

tf

years

Ec := -0.80 volt

Environmental Resistivity (Seawater, 21 deg C) := 0.225 ohm m

(Section 6.3.9 DNV-RP-B401, 2010)

fcm = 0.08

fcf = 0.14

(Section 5.4.1 DNV-RP-B401, 2010)

(Figure 10-1 DNV-RP-B401 2010,

The salinity is assumed 35ppt as

average value)

Page 1 of 5

1.2 Half Shell Bracelet Anode Data (Al Based)

Clearance Between Anode ID & coating OD

t g := 0mm

Anode Inside Diameter

ID a := D + 2 t c + 2 t g

Anode Thickness

t a := 40mm

Anode Length

La := 450mm

Half Shell Gap

ga := 100mm

Anode Material Density

a := 2700 kg m

Anode Usage Factor

u := 0.8

(Table 10-8, DNV-RP-B401, 2010)

Design Closed Circuit Anode Potential

(Seawater)

Ea := -1.05 volt

(Table 10-6, DNV-RP-B401, 2005)

Electrochemical Capacity (Seawater)

a := 2000 A hr kg

ID a = 280.1 mm

-3

-1

(Table 10-6, DNV-RP-B401, 2005)

2.0 CALCULATIONS

2.1 Net Mass per Anode

2

Surface Area of Anode

SAa := ( ID a + 2 t a) - 2 ga La

SAa = 0.419 m

Cross-Sectional Area of Anode

XAa := (ID a + t a) - 2 ga t a

XAa = 0.032 m

Volume of Anode

V a := XAa La

V a = 0.015 m

Net Mass per Anode as per calculation

mac := V a a

mac = 39.153 kg

Net Mass per Anode as per availability from

Vendor Catalogue

ma := 38kg

ma = 38 kg

Surface Area to be Protected

Acm := D Lp

Acm = 1.373 10 m

Design Steel Current Density Demand

Correction for Steel Temperature (T)

i cmt := ifTop < 25 C , icm , i cm + ( Top - 25 C) Tc

2.2 Mean Current Requirement

4 2

-2

i cmt = 0.09 A m

Mean Coating Breakdown Factor

tf

- 30

years

fcmt := iftf < 30 years , fcm , fcm + 0.002

fcmt = 0.08

Page 2 of 5

Current Demand for Specific Surface Area

Icm := Acm fcmt i cmt

Icm = 98.838 A

Electrochemical Efficiency

:= a

= 2 10 A hr kg

Total Anode Mass

M :=

Anode Current Capacity

ca := ma u

Minimum Number of Anodes Required

nm :=

Maximum Required Anode Spacing (meter)

Maximum Required Anode Spacing (number

of joints)

-1

Icm tf

u

M = 8117.07 kg

4

ca = 6.08 10 A hr

M

nm = 213.607

ma

Lspm :=

Lp

Lspm = 74.904 m

nm

Lspm

Jointsm :=

Lj

Jointsm = 6.14

Mean Currrent Requirements Results:

RESULTmean := if( nm ca Icm t f , "The Mean Current Requirements are met" , "Not OK" )

RESULTmean = "The Mean Current Requirements are met"

2.3 Final Current Requirement

End of Life Anode Mass

mf := ma ( 1 - u)

End of Life Anode Volume

V f :=

End of Life Anode CSA (Assume Anode

Length doesn't change)

XAf :=

mf

mf = 7.6 kg

-3 3

V f = 2.815 10

Vf

La

-3 2

XAf = 6.255 10

End of Life Anode Outer Diameter

Initial Aprroximation

Given

ODf := IDa

XAf = ( ODf - 2 ga) ( ODf - ID a)

ODf := Find( ODf )

ODf = 0.289 m

End of Life Anode Surface Area

SAaf := ( ODf - 2 ga) La

SAaf = 0.318 m

End of Life Anode Resistance

Raf :=

End of Life Anode Current Output

Iaf :=

0.315

SAaf

Ec - Ea

Raf

Raf = 0.126 ohm

Iaf = 1.991 A

Page 3 of 5

The Design Final Current Density for Steel,

Corrected for Temperature

i cft := ifTop < 25 C , i cf , i cf + ( Top - 25 C) Tc

-2

i cft = 0.11 A m

4 2

Steel Surface Area to be Protected

Acf := D Lp

Final Coating Breakdown Factor

fcft := ift f < 20 years , fcf , fcf + 0.004

Acf = 1.373 10 m

tf

- 20

years

fcft = 0.14

End of Life Current Demand for Surface Area

to be Protected

Icf := Acf fcft icft

Minimum Number of Anodes Required

nf :=

Maximum Required Anode Spacing (meter)

Maximum Required Anode Spacing (number

of Joints)

Icf

nf = 106.2

Iaf

Lspf :=

Lp

Lspf = 150.659 m

nf

Jointsf :=

Icf = 211.404 A

Lspf

Jointsf = 12.349

Lj

Final Current Requirements Results

RESULTfinal := if( nf Iaf Icf , "The Final Current Requirements are met" , "Not OK" )

RESULTfinal = "The Final Current Requirements are met"

2.4 Required Anode Spacing and Number of Anodes

Required Anode Spacing (number of Joints)

Required Number of Anodes

Jointsrequired := min( Jointsm, Jointsf )

Jointsrequired = 6.14

Jointsrounded := floor (Jointsrequired)

Jointsrounded = 6

N required :=

Lp

Jointsrounded Lj

N rounded := ceil( N required)

N required = 218.579

N rounded = 219

Page 4 of 5

2.5 Check Final Anode Thickness

Steel Surface Area Protectable per Anode

Acmc := D (Jointsrounded Lj )

Acmc = 62.803 m

Current Demand for Surface Area to be

Protected per Anode

Icmc := Acmc fcmt i cmt

Icmc = 0.452 A

Mass of Anode Used to Protect the Surface

Area

mused :=

Remaining Mass per Anode (Final Anode

Mass)

mfinal := ma - mused

Final Anode Volume

Vol final :=

Final Anode Thickness

t af :=

Icmc t f

mused = 29.708 kg

mfinal

mfinal = 8.292 kg

-3 3

Vol final = 3.071 10

Volfinal

t af = 9.643 mm

SAaf

(ODf - D - 2 tc)

Final Anode Thickness requirement

t af_req :=

Check Final Anode Thickness

Check_taf := if( taf t af_req , "OK" , "Not OK" )

t af_req = 4.419 mm

Check_taf = "OK"

Page 5 of 5

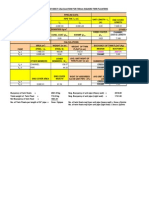

23 - 41 Willowdale Place, Aberdeen, AB24 5AQ

AF Defender Rigid Pipe Aluminium Bracelet Anodes B1

Examples

Anode

Code

(A =Al

Bracelet

Wt x 10 )

Anode ID

(mm)

(NB pipe)

D double, SSingle band

Anode

OD

(mm)

O/all

Length

(mm)

Anode

Weight

(Nett kg/

Gross kg)

AFA B 200

(4) 118 D

198

416

20/25

AFA B 126

(6) 170 S

250

235

12.6/16

AFA B 186

(6) 170 S

250

368

18.6/16

AFA B 235

(8) 225 D

315

410

23.5 / 28.4

AFA B 333

(8) 223.5

303.5

475

33.3/37.7

(10) 280 S

360

325

28 /35

(10) 280 D

360

450

38/35

(12) 328 S

408

290

29.2 / 34

(12) 328 S

408

425

42 / 46

AFA B1200

(16) 410 D

492

800

120/ 135

AFA B350

(16) 435 D

515

280

35/47.5

AFA B610

(20) 512 D

592

450

61/85

AFA B520

(20) 520 D

610

315

55/69

AFA B550

(20) 550 D

640

300

55 / 70

AFA B570

(22) 570 D

660

295

55/71

(10) 286

Rubber lined,

40mm to363 D

Hinged

453

680

75/90

AFA B 280

AFA B 380

AFA B 292

AFA B 400

AFA B790

Design

Examples

Rigid pipes

.Fully Bolt on gusseted

bands

(Single, S or Double, D)

Tapered ends

Continuity straps;

Epoxy coat inside

neoprene liner optional

Example: High temp pipe anode

heavy rubber lined to order

* All weights and dimensions are nominal

Material Specification:

AF Defender G3 AF Al-Zn-In-Si anode alloy

Fe

Si

Cu

Zn

In

Others

Al

0.12 max.

0.08-0.21

0.006 max.

2.8 6.5

0.01 0.02

0.02 max

remainder

Potential 1.09* Volts Ag/AgCl

Capacity (Amp Hrs) 2540* per Kg min Density 2750Kg/m3

* AFDefender G3 alloy performance Data for long term test by DNV Certificate No S-5615 to DNV RP B401 Appendix B

Aluminium and Zinc Castings Aluminium Offshore Anodes Zinc & Al Marine Hull Anodes

Tank Anodes Pipeline Anodes Down-hole Centralisers and Clamps Ballast Weights

AFA Bracelet Anodes Sheet B 1 Rigid Pipes taper NEW sept 09 to Ab internet (2).doc

Potrebbero piacerti anche

- Gangway Tower Preservation Procedure On SiteDocumento4 pagineGangway Tower Preservation Procedure On SiteSalim Mohd RazNessuna valutazione finora

- 001 Manual Data Sheet PipaDocumento3 pagine001 Manual Data Sheet Pipawahyu hutamaNessuna valutazione finora

- KITZ Bronze Brass Valves E-101-11Documento0 pagineKITZ Bronze Brass Valves E-101-11uyab1989Nessuna valutazione finora

- Data Sheet FOR Pig Signal: Cikande - Bitung Distribution Pipeline Project Pt. Perusahaan Gas Negara Data SheetDocumento3 pagineData Sheet FOR Pig Signal: Cikande - Bitung Distribution Pipeline Project Pt. Perusahaan Gas Negara Data Sheetalfa vimalaNessuna valutazione finora

- Data PipaDocumento9 pagineData PipaediabcNessuna valutazione finora

- PHEWMO-OrF-Z-PRC-0033 Rev.B Prosedur Pemasangan Anchor BoltDocumento14 paginePHEWMO-OrF-Z-PRC-0033 Rev.B Prosedur Pemasangan Anchor Boltchristian210789Nessuna valutazione finora

- RAB Penambahan Instalasi Pipa Loading CPODocumento1 paginaRAB Penambahan Instalasi Pipa Loading CPOMuslim MunawarNessuna valutazione finora

- Pump Sizing Fire Hydrant MojoDocumento2 paginePump Sizing Fire Hydrant MojoAnonymous 6S9tcbhNessuna valutazione finora

- Form Welding SchematicDocumento1 paginaForm Welding SchematicZainudinNessuna valutazione finora

- Storage Tank Test & Inspection Report enDocumento10 pagineStorage Tank Test & Inspection Report enMarketing CTNNessuna valutazione finora

- Pengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMDocumento15 paginePengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMMulYadi100% (1)

- Kebutuhan Wrapping PipaDocumento4 pagineKebutuhan Wrapping Pipapanji uteNessuna valutazione finora

- Perhitungan Magnesium AnodeDocumento2 paginePerhitungan Magnesium AnodeAndre KurniawanNessuna valutazione finora

- Corrosion Rate CalculationDocumento2 pagineCorrosion Rate CalculationPawan PatilNessuna valutazione finora

- Katalog TSP PTDocumento24 pagineKatalog TSP PTendroNessuna valutazione finora

- Pressure Gauge Dan Diff Gauge Datasheet - Rev.ADocumento20 paginePressure Gauge Dan Diff Gauge Datasheet - Rev.Asugeng wahyudiNessuna valutazione finora

- Tank Settlement Record T-05Documento8 pagineTank Settlement Record T-05Marvan Audy BurikoNessuna valutazione finora

- Junction Box DatasheetDocumento1 paginaJunction Box DatasheetNilesh ChavanNessuna valutazione finora

- Perhitungan Drop TeganganDocumento101 paginePerhitungan Drop TeganganRoby Surya KuncoroNessuna valutazione finora

- Mto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYDocumento4 pagineMto Valve: CHKD Appd Appd Date DEC DSP/PPN REV Date Description BYAnonymous 6S9tcbhNessuna valutazione finora

- Occpl: Hydro & Pneumatic Test ProcedureDocumento3 pagineOccpl: Hydro & Pneumatic Test ProcedureNupesh katreNessuna valutazione finora

- Fluxi 2000 TZ EN-03 - 18Documento4 pagineFluxi 2000 TZ EN-03 - 18Praveen KumarNessuna valutazione finora

- Anode CalculationDocumento1 paginaAnode CalculationFian ArdiyanaNessuna valutazione finora

- Cy3 - Te MeteringDocumento22 pagineCy3 - Te MeteringSilpa Asti Nura100% (1)

- Form Document Fabrication Review ChecklistDocumento2 pagineForm Document Fabrication Review ChecklistIrnaldi Yoza WijayaNessuna valutazione finora

- Datasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDocumento4 pagineDatasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDylan RamasamyNessuna valutazione finora

- List of CPI Specification & StandardDocumento6 pagineList of CPI Specification & StandardErick SavrinaldoNessuna valutazione finora

- Sop-Pemasangan Spectacle BlindDocumento5 pagineSop-Pemasangan Spectacle BlindRidwan PradityaNessuna valutazione finora

- Reverse Engineering Pressure Vessel ChecklistDocumento5 pagineReverse Engineering Pressure Vessel ChecklistES RouzaNessuna valutazione finora

- D0307 (MECH) Painting Procedure For Boiler Steel Structure - Rev 0Documento18 pagineD0307 (MECH) Painting Procedure For Boiler Steel Structure - Rev 0Surya Darma100% (1)

- UBC 1997 Vs SNI 03-1726-2002Documento25 pagineUBC 1997 Vs SNI 03-1726-2002Wiratman PasauNessuna valutazione finora

- Pig Receiver & LauncherDocumento6 paginePig Receiver & LauncherSeptian FirdausNessuna valutazione finora

- Bab 5 Pressure Design of Pipeline & Components PrintDocumento41 pagineBab 5 Pressure Design of Pipeline & Components PrintRadinal Fernandez SimanjuntakNessuna valutazione finora

- Minimum Length and Spacing For Welded Nozzles PDFDocumento7 pagineMinimum Length and Spacing For Welded Nozzles PDFSoniNessuna valutazione finora

- Storage Tank Data SheetDocumento2 pagineStorage Tank Data SheetsandyaNessuna valutazione finora

- Data Sheet Meter Turbin G.65Documento1 paginaData Sheet Meter Turbin G.65HerruSetiawanNessuna valutazione finora

- 11.sacrificial Cathodic ProtrctionDocumento5 pagine11.sacrificial Cathodic ProtrctionChayon MondalNessuna valutazione finora

- Anode Calculation For TheinbyuDocumento1 paginaAnode Calculation For TheinbyunyaungzinNessuna valutazione finora

- Hydrotest Report 13 Sept - 14 Sept 2018 PDFDocumento10 pagineHydrotest Report 13 Sept - 14 Sept 2018 PDFDjuangNessuna valutazione finora

- Catalog of Seamless Steel Line Pipe of NSSMCDocumento8 pagineCatalog of Seamless Steel Line Pipe of NSSMCRoshan ShanmughanNessuna valutazione finora

- Document: NO.:: Ultrasonic ExaminationDocumento41 pagineDocument: NO.:: Ultrasonic ExaminationDamar WardhanaNessuna valutazione finora

- Pipeline Toolbox InfoDocumento2 paginePipeline Toolbox InfoKIKA LASSARININessuna valutazione finora

- Filtro y StrainerDocumento2 pagineFiltro y StrainerJose HuguetNessuna valutazione finora

- Cathodic Protection Calculation of No of Magnesium Anodes Design DataDocumento1 paginaCathodic Protection Calculation of No of Magnesium Anodes Design DataHemantk8731Nessuna valutazione finora

- MTO ValveDocumento2 pagineMTO ValveAgus MarpaungNessuna valutazione finora

- Format MTODocumento1 paginaFormat MTOHermantoro PradanaNessuna valutazione finora

- Cp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Documento1 paginaCp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Triana Rosma Fikriyati DinaNessuna valutazione finora

- Qualified Welder List According To Asme IxDocumento5 pagineQualified Welder List According To Asme IxAhmad Nabil ElsharkawyNessuna valutazione finora

- Standar & Kode PipaDocumento8 pagineStandar & Kode PipaDzaka LanaaNessuna valutazione finora

- Tank ProcedureDocumento5 pagineTank ProcedurejacquesmayolNessuna valutazione finora

- "Boat/Surfer Landing": AssignmentDocumento1 pagina"Boat/Surfer Landing": AssignmenteNessuna valutazione finora

- Pembangunan JOBBER TBBM Tembilahan: Calculation For Bundwall CapacityDocumento3 paginePembangunan JOBBER TBBM Tembilahan: Calculation For Bundwall Capacitycharleshutabara951Nessuna valutazione finora

- An Overview of Cathodic Protection Potential MeasurementDocumento7 pagineAn Overview of Cathodic Protection Potential MeasurementKhanh DTNessuna valutazione finora

- Calculation Sheet For 700mm SQ Metal FloatersDocumento3 pagineCalculation Sheet For 700mm SQ Metal FloatersAdagharaNessuna valutazione finora

- B313 Mitre Ver 1.1Documento5 pagineB313 Mitre Ver 1.1nizardsouissiNessuna valutazione finora

- Cathodic Calculation (ICCP) Single ShalloWellDocumento11 pagineCathodic Calculation (ICCP) Single ShalloWellArif RusyanaNessuna valutazione finora

- Wrapping and Coating Inspection Report: Lanco Infratech Limited 2X600 MW Power Project MBMPL, Anuppur, M.PDocumento2 pagineWrapping and Coating Inspection Report: Lanco Infratech Limited 2X600 MW Power Project MBMPL, Anuppur, M.PSimbu ArasanNessuna valutazione finora

- Claulation For Check Suitability of IPSDocumento45 pagineClaulation For Check Suitability of IPSannuvyas100% (1)

- Cathodic Protection Analysis Based On DNV RP F103Documento6 pagineCathodic Protection Analysis Based On DNV RP F103firmansyahperdanaNessuna valutazione finora

- Earthing CalculationDocumento14 pagineEarthing CalculationNatarajan Ramakrishnan100% (18)

- J5N0GR022483197Documento2 pagineJ5N0GR022483197Deo HaritaNessuna valutazione finora

- Pelatihan Ocean Summit - II GenesisDocumento32 paginePelatihan Ocean Summit - II GenesisDeo HaritaNessuna valutazione finora

- Routing SelectionDocumento42 pagineRouting SelectionDeo HaritaNessuna valutazione finora

- Drainase SementaraDocumento8 pagineDrainase SementaraDeo HaritaNessuna valutazione finora

- 02 Perancangan Elemen TarikDocumento30 pagine02 Perancangan Elemen TarikHijir Della WirastiNessuna valutazione finora

- In-Situ Soil Testing - Offshore Testing - Introduction PDFDocumento2 pagineIn-Situ Soil Testing - Offshore Testing - Introduction PDFDeo HaritaNessuna valutazione finora

- 02 Perancangan Elemen TarikDocumento30 pagine02 Perancangan Elemen TarikHijir Della WirastiNessuna valutazione finora

- TowingDocumento19 pagineTowingDeo HaritaNessuna valutazione finora

- Perusahaan 1. Company NameDocumento2 paginePerusahaan 1. Company NameDeo HaritaNessuna valutazione finora

- 01 Grafik CY Hal-169Documento20 pagine01 Grafik CY Hal-169Deo HaritaNessuna valutazione finora

- Foundation DesignDocumento41 pagineFoundation DesignDeo Harita100% (1)

- Bangunan Pantai & Lepas PantaiDocumento17 pagineBangunan Pantai & Lepas PantaiDeo HaritaNessuna valutazione finora

- Acero InoxidableDocumento2 pagineAcero InoxidableSergio Alejandro Soto MartínezNessuna valutazione finora

- Violence Against NursesDocumento22 pagineViolence Against NursesQuality Assurance Officer Total Quality ManagementNessuna valutazione finora

- Atex ExplainedDocumento3 pagineAtex ExplainedErica LindseyNessuna valutazione finora

- Operating Instruction PMD55Documento218 pagineOperating Instruction PMD55Dilip ARNessuna valutazione finora

- USA v. Sussmann - Durham Filing - Motion On Potential Conflicts of InterestDocumento13 pagineUSA v. Sussmann - Durham Filing - Motion On Potential Conflicts of InterestWashington Examiner100% (3)

- Coreapb3: Nivin PaulDocumento19 pagineCoreapb3: Nivin PaulNivin PaulNessuna valutazione finora

- Ngo OrganizationsDocumento2 pagineNgo Organizationsapi-295384272100% (1)

- Project JavascriptDocumento58 pagineProject JavascriptashwinNessuna valutazione finora

- HboDocumento126 pagineHboKunal ChaudhryNessuna valutazione finora

- Thick Walled Cylinders and SpheresDocumento0 pagineThick Walled Cylinders and Spherescrossfirex30Nessuna valutazione finora

- Debugging With The PL/SQL Debugger: PhilippDocumento51 pagineDebugging With The PL/SQL Debugger: PhilippBenjytox BenjytoxNessuna valutazione finora

- LabVIEW Core 3 2013 - Course ManualDocumento135 pagineLabVIEW Core 3 2013 - Course Manualtalaindio100% (2)

- STB9NK60Z, STP9NK60Z, STP9NK60ZFPDocumento19 pagineSTB9NK60Z, STP9NK60Z, STP9NK60ZFPyokonakagimaNessuna valutazione finora

- Complaint - Burhans & Rivera v. State of New York PDFDocumento34 pagineComplaint - Burhans & Rivera v. State of New York PDFpospislawNessuna valutazione finora

- GX Deloitte 2017 TMT PredictionsDocumento60 pagineGX Deloitte 2017 TMT PredictionsMontevideo PortalNessuna valutazione finora

- EXHIBIT 071 (B) - Clearfield Doctrine in Full ForceDocumento4 pagineEXHIBIT 071 (B) - Clearfield Doctrine in Full ForceAnthea100% (2)

- Thesun 2009-07-09 Page05 Ex-Pka Director Sues Nine For rm11mDocumento1 paginaThesun 2009-07-09 Page05 Ex-Pka Director Sues Nine For rm11mImpulsive collectorNessuna valutazione finora

- File 1379580604 PDFDocumento9 pagineFile 1379580604 PDFMuhammad Salik TaimuriNessuna valutazione finora

- CV - Oscar ChampionDocumento3 pagineCV - Oscar ChampionKarina Gamarra NinaNessuna valutazione finora

- Murugan Temple of North America: Ahkpuf F Gankd - FZGJP JizDocumento8 pagineMurugan Temple of North America: Ahkpuf F Gankd - FZGJP JizOurMuruganTempleNessuna valutazione finora

- Cameron Residences - Official Project Brief - 080719Documento47 pagineCameron Residences - Official Project Brief - 080719neil dNessuna valutazione finora

- BSM - Company ProfileDocumento15 pagineBSM - Company ProfileLarasanto Cipta AgungNessuna valutazione finora

- Text-Book P3Documento147 pagineText-Book P3Nat SuphattrachaiphisitNessuna valutazione finora

- Job Search & Interview Skills: or Some Real-World Advice That May Prove Useful To YouDocumento97 pagineJob Search & Interview Skills: or Some Real-World Advice That May Prove Useful To YouShah NawazNessuna valutazione finora

- DLL Health 10 Q1-W7Documento8 pagineDLL Health 10 Q1-W7Robert ManiboNessuna valutazione finora

- Sevana - Hospital Kiosk ConceptNoteDocumento103 pagineSevana - Hospital Kiosk ConceptNotemanojNessuna valutazione finora

- MyFlixer - Watch Movies and Series Online Free in Full HD On MyFlixerDocumento1 paginaMyFlixer - Watch Movies and Series Online Free in Full HD On MyFlixerGeanina OlteanuNessuna valutazione finora

- Plant Management TafskillsDocumento4 paginePlant Management TafskillsTHEOPHILUS ATO FLETCHERNessuna valutazione finora

- Indiabulls PILDocumento64 pagineIndiabulls PILPGurus100% (1)

- 04 Handout 1 (Midterms)Documento14 pagine04 Handout 1 (Midterms)Emmanuel DelarosaNessuna valutazione finora

- Train Details of New DelhiDocumento94 pagineTrain Details of New DelhiSiddharth MohanNessuna valutazione finora