Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Engr. Christian R. Orozco

Caricato da

Jun KhoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Engr. Christian R. Orozco

Caricato da

Jun KhoCopyright:

Formati disponibili

EVALUATION OF STRENGTH PERFORMANCE AND ENVIRONMENTAL

BENEFITS OF USING PERVIOUS CONCRETE IN THE PHILIPPINES

Christian R. Orozco, M.Sc.1, Francis Jerome R. de Lara2 and April Eunice E. Esmilla2

Assistant Professor, Institute of Civil Engineering, University of the Philippines, Diliman, Quezon City, Philippines

Telefax: (+632) 4343635 Email: crorozco@up.edu.ph

2

Institute of Civil Engineering, University of the Philippines, Diliman, Quezon City, Philippines

Abstract : Pervious concrete is a type of concrete having an increased number of interlocking voids as compared to the

conventional concrete. It is popular in many countries because of its advantages over conventional concrete and asphalt

pavements. The US Environmental Protection Agency (EPA) recognizes pervious concrete as Best Management Practice for

managing storm water runoff and providing first-flush pollution control. In the Philippines, the use of pervious concrete is not

very popular. This paper discusses the environmental benefits of using pervious concrete in the Philippines for pavement

applications. Laboratory experiments were carried out in order to quantify and assess infiltration, noise reduction, temperature

and compressive strength of pervious concrete with varying mix proportions of water, cement, coarse aggregates and fine

aggregates. It was found out that while pervious concrete has relatively lower strength compared with conventional concrete, it

could significantly reduce noise and temperature. Statistical analysis showed that the water-to-cement ratio and percent fine

aggregates are significant factors affecting strength and infiltration. Results of infiltration experiments were correlated with

strength performance. A correlation coefficient value of -0.895 was obtained suggesting strong negative relationship between

strength and infiltration performance.

to mitigate

runoff in urban areas [2].

Key words : Times Roman, Italic, 10pt, 3 to 5 words, one black line

below ABSTRACT

INTRODUCTION

Pervious concrete is a combination of coarse aggregates,

cement, water and sometimes with little (or no) fine

aggregates. Pervious concrete is a special type of concrete

used primarily for road pavement applications [1]. Addition

of fine aggregates enhances the strength but decreases

infiltration rate of concrete [5]. Since pervious concrete has

many voids, its compressive strength is lower than

conventional concrete but has the same useful life of about 20

to 40 years depending on the manner of installation. The

minimal amount of fine aggregates in pervious concrete

makes it highly porous which causes precipitation to directly

pass through it. The use of pervious concrete has been

recognized by LEED, a rating system developed by the US

Green Building Council (US GBC) to evaluate the

environmental performance of a building, as it has been found

1.1 Uses and Benefits of Pervious Concrete

While the use of pervious concrete is limited in the

Philippines, it has been in use in various countries all over the

world. As given by a lot of reviews and journals, this type of

concrete is considered an environmentally friendly paving

material. Thus, since its first introduction in the United States

in the mid of 1970s, pervious concrete has been applied in

different countries in the world according to Shu et al. [6].

Pervious concrete is importantly applied for sustainable

construction. According to Obla [3], it is recognized by the

EPA for pollution control and storm water management.

Hence, the use of pervious concrete enables more efficient

land use through the elimination of the need for retention

ponds and similar structures according to Tennis [7].

Common applications include parking lots, sidewalks,

greenhouse floors and swimming pool decks.

1.2 Manages Runoff

Pervious concrete effectively controls runoff by capturing the

first flush of surface runoff, where the pollutants in the initial

influent are then filtered. It serves as a medium where it

allows water to pass through it, thus, lowering the potential

flooding of an area by retaining water temporarily until it

infiltrates into the soil matrix. Yang et al. [9] also noted that

pervious concrete pavement includes advantages such as the

quick filtration of rainwater to the ground so that groundwater

can be renewed, the absorption of vehicular noises, and the

adjustment of temperatures.

1.3 Noise Reduction

The porous nature of the surface of pervious concrete is

believed to minimize the pumping of air (the pumping of air

in and out of the tread blocks of the tire, which is currently

thought to be one of the primary noise generation

mechanisms), thereby reducing the noise generation while the

pores inside the material also absorb sound energy through

internal friction [4]. Moreover, a porosity of 15-25% in the

material structure allows sound waves to pass through and

dissipate its energy

Reduces Temperature

Pervious concrete is used in warmer climates as a cooler

pavement alternative to asphalt or conventional concrete. One

such documented use of pervious concrete, specifically PCPC

(or Portland Cement Pervious Concrete), is that of a fully

monitored parking lot composed of half PCPC and half

conventional concrete at the Iowa State University as part of

the Iowa Pervious Concrete Storm water Project. In this

project, it was observed that pervious concrete pavements

become hotter than conventional concrete when subject to

direct sunlight, and are similar in temperature when the

general temperature in the area is low. Therefore, there is less

heat storage capacity in the pervious concrete than in the

conventional one.

1.4 LEED (Leadership in Energy and Environmental

Design)

Pervious concrete has been considered as a green construction

material for road pavement, as it has been recognized by

LEED [8]. According to its official website, Leadership in

Energy and Environmental Design (LEED) is a rating system

that is recognized as the international mark of excellence for

green building in over 132 countries. It is a rating system

developed by the U.S. Green Building Council (US GBC) to

provide independent, third-party verification that a building,

home or community was designed and built using strategies

aimed at achieving high performance in key areas of human

and environmental health: sustainable site development,

water savings, energy efficiency, materials selection and

indoor environmental quality. LEED provides building

owners and operators with a framework for identifying and

implementing practical and measurable green building design,

construction, operations and maintenance solutions.

Each category in a LEED rating system consists of

prerequisites and credits. Prerequisites are required elements,

or green building strategies that must be included in any

LEED certified project. Credits are optional elements, or

strategies that projects can elect to pursue to gain points

toward LEED certification. LEED prerequisites and credits

work together to provide a common foundation of

performance and a flexible set of tools and strategies to

accommodate the circumstances of individual projects. LEED

points are not gained directly by the use of a product but by

meeting a specific sustainability goal of the rating program.

Specific credits where pervious concrete can aid the designer

include:

LEED Credit SS-C6.1 Storm Water Management Rate and

Quantity

LEED Credit SS-C6.1 Storm Water Management Quality

Control

Pervious concrete is recognized by the US Environmental

Protection Agency (EPA) as Best Management Practice for

managing stormwater runoff and providing first-flush

pollution control.

Pervious concrete offers a number of advantages over using

conventional concrete especially with respect to

environmental benefits. As a solution to mitigating urban

runoff, pervious concrete drains water to the ground thereby

minimizing the need of constructing a drainage system. More

areas can therefore be utilized for a different purpose. Due to

the interlocking voids of pervious concrete, water could pass

through this enabling the recharge of groundwater.

MATERIALS AND METHODS

To investigate the strength and infiltration performance of

pervious concrete, a total of forty-five (45) samples of 4

inches diameter by 8 inches length pervious concrete were

casted in the laboratory as shown in Figure 2. Different

parameters were varied such as the water to cement ratio and

percent of fine aggregates. The water cement-ratio used were

0.30, 0.35 and 0.40 while the percent fines were varied from

5% to 15% with an increment of 2.5% yielding 5 different %

fine aggregate cases per water-to-cement ratio. Three

specimens were prepared for each of the test cases. Coarse

aggregates used were those that passed through 9.5 mm and

retained in 4.75 mm sieves. The samples were cured for 28

days.

RESULTS AND DISCUSSION

3.1 Noise Reduction

In this experiment, several objects made from different

materials were subjected to free-fall on both conventional and

pervious concrete surfaces, respectively, from a height of 7.5

inches. The objects were an ornament made from glass, a

plastic container, a cork, a coin, a small block of concrete, and

a tin container as shown in Figure 4. The sound meter, as

shown in Figure 5 is 12 inches away from the conventional

and pervious concrete surface, respectively. After dropping

the objects onto the concrete surfaces, sound (in dB) is then

recorded after the values have registered on the sound meter.

Six graphs were produced for each object dropped on the

concrete surface. The graphs were produced by analyzing the

sound/noise produced (ordinate) and the corresponding

percent fines the sample has (abscissa).

The variability of the noise produced for each type of object

may be due to the fact that the objects fall on parts of the

pervious concrete randomly, therefore producing random

values for noise. There is the probability that the objects

might fall on the crevices or on the solid interfaces/edges in

the pore structure. The shape of the material to be dropped

could also be accounted for. Values become more random for

more irregularly-shaped objects. The w/c ratio does not pose

significant influence on the amount of sound produced per

type of object. Percent fines, however, has influence to the

sound produced after dropping the materials onto both the

pervious and the conventional concrete surfaces. The general

trend for all the objects was that the sound produced increases

at 10% fines and decreases at 12.5%.

3.2 Temperature Reduction

This experiment quantifies these observations by making

laboratory specimen of a standard conventional concrete

pavement in the Philippines and a pervious concrete

pavement. The specimen consisted of a compacted soil as

the bottom layer, the subbase as the middle layer, and the

pavement as the top layer. These were contained on a

12x12x18 inches mold. Sticks and straws were placed per

layer so that the slot for the laboratory thermometer for

measuring the temperature per layer interface is secured.

During mixing for the pervious concrete, the w/c used has a

value of 0.35, with zero fines added to the mix. On the other

hand, the conventional concrete mix was designed for the

common pavements in the Philippines with a strength of 24.1

MPa. The proportions for coarse aggregates, fine aggregates,

cement and water were obtained by measuring each of its

mass in kilograms. Table 6 presents the amount of proportions

of aggregates, cement and water for the pervious and

conventional concrete.

Data for the ambient temperature, the top interface

temperature and the bottom interface temperature were

obtained for this experiment. The results obtained were

graphed on the ordinate versus a 48-hour duration and fourhour increments on the graphs abscissa as shown in Figure 6 .

Two graphs were produced for each interface of soil layer. It

could be observed that the fluctuations in temperature for the

pervious and conventional concrete are consistent. Moreover,

it could also be observed that the pervious concrete

temperature is generally lower than those of the conventional

concrete. The inconsistency with the trend for the ambient

temperature when compared to the trend for the concrete

surfaces shows that the concrete surfaces have absorbed heat

during each day of the experiment duration. The graph for the

bottom interface temperatures, also has implications

regarding heat absorption of the concrete surfaces. The

temperatures are lower than the top interface and the ambient

temperature. From the 9.30AM mark for Day 1 until the day

ends, the trend for the pervious and conventional concrete

bottom interface temperatures increases as the temperature

during the day increases and relatively decreases as the

temperature decreases when the day goes on. This relatively

insignificant decrease in temperature is due to the temperature

absorption of the concrete surface on the topmost layer. As

the day changes to Day 2, ambient temperature decreases

more. Temperatures of both pavements also decrease with the

time and ambient temperature. It is, however, higher than

those of the ambient temperature because it is enclosed under

the concrete surfaces. As one can observe, there is a

threshold time for the behavior of temperatures for the

pervious and conventional concrete temperatures to change.

On hotter temperatures (during the afternoon), the

temperature for the bottom interface of conventional concrete

is lower than those of the pervious concrete since the top layer

absorbs more heat than the pervious surface. Conventional

concrete has higher temperature than pervious concrete on

lower ambient temperatures because as similarly observed

from previous documented experiments, conventional

unique characteristics with each other, 0.3 w/c is increasing,

0.4 w/c is decreasing and 0.35 w/c exhibits normal

distribution curve. It is increasing from 2.5% fines to 10%

fines and decreasing as it approaches 15% fines.

Adding more fine aggregates in 0.4 w/c increases

compressive strength in contrast to the compressive strength

of 0.3 w/c that decrease upon adding more fines. When using

0.4 w/c, fine aggregates function as filler to the voids caused

by coarse aggregates thus, increasing the pervious concretes

strength. On the other hand, when you increase the percent of

fines using 0.3 w/c, the mixture becomes gritty. This will

decrease the compressive strength of pervious concrete.

For 0.35 w/c, adding fine aggregates up to 10% by total

aggregates weight increases the strength of pervious concrete.

However, adding more fine aggregates makes the concrete

mix gritty thus decreasing the concretes strength.

Upon increasing the water content of pervious concrete

mixture, the compressive strength of sample also increases.

When water-cement ratio is increased, more water will

combine with cement and fine aggregates making the

pervious concrete mixture more pasty. This paste will

increase the binding strength so its compressive strength

increases.

concrete has larger heat storage capacity than the pervious

concrete. Therefore, both observing the trends for the top and

bottom interfaces of both conventional and pervious concrete

pavements, it could be deduced that the conventional concrete

has higher heat storage capacity than those of pervious

concrete pavements.

Correlation

Performance

3.4

between

Strength and Infiltration

3.3 Compressive Strength Test Results

Pervious concrete sample exhibits different behavior of

failure compared to conventional concrete. Since it has pores,

the coarse aggregates splatter when the maximum

compressive strength of the sample is achieved. Figure 7

shows the result of compressive strength experiment. Similar

to the result of the infiltration rate test, it was found out that

both the water-to-cement ratio and percent fines affect the

compressive strength of concrete. Two-way analysis of

variance (ANOVA) carried out using statistical software

Minitab gives a p-value of < 0.05 for both of the factors and

their interaction. The graphs of water-cement ratio exhibit

Figure 8 shows the scatterplot between the compressive

strength and the infiltration performance of pervious concrete.

Statistical analysis showed that there exist negative

relationship between the infiltration rate and the compressive

strength (p-value < 0.05 and Pearson correlation coefficient =

-0.895). This decrease in the infiltration performance of

concrete when the strength is increased can be attributed with

the presence of less voids or increased in percent fines which

limits the infiltration of water in the concrete.

SUMMARY AND CONCLUSION

This paper has discussed the strength performance and the

environmental benefits that arise from the use of pervious

concrete over the conventional concrete. The environmental

benefits of pervious concrete include temperature reduction,

noise reduction, runoff management and filtering of

pollutants. The first three environmental benefits have been

confirmed and backed-up by related literature, and were

quantified and further investigated by the experiments as

indicated in this paper. Noise and temperature reduction

experiments had quantified results as concluded from prior

researches.

This paper also presented the result of experiment conducted

to evaluate strength and infiltration performance of pervious

concrete with varying percent fine aggregates. The result of

the study verified that as the percent of fine aggregate

increases, the compressive strength decreases and the

infiltration capacity increases.

It has been shown that one of the disadvantages regarding the

use of pervious concrete is its low compressive strength. In

order to increase the compressive strength of pervious

concrete, fine aggregates should be added. Based from the

experiment for compressive strength, it was further

investigated that for a w/c of 0.35 to 0.4, the fine aggregates

acts as fillers for the voids in between the coarse aggregates;

it is the value for the w/c by which the method of addition of

the fine aggregates for additional strength could be applied.

The addition of fine aggregates for a w/c of 0.3 makes the

pervious concrete mixture gritty, thus there occurs no increase

in strength. One of the effects that results from adding the fine

aggregates for additional strength of the concrete is that the

infiltration rate for the pervious concrete decreases because

the amount of voids that lets the water pass through decreases.

It was also shown that strong linear relationship exists

between the infiltration rate and strength performance of

concrete.

RECOMMENDATIONS

Further study needs to be conducted for the utilization of

pervious concrete in the Philippines. The need for quantifying

the amount of pollutants filtered by the pervious concrete

could be investigated further. The importance of this study

entails risks of pollutants reaching the water table. Through

this study, not only the amount of pollutants filtered could be

quantified but it could also investigate which type of

pollutants the pervious concrete could efficiently filter out

before it gets into the soil and eventually into the aquifer

below. Through this study, further measures could be

improved and advantages and improvements on the costing

(especially regarding maintenance) could further be

investigated. For further investigation on the compressive

strength of pervious concrete, the size of coarse aggregates

could also be varied. The variety of the size of coarse

aggregates to be used could also be taken into account; and

whether or not it has positive effects in increasing the strength

of pervious concrete while at the same time not having to

sacrifice the infiltration rate. In investigating the infiltration

rate for pervious concrete, different locations around the

Philippines could be selected in order to account for the

average amount of rainfall and the infiltration rate for a

specific type of soil for a certain location. Life Cycle Analysis

and Life Cycle Cost Analysis for pervious concrete could also

be analyzed in order to compare the usefulness of pervious

concrete versus conventional and asphalt concrete in terms of

cost and environmental impact.

ACKNOWLEDGMENT

The author would like to acknowledge the funding support

from the UP ERDFI and UPD College of Engineering thru the

Faculty Research and Incentive Award

REFERENCES

[1] American Concrete Institute (ACI), (2006) Pervious Concrete

(ACI 522R-06).

[2] Delatte, N., and Cleary J. (2006) Developing a structural design

method for pervious concrete pavements, International

Center for Aggregates Research (ICAR) 2006 14th Annual

Symposium

[3] Obla, K.H. (September 2007) Pervious concrete for sustainable

development, Recent Advances in Concrete Technology

[4] Neithalath, N., Weiss, J., and Olek J. (2006) Characterizing

Enhanced Porosity Concrete using electrical impedance to

predict acoustic and hydraulic performance, Cement and

Concrete Research, Vol. 36, Issue 11, 2074-2085

[5] Orozco, et al (2013). Evaluation of Strenth and Infiltration

Performance of Pervious Concrete with Varying Percent

Fine Aggregates. Proceedings of the 6th ASEAN Civil

Engineering Conference, Bangkok Thailand.

[6] Shu, X., Huang, B., Wu, H., Dong, Q., and Burdette, E.G. (2011)

Performance comparison of laboratory and field produced

pervious concrete mixtures, Construction and Building

Materials 25, 3187-3192.

[7] Tennis, P.D., Leming, M.L., and Akers, D.J. (2004) Pervious

concrete pavements, Portland Cement Association Serial

No. 2828.

[8] US Green Building Council (n.d.) Leadership in Energy &

Environmental Design, viewed 6 January 2013,

http://www.usgbc.org/leed

[9]

Yang, J., and Jiang, G. (2003) Experimental study on

properties of pervious concrete pavement materials,

Cement and Concrete Research 33, 381-386.

Potrebbero piacerti anche

- Case Studies in Construction Materials: Rishi GuptaDocumento9 pagineCase Studies in Construction Materials: Rishi GuptaRajaSekhararayudu SanaNessuna valutazione finora

- Journalofphysicsiop Nicosanjaya2021Documento8 pagineJournalofphysicsiop Nicosanjaya2021Muhammad Sholahuddin AliyNessuna valutazione finora

- Geopolymer ConcreteDocumento16 pagineGeopolymer ConcreteNGUYENNessuna valutazione finora

- Optimal Mix Design For Pervious ConcreteDocumento9 pagineOptimal Mix Design For Pervious ConcretejanakarajNessuna valutazione finora

- Pavan Savale Capstone 6I MY PROJECT (1) - OrganizedDocumento28 paginePavan Savale Capstone 6I MY PROJECT (1) - OrganizedSE-50 Yogesh KedarNessuna valutazione finora

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsDa EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNessuna valutazione finora

- Using Pervious Concrete As Pavement Chapter-1Documento50 pagineUsing Pervious Concrete As Pavement Chapter-1satish budihalNessuna valutazione finora

- Obla, K.H., 2007. Pervious Concrete For Sustainable Development, Recent Advances in Concrete Technology, Washington DC.Documento6 pagineObla, K.H., 2007. Pervious Concrete For Sustainable Development, Recent Advances in Concrete Technology, Washington DC.AnDhi Lastfresh MuNessuna valutazione finora

- Techbrief: Pervious ConcreteDocumento8 pagineTechbrief: Pervious ConcreteSathish KumarNessuna valutazione finora

- 8495 25474 1 PBDocumento16 pagine8495 25474 1 PBReine AceretNessuna valutazione finora

- Onda - Project ProposalDocumento4 pagineOnda - Project ProposalDeo Kristofer OndaNessuna valutazione finora

- AluminumDocumento7 pagineAluminumcollenedesilvaNessuna valutazione finora

- Hycrete - Integral WaterproofingDocumento43 pagineHycrete - Integral WaterproofingdjokoNessuna valutazione finora

- Case Studies in Construction Materials: Mohamed A. Safan, Zeinab A. Etman, Alaa KonswaDocumento12 pagineCase Studies in Construction Materials: Mohamed A. Safan, Zeinab A. Etman, Alaa Konswadiana cristina arias aldanaNessuna valutazione finora

- Sbe 12 219Documento7 pagineSbe 12 219abdallah_elleithyNessuna valutazione finora

- Pervious Concrete - An Overview: Karthik H. OblaDocumento10 paginePervious Concrete - An Overview: Karthik H. OblaRuthra ManickamNessuna valutazione finora

- IJCRT2005165Documento7 pagineIJCRT2005165Jhe Hann BurcaNessuna valutazione finora

- Study On Sliding Stability of Porous-Concrete Retaining WallDocumento9 pagineStudy On Sliding Stability of Porous-Concrete Retaining Wallraul.chiriacNessuna valutazione finora

- Pervious ConcreteDocumento34 paginePervious ConcreteKarthika SNessuna valutazione finora

- Infiltration and PercolationDocumento22 pagineInfiltration and PercolationMark Gerald Prades RegalaNessuna valutazione finora

- Water Absorbing Raod PPT 2k23Documento20 pagineWater Absorbing Raod PPT 2k23Video Cloud100% (3)

- Green Concrete For Sustainable ConstructionDocumento5 pagineGreen Concrete For Sustainable ConstructionInternational Journal of Research in Engineering and TechnologyNessuna valutazione finora

- Chapter IDocumento4 pagineChapter Isarveshfdk48Nessuna valutazione finora

- Green Concrete: A Seminar Report OnDocumento13 pagineGreen Concrete: A Seminar Report OnUmange RanasingheNessuna valutazione finora

- Chapter-1 General:: Light Weight Concrete Block Using Plastic Dept of CeDocumento51 pagineChapter-1 General:: Light Weight Concrete Block Using Plastic Dept of CeNaveen Gowda k sNessuna valutazione finora

- Applications of Pervious Concrete in Road PavementsDocumento15 pagineApplications of Pervious Concrete in Road PavementsIJRASETPublicationsNessuna valutazione finora

- Developing A Framework For Low-Volume Road Implementation of Pervious Concrete PavementsDocumento15 pagineDeveloping A Framework For Low-Volume Road Implementation of Pervious Concrete PavementsmargarethsmNessuna valutazione finora

- Major ProjectDocumento18 pagineMajor ProjectAwesomeNessuna valutazione finora

- Performance Assessment of Pervious Concrete Road On Strength and Permeability by Using Silica FumeDocumento18 paginePerformance Assessment of Pervious Concrete Road On Strength and Permeability by Using Silica FumeIJRASETPublicationsNessuna valutazione finora

- Porous Concrete For Ground Water RechargeDocumento15 paginePorous Concrete For Ground Water Rechargesamarthd1103Nessuna valutazione finora

- Pervious ConcDocumento11 paginePervious ConcSuman Sudhangsu Chanda100% (1)

- Irjet V5i5381 PDFDocumento4 pagineIrjet V5i5381 PDFAjay Kumar GantiNessuna valutazione finora

- THESIS To Be Printed2Documento75 pagineTHESIS To Be Printed2Hazel Karen Leona Palaran71% (7)

- Determination of Flow Rate of Water in Concrete by Rilem Tube MethodDocumento12 pagineDetermination of Flow Rate of Water in Concrete by Rilem Tube MethodKishore Nayak k100% (1)

- UntitledDocumento20 pagineUntitledbinnu SurlaNessuna valutazione finora

- Laporan Perencanaan Teknis JembatanDocumento7 pagineLaporan Perencanaan Teknis JembatanmirzaNessuna valutazione finora

- Permeable Concrete Eco-Paving As Best Management Practice in Australian Urban Road EngineeringDocumento11 paginePermeable Concrete Eco-Paving As Best Management Practice in Australian Urban Road Engineeringhasan syukurNessuna valutazione finora

- Concreto Permeable: Desarrollo Urbano de Bajo Impacto: 65 Comentarios Promedio de ValoraciónDocumento6 pagineConcreto Permeable: Desarrollo Urbano de Bajo Impacto: 65 Comentarios Promedio de ValoraciónJafet Gonzales AbantoNessuna valutazione finora

- Water PollutionDocumento8 pagineWater PollutionAzher UddinNessuna valutazione finora

- C-P57-FullPaper Soil StabilizationDocumento13 pagineC-P57-FullPaper Soil Stabilizationmunna 00170Nessuna valutazione finora

- Jiang 2020 IOP Conf. Ser. Earth Environ. Sci. 455 012081Documento7 pagineJiang 2020 IOP Conf. Ser. Earth Environ. Sci. 455 012081Eko Indra WatiNessuna valutazione finora

- 69 Zasiah ICMEREDocumento7 pagine69 Zasiah ICMEREAhmed EsamNessuna valutazione finora

- Green Concrete: A Seminar Report OnDocumento13 pagineGreen Concrete: A Seminar Report Onsumay banerjeeNessuna valutazione finora

- Effects of Curing and Cement Type On Leak Deterioration of Concrete in Water Tanks 2165 784X 1000322Documento9 pagineEffects of Curing and Cement Type On Leak Deterioration of Concrete in Water Tanks 2165 784X 1000322kamranNessuna valutazione finora

- Green Concrete: K.L.E. College of Engineering and Technology 1Documento26 pagineGreen Concrete: K.L.E. College of Engineering and Technology 1Mohak NagraniNessuna valutazione finora

- Porous Concrete As An Anti-Aquaplaning Building MaterialDocumento11 paginePorous Concrete As An Anti-Aquaplaning Building Materialraul.chiriacNessuna valutazione finora

- CPP Pervious RoadDocumento4 pagineCPP Pervious Roadatharv paritNessuna valutazione finora

- Advances in Concrete TechnologyDocumento10 pagineAdvances in Concrete TechnologytusshaarpatilNessuna valutazione finora

- Porous ConcreteDocumento22 paginePorous ConcreteROSHAN OJHA100% (8)

- Capstone Pk12Documento15 pagineCapstone Pk12Mukund SambareNessuna valutazione finora

- Full Projects (1) - Green ConcreteDocumento19 pagineFull Projects (1) - Green ConcreteIbrahim Abshir JamaNessuna valutazione finora

- Act 6 To Be PrintedDocumento11 pagineAct 6 To Be PrintedMc SanidadNessuna valutazione finora

- Advanced Construction Materials For Highway ApplicationsDocumento4 pagineAdvanced Construction Materials For Highway Applicationsyihenew assefaNessuna valutazione finora

- Partial Replacement of Fine Aggregate Using Sludge in ConcreteDocumento16 paginePartial Replacement of Fine Aggregate Using Sludge in ConcreteBala GaneshNessuna valutazione finora

- 2018-Pervious Concrete As An Alternative Pavement Strategy A State-Of-The-Art Review-Debnath - & - SarkarDocumento17 pagine2018-Pervious Concrete As An Alternative Pavement Strategy A State-Of-The-Art Review-Debnath - & - SarkarsevaNessuna valutazione finora

- Pozzolan SCDocumento10 paginePozzolan SCAgikx ChabeNessuna valutazione finora

- Nagmani Final ProjectDocumento34 pagineNagmani Final ProjectPrints BindingsNessuna valutazione finora

- Section 02795 Porous Paving: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocumento6 pagineSection 02795 Porous Paving: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDNessuna valutazione finora

- Final Revision 102418 PDFDocumento75 pagineFinal Revision 102418 PDFJustin ToreroNessuna valutazione finora

- 01 PBD - 16F DOTCConfRmRnv - FINAL 9 1 PDFDocumento109 pagine01 PBD - 16F DOTCConfRmRnv - FINAL 9 1 PDFJun KhoNessuna valutazione finora

- Google Earth Property SurveyingDocumento28 pagineGoogle Earth Property SurveyingJun KhoNessuna valutazione finora

- Quantity DistanceDocumento4 pagineQuantity DistanceJun KhoNessuna valutazione finora

- BIM-based Work Environment of Value Engineering in Sustainable ConstructionDocumento6 pagineBIM-based Work Environment of Value Engineering in Sustainable ConstructionJun KhoNessuna valutazione finora

- Cpes PpaDocumento12 pagineCpes PpaJun KhoNessuna valutazione finora

- UnsolProp B Unsol Timeline PDFDocumento8 pagineUnsolProp B Unsol Timeline PDFJun KhoNessuna valutazione finora

- EIS Pasay Harbor ReclamationDocumento515 pagineEIS Pasay Harbor ReclamationJun Kho100% (1)

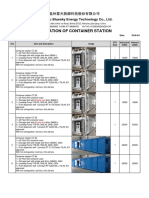

- Quotation of Container Station: Wenzhou Bluesky Energy Technology Co., LTDDocumento3 pagineQuotation of Container Station: Wenzhou Bluesky Energy Technology Co., LTDJun KhoNessuna valutazione finora

- 2013 Revised JV GuidelinesDocumento3 pagine2013 Revised JV GuidelinesJun KhoNessuna valutazione finora

- Quality Policy StatementDocumento1 paginaQuality Policy StatementJun KhoNessuna valutazione finora

- Bid DocumentsDocumento18 pagineBid DocumentsJun KhoNessuna valutazione finora

- Topic 9 - Engr. Juanito C. CunananDocumento59 pagineTopic 9 - Engr. Juanito C. CunananJun KhoNessuna valutazione finora

- Unsolicited ProposalDocumento52 pagineUnsolicited ProposalJun KhoNessuna valutazione finora

- All-In-One Solar LED Street Light QuotationDocumento2 pagineAll-In-One Solar LED Street Light QuotationJun KhoNessuna valutazione finora

- Complete - River Case Study - The GangesDocumento3 pagineComplete - River Case Study - The Gangesleolee181015Nessuna valutazione finora

- WHO EmergencyDocumento64 pagineWHO EmergencysandeepanchoudhuryNessuna valutazione finora

- Order Denying SJ Motions 083115Documento13 pagineOrder Denying SJ Motions 083115petersoe0Nessuna valutazione finora

- CEN 602 - Tutorial #2Documento3 pagineCEN 602 - Tutorial #2Chayank 2Nessuna valutazione finora

- Nissen Wagon Works Master Plan Report (Fall 2016)Documento52 pagineNissen Wagon Works Master Plan Report (Fall 2016)CP TewNessuna valutazione finora

- ProposalDocumento13 pagineProposalJack JackNessuna valutazione finora

- 2015 Eagle Drainage Design Standards PDFDocumento21 pagine2015 Eagle Drainage Design Standards PDFNabil AhmedNessuna valutazione finora

- 302 1006 003 Make Up750ml MEK United StatesDocumento8 pagine302 1006 003 Make Up750ml MEK United StatesLeonor Virginia GalindezNessuna valutazione finora

- Matec Catalog Technical PDFDocumento21 pagineMatec Catalog Technical PDFMa. Cristina EspinosaNessuna valutazione finora

- FACT SHEET: No. 6 Fuel Oil (Bunker C) SpillsDocumento2 pagineFACT SHEET: No. 6 Fuel Oil (Bunker C) Spillsmartini.simNessuna valutazione finora

- OSWAMS Solid WasteDocumento18 pagineOSWAMS Solid Wastesalum abasiNessuna valutazione finora

- Water Supply AND Sanitary Engineering: by RangwalaDocumento5 pagineWater Supply AND Sanitary Engineering: by RangwalaBharat GouripurNessuna valutazione finora

- Algal BloomsDocumento3 pagineAlgal BloomsAroma MangaoangNessuna valutazione finora

- How Is Wastewater Harmful?: BlackwaterDocumento6 pagineHow Is Wastewater Harmful?: Blackwaterashutosh paridaNessuna valutazione finora

- A Surface Water Scenario in Dhule District of MaharashtraDocumento6 pagineA Surface Water Scenario in Dhule District of MaharashtrakiranNessuna valutazione finora

- Alderley PWT BrochureDocumento8 pagineAlderley PWT BrochurechirinoslaaNessuna valutazione finora

- MST-SS - General Geoography - Reaction PaperDocumento14 pagineMST-SS - General Geoography - Reaction PaperMia BumagatNessuna valutazione finora

- Drainage System: by Asst. Professor S.Kumar Budha College of ArchitectureDocumento31 pagineDrainage System: by Asst. Professor S.Kumar Budha College of ArchitecturemimahmoudNessuna valutazione finora

- Upang Cea 2bsar Arc142 P1Documento66 pagineUpang Cea 2bsar Arc142 P1Park JiminNessuna valutazione finora

- Documents - Pub Eia Guidance Manual Final Ports Harborsmay 10Documento145 pagineDocuments - Pub Eia Guidance Manual Final Ports Harborsmay 10Priyanka BandagaleNessuna valutazione finora

- P0408 HM TP M TS 003Documento79 pagineP0408 HM TP M TS 003SurangaGNessuna valutazione finora

- Revelstoke Liquid Waste Management Plan - Stage 1Documento272 pagineRevelstoke Liquid Waste Management Plan - Stage 1AlexCooperRTRNessuna valutazione finora

- Jwarp 2022062116351401Documento14 pagineJwarp 2022062116351401aldoNessuna valutazione finora

- JCP-1500-3000 SeriesDocumento1 paginaJCP-1500-3000 SeriesAlban HysomemajNessuna valutazione finora

- DIY Homemade Septic System PDFDocumento9 pagineDIY Homemade Septic System PDFCebu CribsNessuna valutazione finora

- Hfdwa Appendices PDFDocumento572 pagineHfdwa Appendices PDFernesticoNessuna valutazione finora

- Revised Final Year Project TopicsDocumento3 pagineRevised Final Year Project TopicsIan KahuthiaNessuna valutazione finora

- Trickling FiltersDocumento16 pagineTrickling FiltersGunnar AgarwalNessuna valutazione finora

- Is 13134Documento14 pagineIs 13134Sowjanya ChNessuna valutazione finora

- ECM Legislation (Contractors)Documento2 pagineECM Legislation (Contractors)moe3kaNessuna valutazione finora