Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Juki DDL 555 Manual

Caricato da

Marc Vanderloo100%(2)Il 100% ha trovato utile questo documento (2 voti)

1K visualizzazioni15 pagineManual for the Juki DDL 555 industrial sewing machine.

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoManual for the Juki DDL 555 industrial sewing machine.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

100%(2)Il 100% ha trovato utile questo documento (2 voti)

1K visualizzazioni15 pagineJuki DDL 555 Manual

Caricato da

Marc VanderlooManual for the Juki DDL 555 industrial sewing machine.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 15

BE2270TOBUA

f DDL 227

, j tout ODL 552-553-555

HIGH SPEED SINGLE NEEDLE,

TOKYO JUHI INDUSTRIAL CO.. LTD.

We thank you for parhasng UKE Hone] DDL 227, BDL-SS2 53585. ih speed, sgl

ole tks adn ewig machines

DDDLSS2 fy best wae for seuany poner ike; DISS 6 deen a custo fr

sewing bey weight mater mst DDIL329, DDLSSS inequppe with cine feed mechani

foravle ea al nape ih xsoning mos sis, Newnes Oot gentlemen

‘The thread take, swing hook, ed mechani, ee ate all of lly signed an

sonata fos hig spot ong. Tito. a hsp eine, the aie oud noi

eture ogeating thee malas, plane tea Uh INSHRI CHION BDK cael and

swing these chins

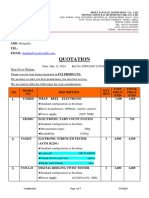

SPECIFICATIONS

oss [Ts

See

Seog Seu” [au

Ted

— app teed wean

‘Astonatc icing rokNy HOOK ig ot Bok tt 79

Dia wit—=18 | opa2s7 att=22 Dist eI

Teedumwint] Mae esp | Mas. Sapa tas 2

el Prato ten Pits

[ser o z

Ca Nowe Noe esc 9st

Tabciting

‘ll

Tie

ow Batis OM Nat

CONTENTS

Motor ply an the bet

Cotes petting the acne

atekston

nog the pes

he pre ta tee

ight of te fet do

he snick kngth

sjsting the tah figth ADDI-S58, HDL

Rovere sing DDL:S8S, DLE)

png the eight ots presse har

ing the aun of the ead ake

the eng pss of hee ev DBL SSS)

Ths INSTRUCHION HOOK mi

z

g

2

INSTALLING THE OIL RESERVOIR

ell

am wi [|

MOTOR PULLEY AND THE BELT

Hh amber of

orp

poss

Boss

r

Psa

nse

S30 sp

‘Ton im

oad S52 8 tt

tes iia DDLSSS a8 hy

tip ted ihspoke DDLSSS ats

fo 3.8 and

Urata 4S spo. Foe

et Spine aM C2

{he dimen 3 the

speed

edo ab

‘heen

CAUTIONS ON OPERATING THE MACHINE

1. ot sae the hin, ane ay chest, tne the i et

2 Mfobpe tas the maine toad Ube pera Day AOE HO TE wh

eet

4 Afugh the ahi can aan asa se. ft the ft i

to DDL SE ere at ml 3

LUBRICATION

Before operating the machine

Ter ap the a sereir with JUKE

Defi Oi No. Twp tote atk HIGH

2, Wateh and ee tt theo ve does not

fo below the "LOW" mak

3. Under noua condos an the wah

bran’ ater it fed up iol the

fet pur apts! theo sige wind

{ceution)

1p Whew the i oy ay ange wit nes

feat oi dhe ol pg of he sero

Kermoved, ol wil ote ont.

ay When the machise to bs Ton fot the fst

tine when 35 le fou eat enh

tune, rm the machine at 3,000-3,500

0 Smt (ms a ow

‘el

ot #85, o0L227 Me hun 3,500 p.m. a

Tansanpy to stlous pat i erased

(sig window

ise at eank

rune of eco

“oi weustng va |

LN

‘ronshal

‘counters

1. Adjusting the oil supply to the face

part

when adjusting te oi anpply 1 the sheen’

feup and esdle bar clan component,

femove te face piste and the ol preventing

Plate stadt by taming the oil austng

pint ho tp of the main sa

Wen tne rod mark othe adtion win

mes near theca, the soem gt

fe

2 When the ted mark: camesf0 the opposite

fide the sank he sual gle ore.

(caution)

The cll wmaunt dost at change immetly

te in aden, £0 he aug. Rave

2, The oil adjusting pin

1. The oil adjusting pin has 9 awed grove

own in the tips, When ths grove

Unt oe al ole of the man

ste

2° fe hol the aout ges es

3, The ted mak on the ol adpster Sows the

th thou Ue carved goo

3, Adjusting the oil supply to the hook

‘components

‘ne simply of it te the hook vonpanent

fed by the ol tga cae 0

itis ave ened toward sig,

th amount pe 198

2. ins wae sti to =, 8800, the

roan ot le

THREADING THE MACHINE

tae te hand wel ight an ple te ead ate the est poston

1. Pass the needle th a, ts

2, Past the tread 10 fiom Rt

2 PET SN oma of he the om the nse ee

PREPARATION OF THE BOBBIN THREAD

& removing the bobbin case

Winding the Bobbin Un

‘

‘THE THREAD TENSION

\|eliceoe.

©:

VY] Wired okey

ig

avin ey

i

heal temton 1 Teor ace

UW

Adjusting the needle thread tension

fea sitehes are formed when the needle

vd ihe Babin thtead are perfectly

ed at the center of he eth

fon the necile tend i adjsed

eed enon ut

to ngh fomake the tension stonger

ado che lf to make mene

“Thiend take-up spring

‘To chang the moving tnge of the dead

tenon spn

1. Keone the sctew of the tvead tension

back.

2 Rotate the thea tension bat

‘To change the sengih Fhe tend take

wp sring

1. Loop tne set stew, move the thread

fenon ta

2 Loosen the tex! teason Dor se stew

and adja.

3. Wen the thesd femion bar tard to

Tit the pring wil get stronger and

6 ll wil Get weaker

hvcal too

“Tead take-up spring

bobbin thread tension

fad tenon srw af he bobbin

he bob shea een,

right 19 make tho bobbin

Ahvend tenon tong ad t eft to make

°RESSER FOOT AND FEED DOG

3, Ale ag

the machine

‘The eight of

bight

Ingtork

More @

za

Aajusting the pressure of

1. Tu the presse a

to make the presute stonge,

Turn this sree tee a make the pose

Presser lifter

‘he pester foot ll po Hp

115,64°1 from the that ya sxe

Pah ven hand fe, the preset et

Titer, the pre foot wil po ap

Tibi 35/60 fot he the lt wae

Height ofthe feed dog

7 st the a of the ed

omen th camping sen of he sd

Weed dog bss pan ds and

3. After adjusting sy

‘THE STITCH LENGTH

Adjusting the stitch length

(oot ss2 001 5531

“he sie ngth of DDL-SS2 and DOLSSD

jae bythe ‘tte canter

of the upper sift of the army Rotate Oe

and wheels you hep pening done the

Whom ihe Qatton de dow dey int dhe

roore of the rathet (ye eas eH) ah

foe tatin Tather ap by etaling the

Ihde, atch the er of alee

seanted (ith the adcatr st the hae

Wi ts. length of seh en be ase

The Byers onthe fas weet inte he

umber of siteber per ow inh Rekoe the

Pash button an ef tat the baton returns

{othe engl postion

Gepieand lor DDLS33 W353

{Cauton) Do ot touch the Baton whe the

‘eat ofthis md te aot

the Feed aging atom 12

the fed eve

ruluete

tip or elt and

coming ot from he ane

+ Themes se engi 5/32

Reverse sewing |DDL-835, 001.2271

7] 1 For severe sewing, pos the feed vet

2. Ae nga ths lover is Kept dwn, revere

sewing can be ptfonnel

2 Release this lever and he fe er wi

tov to ong poem ana noma ae

stchig ean be fs

INSERTING THE NEEDLE

uy pa

INSTALLING AND REMOVING

aa RR OPA

is]

Feed tae

Mook took

(@) fet

br DDLSS2, DDL-SS5 ant el,

the BR's Tm and for BDESS3 moe

2 Tenn ths woe lone

3 thd the oe wt he he grt

ff the nee ves hese

Unset de nse dept thence ok

Then sees fghen the noclle lat

THE SEWING HOOK

Dering the vue

Ind ott the ho

Ik changes ie

the hook ths ew sto Lal

Tata ea

be hehe

‘he

X Remove the

ever the 3 ete oth seg

5. Rotate tle hand ssl on rane ap the

Fas to tgs pon

Ga place 11 the poo as fm

the Hee

~w-

RELATION BETWEEN THE HOOK AND THE NEEDLE

Match hs needle with the sewing Mook as

follows:

1 Rotate the hand heel an ng the nce

ta foe Hoest potion.

2, Loon he needle at camping se re

2 cramp sre

(vse

Whee marking he timing af the needle and

the sewing, Hook, Be sate To set the fed

jest sh 10 "0

{Determine the height of the neve bar)

2. Match she upper eave line of the needle

tar wi the Tower edge of te noele Ba

lower bashing

4. Ths Me nee bar taping set ee

ST

OL TH NLEDLE XK

posi

IWIN MOOK

(Determine the position of the sewing

hook)

5 Loos the 3 cetping sree of the Nook

that th ook cas Be rotated ely th

‘Me the Book th your Hand the

passing sion,

>, Rotate the had wheel ad match the her

Sane line of the nese br wih the ler

ge of te nt bar loser Ueing

athe

9, Mate nce between the teede

fn th hook Ble pont (0 0.08 mp and

Seve hook | 9, Steurey tighten the hook clmping se

Te

re

ADJUSTING THE HEIGHT OF THE PRESSER BAR.

(DDL-555)

When the eight oF the direction of the

pester bar Is to be changed due (0 the

change of piener foot

1. Remove the cubbet pg of the face pate,

2. From this hol, gust by loosening the

premer sor clamping sie:

a, fer the austen, secute phten Me

‘The amount of the sven! takeup should

te changed scoring tothe length of ates

for Ohckress of the sewing cloth 10 progice

Heal trend tenon,

1 When sewing Heavy welght mater, move

(he ted ide to your ltt

“The that tkeup Sout of th

eb more

2, When sehing Upht weight mater, move

the head guide to your 1h

‘The tend fakeup amount ges es

ADJUSTING THE PRESSING PRESSURE OF THE FEED LEVER

The reversing. sing of the te

sttengiened somewhat 0 thit at

ening, no mater what Kid

te formed, the ver ten ost

gia poston

Wen the shin pe 4 wna oe when the

Inachine iy be um by Towering the pa,

{he preningprewore of the led ver ca

Feseed by tosening heading aut aE

‘he aeeompanying Neue

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Der Kleine RieseDocumento20 pagineDer Kleine RieselectoadictaNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Sarabande KuhnauDocumento1 paginaSarabande KuhnauMarc VanderlooNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Skirt TCDocumento1 paginaSkirt TCMarc VanderlooNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Direct Skirt SystemDocumento1 paginaDirect Skirt SystemMarc VanderlooNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Handmade Buttonholes Illustration PDFDocumento1 paginaHandmade Buttonholes Illustration PDFMarc VanderlooNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- (1913) Phonology & Grammar of Modern West Frisian: With Phonetic Texts & GlossaryDocumento194 pagine(1913) Phonology & Grammar of Modern West Frisian: With Phonetic Texts & GlossaryHerbert Hillary Booker 2nd100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Making A Lounge JacketDocumento20 pagineMaking A Lounge JacketMarc VanderlooNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Inlays and TurningsDocumento10 pagineInlays and TurningsMarc VanderlooNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Alterations 3 - CoatsDocumento14 pagineAlterations 3 - CoatsMarc VanderlooNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Alterations 5 - SleevesDocumento5 pagineAlterations 5 - SleevesMarc VanderlooNessuna valutazione finora

- Alterations 1 - TrousersDocumento5 pagineAlterations 1 - TrousersMarc VanderlooNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Alterations 2 - WaistcoatsDocumento7 pagineAlterations 2 - WaistcoatsMarc VanderlooNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Picken - TailoringfullDocumento57 paginePicken - TailoringfullMarc VanderlooNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Early Journal Content On JSTOR, Free To Anyone in The WorldDocumento18 pagineEarly Journal Content On JSTOR, Free To Anyone in The WorldMarc VanderlooNessuna valutazione finora

- How To Repair ShoesDocumento82 pagineHow To Repair ShoesMoreMoseySpeed100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Sailor of King GeorgeDocumento300 pagineSailor of King GeorgeMarc VanderlooNessuna valutazione finora

- Handbook of Watch and Clock RepairsDocumento178 pagineHandbook of Watch and Clock RepairsRyan Bisaro100% (4)

- Wall StreetDocumento382 pagineWall Streetpaul-hodorogea-8456100% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Survitec: JSF F-35 Agile Pilot Flight EquipmentDocumento12 pagineSurvitec: JSF F-35 Agile Pilot Flight EquipmentChris Efstathiou100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Bloody ChamberDocumento29 pagineThe Bloody ChamberIlham YUSUFNessuna valutazione finora

- 5101 Cyberspace Sprawlgangs & MegacorpsDocumento65 pagine5101 Cyberspace Sprawlgangs & MegacorpsMarco CorrengiaNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Blyton Enid Story BookDocumento97 pagineBlyton Enid Story BookEvie Lindiawati GunawanNessuna valutazione finora

- Q4 HE Dressmaking 10 Week3 4Documento4 pagineQ4 HE Dressmaking 10 Week3 4jessa magcayanNessuna valutazione finora

- Expansion and Death of DiorDocumento3 pagineExpansion and Death of DiorTHU HIỀN TRẦNNessuna valutazione finora

- Tie-Dye and BatikDocumento8 pagineTie-Dye and BatikRebecca Randall Bryan Gallery, Coastal Carolina UniversityNessuna valutazione finora

- Complete The Sentences With: Gerund or The Infinitive. Then, Match The Sentences With The PicturesDocumento1 paginaComplete The Sentences With: Gerund or The Infinitive. Then, Match The Sentences With The Picturesmadalinaaaa1979Nessuna valutazione finora

- Sex Chart 2Documento3 pagineSex Chart 2Camila Wilson86% (49)

- BFP Handbook Final Oct20Documento448 pagineBFP Handbook Final Oct20Jeremy Gardose Atanacio100% (5)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Total Number of Orders (Per Design)Documento28 pagineTotal Number of Orders (Per Design)Monica Ann Louise IntongNessuna valutazione finora

- N5900B 2 ManualDocumento12 pagineN5900B 2 ManualYadgar ZanganaNessuna valutazione finora

- Push and PullDocumento48 paginePush and PullAmber De Los SantosNessuna valutazione finora

- Beauty Is in The Eye of The BeholderDocumento1 paginaBeauty Is in The Eye of The BeholderStefenny PanggadewiNessuna valutazione finora

- Upp Int 3 End of Term Test ONLY Reading and ListeningDocumento3 pagineUpp Int 3 End of Term Test ONLY Reading and ListeningWilson Rafael Otalora RamirezNessuna valutazione finora

- Different Categories of GarmentsDocumento19 pagineDifferent Categories of GarmentsPragati JoshiNessuna valutazione finora

- Refashioning Performance Management: Presented by Harshil Doshi Lushna Mahapatra Meghna PeethambaranDocumento16 pagineRefashioning Performance Management: Presented by Harshil Doshi Lushna Mahapatra Meghna Peethambaranmeghna100% (1)

- Concreting Safety Checklist: Oh & S Management SystemDocumento2 pagineConcreting Safety Checklist: Oh & S Management Systemmunna yadavNessuna valutazione finora

- Beko WT Series ManualDocumento88 pagineBeko WT Series ManualBOSCHCLASSIXX1200Nessuna valutazione finora

- hALLOWEEN QUESTIONSDocumento2 paginehALLOWEEN QUESTIONSKatiaAFGamarraNessuna valutazione finora

- Confusing WordsDocumento3 pagineConfusing WordsUyen VuNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Autumn Off Duty SafetyDocumento20 pagineAutumn Off Duty SafetyDeepu RavikumarNessuna valutazione finora

- MN Wool World X LLC Quote Yg086d Yg026t Yg002c1 EtcDocumento7 pagineMN Wool World X LLC Quote Yg086d Yg026t Yg002c1 EtcLyracism UguumurNessuna valutazione finora

- Vca Jordan Apparel Final Report - Cbi4Documento76 pagineVca Jordan Apparel Final Report - Cbi4Rajnish ShuklaNessuna valutazione finora

- Seishun Buta Yarou Series - Volume 01Documento315 pagineSeishun Buta Yarou Series - Volume 01Tommy YothsackdaNessuna valutazione finora

- Reading 4: Topic 1. Understanding Topics in A Sentence 2. Identifying Topic in A SentencesDocumento14 pagineReading 4: Topic 1. Understanding Topics in A Sentence 2. Identifying Topic in A SentencesLijah Adena HasibuanNessuna valutazione finora

- The Monkey's PawDocumento15 pagineThe Monkey's PawHannah NessNessuna valutazione finora

- DMDave Adventure - The Atrophy of Flesh (2nd Level)Documento11 pagineDMDave Adventure - The Atrophy of Flesh (2nd Level)Diogo FonsecaNessuna valutazione finora

- Terminology & Definitions A.: Sewing Room Terms & DefinitionsDocumento9 pagineTerminology & Definitions A.: Sewing Room Terms & DefinitionsAbdur Rauf Khan100% (1)

- How To Use Greist AttachmentsDocumento36 pagineHow To Use Greist Attachmentsfmaria64100% (9)

- Vintage Knit Hats: 21 Patterns for Timeless FashionsDa EverandVintage Knit Hats: 21 Patterns for Timeless FashionsValutazione: 4 su 5 stelle4/5 (4)

- Bulletproof Seduction: How to Be the Man That Women Really WantDa EverandBulletproof Seduction: How to Be the Man That Women Really WantValutazione: 4.5 su 5 stelle4.5/5 (169)