Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bearings in Vibrating Screens

Caricato da

nestor159357100%(1)Il 100% ha trovato utile questo documento (1 voto)

374 visualizzazioni38 paginerodameintos

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentorodameintos

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

374 visualizzazioni38 pagineBearings in Vibrating Screens

Caricato da

nestor159357rodameintos

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 38

‘The SKF Group is an international manufacturing and

‘marketing organisation operating in more than 130

countries. SKF has some 100 factories worldwide,

SKF sales units are backed up by some 200 branch

sales offices and over 7 000 distributors and retailers.

Worldwide availability of SKF bearings is supported

by a comprehensive technical advisory service. Apart

from rolling bearings, SKF manufactures linear bear-

ings, plain bearings, bearing housings, ball and roller

screws, textile machinery components, airframe com-

ponents, seals, retaining rings, machine tools and a

variety of precision machine components. The experi-

‘ence gained in these various fields provides SKF with

the knowledge and expertise so necessary for the de-

velopment, manufacture, and application of advanced

engineering products.

© Copyright SKF 1993

‘The contents of this publication are the copyright of

the publisher and may not be reproduced (even ex-

tracts) unless permission is granted. Every care has

been taken to ensure the accuracy of the information,

in this publication but no liability can be accepted for

any errors or omissions.

Publication 4202 E

Reg. 842 3 - 5 000 : 1993-06

Printed in Sweden by Skandia-Tryckeriet

Bearings in vibrating screens

Application handbook

Contents

Nomenclature.

Basic requirements and recommendations ...

Design of equipment and process :

Bearing performance requirements.

Bearing design

Spherical roller bearings...

Cylindrical roller bearings

Bearing selection

Vibrating screens with free movement or two-bearing screens) "

Circular motion or four-bearing screens 12

Vibrator units with linear motion ... . 13

ibrator motors e 14

Additional calculation methods... 14

‘Spherical roller bearings. 14

Cylindrical roller bearings 14

Bearing application

Fitting practices :

Outer ring ovality - a

Sealing

Typical appiications Tra ‘

‘Two-bearing or free movement screen with grease lubrication...

‘Two-bearing or free movement screen with oil bath lubrication

‘Two-bearing or free movement screen with oil circulation

Four-bearing screen with grease lubrication

Linear motion mechanism with oil mist lubrication ...

Linear motion gearbox z

Vibrator motor.

Lubrication...

Grease lubrication

Oil lubrication :

Mounting and maintenance

Bearing tables

Spherical roller bearings .

Cylindrical roller bearings

SKF

Nomenclature

g

3

z

Quantity

Basic dynamic load rating

Basic static load rating

Maximum housing diameter

Minimum housing diameter

Calculation factor

Axial force

Maximum permissible axial load

Mass of vibrating screen sieve without charge

Mass of vibrating screen counterweights

Calculation factors

Rotational speed

Equivalent dynamic load

Equivalent dynamic radial load

Bearing fatigue load limit

Radius of vibration

Maximum deviation from axis of os

Distance between common centre of gravity of the

‘counterweights and the shaft axis

Number of bearings

Number of eccentric bearings

Number of frame bearings

Labyrinth seal gap dimensions, axial

Labyrinth seal gap dimensions, radial

Calculation factors

PPPs

ar

DO7.N2 990

Bp 7.0v VS.

x

x

Calculation factor

Diametral clearance after mounting

Viscosity r

Angular velocity

aay

exPe

ey Ee (10)

Ps (14)

,87 P, + YF,

Appropriate values of the calculation factors e, Y, and

Y, are found in the bearing tables for each bearing,

sée pages 32 and 33.

14

Cylindrical roller bearings

indrical roller bearings with flanges on both inner

iets rings can carry axial loads if the orientation

of the flanges permits, eg type NJ. For the cylindrical

roller bearing series 23 the equations become:

P=P, when FJ/P,se (12)

P=0,92P,+YF, when F/P,>@ (13)

where

@ = calculation factor

2 for bearings of series 10, 2, 3 and 4

,3 for bearings of series 22 and 23

Y = axial load factor

.6 for bearings of series 10, 2, 3 and 4

4 for bearings of series 22 and 23

Since axially loaded cylindrical roller bearings will only

operate satisfactorily when they are subjected to a

simultaneously acting radial load, the ratio F,/P,

should not exceed 0,5 for EC design bearings.

Dynamic axial load carrying capacity

Bearings with flanges on both inner and outer rings

can support axial loads in addition to radial loads.

Their axial load carrying capacity is not primarily

determined by the fatigue strength of the material but

by the load carrying capacity of the sliding surfaces at

the roller end and flange contact, and thus mainly

governed by the lubrication, operating temperature

issipation from the bearing. Assuming the

conditions cited below, the permissible axial load can

be calculated with sufficient accuracy from

k,C, 10%

Fyp= t=, _ &P,

(4)

where

F,.= maximum permissible axial load, N

Cf = basic load rating, N

P, = equivalent radial load, N (see pages 11 to 14)

n' = operating speed, r/min

d_ =bearing bore, mm

k, = 1,5 with oil lubrication and 1 with grease

lubrication

ky =0,15 with oil lubrication and 0,1 with grease

lubrication

The above equation is based on conditions which are

considered typical for normal bearing operations:

= a difference of 60 °C between the bearing operating

temperature and the ambient temperature;

— a specific heat loss from the bearing of

0,5 mWimm? °C;

= avviscosity ratio x = 2.

SKF

The viscosity ratio x is the ratio of the actual viscosity

v at the operating temperature to the requisite viscos-

ity v, for adequate lubrication at that temperature, For

grease lubrication, the base oil viscosity should be

Used for v. If x is less than 2 friction will increase and

there will be wear.

The values of the permissible axial load F,, ob-

ied from the equation are valid for a contiriuously

acting constant axial load. Where the axial loads act

only for short periods, the values may be multiplied by

2 oF for shock loads by 3.

The constantly acting axial load F, (in Newtons)

applied to the bearing should never &xceed the nu-

merical value of 1,2 D® (where D = outside diameter

of the bearing in mm) and the occasional shock loads

should never be greater than the numerical value of

3D

To obtain an even flange load and a sufficient

running accuracy of the shaft, the axial runout of the

abutment surfaces of the associated components of,

cylindrical roller bearings subjected to heavy axial

loads should be given particular attention.

SKF

15

Bearing application

Fitting practices

The bearing housings should be made of steel or

spheroidal graphite cast iron. In order to eliminate the

risk of deformation, the thickness of the housing

material in the radial direction should correspond to at

least 40% of the bearing width.

On account of the rotating load on the outer ring of

the eccentric bearings these must be fitted with an

interference fit in the housing to prevent movement of

the outer ring relative to the housing and consequent

wear. Satisfactory operation is generally obtained with

‘small and medium sized bearings when the housing

seating is made to N6 tolerance; PS is the suitable

tolerance with large bearings. As explained earlier

‘small axial movements of the shaft must be accom-

modated. With cylindrical roller bearings (NJ type) this

movement can be tolerated due to the internal design

of the bearing, thus the inner ring can be mounted with

an interference fit to the shaft. The recommended

shaft tolerance is k6, these tolerances are shown in

Table 1. For spherical roller bearings such movement

cannot be accommodated within the bearing and thus

the inner ring of the non-locating bearing must be

easily displaceable on the shal, the recommended

tolerance for the journal seating is 16 or g6, these

tolerances are shown in Table 2.

The frame bearings of four bearing screens can be

fitted with withdrawal sleeves and the journal tolerance

h9/ITS is applicable, while H7 is the recommended

housing tolerance.

‘The bores for the bearing housings in the soreen

box sides or in the spacer tube flanges should be

made to H7 tolerance and the corresponding mating

surface of the housing machined to h7.

Outer ring ovality

The roundness of the housing directly influences the

roundness of the bearing outer ring. Thus if the hous-

ing is out of round the bearing outer ring adopts a

similar shape. In the application of frame mounted

bearings any ovality of the outer rings has an influ-

SKF

ence on the bearing performance. This is because the

load zone rotates with respect to the outer ring and

thus the effective clearance of the bearing changes

during every rotation of the bearing. The effect of any

housing ovality is also influenced by the residual radial

clearance of the bearing after mounting (A,). A graph

showing the influence of bearing residual radial clear-

ance on spherical roller bearing rating life (Ljo,) for

different levels of housing ovality is shown in fig 10.

The graph only considers the effect of ovality on

bearing rating life. However bearing ring ovality has

the additional effects of increasing the risk of fretting

and increasing operating temperature, thus reducing

grease life, so the actual effect on bearing service life

could be greater than that shown on the graph.

It can be seen from the graph that with a completely

round housing an increase in bearing life is obtained

with a slight preload (or negative clearance). The

graph also indicates that any further decrease in

clearance (eg from heat) will dramatically reduce the

bearing life. For this reason itis important that the

bearing should always operate with clearance.

The graph is non-dimensional (using the factor 8g in,

both the clearance and ovality terms) to allow the

graph to be applied to any spherical roller bearing.

Terms used in the graph are given below,

087

yo ~ 0,002 (D -9 (2) () (18)

0

where

Cy = basic static load rating, N

F, =radial load, N

1 = beating bore, mm

earing outside diameter, mm

earing width, mm

7

Bearing application

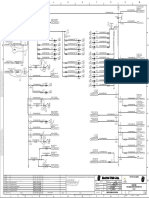

Table 1 Shaft and housing tolerances, cylindrical roller bearings

Bearing Shaft! Deviations Gylindricity Housing’ Deviations —_Cylindricty,

tolerance (oial radial” tolerance (otal racial

runout) runout).

msi2 irae

=o mm ym hm mmm km :

NW 905 EC Skee ei 45 ezine 4

NY 2305 EC 255 AN 2 45 e2IN6 4

NJ 306 EC SUNS een Neo 2 45 72N6 4

NJ 2306 EC SONS 2 45 72IN6 4

Nd 307 EC 35K5 13 55 BONG 4

NJ 2307 EC. S5n5 133 55 BONE 4

NJ 308 €C ads aa 55 SONNE 5

NJ 2308 EC ans 133 55 SONG 8

NJ 309 EC “R518 55 to0/Ne 8

NJ 2309 EC “KB 133 55 00/6 5

NJ3I0EC SOK 133 55 4106 5

NI2310 EC SOS 13D 55 +106 8

Nu2311 EC. 5K 152 65 120/N6 5

NU2312 EC cos 182 85 40/N6 6

NJ2313 EC oD 85 1406 6

NU2314 EC ows 1B 85 150N6 6

Nu2315 EC Tsims okt 66 160/28 6

NJ2316 EC. aoums bk 65 1706 6

NJ 2317 EC ems 28878 18026 6

NJ 2318 EC soms 281378 4190/6 7

NJ 2320 EC jooms 281378 2i5PS zi

NJ 2322 EC Moms 2813. 5 2A0/E8 7

NJ 2324 EC soms 281378 260/P6 a

NJ 2325 EC j90ms $315 280'P6 8

NJ 2328 EC woms 3315 ‘300'P6 8

NJ2330 EC toms 335 2016 8

Other terms used in the graph:

4,= diametral intemal clearance after mounting, mm.

Diax~ Dmin = housing ovality, mm (see graph)

Example

Bearing 22320 CCJAW33VA405

d= 100mm

215mm

73mm

800 000 N

140 000 N

4, = 0,065 mm

Diag ~ Drag = 0,130 mm

Equation 15 gives

0,065

Thus,

Ae 24 ang On=Pnin 2

50 ‘0

18

From the graph,

L

= =0,75

by

Thus with this degree of housing ovality the bearing

will give 25 % lower rating life than if the housing were

completely round.

This analysis highlights the importance of housing

roundness. In some cases housings can become oval

during the life of the machine. This means that any

replacement bearing fitted to an old housing might be

performing in adverse conditions. Care should be

taken therefore to inspect the roundness of housings

when replacement bearings are fitted and remedial

action taken if the housing bore is unacceptably out of

round

SKF

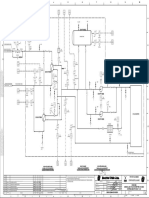

Table 2 Shatt and housing tolerances, spherical roller bearings

Bearing Shay Deviations Surface Cylindricity Housing’ Deviations Cylindricty

tolerance roughness (jlal racial’ tolerance (otal racial

R, runout) runout)

ir572 iraia

= mm ym am Bm mm uum um

22308 CCIW93A15 4098-9 18 55 pone = 38 18 g

22309 CCIW/33A15 45969 16 85 iON == 38 = 16S

22810 CCW33A15 sogs 8 t6 55 MONG 38-16

22311 CCMWS3A15 S598 - 10 18 85 sone 38-165

22312 CCWS3A15 6096 © = 10 16 65 YONG 45-206

22313 CCIW33A15 8595-10 16 65 140N6 45-206

22314 COWS3A15 7olg6 © = 10 16 65 1S0IN6 45-20 6

22315 CCJAIW3V A405 7598-10 16 65 160/PE of -3 6

22516 CCJAWS3VA405 e096 © 10 16 6s 1706 61-88

22317 COJAW33VA405 B56 36 6 18 106 61-95

gore — 36 8 75 ygore = 70-417

9516 36 6 75 pops = 70 417

roots = 36 18 78 215P6 70 417

14016 = —36 16 ze Bagg 70-417

12016 — 36 16 7 260PE 9 47 8

19018-4368 16 a 280/P6 a

qaorg = 43-6816 9 00/6 a

1sofs = 43-68 116 9 20/6 8

16016 = 43 46 9g 340/P6 8

yore = 43-68 116 9 360/26 8

yeors = 43 68 116 3 380/P6 8

19016 -50 -79 1,6 10 4onre = 87-519

2oors = -50 -79 16 10 4206-95-55 10

Graph showing influence of residual clearance and housing ovalty on spherical roller bearing tite

Te

SKF 19

Bearing application

Sealing

The New Life Theory of SKF, developed to determine

the lives of bearings in realistic service conditions,

highlights the importance of cleanliness. In view of the

fact that vibrating machines normally work in very

dusty surroundings, the sealing must be effective so

that foreign matter will not penetrate and reduce the

life of the bearings. Even a small ingress of con-

tamination can have a dramatic effect on bearing life.

is generally recommended to use labyrinth seals, the

‘gaps of which should be dimensioned according to fig

8. Itis important to note that labyrinth seals are only

effective so long as the passages are purged regularly

with clean grease. Maintenance procedures should be

‘drawn up to accommodate this requirement.

\V-ring seals are often used in conjunetion with

labyrinth seals. Examples of such arrangements are

shown in figs 12 to 17. V-ring seals provide a good

standard of sealing for most applications.

In applications which demand a superior sealing

arrangement the V-ring seal should be replaced by a

sprung lip seal (garter lip seal), e.g. CR HDW"’. For

grease lubricated applications the seal should be

orientated facing ‘outwards’ as shown in fig 11. In oil

lubricated applications the seal orientation should be

reversed to retain the oil and an additional seal used

to prevent the ingress of contamination; this principle

is shown in fig 14, page 23.

From CR Industes, a member of the SKF Group

‘Sprung radial ip seal

1”

SKF

Typical applications

Two-bearing or free movement

screen with grease lubrication

The sealing cover and collar on the journal incorporate

a labyrinth seal, see fig 12. In order to achieve an even

better sealing effect the labyrinth arrangement is

supplemented with a V-ring. The bearing is protected

on its inner side by a gap seal

‘Two-bearing or free movement screen with grease lubrication

Grease is supplied through the holes in the middle

of the outer ring (W33 feature) and in this way both

rows of rollers can be lubricated effectively. Upon

relubrication the old grease is pressed out past the

\V-ring and through the inboard gap seal as well.

Note: the drive side is drawn above the centreline,

the non-drive side below.

2

SKF

a

Bearing application

Two-bearing or free movement

screen with oil bath lubrication

A labyrinth seal in combination with a V-ring arrange-

ment is also recommended when cil lubrication is,

employed, see fig 13. The inner V-ring, which is to

prevent leakage of oil, must be installed with the lip

facing outwards. Extra protection against foreign

matter is obtained by using another V-ring with the lip

facing inwards. The outer section of the labyrinth can

be filled with grease via a duct in the sealing cover. A

deflector disc adjacent to the bearing reduces the flow

of cil towards the sealing

Oil is supplied and drained off through holes in the

bearing housing that are normally plugged. The oil

should be maintained at a level in line with the centre

of the lowest roller and it must be possible to check

the level from outside.

Note: the drive side is drawn above the centreline,

the non-drive side below.

Two-bearing screen or free movement screen with oil bath lubri

13

22

SKF

Two-bearing or free movement

screen, oil circulation lubrication

The seals in the outer side of the bearing arrangement

are designed in the same way as for oil bath lubrica-

tion. The lip type seal on the inner side prevents.

leakage of oil into the spacer tube, see fig 14.

Oil is supplied through the holes in the middle of the

outer ring and there is a duct in the base of the hous-

ing through which the oil can pass from one side of the

bearing to the other. The outlet is situated in such a

way that the oil level is always in line with the centre of

the lowest roller. The housing is equipped with a

separate drainage.

Note: the drive side is drawn above the centreline,

the non-drive side below.

‘Two-bearing or free movement screen, cil circulation lubrication

4

SKF

23

Bearing application

Four-bearing screen with grease

lubrication

The eccentric bearings are applied in the same way as

the bearings in screens with free movement.

The frame bearings are mounted on withdrawal

sleeves. The housings for these bearings have laby-

rinth seals on both sides in combination with V-rings,

see fig 15. In order to prevent the withdrawal sleeve

being inadvertently forced further up into the bearing

when the pulley or end sleeve is being mounted, the

width of the sealing collar must be selected so that it is

somewhat less than the distance between the with-

drawal sleeve and the outer shoulder of the shaft.

‘Shims are then placed between the withdrawal sleeve

and the collar so that the outer face of the collar and

shoulder are in alignment.

Note: the drive side is drawn above the centreline,

the non-drive side below.

Four-bearing screen with grease lubrication

6

24

SKF

ear motion mechanism with oil

mist lubrication

Fig 16 shows a vibrator unit for a dump grate used in

foundries for shaking the castings out of the moulds

and separating sand from castings.

In this case the bearings are lubricated by oil mist

supplied through holes in the outer ring (W33 feature)

The oil level is regulated by means of washers on the

inner side of the bearings. Surplus air is expelled

through the V-ring seals, labyrinths and through holes

in the casing.

Linear motion mechanism with oll mist lubrication

16

SKF

Bearing application

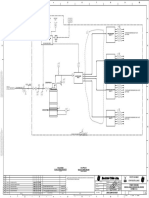

Linear motion gearbox

Separate eccentric motion gearboxes are sometimes

attached to the screen box rather than using an integ-

ral mechanism, see fig 17. This has the benefit of

allowing a spare unit to be fitted to the screen while

the first undergoes maintenance, thereby reducing the

downtime of the vibrating screen.

The arrangement uses oil bath lubrication and is,

sealed with a combined V-ring and labyrinth arrange-

ment. In order to minimise the flow of oil to the seal

region a deflector disc is also used. Provision for a

non-located bearing is not always necessary in this

arrangement. This is because the shaft is short; thus

the amount of axial movement of the shaft relative to

the housings due to thermal effects is small. When this

movement is sufficiently small the bearing perform-

ance is not affected if fully located.

The eccentric weights are attached symmetrically

outboard of each bearing, thereby minimising shaft

bending. The illustration shows cylindrical roller bear-

ings, however spherical roller bearings are also used

in this application.

Linear motion gearbox

aE

Detail of grease

lubreationfeature

for Tabyanth

7

Deatit of

‘ll etuen

feature

26

SKF

Vibrator motor

Vibrator motors are widely used on smaller vibrating

‘screens. Being completely enclosed sealing is made

somewhat more simple. Fig 18 shows a vibrator motor

incorporating cylindrical roller bearings with grease

lubrication.

Most units do not have a relubrication feature and

are sealed-for-life units. The bearings are mounted to

give axial clearance to accommodate axial thermal

movements of the shaft.

It should be noted that in smaller vibrator motors

deep groove ball bearings can also be used. Such

units are uncommon on vibrating screens.

‘Vibrator motor

18

SKF

a7

Bearing application

Lubrication

Grease lubrication

If operating conditions permit, grease lubrication

should be selected for the bearings in vibrating ma-

chinery, as this method enables a relatively simple

design of the arrangement as a whole, and of the

seals in particular, to be achieved. In normal cases a

lithium base grease may be used having a consistency

of 2 or 3.on the NGLI scale and with a minimum base

oil viscosity of 90 to 160 mm‘/s (90 to 160 cSt) at

40 °C. The grease should contain rust inhibiting and

EP additives, eg SKF LGEP 2. Experience has shown

that a supplementary addition of 1 to 3% molybdenum

disulphide is also beneficial, e.g. SKF LGEM 2. In view

of the vibrations, the mechanical stability of the grease

has to be good in order to prevent excessive softening

or oil separation from the soap base (bleeding). When

hot material is being screened, the operating temper-

ature of the bearing will require the use of a high

temperature grease, such as a sodium-synthetic

grease or bentonite grease.

Particulars of suitable amounts of grease and

relubrication intervals are listed in Table 4. The

installation of an automatic lubricator, administering

‘small quantities of grease intermittently, will facilitate

maintenance and at the same time improve lubrica-

tion

Oil lubrication

Oil lubrication has to be employed when the speed or

temperature precludes the use of grease. Oil bath

lubrication is then the simplest method. Circulating oil,

possibly combined with a cooling system, is some-

times used, particularly for large screens, in order to

control the bearing temperature. Oil mist lubrication is

used primarily for small bearing arrangements running

at high speeds, the positive pressure providing effect-

ive protection against the ingress of contamination.

An oxidation resistant. |mnineral oil having a minimum

viscosity of 40 to 80 mm/s (40 to 80 cSt) at 40 °C is

recommended and this oil should contain EP, rust

inhibiting and foam prevention additives. The oil level

‘should be in line with the centre of the lowest roller. Oil

quantity recommendations for spherical roller bearings

are given in Table 5. The level and condition of the oil

must be checked regularly. Normally the oil should be

changed after six months of operation.

‘Table 4 Recommendations for grease lubrication for spherical roller bearings, series 223

Bearing Grease charge Relubrication interval

fonmounting on relubricating —900/min 1.2001/min 1500 imin 2.000 min

= a working hours

22308 CCIW33A15 20 5 300 200 180 50

22309 CCIW33A15 25 5 300 200 150 50

22310 CCIW33A15 30 5 300, 200 100 50

22311 CCAVSRA1S 35 5 300 200 100. 50

22312 CCAWS3A15 45 5 250 150 109 50

22313 CCIW33A15 55 10 250 180 400 50

22814 CCIW33A15 60 10 250 150 100 50

22315 CCJAW33VA405 90 10 200 100 50 19

22816 CCUNW33VA405. 110 10 200 400, 50 10

22317 CCUNWS3VA405 120 15 200 100 50 10

22318 CCUAWS3VA405 140 18 150 100 50, 10

22319 CCJAW33VA405 160 18 180 100 50.

22320 COUAW33VA405 200 20 100 50 50

22822 CCJAWS3VA05 250 20 100 50 10

22824 CCJAWS3VA405 350 20 400 50 10

22326 CCJAW33VA405 400 30 100 50 10

zzsze couarwsayadgs 450 30 50 10

550 80 50, 10

Zee ceuaMsavades 650 40 50, 10

22334 CCJAW33VA405 750 40 10

22336 GCJAW33VA405 900 50 10

22338 CCJNW33VA405 1000 50 10

22340 CCJAW33VA405 1200 50 40

28

SKF

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 0320-CRC-0003-01 0320-CRC-0003-04 0320-CRC-0003-03: Pebble Cone Crusher N°3Documento1 pagina0320-CRC-0003-01 0320-CRC-0003-04 0320-CRC-0003-03: Pebble Cone Crusher N°3nestor159357Nessuna valutazione finora

- SI G NE D: SlopeDocumento1 paginaSI G NE D: Slopenestor159357Nessuna valutazione finora

- No Requiere Aprobación Del Cliente: in WorkDocumento1 paginaNo Requiere Aprobación Del Cliente: in Worknestor159357Nessuna valutazione finora

- 1"-0240-WR-01301-S1E0B: Fresh Water 1453 M6-0320-00013Documento1 pagina1"-0240-WR-01301-S1E0B: Fresh Water 1453 M6-0320-00013nestor159357Nessuna valutazione finora

- 0320-CRC-0002-01 0320-CRC-0002-04 0320-CRC-0002-03: Pebble Cone Crusher N°2Documento1 pagina0320-CRC-0002-01 0320-CRC-0002-04 0320-CRC-0002-03: Pebble Cone Crusher N°2nestor159357Nessuna valutazione finora

- Ig N e D: Ags Cle WMV JCT WMV Ral VSM AcpDocumento1 paginaIg N e D: Ags Cle WMV JCT WMV Ral VSM Acpnestor159357Nessuna valutazione finora

- 0320-CRC-0001-04 0320-CRC-0001-03 0320-CRC-0001-01: Pebble Cone Crusher N°1Documento1 pagina0320-CRC-0001-04 0320-CRC-0001-03 0320-CRC-0001-01: Pebble Cone Crusher N°1nestor159357Nessuna valutazione finora

- G N e D: 0310-STP-0248 0310-ZMW-0047 0310-CSC-0002 0310-CNH-0143 0310-CNH-0145 0310-ZMW-0047 & 0048Documento1 paginaG N e D: 0310-STP-0248 0310-ZMW-0047 0310-CSC-0002 0310-CNH-0143 0310-CNH-0145 0310-ZMW-0047 & 0048nestor159357Nessuna valutazione finora

- 220 M6 0310 00031Documento1 pagina220 M6 0310 00031nestor159357Nessuna valutazione finora

- 220 M6 0310 00051Documento1 pagina220 M6 0310 00051nestor159357Nessuna valutazione finora

- 220 M6 0310 00047Documento1 pagina220 M6 0310 00047nestor159357Nessuna valutazione finora

- Ig N e D: WMV Ral VSM AcpDocumento1 paginaIg N e D: WMV Ral VSM Acpnestor159357Nessuna valutazione finora

- 220 M6 0320 00001Documento1 pagina220 M6 0320 00001nestor159357Nessuna valutazione finora

- 220 M6 0310 00040Documento1 pagina220 M6 0310 00040nestor159357Nessuna valutazione finora

- Ig N e D: CVV JCT VSM CVVDocumento1 paginaIg N e D: CVV JCT VSM CVVnestor159357Nessuna valutazione finora

- To Feed End Bearing Seal Plate (Left Side)Documento1 paginaTo Feed End Bearing Seal Plate (Left Side)nestor159357Nessuna valutazione finora

- 220 M6 0310 00032Documento1 pagina220 M6 0310 00032nestor159357Nessuna valutazione finora

- 0310-Vsa-0038 0310-Vsa-0039 0310-Vsa-0040 0310-Vsa-0041Documento1 pagina0310-Vsa-0038 0310-Vsa-0039 0310-Vsa-0040 0310-Vsa-0041nestor159357Nessuna valutazione finora

- G N e D: Ral Cle WMV Ags WMV Ral VSM AcpDocumento1 paginaG N e D: Ral Cle WMV Ags WMV Ral VSM Acpnestor159357Nessuna valutazione finora

- To Feed End Bearing Seal Plate (Left Side)Documento1 paginaTo Feed End Bearing Seal Plate (Left Side)nestor159357Nessuna valutazione finora

- 220 M6 0310 00030Documento1 pagina220 M6 0310 00030nestor159357Nessuna valutazione finora

- 220 M6 0310 00046Documento1 pagina220 M6 0310 00046nestor159357Nessuna valutazione finora

- 0310-Vsa-0029 0310-Vsa-0030 0310-Vsa-0031 0310-Vsa-0032Documento1 pagina0310-Vsa-0029 0310-Vsa-0030 0310-Vsa-0031 0310-Vsa-0032nestor159357Nessuna valutazione finora

- 220 M6 0310 00019Documento1 pagina220 M6 0310 00019nestor159357Nessuna valutazione finora

- 0310-Vsa-0020 0310-Vsa-0023 0310-Vsa-0021 0310-Vsa-0022: 3/4"-0310-Ho-01601-Spe0qDocumento1 pagina0310-Vsa-0020 0310-Vsa-0023 0310-Vsa-0021 0310-Vsa-0022: 3/4"-0310-Ho-01601-Spe0qnestor159357Nessuna valutazione finora

- Slope: G N E DDocumento1 paginaSlope: G N E Dnestor159357Nessuna valutazione finora

- FrsshuDocumento1 paginaFrsshunestor159357Nessuna valutazione finora

- FrsshuDocumento1 paginaFrsshunestor159357Nessuna valutazione finora

- To Feed End Bearing Seal Plate (Left Side) : 1"-0310-AP-04935-C1E2ADocumento1 paginaTo Feed End Bearing Seal Plate (Left Side) : 1"-0310-AP-04935-C1E2Anestor159357Nessuna valutazione finora

- 0310-HXT-0005 0310-CNB-0008 0310-HXT-0005 & 0006: 6"-0310-Cr-01201-C1e2aDocumento1 pagina0310-HXT-0005 0310-CNB-0008 0310-HXT-0005 & 0006: 6"-0310-Cr-01201-C1e2anestor159357Nessuna valutazione finora