Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

RCS: 90 & Above Round: Above 100: Heat. No. To Be Provided On Each Bar

Caricato da

Amit Kumar Uke0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

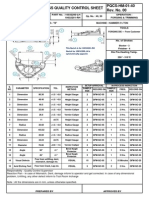

35 visualizzazioni2 pagineThe document outlines the inspection flow chart for rolled steel products from a blooming mill. It details the inspection process from receiving the material through pit or non-pit cooling, inspection including visual, magnetic particle, ultrasonic testing and more. If defects are found, materials may undergo rectification or be marked with red paint before final dispatch.

Descrizione originale:

A flow chart on inspection of steel plant.

Titolo originale

Inspection Flow

Copyright

© © All Rights Reserved

Formati disponibili

XLS, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThe document outlines the inspection flow chart for rolled steel products from a blooming mill. It details the inspection process from receiving the material through pit or non-pit cooling, inspection including visual, magnetic particle, ultrasonic testing and more. If defects are found, materials may undergo rectification or be marked with red paint before final dispatch.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

35 visualizzazioni2 pagineRCS: 90 & Above Round: Above 100: Heat. No. To Be Provided On Each Bar

Caricato da

Amit Kumar UkeThe document outlines the inspection flow chart for rolled steel products from a blooming mill. It details the inspection process from receiving the material through pit or non-pit cooling, inspection including visual, magnetic particle, ultrasonic testing and more. If defects are found, materials may undergo rectification or be marked with red paint before final dispatch.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

Inspection Flow Chart for Rolled Product (Blooming Mill)

Hot Rolled Product

Based on Rolling Plan

Pit Cooling

Non- Pit Cooling

Heat. No. to be

Heat. No.

be bar.

provided

on to

each

provided on each bar.

Total No of Pcs

Received Vs

Production

Pit Cooling

Non-Pit Cooling Material

Material

Inspection Bed

Straightening

Grinding

Strip Grinding

RCS: 90 & above

Round : Above 100

Ring Grinding

100% Visual

Inspection

Size: 90 & 110 mm RCS

Size: Above 110 RCS

If any defect found

If any defect found

Size: All Dia / Round

RCS upto 85

20% MPI

If any major

defect found

Acid

Etching

100%

MPI

Green Dot for MPI

Rectification

Based on rectification Re-MPI

to be decided

Re-MPI or

Acid

Etching

Not OK

Red Paint on Cross

Section

Rectification

OK

Sr. No. On each Bar

Dim.- Size,

Twist, Bend

blue Dot

Not OK

Red Paint on Cross

Section

Not OK

Red Paint on Cross

Section

Not OK

Red Paint on Cross

Section

OK

UT

Yellow Strip

OK

Cutting

Spark &

Spectro

Yellow Circle on

Spark area

OK

No of Pcs to be checked / Monitored

before dispatch

Color Coding

Dispatch

Potrebbero piacerti anche

- Process Flow For Order ExecutionDocumento1 paginaProcess Flow For Order ExecutionSathish RNessuna valutazione finora

- 4-Welding Painting Repair-PDocumento8 pagine4-Welding Painting Repair-PNguyen Anh TuanNessuna valutazione finora

- Audit Report Ash HandlingDocumento1 paginaAudit Report Ash HandlingchandrashekharNessuna valutazione finora

- HDG Process Flow Chart PDFDocumento1 paginaHDG Process Flow Chart PDFAnonymous vIbTFwAStxNessuna valutazione finora

- Annex-1-Process Flow ChartDocumento1 paginaAnnex-1-Process Flow ChartDeepak DasNessuna valutazione finora

- Qualification RangeDocumento1 paginaQualification RangeSARSAN NDTNessuna valutazione finora

- Customer Complaint Register 2017Documento6 pagineCustomer Complaint Register 2017KumaravelNessuna valutazione finora

- SOP of MachinesDocumento2 pagineSOP of MachinesSangram Kandekar100% (1)

- Report No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeDocumento1 paginaReport No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeRohit VishwakarmaNessuna valutazione finora

- Windals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportDocumento2 pagineWindals Precision Pvt. Ltd. Rudrapur: Pre-Dispatch Inspection ReportMurtza ArzaiNessuna valutazione finora

- Samples Inspection ReportDocumento5 pagineSamples Inspection ReportArun GuptaNessuna valutazione finora

- F-05 Corrective Action FormDocumento1 paginaF-05 Corrective Action Formsuhara hussainNessuna valutazione finora

- Calibration Training: ReferencesDocumento5 pagineCalibration Training: ReferenceshoussNessuna valutazione finora

- Inspct in Process DatasheetDocumento1 paginaInspct in Process DatasheetKhai HuynhNessuna valutazione finora

- In Process QC FormatDocumento9 pagineIn Process QC FormatSunil ChaubeyNessuna valutazione finora

- CNC HMC Acc CheckDocumento2 pagineCNC HMC Acc CheckKalees WaranNessuna valutazione finora

- PQCS Tube Flange Rough - ForgingDocumento1 paginaPQCS Tube Flange Rough - ForgingBalram JiNessuna valutazione finora

- Root Cause Analysis - ToolDocumento11 pagineRoot Cause Analysis - ToolmuneerppNessuna valutazione finora

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceDocumento2 pagineMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceRohit VishwakarmaNessuna valutazione finora

- Supplier Evaluation Checklist F-PU-05 - FILLEDDocumento2 pagineSupplier Evaluation Checklist F-PU-05 - FILLEDNav Talukdar100% (1)

- In-House Rework & Rejection ReportDocumento3 pagineIn-House Rework & Rejection ReportmuthuselvanNessuna valutazione finora

- In-House Calibration SheetDocumento4 pagineIn-House Calibration SheetKannan MurugesanNessuna valutazione finora

- QA-R-12 Calibration History CardDocumento1 paginaQA-R-12 Calibration History CardRaja DuraiNessuna valutazione finora

- Apqp PhasesDocumento3 pagineApqp PhasesBharatNessuna valutazione finora

- Al PSW FormatDocumento2 pagineAl PSW Formatabhayjha1988Nessuna valutazione finora

- Causes & Preventation of Defects (Burr) in Sheet Metal Component PDFDocumento5 pagineCauses & Preventation of Defects (Burr) in Sheet Metal Component PDFMajad RazakNessuna valutazione finora

- In House PPM MonitoringDocumento2 pagineIn House PPM MonitoringSrinath NavadaNessuna valutazione finora

- Performance Management Sytem of VKL (Vishnu) Spices PVT LTDDocumento10 paginePerformance Management Sytem of VKL (Vishnu) Spices PVT LTDAshwin Davis RCBSNessuna valutazione finora

- Quality Assurance Manual: Preventive Action Section 8 Rev: E 0 Date: 15/08/09 Page 1 of 2Documento2 pagineQuality Assurance Manual: Preventive Action Section 8 Rev: E 0 Date: 15/08/09 Page 1 of 2Ngonidzashe ZvarevasheNessuna valutazione finora

- Process Flow ChartDocumento11 pagineProcess Flow Chartsudar1477Nessuna valutazione finora

- ISO Process PlanDocumento1 paginaISO Process PlanTeti AzrilNessuna valutazione finora

- Master TimingDocumento4 pagineMaster TimingPk NimiwalNessuna valutazione finora

- Quality Control Form - 1Documento1 paginaQuality Control Form - 1ravi ajithNessuna valutazione finora

- Incoming Material FormatDocumento22 pagineIncoming Material Formattuan mai vanNessuna valutazione finora

- Supplier Production Part Approval Process (PPAP) Training Please Mute Your Phone For This TrainingDocumento17 pagineSupplier Production Part Approval Process (PPAP) Training Please Mute Your Phone For This TrainingRicky MarkNessuna valutazione finora

- Gauge Validation ReportDocumento71 pagineGauge Validation ReportPreetam GiteNessuna valutazione finora

- FME-170011-DWRDocumento6 pagineFME-170011-DWRKyNessuna valutazione finora

- Duramedical SDN BHD: Oral Dam Manufacturing & Quality Control, Description & Process Flow ChartDocumento5 pagineDuramedical SDN BHD: Oral Dam Manufacturing & Quality Control, Description & Process Flow ChartYap Jian JieNessuna valutazione finora

- FINAL Inspection Report PO#KL-3448 PDFDocumento21 pagineFINAL Inspection Report PO#KL-3448 PDFArslan HaiderNessuna valutazione finora

- F-QC-05 Deviation NoteDocumento1 paginaF-QC-05 Deviation NoteKaran MalhiNessuna valutazione finora

- Internal Rejection LevelDocumento1 paginaInternal Rejection LevelISO CERTIFICATION-ROHSNessuna valutazione finora

- PPAP Check ListDocumento4 paginePPAP Check ListSameer SaxenaNessuna valutazione finora

- 8.fixture Inspection ReportDocumento1 pagina8.fixture Inspection ReportBASAVA ENGINEERINGNessuna valutazione finora

- BGL-FM-HR-38 Training Cum Effectiveness Record 01Documento2 pagineBGL-FM-HR-38 Training Cum Effectiveness Record 01Mohit SinghNessuna valutazione finora

- Vendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefDocumento3 pagineVendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefAmit KumarNessuna valutazione finora

- Z TMT Bill DetailsDocumento340 pagineZ TMT Bill DetailssantrssbNessuna valutazione finora

- Purpose:: Procedure Manual FifoDocumento3 paginePurpose:: Procedure Manual FifoartiNessuna valutazione finora

- Bgl-Fm-Qa-10a Daily Rework RecordDocumento1 paginaBgl-Fm-Qa-10a Daily Rework RecordMohit SinghNessuna valutazione finora

- Inspection Plan NDTDocumento7 pagineInspection Plan NDTEdison WalitNessuna valutazione finora

- Pt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesDocumento0 paginePt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesZoebairNessuna valutazione finora

- F-PD-11 Tool Development Plan (Micro Plan)Documento3 pagineF-PD-11 Tool Development Plan (Micro Plan)Trivesh SharmaNessuna valutazione finora

- Procedure For New DevelopmentsDocumento2 pagineProcedure For New DevelopmentsspdhimanNessuna valutazione finora

- QAP K-HouseDocumento4 pagineQAP K-HouseAbhinash TamangNessuna valutazione finora

- Rejection Record.Documento10 pagineRejection Record.karan shahNessuna valutazione finora

- Cutting Plan FormatDocumento1 paginaCutting Plan FormatPrinceRaghavNessuna valutazione finora

- Inprocess Inspection ReportDocumento1 paginaInprocess Inspection ReportSanjay KumarNessuna valutazione finora

- FIR-garments PDFDocumento4 pagineFIR-garments PDFTarun PariharNessuna valutazione finora

- CUSTOMER Complaint - PrintDocumento1 paginaCUSTOMER Complaint - PrintSachin Kumbhar100% (1)

- M/S Process Flow DiagramDocumento6 pagineM/S Process Flow DiagramUttam SainiNessuna valutazione finora

- Momentum PicksDocumento27 pagineMomentum PicksAmit Kumar UkeNessuna valutazione finora

- Momentum PicksDocumento25 pagineMomentum PicksAmit Kumar UkeNessuna valutazione finora

- Momentum PicksDocumento25 pagineMomentum PicksAmit Kumar UkeNessuna valutazione finora

- 10 Pellet-Grate-Kiln TechDocumento14 pagine10 Pellet-Grate-Kiln TechAmit Kumar UkeNessuna valutazione finora

- Momentum PicksDocumento27 pagineMomentum PicksAmit Kumar UkeNessuna valutazione finora

- Momentum PicksDocumento29 pagineMomentum PicksAmit Kumar UkeNessuna valutazione finora

- Engineering College Ranking 2022Documento25 pagineEngineering College Ranking 2022Amit Kumar UkeNessuna valutazione finora

- Nigam Institute of EngineeringDocumento6 pagineNigam Institute of EngineeringAmit Kumar UkeNessuna valutazione finora

- 05.5 Appendix 5 Awareness Training Report Preview ENDocumento1 pagina05.5 Appendix 5 Awareness Training Report Preview ENAmit Kumar UkeNessuna valutazione finora

- ePGP IIM Raipur Brochure MinDocumento31 pagineePGP IIM Raipur Brochure MinAmit Kumar UkeNessuna valutazione finora

- List of Problems in Automatic Ut MachineDocumento1 paginaList of Problems in Automatic Ut MachineAmit Kumar UkeNessuna valutazione finora

- Brochure MobileDocumento20 pagineBrochure MobileKunal SahuNessuna valutazione finora

- PM KPI TrackerDocumento7 paginePM KPI TrackerAmit Kumar UkeNessuna valutazione finora

- 22.1 Appendix 1 Matrix of Key Performance Indicators Preview ENDocumento1 pagina22.1 Appendix 1 Matrix of Key Performance Indicators Preview ENAmit Kumar UkeNessuna valutazione finora

- Project Completion ReportDocumento5 pagineProject Completion ReportAmit Kumar UkeNessuna valutazione finora

- (COVID-19) : See Case Investigation WorkflowDocumento1 pagina(COVID-19) : See Case Investigation WorkflowAmit Kumar UkeNessuna valutazione finora

- Corporate Responsibility Policy: Maintain A Strict Code of ConductDocumento1 paginaCorporate Responsibility Policy: Maintain A Strict Code of ConductAmit Kumar UkeNessuna valutazione finora

- Bypass Form Fill Up InstructionDocumento2 pagineBypass Form Fill Up InstructionAmit Kumar UkeNessuna valutazione finora

- 00 Procedure For Document and Record Control Integrated Preview enDocumento3 pagine00 Procedure For Document and Record Control Integrated Preview enUnokhogie EmmanuelNessuna valutazione finora

- Reduce False Alarm: Strength Through IntegrationDocumento12 pagineReduce False Alarm: Strength Through IntegrationAmit Kumar UkeNessuna valutazione finora

- Introduction To Ultrasonic PrinciplesDocumento34 pagineIntroduction To Ultrasonic PrinciplesAmit Kumar Uke100% (1)

- Covid-19 Consequence ManagDocumento3 pagineCovid-19 Consequence ManagAmit Kumar UkeNessuna valutazione finora

- Quality Report Date:: Sr. No. Heat No. Grade Cast Size To Be Rolled Customer DeviationDocumento3 pagineQuality Report Date:: Sr. No. Heat No. Grade Cast Size To Be Rolled Customer DeviationAmit Kumar UkeNessuna valutazione finora

- Grades of Steels Rolled in Bar & Bloom Mill: Case Carburising Grades Engineering and Forging Quality SteelDocumento2 pagineGrades of Steels Rolled in Bar & Bloom Mill: Case Carburising Grades Engineering and Forging Quality SteelAmit Kumar UkeNessuna valutazione finora