Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pipe Test Pressures Template

Caricato da

ARNOUXCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pipe Test Pressures Template

Caricato da

ARNOUXCopyright:

Formati disponibili

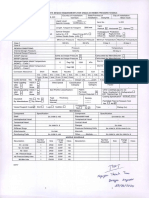

Pipe Hydrostatic Test Pressure Calculation Input Sheet

Revision 2 - December 2009

Only enter data values on light yellow blocks !!

Line Number

Line Class

Design Pressure

Design Temperature

Test temperature

O-7-596-1 1/2"-C & 007-O-496

C

1700 kPa

300 oC

572.00 oF

37.777 oC

100.00 oF

Pipe / Fittings Material

Pipe diameter

Pipe schedule

Measured wall thick

*

Measured pipe OD

*

Wall thick (less mill tol)

Pipe diameter used (OD)

Pipe / Fittings Inputs

A106 B

1

NPS

80

SCH thick

mm

mm

4.45 mm (per SCH)

48.26 mm (per SCH)

Y values:

Ferritic steel

Austenitic steel

Other ductile metal

Cast iron

Other Pipe Inputs

Mill tolerance

12.5 %

Mill tolerance

mm

Corrosion allow

1 mm

Joint Efficiency

1Y Coeficient

0.4 Test joint eff

1Type of pipe

Austenitic steel

Table 304.1.1 Y value (@ test temp)

0.40

A234 WPB

48.26 mm

5.08 mm

Hydrostatic Head

(if known)

(leave alone)

(No prob)

0m

0 kPa

* Enter value here when using a measured pipe, leaving blank = new pipe

Yield and Allowable Stress Values - Pipe

Material Yield Stress

35 KSI

241.32 MPa

For design temperature

Stress at T1

0 oF

A106 B KSI

Stress at T2

600 oF

17.3 KSI

At test temperature

Stress at T1

0 oF

20 KSI

Stress at T2

100 oF

20 KSI

Test Calculations - Pipe

Minimum Test Pressure

kPa

Test Pressure Selected

7655 kPa

Maximum Allowable Stress

217.18 MPa

Stress in new pipe due to test pressure

38.4937 MPa

Stress in corroded pipe due to test press

50.5563 MPa

Date:

By:

18 November 2014

Per tables in ASME B31.3 - Hidden Database

Per SP 50-9 Round to nearest:

kPa

Acceptable

Acceptable

Yield and Allowable Stress Values - Fittings

Material Yield Stress

35 KSI

241.32 MPa

For design temperature

Stress at T1

500 oF

A234 WPB KSI

Stress at T2

600 oF

17.3 KSI

At test temperature

o

Stress at T1

20 KSI

F

o

Stress at T2

F

20 KSI

Test Calculations - Fittings

Minimum Test Pressure

kPa

Test Pressure Selected

7655 kPa

Maximum Allowable Stress

217.18 MPa

Stress in new fitting due to test pressure

38.4937 MPa

Stress in corroded fitting due to test press

50.5563 MPa

OD's

1

1

1

2

2

3

3

4

5

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

SCH's

5S

10

10S

20

30

40

40S

STD

60

80

80S

XS

100

120

140

160

XXS

Per tables in ASME B31.3 - Hidden Database

Per SP 50-9 Round to nearest:

50 kPa

Acceptable

Acceptable

Inputs for determining acceptable test pressure for flanges (ASME B16.5)

51.1 bar

Acceptable

100oF rating for flange material group

Inputs for determining acceptable test pressure for valve bodies (ASME B16.34)

51.1 bar

Acceptable

100oF rating for Valve material group

Per tables in ASME B16.5

References

Pipe

ASME B31.3 para.345.4.2

ASME B31.3 para.345.4.3

Notes:

Flanges

ASME B16.5 para.2.5

Valves

ASME B16.34 Para 2.5.3

ASME B16.34 Para 4.3.3

ASME B16.34 Para 7.1

Hidden Calculations

Allow stress @ design temp

Allow stress @ test temp

Stress ratio (R)

Minimum Test Pressure

Maximum allowable stress

Corroded wall thick

Stress in corroded pipe

New wall thick

Stress in new pipe

Reference

Data / Pipe

KSI

20 KSI

MPa

137.90 MPa

SP50-9 -> max R=6.5

ASME B31.3 para.345.4.2

kPa

217.18 MPa

3.445 mm

50.556 MPa

4.445 mm

38.494 MPa

Acceptable

Acceptable

Calculate flange allowable stress

1111.71 PSI

1.5 times the 100 oF rating

Rounded up to next 25 PSI

1125 PSI

Max allow flange test pressure

7756.60 kPa

Reference

ASME B16.5 para 2.5

Acceptable

Calculate valve allowable stress

1111.71 PSI

1.5 times the 100 oF rating

Rounded up to next 25 PSI

1125 PSI

Max allow flange test pressure

7756.60 kPa

ASME B16.34 para.2.5.3

Acceptable

Note: Hydrostatic test pressure for new and corroded pipe

Allow stress @ design temp

Allow stress @ test temp

Stress ratio (R)

Minimum Test Pressure

Maximum allowable stress

Corroded wall thick

Stress in corroded pipe

New wall thick

Stress in new pipe

Reference

Data / Fittings

KSI

KSI

MPa

MPa

SP50-9 -> max R=6.5

ASME B31.3 para.345.4.2

kPa

217.18 MPa

3.445 mm

50.556 MPa

4.445 mm

38.494 MPa

Acceptable

Acceptable

Calculate flange allowable stress

1111.71 PSI

1.5 times the 100 oF rating

Rounded up to next 25 PSI

1125 PSI

Max allow flange test pressure

7756.60 kPa

Reference

ASME B16.5 para 2.5

Acceptable

Calculate valve allowable stress

1111.71 PSI

1.5 times the 100 oF rating

Rounded up to next 25 PSI

1125 PSI

Max allow flange test pressure

7756.60 kPa

ASME B16.34 para.2.5.3

Acceptable

Material Database

Row

2

Column

1

7

Yield

30

35

35

35

25

25

25

25

25

30

PIPES:

Material

0

Please Select

API 5LB

A106 B

A333 Gr 6

A333 Gr 3

A312 TP304L

A312 TP316L

A312 TP321H

A358 TP304L

A358 TP316L

A335 Gr P11

Allowable Stresses in kips/in2 at degF

100

200

300

20

20

20

21.7

16.7

16.7

16.7

16.7

16.7

20

20

20

20

19.6

16.7

16.7

16.7

16.7

16.7

18.7

20

20

20

19.6

16.7

16.7

16.7

16.7

16.7

18

400

500

600

650

700

750

800

850

900

950

1000

1050

1100

20

20

20

18.7

15.8

15.5

16.7

15.8

15.5

17.5

18.9

18.9

18.9

17.8

14.8

14.4

16.1

14.8

14.4

17.2

17.3

17.3

17.3

16.8

14

13.5

15.2

14

13.5

16.7

17

17

17

16.3

13.7

13.2

14.9

13.7

13.2

16.2

16.5

16.5

16.5

15.5

13.5

12.9

14.6

13.5

12.9

15.6

13

13

13

13.9

13.3

12.6

14.3

13.3

12.6

15.2

10.8

10.8

10.8

11.4

13

12.4

14.1

13

12.4

15

8.7

8.7

8.7

9

12.8

12.1

14

12.8

12.1

14.5

6.5

6.5

6.5

6.5

11.9

11.8

13.8

11.9

11.8

12.8

4.5

4.5

4.5

4.5

9.9

11.5

13.6

9.9

11.5

9.3

2.5

2.5

2.5

2.5

7.8

11.2

13.5

7.8

11.2

6.3

1.6

1.6

1.6

1.6

6.3

10.8

9.6

6.3

10.8

4.2

1 NA

1 NA

1 NA

1 NA

5.1

10.2

6.9

5.1

10.2

2.8

1150

1200

NA

NA

NA

NA

4

8.8

5

4

8.8

1.9

1250

NA

NA

NA

NA

3.2

6.4

3.6

3.2

6.4

1.2

1300

NA

NA

NA

NA

2.6

4.7

2.6

2.6

4.7

1.2 NA

1350

NA

NA

NA

NA

2.1

3.5

1.7

2.1

3.5

1400

NA

NA

NA

NA

1.7

2.5

1.1

1.7

2.5

NA

1450

NA

NA

NA

NA

1.1

1.8

0.8

1.1

1.8

NA

1500

NA

NA

NA

NA

1

1.3

0.5

1

1.3

NA

0.9

1

0.3

0.9

1

NA

*** Above table can be added to up to line above this line and formulas will still pick up the added information

Row

2

Column

1

7

Yield

30

35

25

25

25

30

35

35

35

40

FITTINGS:

Material

Allowable Stresses in kips/in2 at degF

0

100

200

300

Please Select

A234 WP11

20

18.7

18

A234 WPB

20

20

20

A403 304 WPS

20

20

20

A403 316 WPS

20

20

20

A403 WP 304L

16.7

16.7

16.7

A403 WPS 32

20

20

20

A420 WPL3

21.7 NA

NA

NA

A420 WPL3

21.7 NA

NA

NA

A420 WPL-6

20

20

20

A182 F 11 CL2

23.3

23.3

23.3

400

500

600

650

700

750

800

850

900

950

1000

1050

1100

17.5

20

18.7

19.3

15.8

20

17.2

18.9

17.5

17.9

14.8

19.3

16.7

17.3

16.4

17

14

18.3

16.2

17

16.2

16.7

13.7

17.9

15.6

16.8

16

16.3

13.5

17.5

15.2

13

15.6

16.1

13.3

17.2

15

10.8

15.2

15.9

13

16.9

14.5

8.7

14.9

15.7

12.8

16.7

12.8

6.5

14.6

15.5

11.9

16.6

9.3

4.5

14.4

15.4

9.9

16.4

6.3

2.5

13.8

15.3

7.8

16.2

4.2

1.6

12.2

14.5

6.3

11.7

2.8

1 NA

9.7

12.4

5.1

9.1

NA

NA

NA

2.8

NA

NA

20

22.5

NA

NA

18.9

21.7

NA

NA

17.3

20.9

NA

NA

17

20.5

*** Above table can be added to up to line above this line and formulas will still pick up the added information

NA

NA

16.8

20.1

NA

NA

13

19.7

NA

NA

10.8

19.2

NA

NA

7.8

18.7

NA

NA

5

13.7

NA

NA

3

9.3

NA

NA

1.5 HA

6.3

NA

NA

NA

4.2

1150

1200

1.9

NA

7.7

9.8

4

6.9

NA

NA

NA

1.9

1.2 NA

NA

6

7.4

3.2

5.4

NA

NA

NA

1.2

1250

1300

NA

NA

4.7

5.5

2.6

4.1

1350

NA

NA

3.7

4.1

2.1

3.2

NA

NA

NA

1400

NA

NA

2.9

3.1

1.7

2.5

NA

NA

NA

1450

NA

NA

2.3

2.3

1.1

1.9

NA

NA

NA

1500

NA

NA

1.8

1.7

1

1.5

NA

NA

NA

1.4

1.3

0.9

1.1

NA

NA

NA

RNE Engineering and Projects (Pty) Ltd

P.O. Box 1490 Sasolburg 1947

Tel: (016) 970 8100 Fax: (016) 970 8110

Date:

Tuesday, November 18, 2014

Designer:

Hydrostatic Test Pressure for New and Corroded Pipe

Line Design Data

Symbol

Value

Unit

1700 kPa

DT

300 oC

TT

37.777 oC

Pipeline Parameters

Line Class / Line Number

O-7-596-1 1/2"-C & 007-O-496

Nominal Line Size

NPS

Pipe Outside Diameter

OD

48.26 mm

Schedule as per line Class

SCH

80

Wall thickness as per Schedule

inch

5.08 mm

Mill Tollerance

12.5 %

Corrosion Allowance

Pipe Material

1 mm

A106 B

Sy

Pipe Material Yield Stress

Fittings Material

241.316495 MPa

A234 WPB

Fittings Material Yield Stress

Sy

Joint Efficiency

1.0

Y Coefficient

0.4

241.316495 MPa

References:

Using formulas from ASME B31.3 and other accepted engineering practices

St

Sd

Pt f Pt

S a 0. 9 S y E

Pressure Test Factor

Stress Ratio

Minimum Test Pressure

circ

P D P Y

2 E t

E

Symbol

Value

1.5

Unit

Result

St S d

Pt

Selected Test Pressure

kPa

7655

kPa

Checking stresses in pipe from selected hydro test pressure > corrected yield

Maximum Allowable Stress in Pipe / Fittings

Stress Induced in New Pipe / Fitt due to Test Pressure

Sa

circ t n

217.18

MPa

38.49

MPa

Acceptable

Stress Induced in Corroded Pipe / Fitt due to Test Pressure

circ tc

50.56

MPa

Acceptable

Check 1.5 x rating of flanges and valves @ test temperature > selected test pressure

For Flange Material Group

7756.60

kPa

Acceptable

For Valve Material Group

7756.60

kPa

Acceptable

Notes:

Hydrostatic Test Pressure:

7655 kPa

__________________________________________________

_________________________________________

CALCULATED BY:

CHECKED BY:

Result

Reference

1

SP 50-9

2

Acceptable

Acceptable

Acceptable

ASME B16.5

Acceptable

ASME B16.5

________________________

Potrebbero piacerti anche

- Imperial Piping Weight Load Calculation WorkbookDocumento13 pagineImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Motor Control Center Details for Umiam Stage-II Hydro ProjectDocumento14 pagineMotor Control Center Details for Umiam Stage-II Hydro ProjectKunik Swaroop0% (1)

- ASME-B31-4 CalcDocumento9 pagineASME-B31-4 Calcshafeeqm3086100% (1)

- Data Assigment 1Documento32 pagineData Assigment 1Sukhwinder Kaur100% (1)

- ASME Action Check ListDocumento3 pagineASME Action Check Listarunrad100% (1)

- Small Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFDocumento6 pagineSmall Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFhussamammarNessuna valutazione finora

- Comparision of Piping CodeDocumento14 pagineComparision of Piping CodeAnonymous J1vjrU2Nessuna valutazione finora

- Wall Thickness ASME B31.1Documento97 pagineWall Thickness ASME B31.1Reza SyahrezaNessuna valutazione finora

- Course ASME VIII - Div 1Documento406 pagineCourse ASME VIII - Div 1Anonymous mfFwcJih82100% (9)

- Pipe Wall Thickness Calculation @MechEngineersDocumento77 paginePipe Wall Thickness Calculation @MechEngineersHeri KurniawanNessuna valutazione finora

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Documento6 pagineCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanNessuna valutazione finora

- Pipe Thickness Calculation For Straight Pipe Under Internal PressureDocumento7 paginePipe Thickness Calculation For Straight Pipe Under Internal PressureMakhdoom Ibad HashmiNessuna valutazione finora

- Equivalent ASTM MaterialDocumento34 pagineEquivalent ASTM Materialgolf0910251891% (45)

- Wall Thickness Pipeline (Gas) B31Documento25 pagineWall Thickness Pipeline (Gas) B31Rais Brian Abdurahman100% (6)

- Sample Design Calculation Template for Surge Vessel ThicknessDocumento3 pagineSample Design Calculation Template for Surge Vessel ThicknessRamachandran Venkatesh0% (1)

- Allowable Nozzle LoadsDocumento7 pagineAllowable Nozzle LoadsSiva baalanNessuna valutazione finora

- Shell CalculationsDocumento3 pagineShell CalculationsBaher Elsheikh100% (7)

- Sal de CrosetatDocumento3 pagineSal de CrosetatMădălina Pisău100% (1)

- Pt. Bahana Karya Mandiri: Data SheetDocumento8 paginePt. Bahana Karya Mandiri: Data SheetBowo Edhi WibowoNessuna valutazione finora

- 2 - 1 Ellipsoidal Head Blank DiameterDocumento1 pagina2 - 1 Ellipsoidal Head Blank Diameterdownloadmonster100% (2)

- Design of Pressure Vessel NewDocumento200 pagineDesign of Pressure Vessel NewneelNessuna valutazione finora

- Asme SectionsDocumento56 pagineAsme SectionsalperbogaNessuna valutazione finora

- Flange Asme ViiiDocumento21 pagineFlange Asme Viiizahidwahla1Nessuna valutazione finora

- ASME B31 3 Calculator V2Documento11 pagineASME B31 3 Calculator V2gerrydimayuga100% (3)

- Bolts TechnicalData PDFDocumento48 pagineBolts TechnicalData PDFAnonymous smFxIR07Nessuna valutazione finora

- Asme b31 3 03 PDFDocumento3 pagineAsme b31 3 03 PDFAtallah BoufatahNessuna valutazione finora

- 2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Documento20 pagine2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Sridhar Vijayan100% (2)

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDocumento4 pagineLethal Service - Quick Guide - Pressure Vessel EngineeringVilas AndhaleNessuna valutazione finora

- Area Reinforcement CalculatorDocumento5 pagineArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocumento8 pagineAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- Module 4Documento24 pagineModule 4MARIE ANN DIAMANessuna valutazione finora

- Asme BPV PDFDocumento59 pagineAsme BPV PDFRaju SkNessuna valutazione finora

- Calculation - ASME VIII Div.1Documento10 pagineCalculation - ASME VIII Div.1bargez100% (1)

- Wind Buckling of Metal Tanks During Their ConstructionDocumento7 pagineWind Buckling of Metal Tanks During Their ConstructionARNOUXNessuna valutazione finora

- Serial Number AutoCAD 2014Documento5 pagineSerial Number AutoCAD 2014Punith Ky67% (9)

- Code Comparison ASME B31.1 Vs B31.3 Vs B31.8Documento27 pagineCode Comparison ASME B31.1 Vs B31.3 Vs B31.8khaireddinNessuna valutazione finora

- Heat Exchanger DesignDocumento7 pagineHeat Exchanger Designsiva sankarNessuna valutazione finora

- Pipes. Wall Thickness Calculation According ASME B31.3Documento125 paginePipes. Wall Thickness Calculation According ASME B31.3musaveerNessuna valutazione finora

- ASME Code Calculations and DrawingsDocumento2 pagineASME Code Calculations and DrawingsRicardo Paz SoldanNessuna valutazione finora

- AD Merkblatt CalculationsDocumento13 pagineAD Merkblatt CalculationsARNOUX80% (5)

- AD Merkblatt CalculationsDocumento13 pagineAD Merkblatt CalculationsARNOUX80% (5)

- ASME SecVIII Div-2 Hydro TestDocumento2 pagineASME SecVIII Div-2 Hydro Testsouren1975Nessuna valutazione finora

- ASME B31.3 Tri-Clamp FEA Stress Analysis ReportDocumento18 pagineASME B31.3 Tri-Clamp FEA Stress Analysis ReportBertrandMezatioNessuna valutazione finora

- Pipe BranchDocumento761 paginePipe Branchjnmanivannanmech50% (2)

- AS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESSDocumento33 pagineAS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESSaike_5Nessuna valutazione finora

- Vessel Weld EfficiencyDocumento1 paginaVessel Weld EfficiencyAlvin SmithNessuna valutazione finora

- Bandlock 2 Horizontal QOCDocumento24 pagineBandlock 2 Horizontal QOCARNOUXNessuna valutazione finora

- Pipe Reinforcement Calculation (ASME-B31.3)Documento3 paginePipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Hydrostatic Strength of HDPE Pipes - Test ProcedureDocumento5 pagineHydrostatic Strength of HDPE Pipes - Test ProceduremuhamedzNessuna valutazione finora

- Open Die ForgingDocumento7 pagineOpen Die ForgingCharanjeet Singh0% (1)

- API 570 Authorized Piping Inspector Preparatory Program Mock Exam QuestionsDocumento13 pagineAPI 570 Authorized Piping Inspector Preparatory Program Mock Exam QuestionsShanawas Abdul Razak80% (5)

- Text Linguistics and Classical Studies - Facebook Com LinguaLIBDocumento129 pagineText Linguistics and Classical Studies - Facebook Com LinguaLIBEnglish Buzz100% (1)

- ASME/ASTM standards overview for mechanical engineersDocumento3 pagineASME/ASTM standards overview for mechanical engineersrajesh100% (2)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Documento1 paginaPipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNessuna valutazione finora

- Design Sheet As Per ASME 31.8 2012 For 12inch TeeDocumento3 pagineDesign Sheet As Per ASME 31.8 2012 For 12inch TeechethanNessuna valutazione finora

- ASME Sec I Cylinder Thickness and Pressure Calculation FormulasDocumento1 paginaASME Sec I Cylinder Thickness and Pressure Calculation Formulasramananrv123Nessuna valutazione finora

- Ngurv Ter - : de en Ow06/002.0Documento2 pagineNgurv Ter - : de en Ow06/002.0tranhonghakd5533Nessuna valutazione finora

- ASME CALculationDocumento6 pagineASME CALculationMakrame BattazNessuna valutazione finora

- N11 Nozzle CalDocumento9 pagineN11 Nozzle Calגרבר פליקסNessuna valutazione finora

- Pressure & Temperature ClassificationDocumento1 paginaPressure & Temperature Classificationkeo85100% (1)

- Ped Eam-0526-24-1-2006-03Documento6 paginePed Eam-0526-24-1-2006-03nathachaiNessuna valutazione finora

- PRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONSDocumento5 paginePRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONSUmar Aslam0% (1)

- NAB Deltapi 2011Documento6 pagineNAB Deltapi 2011manashbdNessuna valutazione finora

- Tubing Selection Guide - ParkerDocumento4 pagineTubing Selection Guide - Parker1amonet2Nessuna valutazione finora

- Astm A529 1972Documento5 pagineAstm A529 1972dharlanuctcom0% (1)

- Medidor de Gas - Smith MeterTM Turbine Meters FMCDocumento5 pagineMedidor de Gas - Smith MeterTM Turbine Meters FMCjplutodNessuna valutazione finora

- Instrument Tubing Selection Guide: Contact InformationDocumento4 pagineInstrument Tubing Selection Guide: Contact InformationdagauthamNessuna valutazione finora

- Jis G3462 PDFDocumento19 pagineJis G3462 PDFhbookNessuna valutazione finora

- Jis G3455 PDFDocumento12 pagineJis G3455 PDFhbookNessuna valutazione finora

- Steel PipesDocumento16 pagineSteel PipesAdam GordonNessuna valutazione finora

- Full Lift Spring Loaded Open PDFDocumento4 pagineFull Lift Spring Loaded Open PDFVenkatespatange RaoNessuna valutazione finora

- 500 Pressure SensorDocumento5 pagine500 Pressure SensorMabel Lorena Ochoa ContrerasNessuna valutazione finora

- Steel Line Pipe, Black, Plain End, Longitudinal and Helical Seam, Double Submerged-Arc WeldedDocumento6 pagineSteel Line Pipe, Black, Plain End, Longitudinal and Helical Seam, Double Submerged-Arc WeldedOrkun OrhanNessuna valutazione finora

- PP Socket Fusion-Dimensional DataDocumento21 paginePP Socket Fusion-Dimensional DataARNOUXNessuna valutazione finora

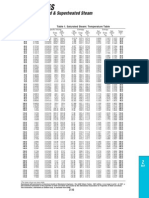

- Steam Tables: Properties of Saturated & Superheated SteamDocumento11 pagineSteam Tables: Properties of Saturated & Superheated SteamARNOUXNessuna valutazione finora

- Pipes and FittingsDocumento1 paginaPipes and FittingsARNOUXNessuna valutazione finora

- Mist Extractor - ProductCatalog PDFDocumento20 pagineMist Extractor - ProductCatalog PDFStephen OgunladeNessuna valutazione finora

- Circ LipsDocumento3 pagineCirc LipsARNOUXNessuna valutazione finora

- Piping ModelDocumento1 paginaPiping ModelARNOUXNessuna valutazione finora

- Arcelormittal CladDocumento7 pagineArcelormittal CladARNOUXNessuna valutazione finora

- Wind Pressures and Buckling of Cylindrical Steel1Documento17 pagineWind Pressures and Buckling of Cylindrical Steel1ARNOUXNessuna valutazione finora

- AIA Technical Forum - M o M - 21-11-2013Documento9 pagineAIA Technical Forum - M o M - 21-11-2013ARNOUXNessuna valutazione finora

- Laminate SelectionDocumento1 paginaLaminate SelectionARNOUXNessuna valutazione finora

- Pressure Equipment RegulationsDocumento20 paginePressure Equipment RegulationsARNOUXNessuna valutazione finora

- Arcelormittal CladDocumento7 pagineArcelormittal CladARNOUXNessuna valutazione finora

- Design Against FatigueDocumento70 pagineDesign Against FatigueARNOUXNessuna valutazione finora

- Technologist ReRegistration AppFormDocumento14 pagineTechnologist ReRegistration AppFormARNOUXNessuna valutazione finora

- DIN Flange Summary ChartDocumento1 paginaDIN Flange Summary ChartARNOUXNessuna valutazione finora

- Steam Tables: Properties of Saturated & Superheated SteamDocumento11 pagineSteam Tables: Properties of Saturated & Superheated SteamARNOUXNessuna valutazione finora

- Standard Bolt Torque Settings For Non-Metallic FlangesDocumento1 paginaStandard Bolt Torque Settings For Non-Metallic FlangesARNOUXNessuna valutazione finora

- Trunnion DetailDocumento1 paginaTrunnion DetailARNOUXNessuna valutazione finora

- BomDocumento1 paginaBomARNOUXNessuna valutazione finora

- Roller Bearings Selection ManualDocumento4 pagineRoller Bearings Selection ManualARNOUXNessuna valutazione finora

- DIN Flange Summary ChartDocumento1 paginaDIN Flange Summary ChartARNOUXNessuna valutazione finora

- Vapor PressureDocumento120 pagineVapor PressureARNOUXNessuna valutazione finora

- Bill of QuntitiesDocumento7 pagineBill of QuntitiesARNOUXNessuna valutazione finora

- Yr 6 Maths G-6 E P-I PDFDocumento168 pagineYr 6 Maths G-6 E P-I PDFdina171279Nessuna valutazione finora

- AtmegaDocumento22 pagineAtmegaMUKILANNessuna valutazione finora

- SMD Meter User's ManualDocumento2 pagineSMD Meter User's ManuallucianoNessuna valutazione finora

- Control Charts For Lognormal DataDocumento7 pagineControl Charts For Lognormal Dataanjo0225Nessuna valutazione finora

- BasrahDocumento19 pagineBasrahDurban Chamber of Commerce and IndustryNessuna valutazione finora

- DesignScript Summary User ManualDocumento20 pagineDesignScript Summary User ManualEsper AshkarNessuna valutazione finora

- Hitachi ZW550Documento12 pagineHitachi ZW550ForomaquinasNessuna valutazione finora

- 93C66 Microwire EepromDocumento13 pagine93C66 Microwire EepromadrianramonNessuna valutazione finora

- 11xx12xx SMDocumento44 pagine11xx12xx SMfanticelliNessuna valutazione finora

- WCB Customized Superior Quality Slewing Ring GearDocumento173 pagineWCB Customized Superior Quality Slewing Ring GearWCB BEARINGNessuna valutazione finora

- TR01B - Muhammad Aditya Prana Yoga - Analisa Listrik Chapter8.3Documento3 pagineTR01B - Muhammad Aditya Prana Yoga - Analisa Listrik Chapter8.3AzeedNessuna valutazione finora

- Unit 2 MineralogyDocumento53 pagineUnit 2 MineralogyEashan Adil100% (1)

- Unitplan2 Chi-SquareDocumento11 pagineUnitplan2 Chi-Squareapi-285549920Nessuna valutazione finora

- Optical VibrationDocumento6 pagineOptical VibrationKarthick VelayuthamNessuna valutazione finora

- VDVDVXVCFDBCVCDocumento390 pagineVDVDVXVCFDBCVCHafiz Rahmat UllahNessuna valutazione finora

- One Plus 7Documento114 pagineOne Plus 7Priyanka ChudasamaNessuna valutazione finora

- Quantitative Reasoning: Factors, HCF & LCM, FactorialsDocumento2 pagineQuantitative Reasoning: Factors, HCF & LCM, FactorialsNaman JainNessuna valutazione finora

- Primary-Side Regulation PWM Power Switch General Description FeaturesDocumento10 paginePrimary-Side Regulation PWM Power Switch General Description FeaturespopoNessuna valutazione finora

- (Altium Tutorial) PCB Symbol Naming ConventionDocumento7 pagine(Altium Tutorial) PCB Symbol Naming ConventionDefne AktemizNessuna valutazione finora

- Design of Bulk CarrierDocumento7 pagineDesign of Bulk CarrierhoangductuanNessuna valutazione finora

- B1698Documento23 pagineB1698Esteban OrtegaNessuna valutazione finora

- ES Q2 Mod8Documento26 pagineES Q2 Mod8maacovsNessuna valutazione finora

- Compression Test/ Group 1/ Material & Science Eng'GDocumento6 pagineCompression Test/ Group 1/ Material & Science Eng'GNiaz KilamNessuna valutazione finora