Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

THYSSEN (Maquina Mini Gearless DAF-270)

Caricato da

migmarelDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

THYSSEN (Maquina Mini Gearless DAF-270)

Caricato da

migmarelCopyright:

Formati disponibili

A company of

ThyssenKrupp

Elevator

ThyssenKrupp Aufzugswerke

ThyssenKrupp

Operating Manual

Mini gearless DAF270

OPERATING MANUAL

Imprint

All rights reserved

Copyright by: THYSSENKRUPP AUFZUGSWERKE GmbH

P.O. box 23 03 70, D-70623 Stuttgart

Printed in Germany, June 2004

The copyright of this documentation rests with THYSSENKRUPP AUFZUGSWERKE

GmbH. This documentation or extracts of it shall not be copied, distributed or used for the

purpose of competition.

Any reprint, copying or storing in data processing machines in any form or by any means

without prior permission of THYSSENKRUPP AUFZUGSWERKE GmbH is regarded as

infringement of the current Copyright Act and will be prosecuted.

Technical modifications for reasons of improvement or higher standard of Mini gearless

DAF270 are subject to decisions of THYSSENKRUPP AUFZUGSWERKE GMBH

without prior notice.

The responsibility for the content lies with the editor:

THYSSENKRUPP AUFZUGSWERKE GmbH

Preface

We are pleased that you decided to purchase a quality product from THYSSENKRUPP

AUFZUGSWERKE GmbH.

This operating manual assists you in getting familiar with the drive for moving cars - the

Mini gearless DAF270 (which is referred to as DAF270 below) - and its intended

possibilities of use. Important information concerning safety and hazards helps you to

safely use the DAF270.

DAF270 is subject to technical alterations.

ThyssenKrupp Aufzugswerke GmbH

Issue 06.2004

OPERATING MANUAL

Table of contents

Mini gearless DAF270

PAGE

1. Safety

1.1 Explanation of symbols used

1.2 General safety information

2. Transportation and storage

6

7

10

3. Product description

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

Description of DAF270

Functional description

Technical data - machine

Technical data - brake

Pulse encoder

Dimensions

Machine frame

Lubrication

Name plate

12

14

17

20

21

22

25

27

28

4. Mounting of machine

4.1

4.2

4.3

4.4

4.5

Mounting of machine

Motor connection

Connection of magnetic brake

Connection of encoder

Schematic diagram

30

32

33

39

40

5. Putting into service

5.1 Putting machine into service

41

6. Servicing

6.1 Servicing of machine

6.2 Drive brake test

42

43

7. Maintenance

7.1

7.2

7.3

7.4

7.5

Replacing of traction sheave

Replacing of pulse encoder

Replacing of brake monitoring switch

Silencing of brakes

Replacing of brakes

47

49

51

51

52

8. Annex

8.1

8.2

8.3

8.4

8.5

8.6

Tightening torque mechanical strength

Manufacturer's instructions for pulse encoder

Manufacturer's instructions for magnetic brake

Type test examination certificate for brake

Declaration of conformity for brake

Type examination certificate for

calculation of traction sheave shaft

ThyssenKrupp Aufzugswerke GmbH

55

56

61

66

70

72

Issue 06.2004

OPERATING MANUAL

1.1

1. SAFETY

Explanation of symbols used

The following pictographs and designations are used in this operating manual:

Danger

This symbol draws attention to an extreme danger to

life or risk of injury to persons.

Disregard of warning means danger to life!

Danger

This symbol draws attention to an immediate

impending danger to life or risk of injury to persons

caused by electric current.

Warnings must always be observed!

Warning

This symbol draws attention to an impending danger.

Disregard can cause injury to persons or extensive

damage to property.

Warnings must always be observed!

Note

This symbol draws attention to important information

and instructions for operation. Disregard can lead to

damages, hazards or failures.

Inspection

This symbol draws attention to the proper inspection

sequence.

These inspection notices must be observed in any

case. Disregard can lead to injury to persons or

damage to property.

ThyssenKrupp Aufzugswerke GmbH

Issue 06.2004

OPERATING MANUAL

1.2

1. SAFETY

General safety information

Information on the operating manual

Knowledge of the basic safety requirements is a prerequisite for the safe use

and fail-free operation of this component.

This operating manual comprises the most important information how to

safely use the component.

The operating manual and, in particular, the safety information must be

observed by all persons who perform any work on the component.

In addition the rules and requirements concerning the regulations for

prevention of accidents which apply to the installation location must be

observed.

Duties of the owner and / or the installer

The owner and / or the installer ensure that only persons are authorized to

work at the component, who

are familiar with the requirements concerning safe working and prevention

of accidents and who were trained how to use the component.

have read the safety information and the warning notices in this operating

manual.

Note: check the compliance of the employees method of working with the

safety requirements in regular intervals.

Duties of the employees

Persons who are authorized to perform work at the component are obliged

to observe the requirements concerning safe working and prevention of

accidents;

to read the safety information and the warning notices in this operating

manual prior to start working.

Training of the employees

Only trained and instructed, technically competent persons shall perform

work at the component.

The competence of the employees must be clearly defined for all tasks

concerning putting into service, operation, maintenance and repair work.

Organizational measures

The owner or the installer must provide the necessary personal protective

gear. All existing safety devices must be checked regularly in accordance

with the maintenance plan.

ThyssenKrupp Aufzugswerke GmbH

Issue 06.2004

OPERATING MANUAL

1. SAFETY

Informal information about safety measures

The operating manual must always be available at the location of the

installation.

The general and local regulations for the prevention of accidents and

environmental regulations must also be made available and observed.

Clearly and easily visible statutory safety instructions must be made

available for the users.

See to it that all information concerning safety and hazards is always

visibly and legibly made available on the machine.

Use as intended

DAF270 is designed in accordance with the state of the art and the

recognized safety regulations. DAF270 shall only

be used for its intended purpose

be used only if safe operation is ensured

DAF270 shall exclusively be used as drive for lifts.

Any other use or any use exceeding the scope of above definitions is

regarded as use outside of the intended purpose. THYSSENKRUPP

AUFZUGSWERKE cannot be hold liable for any damages resulting from this

and for any damages which are caused by any errors of procedure.

Use within the scope of its intended purpose also comprises

observance of all information of the operating manual

fulfilment of the instructions applying to putting into service, installation

description and inspection and repair work.

Guarantee and liability

The "General Conditions and Terms of Sale" of THYSSENKRUPP

AUFZUGSWERKE GmbH apply generally.

Any claims for guarantee and liability are excluded in the case of injury to

persons or damage to property resulting from one or several of the causes

below:

use of DAF270 outside the scope of its intended purpose

inexpert mounting, putting into service, operating and maintaining of

DAF270

use of DAF270 with defective and/or non-operative safety and

protective devices

disregard of the instructions in the operating manual that apply to

transportation, storage, mounting, putting into service, operation and

maintenance of DAF270

unauthorized constructional modifications of DAF270

unauthorized modification of drive (rating etc.)

unsatisfactory supervision of parts that are subject to wear

inexpert repair work

catastrophes caused by outside influences and Act of God

ThyssenKrupp Aufzugswerke GmbH

Issue 06.2004

OPERATING MANUAL

1. SAFETY

Constructional modifications at DAF270

DAF270 is adjusted at the factory and delivered ready for work.

In the case of any modifications of the machine THYSSENKRUPP

AUFZUGSWERKE GmbH cannot be hold liable.

Use of DAF270 and possible hazards

DAF270 shall only be operated in a closed machine room, provided with

cover and rope guard at the traction sheave or installed in a machine frame

in the headroom. The owner of the installation must verify that the drive is

accessible to trained experts only.

Works at the drive shall only be performed with the drive disconnected from

power supply and the installation protected against unintentional switching

on.

See to it that the safety distance to all revolving parts (marked yellow) is

observed by persons working in the machine room / headroom.

Inexpert handling can cause danger to life for the user or third parties resp.

impairment of the component or material property.

Failures which possibly impair the correct functioning are to be eliminated

immediately.

ThyssenKrupp Aufzugswerke GmbH

Issue 06.2004

OPERATING MANUAL

2.

2. TRANSPORT AND STORAGE

Transport and storage

Packing:

DAF270 is delivered:

a) without machine frame; assembled on a wooden pallet and wrapped in foil.

b) machine and frame assembled and wrapped in foil; wooden edges or a

special pallet screwed below the machine frame.

Remove these transport contrivances before you install the machine on

site.

Transport:

Machine and frame must be perfectly horizontal and the safety precautions

observed.

Transport by means of fork lift:

The forks must be of proper length to prevent the machine from tilting.

See to it that the forks are attached to the frame or transport pallet and

not to the machine.

Pay attention to projecting parts! There is the risk of injury to persons or

damage!

Transport by crane:

Do not stay below suspended loads!

Fasten transport chains or ropes at the machine frame.

See to it that the machine is perfectly horizontal.

Fasten at transport aid and secure against tilting. Do not lift the motor

housing!

Remove transport aids after transport.

Note the pictographs fastened on the packing or other visible places.

Top

Handle with care

Keep dry

Do not expose to

heat

Do not use handheld

grippers

Fasten here

ThyssenKrupp Aufzugswerke GmbH

10

Issue 06.2004

OPERATING MANUAL

2. TRANSPORT AND STORAGE

Dimensions and weight

The weight is indicated on a sticker on the packing of the machine.

For dimensions see delivery note.

For rough data see chapter 3.3 Technical Data

Examination by customer on receipt of goods

Examine the delivered parts for completeness, damage or anything strange.

Report and document transport damage

After receipt of goods make sure that there is no damage caused during

transport.

Information

Immediately document the damage noticed (drawing, photograph,

description of damage).

Immediately send the respective documents to THYSSENKRUPP

AUFZUGSWERKE GmbH.

Unpacking

Information

Dispose packing equipment in accordance with the environmental

standards or make it available for further use.

Special transport aids and transport contrivances remain at the

customer.

Intermediate storage

Even if the component is not mounted directly after delivery, it should be

stored in dry places and protected with humidity-proof covering.

Do not store the component in the open air. Parts without surface coating

lack long-time preservation.

Open ventilation opening.

Environmental conditions

Information

Surrounding at the final site of the machine (humidity, temperature) shall

comply with the requirements for machine rooms. (Between +5 and +40

C according to EN81).

Relative humidity of air shall not exceed 70%.

ThyssenKrupp Aufzugswerke GmbH

11

Issue 06.2004

OPERATING MANUAL

3.1

3. PRODUCT DESCRIPTION

Description of Mini gearless DAF270

5

2

1

Fig. 1

7

Represented without rope guard and covering

DAF270 consists of:

Pos.

1

2

3

4

5

6

7

8

Part designation

Disc on motor shaft

Cheese head screw

M12x 50

Traction sheave

Ventilation opening

Casted housing

Thread for fastening M16

Motor terminal box

Bearing bracket

ThyssenKrupp Aufzugswerke GmbH

12

Pos.

9

10

11

12

13

14

15

16

Part designation

Transport hole

Cover plate for brake

Encoder

Brake terminal box

Encoder connection

Electromagnetic brake

Cable duct thermal contact

Cable duct motor connection

Issue 06.2004

OPERATING MANUAL

3. PRODUCT DESCRIPTION

DAF270 rear view

10

11

12

13

Fig. 2

7

16

15

14

Versions:

The following versions are available:

1. Various drive capacities

2. Motors with electrical rating for inverters with sinusoidal mains

regeneration or braking operation through resistors

3. Various traction sheave diameters

4. Various groove profiles and rope number at traction sheave available

5. (Optional) machine frame variants dependent on dimensions

6. Various types of brake

ThyssenKrupp Aufzugswerke GmbH

13

Issue 06.2004

OPERATING MANUAL

3.2

3. PRODUCT DESCRIPTION

Functional description

Machine: DAF270 consists of a frequency-controlled permanent-magnet

synchronous motor.

DAF270 has two different power ranges, which are differentiated by the letter

behind the type designation:

DAF270 M (medium) for the standard and DAF270 L (large) for the higher

power range. The external housing dimensions differ in size. See chapter 3.6

Dimensions.

The machine has a monobloc housing with integrated bearing bracket on one

side.

The drive shaft with rolling bearings is made of tempering steel.

The front self-aligning bearing and the rear rolling bearing of the bearing

bracket are sealed and life-time lubricated.

DAF270 is designed for 1 : 1 and 2 : 1 suspension with single wrap

(max.180) and downward rope departure.

(The motor terminal box is accessible from below.) In all other cases, turn the

drives and adjust the mounting position to the respective access.

Motor: dependent on motor type and controller the braking energy can be:

a) supplied to resistors;

b) regenerated sinusoidally to the mains. (Only for motors 350V)

The machine is designed for thermal class F but used according to thermal

class B.

DAF270 has a self-ventilated motor (without auxiliary forced ventilation)

Operating temperature (max. 130C 5C) is monitored by a posistor.

Evaluation by means of a frequency inverter. In case of overheating the drive

is de-energized through the inverter.

Traction sheave: the single-block (rim and nub) overhung traction sheave is

attached onto the conical end of the motor shaft and secured against falling

down by screw-connected disc on the front side. The micro-encapsulated

screws are protected against unintensional working loose and provided with

detent edged washers placed under.

The groove flanks are hardened as standard ( 50 HRc).

For further data see chapter 3.3 Technical Data.

The gearless machine does not have a self-locking device.

Brake: an electromagnetically operated, dual-circuit brake is attached to the

motor housing. It consists of two independently operating brake shoes

(tandem), which act onto the motor shaft.

The spring-applied armature disk of the respective magnetic brake is pressed

against the brake lining of the rotor. The rotor is pushed and the second rotor

lining acts on the rigid bearing surface of the brake or the bearing bracket.

ThyssenKrupp Aufzugswerke GmbH

14

Issue 06.2004

OPERATING MANUAL

3. PRODUCT DESCRIPTION

The two rotors are rigidly connected to the motor shaft through interlocked

holes and a hub.

Brake release: the voltage-fed brake magnet coils attract the armature discs

and release the brake rotors.

The brakes cannot be released manually.

The brake torque of each brake circuit permits to stop the car loaded with

rated load at rated speed. The brake torque cannot be adjusted.

Note: the brakes of DAF270 are designed for use as holding brake. Any

dynamic braking is restricted to emergency and test braking. Normal use will

not lead to any noticeable wear on the lining.

This drive brake can in no way replace the safety braking system used for

downward operation.

Attention: the manufacturer of the lift installation must provide proper

measures for brake connection to ensure that the brake can be tested and

emergency rescue performed (even in case of power failure).

Brake monitoring: A separate control switch monitors the momentary brake

position (released/closed) of each brake. Any failure is signaled to the

control. The machine must be shutdown or a further run prevented if the drive

either runs at zero speed with one brake circuit open or starts with one brake

circuit closed.

For terminal diagram see chapter 4.3 and adjusting of brake test switch

chapter 7.3.

An electrical safety device of the overspeed governor or a type-tested safety

device of the same safety level shall initiate the releasing of the brake in case

of overspeed if the braking device of the DAF270 is utilized as ascending

car overspeed protection means. The requirements including range of use

and conditions set out in the annex of type test certificate No. ABV 591 of

01-08-08 must be complied with. See chapter 8.4.

Real value generator: DAF270 is a synchronous machine excited by a

permanent magnet. In energized state the absolute rotor position is supplied

by a sine-cosine-wave absolute position encoder. Speed and shaft position

are detected by high-resolution sine-cosine-wave tracks.

For description of encoder and technical data see chapter 3.5 and

manufacturer's instructions in chapter 8.2.

Environmental conditions: the ambient temperature at the site of

installation shall comply with the requirements for machine rooms and thus

be maintained between +5 and +40 C (in accordance with EN 81).

The relative humidity of air shall not exceed 70%

Attention: in case of temperatures over or under the freezing point, the

braking torque of the disc brake can be reduced due to condensation.

In case of a longer standstill, the friction linings can rust at the friction

surfaces.

Corresponding counter measures are to be made by the owner of the

component.

ThyssenKrupp Aufzugswerke GmbH

15

Issue 06.2004

OPERATING MANUAL

3. PRODUCT DESCRIPTION

Machine frame: the drive DAF270 is designed for installation in the

headroom, but can also be utilized for installation in the machine room. The

machine frame necessary for installation of the machine in the headroom is

delivered optionally.

The drive is delivered completely pre-assembled.

For details concerning machine frame and installation see separate

documents for frame.

LiftEquip: LiftEquip customers obtain a project planning form with design

data and installation instructions for the machine frame.

Material number of the project planning form:

German

9720 000 6756

English

9720 000 6778

Note: an installation frame, which makes delivery of the frame into the

headroom easier, is optionally available.

Please contact LiftEquip, if interested.

ThyssenKrupp Aufzugswerke GmbH

16

Issue 06.2004

OPERATING MANUAL

3.3

3. PRODUCT DESCRIPTION

Technical data machine

Thyssen Compact gearless

DAF270

Version

M 0xx

L 0xx

Diameter traction sheave - DT

[mm]

320

440

490

Rim width traction sheave - B

[mm]

145

132

150

10 x 8

7 x 10

Max. groove number z x d

Groove form traction sheave

Seat or V-groove

Material traction sheave

Max. brake torque acc. test

certificate Mbr

Type test certificate No. of brake

8 x 10

1)

EN-GJL 300 (HB 190 to 300)

2x1700

[Nm]

2x1700

2x1250

ABV 591

Moment of inertia gearless

[kgm]

Moment of inertia traction sheave

[kgm]

0.53

1,50

2,45

Moment of inertia machine

[kgm]

2.63

3,60

5,35

[kN]

43.5

57

57

[kg]

550

570

740

Weight traction sheave

[kg]

35

55

65

Weight machine frame TK

[kg]

400 - 650

Weight machine frame LE

[kg]

400 - 600

Permissible shaft load at traction

sheave Ftzul

Weight machine (incl. traction

2.10

2,90

sheave)

1) Hardened groove flanks are used (min. 50 HRc).

ThyssenKrupp Aufzugswerke GmbH

17

Issue 06.2004

IA

Starting current

kg

1600

CPI26.

CPI32

65

45

2200

0.94

83

14.50

330

24

87

1175

10.7

440

1600

CPI50R

90

68

2200

0.95

88

23.20

350

30

139

1050

15.3

440

1.6

1600

CPI48

90

78

2200

0.94

86

23.20

305

35

139

1025

14.9

440

1.6

1600

CPI48

90

78

2200

0.95

87

25.30

330

35

152

1025

16.3

440

1.75

1600

CPI48.

2)

CPI60

100

89

2200

0.96

90

29.00

320

38

174

1000

18.2

440

2.0

ThyssenKrupp Aufzugswerke GmbH

Pulse encoder data see chapter 3.5

2) 2) With current limitation to 100A!

18

1) The rated output indicated only applies to unbalanced installations under S5 operation (240 F/h, 50% Ed) with max. MA!

Rated load (guide value)

Inverter type

(assigned as standard)

Imax.zul.

MA

Starting torque

Max. permissible current

cos

Power factor

Nm

Efficiency (100%PN)

Hz

fStator

Stator frequency

IN

Rated current

min

U,eff

nRot

Speed

-1

Nm

kW

mm

Effective voltage

MN

PN

Rated torque

Rated output

1)

DT

1)

1.0

2:1

Traction sheave diameter

m/s

2:1

2:1

Elevator speed

2:1

2:1

Issue 06.2004

1000

CPI15

49

34

2200

0.94

79

10.00

330

18

60

1175

7.4

320

1.0

1:1

M008

Suspension

M 002

M 005

M 002

M 000

TYP DAF270

M 001

3. PRODUCT DESCRIPTION

OPERATING MANUAL

IA

Starting current

kg

2000

CPI50R,

CPI100R

100

75

2750

0,96

82

26

430

235

156

1375

22,5

490

2000

CPI26E

490

1,0

2:1

L009

ThyssenKrupp Aufzugswerke GmbH

19

1) The rated output only applies to unbalanced S5 operation (240 F/h, 50% Ed) at max. MA!

Rated load (guide value)

Inverter type

(assigned as standard)

Imax.zul.

MA

Starting torque

Max. permissible current

cos

Power factor

Nm

Efficiency (100%PN)

Hz

fStator

Stator frequency

IN

Rated current

min

U,eff

nRot

Speed

-1

Nm

kW

mm

Effective voltage

MN

PN

Rated torque

Rated output

1)

DT

Traction sheave diameter

1)

Elevator speed

2,0

2:1

Suspension

m/s

L 007

TYP DAF270

OPERATING MANUAL

Issue 06.2004

3. PRODUCT DESCRIPTION

OPERATING MANUAL

3.4

3. PRODUCT DESCRIPTION

Technical data operating brake

Type:

ERS VAR09

SZ1700 / 1250

ERS VAR09

SZ1700 / 1700

Manufacturer

Warner & Tourco

Warner & Tourco

Brake torque

2 x 1250 Nm

2 x 1700 Nm

Version

Dual-surface disc brake

asbestos-free brake

linings

Without overexcitation

207 VDC voltage

Without overexcitation

123 W with voltage

applied

Dual-surface disc brake

asbestos-free brake

linings

103.5 VDC overexcitation

52 VDC withstand voltage

232 W with overexcitation

59 W with withstand

voltage

Operating voltage

(one brake circuit)

Rated output

(one brake circuit)

Maximum ambient temperature 40C

40C

Max. temperature at full load

100C

100C

Maximum speed

250 min

Air gap (stroke per brake

0.35 + 0.05/-0.1 mm

0.35 + 0.05/-0.1 mm

circuit)

Maximum air gap in case of

wear

0.6 mm

0.7 mm

Operating time

Length of connecting line

ED 60 %

ED 60 %

10 m

6m

Weight (incl. accessories)

approx. 84 kg

approx. 84 kg

Type test certificate number

ABV 591

ABV 591

-1

Release monitoring

(per brake circuit)

Switching voltage

Switching capacity

Operating distance at setting

screw

ThyssenKrupp Aufzugswerke GmbH

250 min

-1

1 x microswitch

24 VDC

10 100 mA

0.15 mm

20

Issue 06.2004

OPERATING MANUAL

3.5

3. PRODUCT DESCRIPTION

Pulse encoder

DAF270 is controlled by means of an enclosed incremental hollow shaft

encoder with sine-wave output signals mounted on the rear end of the rotor

shaft.

Connection to control by means of permanently connected shielded

connecting cable of 10 m length with 15-pole sub D connector (RS485) and

UNC screwing.

The cable shield is connected-up to connector and encoder housing.

Connection, installation and drawing see chapters 7.2 and 8.2

Technical data for TTL encoder:

Enclosed hollow shaft encoder with 2 signals with 90 phase shift and

reference mark.

Number of increments (Z):

2048

pulses/revolution

Supply voltage:

5 5%

V

Output driver:

RS 485 / sine

Output signals: analog / serial

1Vss, max. frequency (-3dB) >/= 200kHz /

RS485 EnDat

Working temperature range:

Storage temperature range:

Permissible relative humidity:

Max. on-load current with 5 V

Protection class: IP 64

- 20...+ 100

- 30...+ 80

100

150

C

C

%

mA

Connection and installation instructions:

Connect connector box and reference potential.

Should longer cables be required only use original cables from

HEIDENHAIN.

Note: the build-on pulse encoder is standard and specially adapted to use

with ThyssenKrupp inverter. Use of another type of inverter necessitates a

pulse encoder adapted to the respective connected load.

Use of a second encoder is not provided with DAF270 machine.

Connection assignment at 15-pole Sub-D connector and instructions on

installation and wiring see manufacturer's instructions in chapter 8.2.

ThyssenKrupp Aufzugswerke GmbH

21

Issue 06.2004

OPERATING MANUAL

3.6

3. PRODUCT DESCRIPTION

Dimensions

Dimensions DAF270 M 0xx

550

M20 x 28 deep

550

346

DT=440

Brake connection

Center of

gravity

Fig. 3

ThyssenKrupp Aufzugswerke GmbH

22

Issue 06.2004

OPERATING MANUAL

3. PRODUCT DESCRIPTION

Dimensions DAF270 L 0xx

550

M20 x 28 deep

550

346

DT = 490

Brake connection

Center of

gravity

Fig. 4

ThyssenKrupp Aufzugswerke GmbH

23

Issue 06.2004

OPERATING MANUAL

3. PRODUCT DESCRIPTION

Dimensions DAF270 M 008 (Tepper variant 1 : 1)

M20 x 28 deep

550

550

346

Dt = 320

Brake connection

Fig. 5

ThyssenKrupp Aufzugswerke GmbH

Center of gravity

24

Issue 06.2004

OPERATING MANUAL

3.7

Machine frame

3. PRODUCT DESCRIPTION

(optional)

The machine frame for DAF270 is designed for machine-room-less elevators

to be placed in the headroom.

The frame from ThyssenKrupp Aufzugswerke is intended for 2:1 suspension.

The drive, terminal rope anchorages and the overspeed governor are also

accomodated in the frame. The drive is attached at two profiles and

supported by elastic elements. The frame is supported at the support points

of the profile ends in the headroom.

Fig. 6

Machine frame with mounted drive, overspeed governor and terminal rope

anchorages for headroom installation

ThyssenKrupp Aufzugswerke GmbH

25

Issue 06.2004

OPERATING MANUAL

3. PRODUCT DESCRIPTION

The shaft dimensions and the parallel distance of the ropes at the point of

rope departure (ASL) (tailor-made acc. to customer specifications in

accordance with available versions) define the frame design and dimensions.

DAF270 with frame from LiftEquip for headroom installation.

Fig. 7

ThyssenKrupp Aufzugswerke GmbH

26

Issue 06.2004

OPERATING MANUAL

3.8

3. PRODUCT DESCRIPTION

Lubrication DAF270

DAF270 has lifetime-lubricated rolling bearings. The bearings do not require

lubrication.

ThyssenKrupp Aufzugswerke GmbH

27

Issue 06.2004

OPERATING MANUAL

3.9

3. PRODUCT DESCRIPTION

Name plate DAF270

Version

1. THYSSENKRUPP AUFZUGSWERKE GmbH

A

1

2

3

B3

120 kN

4

5

6

G

Line

1

1

2

2

2

3

3

4

4

4

4

4

4

4

4

4

5

6

Column

A-D

E-F

A

B

D-F

A-E

F

G

H

I

J

K

L

M

N

O

A-F

A-F

ThyssenKrupp Aufzugswerke GmbH

Meaning

Machine type

Serial No. / year of construction

Design

Protection class

Insulation class

Mode of operation

Weight of machine [ kg ]

Rated output [ kW ]

Motor speed [ U / Min.]

Voltage [ V ] (star connection)

Power strength [ A ]

Efficiency

Starting torque [ Nm ]

Power consumption [ A ]

Frequency [ Hz ]

Operating force brake magnet [Nm]

Traction sheave ; max. number of

ropes; rope

28

Issue 06.2004

OPERATING MANUAL

3. PRODUCT DESCRIPTION

2. LiftEquip

A

1

2

3

4

5

6

Line

1

1

2

2

2

2

3

3

Column

A

D

A

B

C

D

A

D

4

4

4

4

4

4

4

4

5

6

ThyssenKrupp Aufzugswerke GmbH

E

F

G

H

J

K

L

M

Content

Machine type

Serial No. / year of construction

Design

Protection class

Insulation class

Maximum axle load [ kN ]

Mode of operation

Weight of machine [ kg ]

Rated output [ kW ]

Motor speed [ U / min.]

Voltage [ V ] (star connection)

Strength of current [ A ]

Efficiency

Starting torque [ Nm ]

Power consumption [ A ]

Frequency [ Hz ]

Note on further data

Traction sheave ; max. number of

ropes; rope

29

Issue 06.2004

OPERATING MANUAL

4.1

4. MOUNTING OF MACHINE

Mounting of machine

Assembly

DAF270 is designed for headroom installation, but may also be used in the

machine room provided that the proper means are made available.

1.) Delivered without machine frame:

Delivery of a frame-less drive necessitates the need to make proper assembly

and fastening means available. The drive may be attached at the side thread

holes dependent on the rope departure direction. Dimensions see chapter 3.6 .

See to it that the motor connection box is accessible.

To comply with the requirements for noise reduction / structure-borne noise

transmission isolation elements shall be inserted between drive fastening and

support.

The tensile force resulting from lateral or diagonal rope departure must be

considered and the drive supported properly.

2.) Delivered with machine frame (optional):

Optionally DAF270 is delivered assembled and aligned on the machine frame.

The frame is assembled in the headroom of the elevator installation in

accordance with the customer's specifications.

The number of rubber elements and their arrangement depends on the

overall weight load and the possible supports.

The necessary or permissible individual load depends on the characteristic

values of the isolation element.

The rubber elements are to be arranged in such a way that the load is

distributed equally.

Design and dimension of the machine frame in accordance with the

customer's specifications.

Note: prior to start setting the machine into operation remove the plastic cover

of the ventilation hole underside the housing. (Fig. 1 pos. 4)

How to align the machine frame

The machine shall be assembled or installed in accordance with the layout

drawing.

Align the rope departure of traction sheave and deflection pulley in

accordance with the drawing so that it is in vertical line with the car rope

pulley or the counterweight pulley. When the ropes are tensioned, the

machine shall be arranged horizontally aligned at the base plate. Use metal

plates to ensure that the base is perfectly horizontal.

ThyssenKrupp Aufzugswerke GmbH

30

Issue 06.2004

OPERATING MANUAL

4. MOUNTING OF MACHINE

How to align the machine on the frame:

The machine is delivered aligned. After disassembly of drive or displacing of

machine (due to exchanged traction sheave, for example) verify that the

machine is properly aligned and re-align, if required.

Note: when the machine is completely installed, tighten the fastening screws

with the pre-set torque. See chapter 8.1.

ThyssenKrupp Aufzugswerke GmbH

31

Issue 06.2004

OPERATING MANUAL

4.2

4. MOUNTING OF MACHINE

Motor connection

Observe terminal diagram at the cover of the motor connection box or

terminal diagram.

Adhere to fig. 8. Verify that the safety instructions and the respective local

building regulations are complied with.

Motor connection data of respective motor type see 3.3

Motor terminal diagram:

for frequency-controlled motors

Th

Th

U

V

W

Grd.

Fig. 8

Fig. 9

Temperature monitoring motor

Connect terminal connection "Th" (thermistor) and PTC tripping device (or

frequency inverter connection provided for that purpose.

Voltage applied shall not exceed 2.5 V.

ThyssenKrupp Aufzugswerke GmbH

32

Issue 06.2004

OPERATING MANUAL

4.3

4. MOUNTING OF MACHINE

Brake connection

Description and important instructions see chapter 3.4 and manufacturer's

instructions in chapter 8.3

Brake and encoder connection

8

10

11

12

5

4

Fig. 10

Brake housing

Conn. PTC resistors motor

Brake test switch D

Encoder connection

Brake voltage connection

Fastening bow

Brake test switch

10

Bearing bracket

Terminal box

11

Cover plate brake

Brake test switch C

12

Encoder

ThyssenKrupp Aufzugswerke GmbH

33

Issue 06.2004

OPERATING MANUAL

4. MOUNTING OF MACHINE

Connection of brake:

Connection

Terminal

Voltage supply of release coils and control switches

The brake release coils are located in the connection box (fig. 10 pos. 5) at

the front brake side.

Connect four-conductor cable - cores 1; 2 (terminals 1; 2) = brake coil D and

cores 3;4 (terminals 3; 4) = brake coil C - and brake circuit.

11 Brake monitoring D

10

9 Brake monitoring C

8

7 Thermal monitoring

6 brake

5 Series connection Th

4 Brake connection

3 brake D

2 Brake connection

1 brake C

Fig. 11

Connection of screened six-core cable from connection box (cores 1;2

(terminal 6; 7) = temperature monitoring brake) and motor temperature

monitoring with evaluator to be made by the customer. The voltage applied

shall not exceed 2.5 V.

Cores 3; 4 (terminals 8; 9) = brake monitoring D;

and 5; 6 (terminals 10; 11) = brake monitoring C,

must be connected to the brake monitoring.

Note: it is recommended to adhere to the instructions and recommendations

of the brake manufacturer as the performance of the brake in service mainly

depends on the circuit selected. See chapter 8.3.

ThyssenKrupp Aufzugswerke GmbH

34

Issue 06.2004

OPERATING MANUAL

4. MOUNTING OF MACHINE

For operating voltage of magnet coils (direct current acc. to

DIN IECE038) see name plate at the brake body.

Connection and corresponding type of brake see table Technical data

chapter 3.4.

When the brake ERS VAR09 SZ1700 / 1700 is connected, make sure that

the necessary overexitation is always maintained. Disregard may affect safe

and quick operation! No overexcitation possible with brake type ERS VAR09

SZ1700 / 1250.

Note: when disconnecting the brake coils alternative power supply is

recommended. Direct power supply necessitates protection of the coils

against the risk of transient overvoltage acc. to VDE 0580.

Details on connection of connector plugs at the brake line ends see fig. 14

and chapter 8.3, Manufacturer's instructions (Warner) point 5.2.1.

Miniature fuse: the fuses in the power supply lines are to be adapted to the

customer's power supply.

Connection temperature monitoring brake:

The PTC thermistor detectors are series-connected (core grey/grey) at the

factory at the brake terminal box (terminal 5-7) via a screened cable. See

terminal assignment and connections at terminal box (fig. 11) and connection

assignment for conductor in fig. 14.

Terminals "Th" are to be connected to a PTC thermistor tripping device by

the customer. The voltage applied shall not exceed 2.5V.

See to it that the distance to all revolving parts is observed by persons laying

connecting cables.

Corresponding counter measures are to be made.

Do not use the same cable duct for connecting lines used for temperature

monitoring and brake test and motor connection line.

Connection release monitoring brakes:

Microswitches are attached at the coil body of the magnet brake. A pre-set

and pre-assembled switch per brake circuit each monitors the brake

condition (opened/closed). The setting shall not be changed.

When replacing make sure that the switch setting is in accordance with the

instructions in chapter 7.3.

Check the switches for proper setting and correct function.

Connection release monitoring switch

Input connection

brown

Break contact

connection black

Make contact

connection blue

Fig. 12

ThyssenKrupp Aufzugswerke GmbH

35

Issue 06.2004

OPERATING MANUAL

4. MOUNTING OF MACHINE

The switch connections are connected at the terminal box (fig. 11) via

a 6-core screened cable (fig. 14) for signal processing.

The connection at the customer is made as break contact.

An evaluation of the signal of both switch conditions must be made

by the customer!

Switching current range min. 10 mA to max. 100 mA at 24 VDC.

Further details see chapter 8.3 Manufacturer's instructions.

After connecting check brake and monitoring switches for correct functioning.

Note: an appropriate access to the brake and microswitches for the

inspection, adjustment or replacement works must be possible.

ThyssenKrupp Aufzugswerke GmbH

36

Issue 06.2004

OPERATING MANUAL

4. MOUNTING OF MACHINE

Magnetic brake with release monitoring

Air gap

4

2

8

9

10

11

12

Fig. 13

1

2

3

4

5

6

7

8

9

10

11

12

Contact extension for release monitoring C

Bearing bracket

Brake lining

Brake coil body C

Brake disc D

Anchor disc D

Brake coil body D

Cheese head screw (switch fastening)

Setting screw brake release C

Brake release switch C (release monitoring)

Eyebolt

Terminal box

ThyssenKrupp Aufzugswerke GmbH

37

Issue 06.2004

ThyssenKrupp Aufzugswerke GmbH

Fig. 14

38

6.

Screening

12 + 3

6.8

Brake monitoring and thermistor connection

70 3

10 000 or 6 000 15

50 3

6.

50 3

6.

At the customer

Adernendhlsen

Brake coil connection

6.8

120 3

Connection side terminal box

at brake

Adernendhlsen

50 3

10 000 6 000 15

1

2

3

4

1

2

3 Core 1

4 Core 2

5

6

7 Core 3

8 Core 4

9 Core 5

10 Core 6

P PHOENIX

Switch D

Switch C

Thermistor

Magnet C and D

conductor

Coil C

Coil D

PHOENIX conductor

OPERATING MANUAL

4. MOUNTING OF MACHINE

Connecting cables magnetic brake

Issue 06.2004

OPERATING MANUAL

4.4

4. MOUNTING OF MACHINE

Encoder connection

The encoder at the rear shaft end is screw-connected to the brake housing

by means of a fastening bracket. See fig. 10.

Connection to control by means of a 10 m long connecting cable with

15-pole sub-D connector.

Pin assignment of connector see chapter 8.2 Manufacturer's instructions.

Description and technical data for encoder connection see chapter 3.5.

ThyssenKrupp Aufzugswerke GmbH

39

Issue 06.2004

OPERATING MANUAL

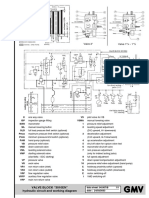

Schematic diagram DAF270

+M

Winding

Motor

Temperature

monitoring

Encoder

Brake magnet

Temperature

monitoring

Brake

Control switch

4.5

4. MOUNTING OF MACHINE

ThyssenKrupp Aufzugswerke GmbH

40

Issue 06.2004

OPERATING MANUAL

5.1

5. PUTTING INTO SERVICE

Putting DAF 270 into service

Before you start putting the machine into service the following points are to

be checked and/or the following works performed:

Check mounting and aligning of machine, frame and rope departure

Check fastening of machine and frame

Tighten screws and secure with pre-set torque (see table tightening

torques in 8.1)

Check supply terminals, earthing of motor and brakes for connection and

test

Check thermal monitoring of motor and brake for connection to

connection PTC thermistor tripping device (not part of the supply

schedule)

Check brake and encoder for correct connection to control

Check lower release hole of drive for removal of plastic cover

Check whether safety, accessory and installations tools are removed

from the danger zone

Check armature base plate and brake connection (chapter 6.2 c)

Check brake control switches for proper connection and functioning

(chapter 7.3)

Perform brake test with one acting brake shoe each (chapter 6.2)

Check brake release (for emergency rescue even in case of power

failure) for proper functioning (not part of supply schedule)

Check rope guard cover or rope support for proper mounting and

distance (max. 2mm) (not part of the supply schedule of machine frame)

Check special mountings (optional) for correct mounting and functioning

Attention: if the drive is operated by a brake control circuit instead of an

emergency braking system (safety gear) against overspeed in upwards

direction, it must be observed that the elevator installation shall only be put

into service with the brake monitoring faultlessly functioning!

Never put the installation into service without brake test switches by

disconnecting the check-back or brake test switches and resetting the nonvolatile memory (EPROM).

Disregard may cause danger to life of persons.

ThyssenKrupp Aufzugswerke GmbH

41

Issue 06.2004

OPERATING MANUAL

6.1

6. SERVICING

Servicing of DAF270

Servicing interval: servicing of the machine should be carried out at least

once a year, preferably in the course of the general elevator servicing.

Note: installation and servicing works shall only be carried out by trained and

qualified personnel.

These persons must know and observe the respective regulations and

requirements for elevator installations as well as the accident prevention

regulations.

Further information concerning proceeding, adjustment and data see

chapters:

Check armature base plate - air gap between armature disc

and brake coil body for wear of brakes

6.2

Check brake deceleration

6.2

Check brake control switches for proper functioning

7.3

Check screw-connections and fastenings for proper

tightening (tightening torque)

8.1

Check grooves of traction sheave and drive fastening for

proper tightening; re-tighten, if required.

7.4

Check groove profiles for damage and wear

Check electrical connections for correct working, sound

condition and proper fastening

Check motor bearings for wear (noise, backlash)

Check protective and safety equipment; test for

correct working

Check protective and safety equipment; check danger and

instruction signs; check signs for proper affixing and visibility

ThyssenKrupp Aufzugswerke GmbH

42

Issue 06.2004

OPERATING MANUAL

6.2

6. SERVICING

Drive brake test

Inspection interval: inspection of the brake shall be carried before initial

operation, after exchange of brake and once a year in the course of the

general elevator servicing.

a) The brake deceleration is tested for each brake circuit

individually.

Note: before testing:

Inspection signs must be made available at the landing doors.

Close the doors acc. to the rules.

Make sure that the car is empty.

While testing the brake circuit with the empty car moving upwards the car

must be at least 2 landings below the upper-most landing.

While testing the brake circuit with the fully loaded car moving downward

the car must be at least 2 landings above the lower-most landing.

The single circuits are tested by applying below voltage at the single brake

coils:

Brake type SZ1700/1700 with excitation / withstand voltage 104 / 52 VDC

Brake type SZ1700/1200 with operating voltage 207 VDC

While testing the brake circuit, the brake of the 2. brake circuit must be

released during the braking operation (even in case of emergency stop).

Withstand voltage must be applied at the magnet coil of the 2. brake

circuit.

Disable release monitoring of the brakes until the respective brake circuit

is tested.

Attention: should the elevator move after release of one brake circuit or fail

to decelerate sensibly during the braking operation, switch the continuously

energised coil off immediately.

The dual circuit braking function is not guaranteed. Check brake!

Testing with deceleration measure:

Check brake deceleration at each brake circuit individually.

Testing may be performed while moving the empty car upwards or the fully

loaded car downwards.

Connect deceleration measure

Activate normal run (brake to be tested is released)

Activate emergency stop as soon as rated speed is reached (brake to be

tested closes). While testing the brake circuits individually, the motor coils

should be de-energized. Motor braking may lead to wrong test results.

Determine deceleration for 1. brake circuit using a measuring device

Compare measurement and reference value

Remove continuous voltage supply at continuously open 2. brake circuit

and connect to 1. brake circuit.

ThyssenKrupp Aufzugswerke GmbH

43

Issue 06.2004

OPERATING MANUAL

6. SERVICING

Repeat test at 2. brake circuit.

Deceleration values:

Minimum deceleration for one brake circuit

0.4 m/s

Minimum deceleration for both brake circuits

1.0 m/s

Attention: after testing the brake, remove the continuous control voltage at

the 2. brake ciruit and establish the original condition (both brakes acting at

the same time). Enable the release control switches at the brakes again.

Simple testing of braking deceleration without measuring device:

(this inspection method only applies to travel heights 7m and control point

observable from brake operation point.)

Inspection sequence:

The details described in a are to be observed.

Provide terminal for continuous power supply at brake circuit of the 2.

brake coil.

Move the fully loaded car at least two landings above the bottom-most

landing.

Mark ropes at the height of the control point.

The control point shall be easily visible from the brake operation position.

(Marking at bracket height, for example).

Move the car upwards to the nearest landing.

While testing, apply continuous control voltage at 2. brake.

Note: voltage must be present even with the main switch disabled. If not,

both brakes will become effective.

Move fully loaded car downwards at normal speed. Observe control point

and ropes from brake operation position.

Switch off main switch as soon as marking reaches the control point.

Measure distance between marking and control point. This distance

corresponds approximately to the stopping distance of the tested brake

circuit.

Remove continous operating voltage and apply at tested brake coil.

Compare stopping distance result and reference value.

Stopping distance

The max. stopping distance for single brake circuit shall not exceed:

1.8 m for installations with VN 1.0 m/s; 3.5 m for installations with VN 1,6 m/s;

5.0 m for installations with VN 2.0 m/s.

(These values only apply to simple testing)

Repeat described testing for 2. brake circuit.

Attention: when the brake is tested, the original switching condition is to be

established (operation of both brake coils at the same time and connection of

brake test switch).

ThyssenKrupp Aufzugswerke GmbH

44

Issue 06.2004

OPERATING MANUAL

6. SERVICING

b) Testing of both brake circuits

When a brake circuit is tested individually, activate emergency stop operation

and repeat testing for both brake circuits.

Deceleration must fall below the stopping distance of the single circuit tests !

c) Inspection of wearing condition:

Put a feeler gauge between coil body and armature disk and check air gap.

The brake must be closed (coils de-energized).

Repeat several times at the circumference.

This method only applies to the front brake which is easily accessible. The

second brake is mounted recessed in the bearing bracket.

Testing the air gap at the second, recessed mounted brake:

Screw the enclosed hexagon screws M8 x 150 (marked red) into

8.4 mm holes at the brake front (see fig.15 pos. 11). Screw in until the

distance between the screwhead and the support is approx. 1-3 mm.

Attach dial gauge and holder at the brake and vertically align the dial gauge

towards the screwhead. (See fig. 15)

Energize brake circuit to be tested shortly several times and read screw

stroke at dial gauge. (The stroke corresponds to the airgap at the front

brake).

Afterwards remove screws and reposit.

Replace brake as soon as the max. limit air gap is reached. Repairs to

be performed at the factory!

Discription of brake replacement see chapter 7.5.

Note: the electro magnet may fail to attract the armature base plate properly

and without delay if the air gap is too large. This means that the brake opens

delayed or fails to open.

Never tighten the red screws (fig.15, pos. 11). Remove the screws before

operation is started. In case of disregard the brakes cannot be closed!

Table air gap brake

Typ

Rated torque

for 2 brake

circuits

1250

2500 Nm

1700

Rated air gap

Limit air gap

ThyssenKrupp Aufzugswerke GmbH

3400 Nm

Rated air gap

Braked

complete

Limit air gap

Braked

complete

0.35 mm

0,1

max. 0.6 mm

0.35 mm

0,1

max. 0.7 mm

brake closed (at zero current), new lining

brake closed (at zero current), worn off lining

45

Issue 06.2004

OPERATING MANUAL

6. SERVICING

Representation: checking of stroke movement of anchor plates (release

gap) at non-accessible brake C.

6

5

7

8

9

10

4

11

12

9

3

8

Fig. 15

9

14

13

11

Brake switch connection (6-pole)

Detent edged washer SK12

Brake connection (4-pole)

Hexagon socket M12x200

Connection box brake

10 Protecting plate

Dial gauge

11 Hexagon socket M8x150

Dial gauge holder

12 Brake magnet housing D

Transport eyebolt M12

13 Encoder

Encoder connection

14 Hexagon socket M12 x 20

ThyssenKrupp Aufzugswerke GmbH

46

Issue 06.2004

OPERATING MANUAL

7.1

7. MAINTENANCE

Replacing of traction sheave

View rotated 90

Fig. 16

1

2

3

4

5

6

7

8

9

Traction sheave

Fitting key 25 x 14 x 90 mm

Disc

Detent edged washer SK16

Hexagon socket M 16 x 50 8.8 microencapsulated

Tightening torque = 195 Nm

Motor shaft

Motor housing

Motor connection box

Forcing hole

Installation sequence traction sheave replacement

Disassembly:

Switch off power supply; secure car and counterweight

Remove rope fixing beam

ThyssenKrupp Aufzugswerke GmbH

47

Issue 06.2004

OPERATING MANUAL

7. MAINTENANCE

Remove load from traction sheave; discard ropes; secure traction sheave

with lifting device

Loosen screws on mounting disc of traction sheave; put screws in outer

hole circle of disk (fig. 16, pos. 3) and loosely screw in traction sheave hub

(holes pos. 8).

Place a washer approx. 5 10mm thick between shaft end and disc.

Tighten screws uniformly and remove traction sheave from motor shaft.

Put traction sheave down using lifting device.

Remove mounting disc from traction sheave

Assembly:

Clean shaft end and traction sheave holes; never make any dimensional

changes in featherkey, groove, shaft or drilled holes

Never grease or oil shaft and holes

Carefully fit new traction sheave to conical end of motor shaft

Bring position of featherkey and groove in line. Push traction sheave on

motor shaft

Assemble traction sheave using already available screws and tighten in

accordance with tightening torque.

Disassemble screws and disc

Check fit cover of traction sheave holes (the pressed on bearing surface of

the traction sheave must project the front shaft at least 1.5 mm)

Fit and screw disc to motor shaft using new micro-encapsulated screws

and detent edged washers

Tighten fastening screws using torque wrench and bring to required torque

of 195 Nm in several operations.

Replace rope; remove securing devices at car and ropes

Screw on rope fixing beam

Attention: the traction sheave may work loose if assembled improperly.

When the traction sheave is to be replaced, enclosed new microencapsulated screws must be used.

Observe screw strength and tightening torque!

Note: only use micro-encapsulated screws twice, since otherwise the

adhesive force is no longer effective

ThyssenKrupp Aufzugswerke GmbH

48

Issue 06.2004

OPERATING MANUAL

7.2

7. MAINTENANCE

Replacing of pulse encoder

1

6

5

Push onto or

remove from

shaft end

Fig. 17

1

2

3

4

5

6

Shaft end

Mounting elbow

Clamp bolt

Fastening screw

Female component encoder

Encoder housing

Technical data, see chapter 2.8

Manufacturer's instructions

chapter 8.3

Disassembly:

Switch off power supply

Remove connector plug of encoder connection on control.

Unscrew clamp bolt at female encoder component using hexagon socket

wrench M2.5 (2 screws pos. 3)

Unscrew encoder and fixing strap at brake (2 x M8)

Carefully remove encoder from shaft end into axial direction

ThyssenKrupp Aufzugswerke GmbH

49

Issue 06.2004

OPERATING MANUAL

7. MAINTENANCE

Assembly:

Clean but do not grease shaft end before you start mounting the

encoder.

The shaft end must be clean and free of grease

Carefully turn and push fixing strap and female encoder component onto

shaft end in direction of arrow until the fixing strap is close to the brake

Carefully tighten clamping bolt (pos.3) in the female component without

distorting the encoder.

The encoder housing must be easy to move on the shaft

Turn encoder housing until the connecting cable is positioned properly.

Align strap holes towards threaded holes of brake; screw-connect fixing

strap at brake

Connect encoder connection to control

Adjust encoder

Attention: when performing test and inspection works never switch the drive

on with the encoder unconnected; this can cause damage of electronic

components in the encoder.

1

2

3

4

6

1

Fig. 18

Hexagon socket screw

Fixing strap

Brake housing

Encoder

Shaft end

Connecting line

Clamping bolt

Note: re-adjust the encoder with the pulse encoder being replaced or the

rotor position changed. Proceeding see operating manual of frequency

inverter.

ThyssenKrupp Aufzugswerke GmbH

50

Issue 06.2004

OPERATING MANUAL

7.3

7. MAINTENANCE

Replacing of brake monitoring switch

Secure car and counterweight

Switch off power supply and protect installation against unintentional

switching on

Disconnect defective switch at connection box (fig. 11) and replace

Mount new switch at brake coil body, fig. 13, pos. 10, and connect to

terminal box

Setting and checking of brake monitoring switch:

Screw in setting screw M4 for switch operation by two to three screw

turns. The switching contact of the brake monitoring switch shall not

touch the setting screw

Apply operating voltage at brake circuit to be set

Set distance between switching contact and setting screw to 0.15 mm

using a feeler gauge

Unscrew setting screw until the contact of the microswitch reaches the

switching point

Remove feeler gauge; disconnect operating voltage

Check microswitch for correct functioning by switching the brakes on and

off repeatedly

Seal fastening screws of release monitoring using sealing wax

Put installation into operation

7.4

Silencing of the brakes

The used noise dampening has been adjusted at the factory. However the

noise dampening is subject to a certain aging dependent on the application

or operational conditions (switching frequency, torque adjustment, natural

drive vibration).

The brake must be completely exchanged, if the noise behaviour of the brake

rises to an inadmissible level.

An exchange of the damping elements is only possible at the manufacturer.

ThyssenKrupp Aufzugswerke GmbH

51

Issue 06.2004

OPERATING MANUAL

7.5

7. MAINTENANCE

Replacing of brakes

4

5

6

7

8

2

9

10

11

12

Air gap

Air gap

Fig. 19

1

Motor shaft

Brake magnet housing

Hexagon screw M8 x 40

Hexagon screw M12 x 200

Motor housing

Encoder

Bearing bracket

10 Fixing strap

Braking rotor

11 Toothed sleeve

Armature base plate

12

ThyssenKrupp Aufzugswerke GmbH

52

O ring

Issue 06.2004

OPERATING MANUAL

7. MAINTENANCE

Replacing of dual-circuit disc brake (Warner)

Note: for safety reasons, the brake must be completely replaced as soon as

the brake is defective or the wear limit reached.

Exchange of the brake to be made in the house Warner.

To replace the brake proceed as follows:

Disasssembly:

Switch off power supply and secure installation against unintentional

switching on

Rest counterweight on buffer; secure car

Remove cover plate at brake

Disconnect or unplug connecting cables between brake monitoring

switch, PTC thermistor and brake connections at brake.

Remove terminal connection between encoder and motor shaft. Remove

fixing strap at brake housing and encoder at the same time. Assembly

instructions see chapter 7.2.

Attention! Prior to continue disassembly screw in enclosed red hexagon

sockets (M8x150). In case of disregard the brake parts will be separated

by spring force.

Screw transport eyebolts (M12) into side threads at the brake housing

circumference. Fix brakes at lifting device

Mark position of connection box at drive

Remove fastening screws (fig. 19 pos. 8)

Carefully push off brake housing and rotor from toothed sleeve (fig. 19

pos. 11) and place aside

Carefully push off rear rotor at bearing bracket (use two screw drives as

lever, if necessary)

Note: the toothed sleeve is pushed over the shaft end of the warmed up

drive (240C). Non-defective pushing off is not possible, therefore. Re-use if

toothing is free from any visible damage.

Assembly:

Fasten new brake at lifting device

Clean and slightly grease toothed sleeve at motor shaft end

Replace defective O rings at toothed sleeve, if necessary

Clean braking surface at bearing bracket of drive using special cleaner

and slightly grease (with DELOTHEN NK1, for example)

Mount front brake rotor to toothed sleeve (make sure that the rotor is

mounted the right way round; hub collar backwards!)

Align new brake towards toothed sleeve using lifting device. Observe

position of connection box (marking at bearing bracket).

Before you start mounting the brake, connect the brake coils and make

sure that the brake is open. In case of disregard, the brake rotor blocks

and the brake housing cannot be moved and aligned while fitting the

screws.

Mount brake and second brake rotor; tighten fastening screws and

observe proper tightening torque.

ThyssenKrupp Aufzugswerke GmbH

53

Issue 06.2004

OPERATING MANUAL

7. MAINTENANCE

Attention: avoid any impact onto the motor shaft as this may cause

deterioration of the rolling bearings. Push rotor manually with a slight

pressure over the toothed sleeve (O ring).

Loosen red transport eyebolts at front side of brake (do not unscrew). Check

air gap of rear brake at bearing bracket using a dial gauge. (See description

in chapter 6.2)

Then unscrew transport eyebolts and reposit. The screws must be available

for future air gap checking and installation works.

Check air gap at front brake using feler gauge

Mount protective cover at brake housing. Observe tightening torque.

(Observe sequence of installation. Disregard may cause deterioration of

the cover!)

Mount pulse encoder (see chapter 7.2)

Connect brake magnet coils, brake monitoring switches, thermal

elements and encoder to control

Remove transport contrivances at car and counterweight

When the drive or the brakes are replaced, check the drive brake for

correct functioning before you start operation. See description in

chapter 6.2.

ThyssenKrupp Aufzugswerke GmbH

54

Issue 06.2004

OPERATING MANUAL

8.1

8. ANNEX

Tightening torque - mechanical strength

Attention: observe required screw strength and tightening torque when

performing any work on the machine or exchanging parts.

Non-microencapsulated screws must be secured against unintentional

working loose using detent edged washers.

The values specified apply to the applications indicated below:

Hexagon socket screws ISO 4762 (DIN 912)

Hexagon bolts ISO 4014 / 4017 (DIN 931 / 933)

To observe the required torque, tighten the screws using a torque

spanner!

Dimension

Strength

Tightening torque MA [Nm]

8.8

10.9

12.9

M4

2,8

4,1

4,8

M5

5,5

8,1

9,5

M6

9,6

14

16

M8

23

34

40

M10

46

67

79

M12

79

115

135

M16

195

290

340

M20

395

560

660

M24

680

970

1150

Attaching encoder on shaft

Attaching encoder on brake

ThyssenKrupp Aufzugswerke GmbH

Clamping bolt

M4 x 4

55

2,5 Nm

1,0 Nm

Issue 06.2004

OPERATING MANUAL

8.2

8. ANNEX

Manufacturer's instruction for pulse encoder

ThyssenKrupp Aufzugswerke GmbH

56

Issue 06.2004

OPERATING MANUAL

8. ANNEX

Mounting dimensions

30 h7

4 x M4

Installation

ThyssenKrupp Aufzugswerke GmbH

57

Issue 06.2004

OPERATING MANUAL

ThyssenKrupp Aufzugswerke GmbH

8. ANNEX

58

Issue 06.2004

OPERATING MANUAL

8. ANNEX

87

45

SW3 (2X))

Md = 2,5

0,5Nm

10 000 mm

ThyssenKrupp Aufzugswerke GmbH

59

Issue 06.2004

OPERATING MANUAL

8. ANNEX

Pin assignment

15-pole sub-D connector (pin)

Data

Clock

Contact

Color

Green

Black

Yellow

Black

Blue

Black

Red

Black

nicht

Not Assigned

belegt

Gray

Red

Purple

Yellow

Inside

Screen

Contact

Color

Brown

Green

White

Green

ThyssenKrupp Aufzugswerke GmbH

Blue

White

White

Black

60

Issue 06.2004

OPERATING MANUAL

8.3

8. ANNEX

Manufacturers instructions - Brake

ThyssenKrupp Aufzugswerke GmbH

61

Issue 06.2004

OPERATING MANUAL

ThyssenKrupp Aufzugswerke GmbH

8. ANNEX

62

Issue 06.2004

OPERATING MANUAL

ThyssenKrupp Aufzugswerke GmbH

8. ANNEX

63

Issue 06.2004

OPERATING MANUAL

ThyssenKrupp Aufzugswerke GmbH

8. ANNEX

64

Issue 06.2004

OPERATING MANUAL

ThyssenKrupp Aufzugswerke GmbH

8. ANNEX

65

Issue 06.2004

OPERATING MANUAL

8.4.

8. ANNEX

Type test examination certificate for brake

ThyssenKrupp Aufzugswerke GmbH

66

Issue 06.2004

OPERATING MANUAL

ThyssenKrupp Aufzugswerke GmbH

8. ANNEX

67

Issue 06.2004

OPERATING MANUAL

ThyssenKrupp Aufzugswerke GmbH

8. ANNEX

68

Issue 06.2004

OPERATING MANUAL

ThyssenKrupp Aufzugswerke GmbH

8. ANNEX

69

Issue 06.2004

OPERATING MANUAL

8.5.

8. ANNEX

Declaration of conformity for brake

ThyssenKrupp Aufzugswerke GmbH

70

Issue 06.2004

OPERATING MANUAL

ThyssenKrupp Aufzugswerke GmbH

8. ANNEX

71

Issue 06.2004

OPERATING MANUAL

8.6

8. ANNEX

Type examination certificate for

calculation of traction sheave shaft

ThyssenKrupp Aufzugswerke GmbH

72

Issue 06.2004

62 430 01 86 0 Issue 06/2004

ThyssenKrupp Aufzugswerke GmbH

A company of ThyssenKrupp Elevator

Bernhuser Strasse 45

73765 Neuhausen a. d. F.

Germany

Tel.: +49 7158/12-0

Fax: +49 7158/12-2585

E-Mail: info@tke-aufzuege-de.thyssenkrupp.com

www.thyssenkrupp-aufzuege.com

Potrebbero piacerti anche

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideDa EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideValutazione: 4 su 5 stelle4/5 (9)

- As-Built Commercial BLDG.1Documento11 pagineAs-Built Commercial BLDG.1John Rom CabadonggaNessuna valutazione finora

- PMC GearlessDocumento72 paginePMC Gearlessمحمدحماد57% (7)

- Elevator Mechanic: Passbooks Study GuideDa EverandElevator Mechanic: Passbooks Study GuideNessuna valutazione finora

- 2009 CPIK All Operating Manual v.1Documento78 pagine2009 CPIK All Operating Manual v.1Oldsnage79% (14)

- CMC4+ Commisioning Oct 14-1Documento28 pagineCMC4+ Commisioning Oct 14-1Pedro Kalvin88% (8)

- Miconic B Et V Doc OtisDocumento45 pagineMiconic B Et V Doc OtisAshraful Shohag100% (5)

- K604016E - 06TXGC MICONIC CommDocumento75 pagineK604016E - 06TXGC MICONIC CommMartynas KarkauskasNessuna valutazione finora

- 3300 AP ReportDocumento14 pagine3300 AP ReportWiratama PutraNessuna valutazione finora

- MCS 220Documento1 paginaMCS 220Taha Alkibsi100% (3)

- Index: Installation Manual 2696 - 06 S1 Decoration Lighting LedsDocumento10 pagineIndex: Installation Manual 2696 - 06 S1 Decoration Lighting LedsSami VehmasNessuna valutazione finora

- Manual TK-50 PDFDocumento76 pagineManual TK-50 PDFelectrolitico60% (10)

- 1.4.4. Control Cabinet Boards - CMC4 - PlusDocumento31 pagine1.4.4. Control Cabinet Boards - CMC4 - PlusSami Vehmas91% (11)

- Commissioning Variodyn VF11 22 33 Et PF1 Doc 2010Documento82 pagineCommissioning Variodyn VF11 22 33 Et PF1 Doc 2010Amarnath Yadav100% (2)

- DY-20 & 30 Manual Rev 1.1Documento141 pagineDY-20 & 30 Manual Rev 1.1hmbx67% (3)

- Elevator Spare Parts: ThyssenkruppDocumento28 pagineElevator Spare Parts: ThyssenkruppBeldescuRobertNessuna valutazione finora

- Adjusting Diana Brake ImemDocumento16 pagineAdjusting Diana Brake Imemgrenui100% (1)

- Elevator Controler Part 4 TKDocumento22 pagineElevator Controler Part 4 TKalfrelia100% (4)

- 11 1 ControlDocumento166 pagine11 1 ControlFabian Virgili67% (3)

- GMV Ventil 3010 - 01 PDFDocumento1 paginaGMV Ventil 3010 - 01 PDFOscar CuellarNessuna valutazione finora

- En Synergy Jan 2015Documento72 pagineEn Synergy Jan 2015anh trong100% (1)

- Elevator Inspector: Passbooks Study GuideDa EverandElevator Inspector: Passbooks Study GuideNessuna valutazione finora

- Overspeed Govenor: Operating ManualDocumento48 pagineOverspeed Govenor: Operating Manualhc_elec100% (1)

- Manual de Taller Excavadora Hitachi Zx200-225-230-270Documento762 pagineManual de Taller Excavadora Hitachi Zx200-225-230-270Edgar Rojas Espejo94% (63)

- P1 Chp12 DifferentiationDocumento56 pagineP1 Chp12 DifferentiationbobNessuna valutazione finora

- Tke Synergy Motor PDFDocumento106 pagineTke Synergy Motor PDFWayne100% (1)

- Ba TW45C 08 12 enDocumento64 pagineBa TW45C 08 12 enangela1590100% (1)

- Vacon DriveDocumento27 pagineVacon DriveRodel Simon100% (3)

- Irc Regulation and Control Instructions: Control System Cmc-3 SeriesDocumento10 pagineIrc Regulation and Control Instructions: Control System Cmc-3 SeriesAshraful Shohag100% (1)

- CPIK Frequency Inverter Operating ManualDocumento76 pagineCPIK Frequency Inverter Operating Manualpopopo123-1100% (2)

- 1.2.5. UCP Board Instruction Manual PDFDocumento16 pagine1.2.5. UCP Board Instruction Manual PDFHabibulla Bavaji100% (1)

- Ucp Cmc4: Installation ManualDocumento16 pagineUcp Cmc4: Installation ManualSami Vehmas100% (2)

- Gearless Machines March 2018 2 PDFDocumento39 pagineGearless Machines March 2018 2 PDFMauro Enrique Ortiz Castelán100% (1)

- 1.4.6. Inverter Control Boards - CMC4+ - Ed2Documento16 pagine1.4.6. Inverter Control Boards - CMC4+ - Ed2Sami Vehmas100% (1)

- CPIK Frequency Inverter Operating Manual PDFDocumento76 pagineCPIK Frequency Inverter Operating Manual PDFpopopo123-1Nessuna valutazione finora

- PDFDocumento239 paginePDFSodov Odbaatar80% (5)

- 1.2.2. UBA Board Use and InstructionsDocumento15 pagine1.2.2. UBA Board Use and InstructionsHabibulla Bavaji100% (1)

- THYSSENKRUPP ElevatorDocumento3 pagineTHYSSENKRUPP Elevatorhamid taher50% (2)

- RCBII RSL Parameters - 4767764251226047386845665916 PDFDocumento67 pagineRCBII RSL Parameters - 4767764251226047386845665916 PDFBartz Santos0% (1)

- Replace Ovf20-Crc PDFDocumento7 pagineReplace Ovf20-Crc PDFRawad Jaber50% (4)

- 1.4.2. Operation Manual - CMC4 - Plus - Ed3Documento110 pagine1.4.2. Operation Manual - CMC4 - Plus - Ed3Sami Vehmas100% (4)

- Gen2 MadridDocumento24 pagineGen2 MadridCristal CristalNessuna valutazione finora

- Frequency Inverter MFC 20 / 21: Operating ManualDocumento102 pagineFrequency Inverter MFC 20 / 21: Operating ManualMiguel Ayala78% (9)

- TK-50 Installation Manual Rev 1.1 - EVO1Documento20 pagineTK-50 Installation Manual Rev 1.1 - EVO1anh trong0% (1)