Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Model CM0900 1 Phase Automatic Transfer Switch Controller

Caricato da

LuisFdoAlvaradoSaboríoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Model CM0900 1 Phase Automatic Transfer Switch Controller

Caricato da

LuisFdoAlvaradoSaboríoCopyright:

Formati disponibili

Model CM0900

1 Phase Automatic Transfer Switch

Controller

McPherson Controls

4501 NW 27 Ave

Miami, FL 33142

Ph 305-634-1511 Fax 305-634-1461

CM0900 Automatic Transfer Switch

TABLE OF CONTENTS

Secti on

Page

SECTOIN 1 : INTRODUCTION

1.1 Preliminary Comments and Safety Precautions............................................................................... 3

1.2 Background ...................................................................................................................................... 3

1.3 Product Overview ............................................................................................................................. 3

1.4 Functions / Features......................................................................................................................... 3

SECTOIN 2 : HARDWARE DESCRIPTION

2.1 General ............................................................................................................................................. 5

2.2 Auto / Test Pushbutton ..................................................................................................................... 5

2.3 Panel LEDs Outputs ....................................................................................................................... 5

2.4 Rear Access Area ........................................................................................................................... 5

2.5 Connector & Terminals Functions .................................................................................................. 5

SECTOIN 3 : OPERATOR PANEL

3.1 General ............................................................................................................................................. 8

3.2 Auto / Test Pushbutton ..................................................................................................................... 8

3.3 Panel LED Outputs........................................................................................................................... 8

SECTOIN 4 : OPERATION

4.1 General ............................................................................................................................................. 8

4.2 Auto Mode ........................................................................................................................................ 8

4.3 Test Mode......................................................................................................................................... 9

4.4 Programming .................................................................................................................................... 9

SECTOIN 5 : INSTALLATION INSTRUCTIONS

5.1 General ............................................................................................................................................. 9

5.2 Panel Cut-Out ................................................................................................................................. 9

5.3 Unit Dimensions ............................................................................................................................ 10

SECTOIN 6 : TYPICAL WIRING

6.1 General ........................................................................................................................................... 10

6.2 Typical connecting wire diagram .................................................................................................... 11

6.3 Connecting wire diagram When the transfer current over 6 Amps ................................................ 13

______________________________________________________________________________________

2

CM0900 Automatic Transfer Switch

SECTION 1 : INTRODUCTION

1.1 Preliminary

Comments

and

Safety

Precautions

This technical document is intended to cover most

aspects associated with the installation, application,

operation and maintenance of the CM0900

Automatic Transfer Switch Controller. It is provided

as a guide for authorized and qualified personnel

application of the CM0900 Automatic Transfer

Switch Controller.

1.2 Background

Transfer switches are used to protect critical

electrical loads against loss of power. The load's

normal power source is backed up by a standby

(emergency) power source. A transfer switch is

connected to both the normal and emergency

sources and supplies the load with power from one

of these two sources. In the event that power is lost

from the normal source, the transfer switch transfers

the load to the standby source. Once normal power

is restored, the load was transferred back to the

normal power source.

When using the CM0900 module in automatic

transfer switch equipment, the switch's intelligence

system initiates the transfer when normal power

falls below or over a preset voltage. If the

emergency source is a standby generator, the

transfer switch initiates generator starting and

transfers to the standby source when generator is

available. When normal power is restored, the

transfer switch automatically transfers back and

initiates engine shutdown after a preset engine

cooling down time delay.

An automatic transfer switch consists of three basic

elements:

1. Main contacts to connect and disconnect the load

to the source of power.

2. A transfer mechanism to affect the transfer of the

main contacts from one source to another source.

3. Intelligence control unit to constantly monitor the

condition of the power sources and thus provide

the intelligence necessary for the switch and

related circuit operation.

This manual deals with the third basic element of

the automatic transfer switch, the required

intelligence automatic controller. All the Automatic

Transfer Switch functions were performed by a door

mounted logic panel CM0900 control unit. The

CM0900 logic panel brings intelligence, supervisory

and adjustable capabilities to automatic transfer

switch equipment.

1.3 Products Overview

The CM0900 Automatic Transfer Switch module is

an intelligence, microprocessor based automatic

transfer switch controller. It is a compact panel

mounted device designed to replace traditional relay

and solid state logic panels.

The CM0900 controller provides an unmatched

degree of programmed flexibility to address the

needs of motor drove switch or magnetic contactor

system. It provides the necessary intelligence to

insure that the switch operates properly through a

series of timing functions. The CM0900 controller

will :

Monitor normal source over and under voltages.

Permit system testing the transfer switch with

load from front panel.

Permit customer plant engine test without load by

external exerciser timer.

Provide the source status and fail alarm

indications on the front panel.

1.4 Functions / Features

The primary function of CM0900 controller is to

accurately monitor power sources and provide the

necessary intelligence to operate a transfer switch

in an appropriate and timely manner.

From installation to programming to usage, the

CM0900 controller was designed with operational

simplicity in mind. The CM0900 controller operates

with system voltage from 160 VAC to 270 VAC at 50

or 60 Hz.

1.4.1 Standard Features

The features can be simply adjusted by customer

via 9 dip-switches, depending upon customer

requirements.

______________________________________________________________________________________

3

CM0900 Automatic Transfer Switch

Feature 1 :Switch Type selected

Feature 6 : Under / Over voltage Sensing

The CM0900 controller provides an unmatched

degree of programmed flexibility to address the

needs of motor drove switch or magnetic contactor

system. ( refer to programming table )

The controller monitors the voltage of the normal

power source.

Feature 2 :Time Delay Normal to Emergency

(TDNE)

TDNE provides a time delay when transferring the

Normal source to the Standby source. It ensures

stability of the Standby source. ( refer to

programming table )

Adjustable TDNE range : 2 10

20 and 30sec

Feature 3 : Time Delay Engine Start (TDES)

TDES delays the initiation of the engine start circuit

in order to override momentary power outages or

voltage fluctuations of the Normal source. The

TDES timer shall start when the Normal source

becomes unavailable. If the Normal source

becomes available while timing, the TDES timer will

reset. The CM0900 controller can perform the time

delay engine start function without control power for

15 seconds. ( refer to programming table )

Build-in un-adjustable Over volt setting : 270VAC

Build-in Over volt reset setting : 265VAC

Build-in un-adjustable Under volt setting : 180VAC

Build-in Under volt reset setting : 185VAC

Feature 7 : External Plant Exerciser

The CM0900 module accepted customer plant

engine test without load on a preset period. There

are 4 terminals on the rear of CM0900 module to

accept external exerciser timer signal input (TB1-3

& TB1-4 ) and to provide AC220V power for external

timer when the normal power is available.( TB1-1 &

TB1-2)

Programming Table

1

Switch Type Selector

TDEN

Time Delay

Emergency to Normal

Feature 4 : Time Delay Emergency to

Normal (TDEN)

Adjustable TDEN range : 2 10

120 and 300sec

120 and 300sec

TDEC

Time Delay

Engine Cool-down

(TDEC)

Adjustable TDEC range : 2 30

TDNE

Time Delay

Normal to Emergency

Feature 5 : Time Delay Engine Cool-down

TDEC permits the generator to continue to run

unloaded after retransfer to the Normal Source has

occurred. Timing begins when the transfer to normal

has been completed. ( refer to programming table ))

MC TYPE

ON

Adjustable TDES range : 2 5 10 and 15sec

TDEN delays the transfer from the Standby source

to the Normal Source to permit stabilization of the

Normal Source before retransfer is made. Timing

begins when the Normal Source becomes available.

( refer to programming table )

MCCB TYPE

OFF

TDES

Time Delay

Engine Start

OFF

OFF

OFF

ON

ON

OFF

ON

ON

OFF

OFF

OFF

ON

ON

OFF

ON

ON

OFF

OFF

OFF

ON

ON

OFF

ON

ON

OFF

OFF

OFF

ON

ON

OFF

ON

ON

2 Seconds

10 Seconds

2 Minutes

5 Minutes

2 Seconds

10 Seconds

20 Seconds

30 Seconds

2 Seconds

30 Seconds

2 Minutes

5 Minutes

2 Seconds

5 Seconds

10 Seconds

15 Seconds

______________________________________________________________________________________

4

CM0900 Automatic Transfer Switch

SECTION 2 : HARDWARE DESCRIPTION

2.5 Connector & Terminals Functions

2.1 General

The following describes the connections to the

connector and terminals on the rear of CM0900

module. (Refer to rear layout Figure 2)

The purpose of this section is to familiarize the

reader with CM0900 hardware, its nomenclature,

and to list the unit specifications. The information

presented is divided into the following parts:

Connector 12 way

PIN NO.

Auto/Test Pushbutton

Panel LEDs Outputs

Rear Access Area

Connector & Terminals

2.2 Auto/Test Pushbutton

The front operator panel supports a long-life

Auto/Test pushbutton. Pushbuttons accomplish their

function when pressed and released. Refer to

Paragraph 3.3 for information concerning the

function. (Refer to Figure 1)

2.3 Panel LEDs Outputs

Eight individual LEDs are lit when performing or

indicating a specific function. For detailed

information on individual LEDs refer to Paragraph

3.3. (Refer to Figure 1)

NOTES

CN1-1

Normal source 220V input

CN1-2

Normal source 220V input

CN1-3

Null

CN1-4

Connect to Standby signal output

CN1-5

Normal connected signal input

CN1-6

Connect to Normal signal output

CN1-7

Connect to Normal signal output

CN1-8

Standby connected signal input

CN1-9

Connect to Standby signal output

CN1-10

Null

CN1-11

Standby source 220V input

CN1-12

Standby source 220V input

Terminals 6 way

PIN NO.

NOTES

2.4 Rear Access Area

TB1-1

External exerciser

220V output

timer

power

The rear access area of the CM0900 controller is

normally accessible from the rear of panel. A wiring

connector and terminals are made at the rear of the

chassis. For detailed information of connecting wire

diagram refer to Paragraph 6.

TB1-2

External exerciser

220V output

timer

power

TB1-3

External plant test signal input

TB1-4

External plant test signal input

TB1-5

Engine remote start signal output

TB1-6

Engine remote start signal output

The CM0900 circuit board build-in 4 high voltage

fuses for normal and standby input protected (Refer

to rear layout Figure 2)

Fuse Table

PIN NO.

NOTES

Fuse1

Normal source protected fuse 6.3A

Fuse2

Normal source protected fuse 6.3A

Fuse3

Standby source protected fuse 6.3A

Fuse4

Standby source protected fuse 6.3A

______________________________________________________________________________________

5

CM0900 Automatic Transfer Switch

Front Panel

Figure 1

Auto/Test

Pushbutton

ATS status

LEDs

Figure 1

______________________________________________________________________________________

6

CM0900 Automatic Transfer Switch

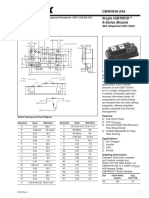

Rear Layout

DIP-SW

F1 F2 F3 F4

PROTECTED

FUSES

1

CN1

6

TB1

12 9

11 8

10 7

Figure 2

______________________________________________________________________________________

7

CM0900 Automatic Transfer Switch

SECTION 3 : OPERATOR PANEL

Normal Under Voltage ( Red )

3.1 General

Indicates that the normal source is unavailable and

the voltage is below 180VAC.

The operator panel, which is normally accessible

from the outside of a panel or door, provides a

means for Auto or Teat functions and parameter

monitoring.

3.2

Auto/Test Pushbutton

Pushing the Auto/Test pushbutton when the

Cm0900 is at TEST position, the CM0900 will run in

automatic mode and a LED is provided to indicate

the auto position.

Pushing the Auto/Test pushbutton when the

Cm0900 is at AUTO position, the CM0900 will run in

engine test mode and a LED is provided to indicate

the test position.

3.3 Panel LED Outputs

Auto Position ( Green )

Indicates that the CM0900 controller is setting to

AUTO function.

Test Position ( Green )

Indicates that the CM0900 controller is setting to

TEST function.

Normal Source Available ( Green )

Indicates that the normal source is available and the

voltage is within the 180 ~270VAC.

Normal Source Connected ( Green )

SECTION 4 : OPERATION

4.1 General

This section specifically describes the operation and

functional use of the CM0900 controller.

Auto mode

Test mode

The practical use of and operation within each

category will be discussed. In this section it is

assumed that prior sections were reviewed and that

operator has a basic understanding of the hardware.

4.2 Auto Mode

The automatic mode of the CM0900 controller

provides for automatic transfer and retransfers from

source to source as dictated by the features

supplied and their programmed values.

The CM0900 controller intelligence and supervisory

circuits which constantly monitor the condition of

both normal and standby power sources thus

providing the required intelligence for transfer

operations.

For example, automatically initiate an transfer of

power when power fails or voltage level drops below

a preset value. Exactly what the CM0900 controller

will initiate in response to a given system condition

depends upon the combination of standard and

selected optional features.

Indicates that the transfer switch is connected to the

normal source.

Standby Source Available ( Green )

Indicates that the standby source is available.

Standby Source Connected ( Green )

Indicates that the transfer switch is connected to the

standby source.

Normal Over Voltage ( Red )

Indicates that the normal source is unavailable and

the voltage is over 270VAC.

______________________________________________________________________________________

8

CM0900 Automatic Transfer Switch

4.3 Test Mode

When the CM0900 is at Auto position, pressed the

Auto/Test pushbutton on the front panel. the

CM0900 will run in with load engine test mode, that

simulates a loss of normal source. The TDES and

TDNE programmed time delays will be performed

as part of the Test.

When the user terminated the engine test mode by

press the Auto/Teat pushbutton, then the controller

will return to automatic mode. When normal power

is available, the transfer switch automatically

transfers back from standby source to normal

source and initiates engine shutdown after a preset

engine cooling down time delay.

4.4 Programming

There are 9 setting dip-switches on the rear of

CM0900 for Switch type, TDEN, TDNE, TDES and

TDEC setting.

For detailed information refer to Paragraph 1.4.1.

SECTION 5 : INSTALLATION INSTRUCTIONS

5.1 General

The CM0900 controller has been designed for front panel mounting.

5.2 Panel Cut-Out ( All Dimensions in MM. )

______________________________________________________________________________________

9

CM0900 Automatic Transfer Switch

5.3 Unit Dimensions ( All Dimensions in MM. )

SECTION 6 : TYPICAL WIRING

6.1 General

It is dangerous to feed high voltage to the CM0900

Printed Circuit boards. The CM0900 controller

operates with system voltage from 160 VAC t0 270

VAC at 50 or 60 Hz.

The CM0900 maximum transfer current is 6 Amps,.

When the switch transfer current over 6 Amps, two

external power relays is recommended. ( The

connecting wire diagram refer to 6.4 section. )

When the system voltage is different from 1 220

VAC, Use ATS-01 programmable ATS controller

module.

______________________________________________________________________________________

10

CM0900 Automatic Transfer Switch

6.2 Typical connecting wire diagram

6.2.1 MCCB Type Wiring Diagram (Set Dip-sw1 to off position)

6.2.2 One Coil Double Throw Typical Wiring Diagram (Set Dip-sw1 to off position)

______________________________________________________________________________________

11

CM0900 Automatic Transfer Switch

6.2.3 Two Coils Double Throw Type Wiring Diagram (Set Dip-sw1 to off position)

6.2.4 Magnetic Contactor Type Wiring Diagram (Set Dip-sw1 to ON position)

______________________________________________________________________________________

12

CM0900 Automatic Transfer Switch

6.3 Connecting wire diagram When the switch transfer current over 6 Amps

6.3.1 MCCB Type Wiring Diagram (Set Dip-sw1 to off position)

6.3.2 One Coil Double Throw Typical Wiring Diagram (Set Dip-sw1 to off position)

______________________________________________________________________________________

13

CM0900 Automatic Transfer Switch

6.3.3 Two Coils Double Throw Type Wiring Diagram (Set Dip-sw1 to off position)

6.3.4 Magnetic Contactor Type Wiring Diagram (Set Dip-sw1 to ON position)

______________________________________________________________________________________

14

Programmable Digital Timer Instructions

IF LIGHT

IS ON YOUR

GENERATOR

IS ALWAYS

RUNNING

Thank you for buying our product. The following instructions

will help you program this timer.

CAUTION:

1. Installation must be according to wire diagram. See the

back of the unit.

2. Press RESET button before use.

3. Recharge the battery when no indication appears in the

display.

BUTTON DEFINITION

Clock: Current time setting or show current time.

Timer: Press this button to enter program mode. There are

8 on / 8 off programs lines.

Day: Sets the day of the week.

Hour: Sets the hour button. 24 HOUR MILITARY TIME

Min: Set the minute button.

Manual: ON/AUTO/OFF select mode.

RESET Cancel all settings. It is the recessed button

next to the circled P with a X through it.

Use ballpoint pen to push it.

ON: RED LED indicator lamp . LED light on when the

internal switch is turned on.

I: SET CURRENT TIME AND DAY OF WEEK

1. Press CLOCK and DAY buttons together. Pulse the DAY

Button to advance to current day.

2. Press CLOCK and HOUR buttons together. Pulse the

HOUR button to advance to current Hour.

3. Press CLOCK and MIN buttons together. Pulse the MIN

button to advance to current time.

4. After setting the day and time, the seconds will

automatically reset.

II: SET PROGRAMS (TIMES ON AND OFF)

1. Press TIMER button once "1ON" will appear at the left side

of display. This is the "1" program that you desire the

device to turn on.

2. Press DAY button to select the program period.

3. Press HOUR button to set hour.

4. Press MIN button to set minute.

5. After setting the "1ON" program. then press TIMER

button again "1OFF" will appear. this is the "1"

program that you desire the device to turn off.

6. Repeat the same procedure until "1OFF" program is

set.

7. Your timer gives you up to 8 different ON and 8

different OFF per program period. You can use all 8

settings per period, or as few as required.

III: REVIEW SET PROGRAMS

1. Pulse TIMER button to advance displayed to each

subsequent ON or OFF settings.

2. To make changes follow instructions under " SET

PROGRAMS".

3. Push CLOCK button to return to current time display.

IV: MANUAL OVERRIDE BUTTON

1. Pulse MANUAL button to select ON/AUTO/OFF

mode.

2. ON mode turns on the device and it will stay on until

manually turned to OFF or AUTO. OFF mode turns off

the device. and it will stay OFF until manually turned to

ON or AUTO.( YOU CAN USE THIS TO TURN ON

THE GENERATOR)

3. In AUTO mode. It will turn ON or turn OFF according

to the programs for which the timer is set.

4. MANUAL OVERRIDE FEATURE: Turn device ON

if already OFF or OFF if already ON. Timer

automatically resumes program on next programmed

cycle. (From ON to AUTO mode, it will stay on until the

next programmed OFF time armed). (From OFF to

AUTO mode, it will stay OFF until next programmed

ON time)

CAUTION

IF THE INDICATOR LIGHT IS ON. THE GENERATOR

IS ON OVERRIDE AND IT IS GOING TO RUN

CONTINUOUSLY WITHOUT CONTROL OF THE

ATS SWITCH

Potrebbero piacerti anche

- Ats 01 ManualDocumento34 pagineAts 01 ManualRoberto BernalNessuna valutazione finora

- SS440 InstructionsDocumento4 pagineSS440 Instructionsgurunathan14Nessuna valutazione finora

- Tad1241ge PDFDocumento14 pagineTad1241ge PDFMasum uddin mondolNessuna valutazione finora

- Zenith ZTG SeriesDocumento8 pagineZenith ZTG SeriesFlo MircaNessuna valutazione finora

- DC20D MKII Genset Controller Upgrade Version For Diesel - Gasoline Engine - EbayDocumento2 pagineDC20D MKII Genset Controller Upgrade Version For Diesel - Gasoline Engine - EbayAliNessuna valutazione finora

- SS15A3P ManualDocumento6 pagineSS15A3P ManualBurce MherjheNessuna valutazione finora

- 8h APDD 672A, SG Tech - Guide 2011Documento90 pagine8h APDD 672A, SG Tech - Guide 2011Joao OliveiraNessuna valutazione finora

- Service: Industrial Generator SetsDocumento147 pagineService: Industrial Generator SetsmohammedNessuna valutazione finora

- KohlerDocumento5 pagineKohlerRajesh S BhattNessuna valutazione finora

- Guia de Componentes MotoresDocumento8 pagineGuia de Componentes MotoresjantonioaragonsNessuna valutazione finora

- Manual ABC 11bDocumento24 pagineManual ABC 11bRoger RodriguezNessuna valutazione finora

- Manual de Partes Sección Motor e Implementos Ggo-01Documento96 pagineManual de Partes Sección Motor e Implementos Ggo-01Eduardo SainzNessuna valutazione finora

- Manual de Instalación Ats Asco Serie 300 No.381333-403Documento8 pagineManual de Instalación Ats Asco Serie 300 No.381333-403Elías NavarroNessuna valutazione finora

- Manual Avr Leroy Somer Mod. R 181 - enDocumento8 pagineManual Avr Leroy Somer Mod. R 181 - enMiguel Angel Pavon CarbonellNessuna valutazione finora

- Manual Kohler 30RYGDocumento4 pagineManual Kohler 30RYGjtamez2009Nessuna valutazione finora

- Product Information Replacement For Onan P/N 332-1956 VR-21 Regulator Control BoardDocumento1 paginaProduct Information Replacement For Onan P/N 332-1956 VR-21 Regulator Control BoardVu Tuong100% (1)

- Deep Sea Electronics PLC: 5110 Autostart Module Operating ManualDocumento40 pagineDeep Sea Electronics PLC: 5110 Autostart Module Operating ManualMaylen RivasNessuna valutazione finora

- Manual de Servicio OTPCDDocumento220 pagineManual de Servicio OTPCDSamuel CastroNessuna valutazione finora

- Enerpac PATG1102NDocumento72 pagineEnerpac PATG1102NAnonymous G6ceYCzwtNessuna valutazione finora

- TP6349Documento60 pagineTP6349Egberto Pino Guerrero100% (1)

- Manual DG6LEDocumento34 pagineManual DG6LEMardin Mauricio Molina PinedaNessuna valutazione finora

- Installation Instructions for PowerCommand Control 1301 Communications KitDocumento3 pagineInstallation Instructions for PowerCommand Control 1301 Communications KitVinhNessuna valutazione finora

- SX440 AVR Setup GuideDocumento4 pagineSX440 AVR Setup GuideMH..2023Nessuna valutazione finora

- OTECA Transfer Switch CumminsDocumento172 pagineOTECA Transfer Switch Cumminspepe100% (1)

- GacDocumento20 pagineGacRhyzza Cortez100% (1)

- HX7 ASD Prog and Op Manual 2642Documento196 pagineHX7 ASD Prog and Op Manual 2642LuchoNessuna valutazione finora

- SED MAN GC2599 002 Manual For GC2599 ControllerDocumento78 pagineSED MAN GC2599 002 Manual For GC2599 ControllerkrishnaNessuna valutazione finora

- QGV Instruction Manual 75 200 2012203696Documento92 pagineQGV Instruction Manual 75 200 2012203696Padron Hugo VictorNessuna valutazione finora

- Manual Stamford Avr SX421 PDFDocumento4 pagineManual Stamford Avr SX421 PDFBrooke EdwardsNessuna valutazione finora

- Technical Manual for TE 804 Electronic ControllerDocumento38 pagineTechnical Manual for TE 804 Electronic ControllerMiguel Angel Pavon CarbonellNessuna valutazione finora

- 15 - PCC 1302 Troubleshooting TablesDocumento15 pagine15 - PCC 1302 Troubleshooting TablesAnbuNessuna valutazione finora

- EA16 Generator Automatic Voltage Regulator Operation ManualDocumento6 pagineEA16 Generator Automatic Voltage Regulator Operation Manualabuzer1981Nessuna valutazione finora

- Kohler APM402Documento4 pagineKohler APM402Marc D. Fisher100% (2)

- Onan Dgab Dgac Dgad Dgae Dl4 Dl6 Dl6t A41 A61 A61t Diesel Genset Parts Manual (08-2011)Documento65 pagineOnan Dgab Dgac Dgad Dgae Dl4 Dl6 Dl6t A41 A61 A61t Diesel Genset Parts Manual (08-2011)Ron SchmittNessuna valutazione finora

- Ecu-9988n Cut Sheet 22july08Documento2 pagineEcu-9988n Cut Sheet 22july08José David Barrios Padrón100% (1)

- Ea06 Manual enDocumento6 pagineEa06 Manual enabuzer1981Nessuna valutazione finora

- Panda PMS 8mini E-TEC Operation Manual (V02)Documento56 paginePanda PMS 8mini E-TEC Operation Manual (V02)Dình Trần100% (1)

- 300reozd S60Documento4 pagine300reozd S60David J SandersNessuna valutazione finora

- Gas Regulator OperationDocumento2 pagineGas Regulator OperationKamal Pakdaman100% (1)

- Linz - New Product - AlumenDocumento4 pagineLinz - New Product - AlumenTTIBCCANessuna valutazione finora

- PED Start Um EN Feb00Documento19 paginePED Start Um EN Feb00Mamadou Djibril Ba100% (1)

- Ec5000 6-09 PDFDocumento5 pagineEc5000 6-09 PDFHusi NihaNessuna valutazione finora

- Dale 3100Documento2 pagineDale 3100Flores Juan Carlos100% (1)

- Davey Xp350p8cDocumento2 pagineDavey Xp350p8cNum470% (1)

- 69UG15 Carrier PartsDocumento80 pagine69UG15 Carrier PartscarlosNessuna valutazione finora

- Operator Operator Manual Manual: Standby Power Generator Set, Powercommand® ControllerDocumento78 pagineOperator Operator Manual Manual: Standby Power Generator Set, Powercommand® ControllerDenis ChonNessuna valutazione finora

- Regulador de Tension Analogico, Manual de Instalacion Operacion y MantenimientoDocumento79 pagineRegulador de Tension Analogico, Manual de Instalacion Operacion y MantenimientoFix0% (1)

- KTA38GC Gas Compression ApplicationsDocumento4 pagineKTA38GC Gas Compression ApplicationsKriangkasem100% (1)

- Service Information: Reference OnlyDocumento4 pagineService Information: Reference OnlyCpe_CarloNessuna valutazione finora

- GPU 2 Manual de InstalaciónDocumento75 pagineGPU 2 Manual de InstalaciónjjcanoolivaresNessuna valutazione finora

- Kohler 400REOZD Detroit Diesel Series 60 Engine Spec SheetDocumento4 pagineKohler 400REOZD Detroit Diesel Series 60 Engine Spec SheetJoanne CordesNessuna valutazione finora

- Páginas Desdeatlas Copco Xats 400 JD t3Documento2 paginePáginas Desdeatlas Copco Xats 400 JD t3german gualavisi100% (1)

- MANUAL ATS ODONTOLOGIA CM0900 Manual IIDocumento16 pagineMANUAL ATS ODONTOLOGIA CM0900 Manual IIGONZALONessuna valutazione finora

- Transfautomaticas ATS-01 PDFDocumento22 pagineTransfautomaticas ATS-01 PDFjuliosieteNessuna valutazione finora

- Ats 01 Manual enDocumento30 pagineAts 01 Manual enccorrea130% (1)

- Ats 380 Manual enDocumento30 pagineAts 380 Manual enMuhammad Yasir IqbalNessuna valutazione finora

- AN025-DC Motor Control With TMC4671Documento11 pagineAN025-DC Motor Control With TMC4671Roland von KurnatowskiNessuna valutazione finora

- Mx150 ManualDocumento28 pagineMx150 ManualThiago BertiNessuna valutazione finora

- CON2000MP3ADocumento23 pagineCON2000MP3AManelNessuna valutazione finora

- GE MX-150 ManualDocumento28 pagineGE MX-150 ManualCristian Munoz60% (5)

- ACE Phase Converter WiringDocumento1 paginaACE Phase Converter WiringLuisFdoAlvaradoSaboríoNessuna valutazione finora

- Delta VFD-B ManualDocumento239 pagineDelta VFD-B ManualRay Rosales100% (2)

- TCA 785 Phase Control IC for Thyristors, Triacs & TransistorsDocumento16 pagineTCA 785 Phase Control IC for Thyristors, Triacs & TransistorsronaldotecnicoNessuna valutazione finora

- 3720 Installation and Operation ManualDocumento138 pagine3720 Installation and Operation ManualLuisFdoAlvaradoSaboríoNessuna valutazione finora

- Igbt 400a 1200VTDocumento4 pagineIgbt 400a 1200VTLuisFdoAlvaradoSaboríoNessuna valutazione finora

- Flowtech StrainersDocumento36 pagineFlowtech StrainersLuisFdoAlvaradoSaboríoNessuna valutazione finora

- Manual ConvertizorDocumento236 pagineManual ConvertizorDanut Spiridon100% (1)

- Variador de FrecuenciaDocumento138 pagineVariador de FrecuenciaLuisFdoAlvaradoSaboríoNessuna valutazione finora