Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Transmission Distribution World August 2015 Supplement

Caricato da

Paula0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni28 pagineLineas de transmision y distribución

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoLineas de transmision y distribución

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni28 pagineTransmission Distribution World August 2015 Supplement

Caricato da

PaulaLineas de transmision y distribución

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 28

TRANSMISSION?

& DISTRIBUTIONS

SAME A te (tee

ARE YQU-USING FL S-GABB?

Engineering software for structural analysis and design of overhead power lines has been

pera ate ae Yee eS

ee ei Cet

ecu ere ig en ue he Ch

we pioneered the integration of finite element analysis on complete lines which is proven

Pe eM MCMC cout

Baa as EET IM Ay

oe Mord

SMe Cee mg

Ren Eimer cuca

ese Me es

eet cd aon

gee ae ea)

Prem Cete cmc tr

Cg ra eA aay

ee ee ae cc

Pee reece en aera

Pees une ss ey

confidence based on sound structural

eeu Rane eam ed

roe eeu

ere Uae Menge te

BY TTaT

Cee ee eeu onset

authorities have with grid owners. With PLS

St Le aed

meeting existing and future requirements for

Runetotem tcuekecricuas

Oe Case eu emcee at

Rogers ceed

Pen ae ae Te

Ce ee eae ee

‘engineers for overhead line engineers. We can

help you insure that NESC, GOgs, ASCE, IEEE,

NS MRe Wa soe oa Mer ed

er ea Rees eeu eee Te

CONTACT DS TODAY TO LEARN HOW PLS WILL HELP YOU MEET THE CHALLENGES

DULL aC CT

DUP I iA

Petsii—ee ik

SvSTEMS TNC

| Email: info@powline.com

Dice

east ereet

SO Raa Ln

_ Madison, Wisconsin 53705. USA

Being Civil in an Electrical World

By Otto J. Lynch, Power Line Systems Inc.

‘went to college to be a civil/structural en-

_gincer so T could design and build bridges,

buildings and dams— big, beautiful struc-

tures, As a college senior interviewing for

‘what would be my first job at Black & Veatch, I

Saraveelag Gea Gelteseh as aces

and building power lines instead.

“Isn't that a job for electrical engineers?”

T remember asking Dave Koehler, who was

interviewing me. He explained transmission

lines were just gigantic multiple suspension

bridges made up of steel, concrete, wood,

aluminum and other materials requiring sur-

veying, site work, foundations and, of course,

project and construction management. Dave went on t0 ex-

plain thatwhile I may only design afew bridges ever my entire

‘career, I could design hundreds of power lines in that time,

I suddenly wished I had stayed awake more during my electri

cal engineering 101 cass.

‘Come to find out, the American Society of Civil Engineers

(ASCE) is actually quite active in the electrical T&D indus-

try, In 1986, shortly before I graduated, Cone M. Wilhoute

‘huired an ASCE conference in Kansas City, Missouri, US.,

‘on “Innovations in the Design of Electrical Transmission

Structures.”

Looking at the names of the people who had been in:

volved with this conference is like visiting the industry's hall

‘of fame. Commitice members who put on this conference and

produced the proceedings were Dan Jackman, Richard Ken-

‘non, Tony DiGioia, Frank Denbrock and, one of my first men-

tors, John Harrison. Papers were presented by Ron Randle,

Edwin Gaylord, Dick Kravitz, Jerome Hansen, Bill Howard

and many others, Two papers were presented by another man

‘who would one day make a significant impact on my career

and life, Alain Peyrot, founder of Power Line Systems Inc,

‘The Structural Engincering Institute (SEI) is one of eight

ASCE institutes that provide technical, educational and pro-

fessional resourees in specialty areas. Under SETis the Elec-

tuical Transmission & Substation Structures (ETS) technical

administrative committee, Mike Miller's column in this sup-

plement coversall of the relevant documents produced by SEL

and ETS. Several of those documents, specifically ASCE-10

Design of Laticed Steel Transmission Structures and ASCE-

48 Design of Steel Transmission Pole Structures, are used and

referenced worldwide.

ASCE's Committee on America’s Infrastructure issues a

“Report Card for America’s Infrastructure" every four years;

the last one was issued in 2018, The energy sector received a

_grade of Ds, which was no change over the 2009 grade. While

improvements had been made on the transmission side of

‘our infrastructure, problems on the distribu

ton side kept us from raising that grade, The

White House issued a report in 2013 that calls

for protecting the electric grid from severe

weather, and the Department of Energy is

calling for using stronger materials for poles

and structures as.a hardening strategy.

In the U.S, many point to the National

Electrical Safety Code (NESC) as the design

code for our electric infrastructure. However,

asis often repeated by many, the NESC is just

a safety code. In Section 1, Rule 010 clearly

states the overall purpose of the NESC, which

does not lst ensuring that lines are designed.

to handle reasonable weather events or how to. do proper

engineering.

Rule O10D specifically states, “This code is not intended,

as a design specification or as an instruction manual” For

structures less than 60 ft (18 m), the only weather conditions

required to be followed for safety were last modified in 1941,

and the wind loads were modified down from what they were

prior to that. It is time we modernize our expected weather

loads for our distribution systems, but the NESC focuses on

safety and not grid strength issues.

ASCE is ready to fill these voids. The various documents

mentioned in Miller's column are design specifications and

instruction manuals, They do instruct how to determine the

expected meteorological loads. They do specify how to de-

sign structures properly. And, contrary to sehat the Departe

mentof Energy isadvocating, wood poles are just fine for use

in our industry —as long as they are designed correctly.

ASGE’s 2015 ETS conference, “Grid Modernization: Tech-

nical Challenges & Innovative Solutions,’ will be in Branson,

“Missouri, There were 168 papers submitted for consideration,

and itwas a difficult process to select the final 35 papers to be

presented at the conference. Highlights from five of these pa-

pers are included in this supplement. In addition to the tech-

nial sessions, there will be an exhibit hall with nearly 100

exhibitors, a workshop on the latest developments in codes

and standards, and a constructionoriented demonstration

day, Please visit www.etsconference.org for program details.

Now, 27 years after first realizing civil engineers playa vital

role in our electrical grids, Ihave the honor of being the chair

‘of what is now the largest transmission line structures confer~

cence in the world. ASCE, SEI, ETS and [all invite you to come

to Branson to learn more from your peers on grid moderniza-

tion from a civil and structural engineering standpoint.

Otto J. Lynch is vice president of Power Line Systems Inc. He

1s a registered professional engineer.

Tannin itn Wa Aut 2018

Sanne etn eee

red at Ieast 50 ft (15 m) of clearance be maintained to the sur-

9 the water. This included the maximum water elevation and

eo ee ee ee eee

August 2015 Transmission & Distribution Wold

TAU

Teepe braced

sall-suporting

sllsupoarting|

‘Thee-ple goed

‘Toes pole unbaced

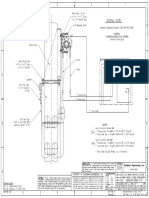

Finally, OG&E did not possess standard structure design

that could accommodate the project requirements or project

schedule, so a new tubular steel design was required, OG&E

secured the servicer of Electrical Consultants Inc. (ECI) to

work directly with Valmont-Newmark (Valmont). The goal

‘was to develop an efficient and innovative structure design

that would meet the needs ofthe project and provide reliable

service forthe life of the transmission line.

Wire in the Air

‘The development of the lake crossing began with the com

ductor design. The design team applied the same conduc:

‘or and sagging criteria used for the majority of the projeet,

which was based on the clearance requirements and project

constrains, For the lake crossing, the required structure

height was estimated to be approximately 275 ft (84 m). The

design team then looked into developing 2 new conductor de-

sign that would allow the structure height to remain below

the 200-£ (6L-m) limitation.

Several conductor types were considered, inchuding eus-

tomary akuninum conductor steebreinforced (ACSR), alae

‘minum conductor steel-supported (ACS8) sizes and newer

conductor types invo

imately, the ECI design team worked directly wi

to develop a specialized ACSRaype conductor with the elec-

‘sical, suength and performance properties that would meet

the needs of the project. The shield wires were similarly de~

signed to be compauible with the conductor sag throughout

the range of operation and with each design load case.

‘Once the conductor, shield wire types and tensions were

catablished for the lake crossing project, structural design

and analysis were conducted. The process began by defining

‘The engineering design team analyzed every type of conventional structure configuration available. The tripod structure configuration

(ight) proved to be the most cost-effective structure meeting all of toe design criteria require forthe lake crossing transmission structure.

the load cases for each structure type. Determining the mag-

nitudles of the point loads, developing preliminary structure

designs and performing the analysis allowed comparisons to

determine the most effective structure design,

"The National Electrical Safety Code defines three specific

Toad cases that must be considered, with the conditions and

load factors included in each case; these served as the pri

‘mary load eases for the structural design of the lake cross-

ing structures. OGRE also established several other loading

criteria based on weather events common in the area and the

level of reliability required for the transmission line. These

criteria included critical wind, extreme ice and uplift load

‘eases. Once the load cases were established, specif proper

ties of the transmission line crossing design were applied to

determine the magnitudes of the loads for each load case.

Structure Types

With the design loads defined, the engineering team fo-

cased on developing the structure configuration tat would

provide the most efficient and costeffeetive solution for the

Take crossing, while Keeping constructabiliy and maintai

ability a priority, Based on design data provided by ECI,

Valmont developed preliminary designs for several conven-

tional structure configurations.

‘The guyed structure was identified as the lowest-cost solu-

tion; however, OGRE preferred to use a selfupporting op-

tion. The Aframe and Fframe options were the next most

effective designs, fainly similar in cost and performance. How-

‘ver, ECI decided a more ficient solution could be possible

with a nontraditional structure configuration,

Experience and engineering principals dictate a triangle

is avery table geometric shape. Additionally a compression-

fugit 2015 [Tanai & ttn Wnt

|

i

MM TRINITY

14

eae eee noes

For more than 50 years, Trinity Meyer Utility

Structures has been America's premier choice

for tubular steel solutions. Fullkscale vertical

structural testing, highly experienced

rere eee

that reduce total installation time and cost are

Eee et an

rs Ser eee et ener tree)

perenne

Fr eu eka

Pe te eens

errs Nees

eee aes

Sea et

Denes

coal

eer

Renee sey

during the SEI/ASCE Conference

on eels aie ed

SI

In the air when the top of the structure is ready to se

tension structural design typically requires smaller pole diam-

ters and shallower foundations than bending moment struc:

tural designs. This was first observed with the analysis of the

A-frame structure option. By incorporating a triangular shape

into the design, an efficent and stable structure could be de

veloped using a compression-tension load system rather than

bending moment system,

Based on this approach, the ECI engineering team devel-

Spedian tnovaline teipotdtype vactint Sonifaration ai the

solution. Preliminary designs indicated the wipod structure

was 46% lighter than the next most efficient design. Once

the preliminary structural analysis was performed, ECT com-

pleted a foundation analysis for each structure type so a total

installed cost comparison could be made to select the most

efficient and costeffective option.

Using the preliminary shaft sizes and ground line reac

tions provided by Valmont, drilled concrete pier foundation

designs were developed based on the criteria established for

the project. The A-frame structure required the smallest foun

dation sizes, while the tripod structure required slightly larger

foundations, as expected. However, the A‘rame required

four foundations, while the tripod structure, with its smaller

‘overall volume of concrete and less installation labor, only re~

quired three foundations.

Tripod Innovations

Based! on the results of the structural and foundation

analyses, the tripod structure provided the most efficient and

costeffective solution, which is why it was selected for imple-

mentation, The Valmont engineering group then began work:

ing to refine the preliminary designs of each tripod structure

further by detailing attachments and engineering the specific

components of the structure.

‘A major challenge for the Valmont engineering group was

designing the central member of the structure where the legs,

arms and body members converge to a common structural

member. This central point ofthe steuctute serves asthe pri-

Using a tripod structure requires paying careful attention to small details. Being a small amount off atthe base could be significant 50 ft

mary load path to transfer the loads from the wires into the

legs and foundations, Several different types of attachments at

varying angles were requited to accommodate the geometry

of the structure. After considerable effort, a design was devel-

oped that provided the structural strength and performance

required,

“The ECI and Valmont engineering groups further collabo-

rated to finalize structure designs and shop drawings for each

tripod structure. The uniqueness of these structures required

‘engineering oversight above dhat typically expended for tr

ditional transmission structure types. After the structural

‘components were fabricated, a trial fic of all structures was per-

formed prior to delivery to ensure constructability, and to pro-

vide installation methods and procedures to the contractor:

ECT also provided on-site engineering and inspection ser-

vices during construction. Overall, the innovative tripod struc-

ture configurations were suecessfully designed, fabricated and

‘constructed, and are in operation today. TDW

Jaron T. Reay isa structural engineering professional working in

the power industry. He graduated from the University of Utah with

‘a MSCE degree in 2004. He worked as a design engineer and

project manager at Electrical Consultants Inc. for 11 years and is

now the manager of transmission engineering in the company’s,

Salt Lake City, Utah, U.S., office. He is a member of ASCE and

the Structural Engineering Institute's technical activities divi-

‘sion’s committee to create 2 manual of practice on guidelines for

wood pole structures for electrical transmission lines.

‘Abe Dilworth is a professional engineer working in the power

industry He graduated from the University of Utah with a BSCE

degree in 2006 and a MSCE degree in 2008. He has been

working for Electrical Consultants In. for nine years as a project

‘engineer and project manager. He spent seven years in the com

anys Salt Lake City, Utah, U.S., ofice before transferring to its

‘office in Phoenix, Arizona, U.S., where he Is currently working as,

4 project manager over transmission line projects.

DE nc 2 rene oser

YOUR PARTNER FOR

Look to Valmont Newmark for a complete product line with

the expertise to engineer, manufacture, and deliver the

Fight pole, tothe right place, atthe right time. Our structures

are based on real world test results optimized for the

highest value. Using our total capabilities, customer-driven

research and development and reputable knowledge in

material technology, no challenge is too big fora solution.

NEWMARK

sity Dison, Valmont Industries, Inc. Two Perictor Park South Suit 475 West« Bimingharn, Alabeme 35243

‘8005335103 Fae 205:968-7201« wmwivaknont newark com

Visit us at SEI-ASCE ETS Conference Booth #200 in Branson

transmission line at a S-mile (8-km)-wide point for the

crossing of the Albemarle Sound in North Carolina, US.

| 182012, Dominion North Carolina Power rebuilt 1154

‘The original transmission line was constructed in 1963,

Which, atthe time, was the longest water crossing in the his-

‘ory of Virginia Electric Power Co’s (VEPCO's) transmission

line program.

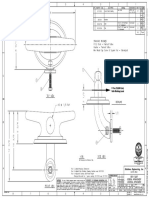

‘The unique challenge for this project was the design of

the connections between the pile caps and piles to meet the

fabrication and installation tolerances called for by the proj-

cations. The demanding installation conditions

required rotating the 34 (0-m)-long, 80-ton (72-tonne)

precast concrete pile caps 180 degrees with a barge-mounted

cect’s spec

[A barge-mountad crane is used for placement of concrete foundatior systems needed to cross the Albemarle Sound,

How to Handle

Offshore Foundations

Challenges abound when it is time

to rebuild an existing line.

By Jason R. Truckenbrod, GAl Consultants Inc.

‘crane and setting the pile caps on top of the 5.5-f (1.7-m)-

diameter prestressed cylinder piles.

‘The project included approximately 34 miles (65 km) of

new transmission line and support structures between a sub-

station in Perquimans County, North Carolina, and a substa-

tion in Washington County, North Carolina.

A Main Challenge

‘One ofthe most challeng

the foundation design for the

tions of the project was

nile section of transinis-

sound. This portion of the

ne is supported by 24 structurabsteel H-frame

hich are supported by a combination of concrete

FE cs 2 rene otter ne

prestressed cylinder piles and pre-

cast pile caps. GAT Consultants Inc

designed the entire 24-foundation

crossing.

‘The water depth at the location

of the transmission Tine crossing var-

ied from 5 ft (1.5 m) near the shore

to approximately 20 ft (6 m) at the

deepest point in the sound. The de-

sign and installation presented many

challenging conditions, including

the tight tolerance neceseary for the

connections between the pile caps

and eylinder piles.

All in the Technique

‘Adding to the difficulty were the

heavy ifs required to install the pile

caps on the cylinder ples, which was

accomplished with a bargemounted

crane. The prestressed concrete cy

Removing the old structures and setting the new foundation system requires a lt of coordina

tion and equipment

inder piles were embedded in the subsurface soils beneath _« Three-pile system with ple cap for 145+ft (+m) Heframe

the riverbed, which intensified the effort required to com- _ Twopile system without pile cap for M5-ft and 115+

bine the components. Two different foundation systems were (85-mn) HLframe with strut.

developed, based on the height of the Hframes, water depth The three-pile system used the pile cap to provide stabil-

and magnitude of the applied loads. The two foundation ity for the bases of the H-frames. The H-frames on the 1wo-

systems are described as follows: pile foundation systems were required to have a horizontal

SUMMIT

UTILITY STRUCTURES

2027 S. 42th St, Bldg 504

‘Alentown, Pa 18103,

(610-797-2225

‘SummtUtityStuctures.com}

“Superior customer

service and quality for

the Transmission,

Distribution, and

ISubstation Industries."

Transmission Poles

Distribution Poles

Industry Certifications: A-Frame Structures

Wireless Hybrid Poles

AISC Certiod Facility } Light Duty Poles

Safety ANSI 49.1 [Substation Structures:

AWSD1.1 Structural | Steel Caissons

AWS D1:5 Bridge Davit Arms

Minority Business J Cross Arms

Enterprise Cross Braces

"ean te ce

,

(Once the piles are set, the concrete caps are lowered into place and attached to the piles.

strut, which was located 2.5 ft (0.76 m) above the base of _‘Thepile design was based on the combined axial and bend:

the frames, for stability. The precast, prestressed concrete ing strength, as well as the lateral deflection and rotation at

cylinder piles were 5.5 ft (1.7 m) in diameter with a 6inch the top ofthe pile. Geotechnical design was performed with

(15mm) wall LPILE software to estimate the soil bearing pressure, deflec-

tion, rotation and member forces within

the cylinder piles,

The piles were cast in 16- (5-m) seg-

ments and then joined together with 32

posttensioning tendons. Each tendon con

sisted of two O.5:nch (12.7-mm)-diameter,

2704s low-relaxation strands. The piles

‘were fabricated in lengths exceeding the

anticipated final design length in case poor

soils were encountered. They were then

‘embedded into the subsurface soil between

40 {Land 60 ft (12 mand 18 m) below the

‘mud line. They were driven into place with

the aid of a steel template, which was held

in place with steel ples driven into the bot-

tom of the sound.

‘Once the required driving resistance

was achieved during installation, the tops

‘oF the piles were cut off to the final wop-of-

pille elevation, 6 ft (2 m) above mean sea

level. The interior surfaces ofthe piles with-

‘After placement, the piles and caps ae checked and Secured in the top 32 ft (10 m) were intentionally

Fey eee reer cost ne

roughened to increase the bond between the cylinder piles

and concrete plug used to connect the pile cap tothe piles.

‘The pile caps for the three-pile system were 34 ft (10 m)

long by 6.5 fe (2 m) wide and 5 ft (1.5 m) high, and the top

clevation of the pile caps was located 11.25 ft (8.4 m) above

‘mean highwater level. The pile caps were designed to pro-

vide torsional, shear and bending resistance to distribute the

fixed based reactions from the two FLframe columns to the

tree supporting eylinder piles.

‘The anchor bolts for the E-frames were cast into the pile

caps and projected out of the top and bottom. The anchor

Inolteprajected 1 (0.9m) ahowe the top. af the pile cape and

were located to accommodate the H-frame base p

allowed the anchor bolts to extend through the

pile cap and project 9.5 ft (2.9 m) below the bottom of the

Which Way Is Up?

The fabricated pile cape had tobe loaded upside down

onto a bange wit tbe 854 anchor bol projections sickig

ip Fein te bation of th je ce Wooten sibs wore

plied on the barge Ws sdepmamodais Ie -Snd

jection athe top of the pile cape Installation ofthe pile expe

Teaeired ling the 804om pile cape with a crane, rotating

them 180 degrecein mbair and then placing te pile cap on

top of the eindr piles, such

cage were inverted itn the einer ples

bolt pro-

at the anchor bolt and rebar

‘Crucial to the project, each clement of the Hiframe and

foundation system was constructed, fabricated and installed

within the tight tolerances. The anchor bolt and rebar cages

that extended out of the bottom of the pile caps fit into the

center ofthe eylinder piles; therefore, ifthe cylinder piles were

installed out of plumb or outside the k

possible the rebar cages would conflict with the inside face of

the eylinder pile dequate concrete cover.

The replacen mission Tine foundations

within the Albematle Sound proceeded smoothly as a re-

sult of the project team's focus on details. The successful

implementation of the innovative design and specifications

prepared for the project further emphasize this attention to

specifics.

The unique solutions developed for this project included

pile cap torsion design, specification of installation tolerane

fs, and specialized concrete mix and transportation specifi-

‘ations for the castin-place concrete. The project provided a

much-needed upgrade to the existing transmission Tine and

ible power to the local community for

will help to deliver rel

Jason Truckenbrod is senior engineering manager within the

power delivery market sector at GAl Consultants Inc., located

In Pittsburgh, Pennsylvania, U.S. With a BSCE degree from the

University at Buffalo, Teuckenbrod has 23 years of experience

in specialized structural and foundation design. He is a mem:

ber of ASCE and the former chair of the Structural Engineering

Institute, Pittsburgh section

RISC & AAIR

Your Experts in:

Structural Assessment/

Asset Management

RELIAPOLE

ihre rard

Let our team of experts assist you in:

Saeed + In-Plant QA/QC

ee ery Ge cay

Steer Gries Betas

eee ried

Sa eet Peer)

(AAIR

o

Pew

ae

PC ga Cac

Pee este ee)

state-of-the-art drone technology.

Se CR CPOE TL VAT

“eansmissin & Distribution Worl August 2015

Structures

ver the past 130 years of electricity in America, the

attention given to transmission line aesthetics has

been mostly an afterthought of, more recently, a

process complication necessary to gain public ac-

ceptance and secure the required permits for a project. Use

ity aestheties have been relegated to playing a publi relations

role. But how should visual impact tie into the engineer's nu-

merous responsibilities to public safety, health and welfare?

‘The engineer must balance competing aspects when de-

signing a transmission line, Three lasting performance char-

acteristics remain once a project is energized: electrical fune-

tion, structural integrity and aesthetic imprint, While the first

‘wo are utilitarian in nature, the last ought to bear aweight of

its own, Utility structures have the power to transform land-

scapes, their impact consumed by the public eye for decades.

‘This provides the impetus for engineers to adopt aesthetics

into design.

the city of Vaasa, Finland.

The Veesa pane, an illusive design by Konehuone, is a 110-KV colurn located in

Visually Appealing

The paradigm of designing transmission

structures to disappear is shifting.

By Mike Khavari and Ken Sharpless, ASEC Inc.

Visual Impacts

Unlike the selfevident function of roads, bridges and

buildings, the function of the T&D industey’s infrastructure

is abstract and intangible to consumers en masse. To the a

erage observer, transmission Hines and the towers that hold

them are static objects, opaque in function and arbitrary in

form. The flow of electrical current through conducting lines

is a qualitative leap away from that of water or waffic. With

power delivery structures, there is no easily discernible rela

tionship between function and forms this fact dynamically

changes the way the individual relates to them.

Despite general unfamiliarity with the technical sory of

hhow electricity arrives atthe average wall socket, consumers

are aware of socitys dependence on reliable energy. The

threat of a blackout captures immediate attention because

the public knows a blackout halts busines, cuts off communi-

cation and endangers lives. This is why power outages make

news headlines

When critical ystems fai, all attention for

cuss on restoration and for good reason: these

lifeline infrastructure services are foundational

for civil and national stability. Consumer expee-

tation for reliable electric service increases as

{quichlyas the benefit the service delivers

‘As demand for energy accelerates, power

delivery infrastructure continues to expand 10

support load growth, meet reliability require-

ments and reach new generation sources. The

lines that carry power through cities, towns and

the countryside are ubiquitous objects of devel-

‘opment, giving context to their surroundings

‘Transmission structures are the iconic remind-

ers of how energy interweaves society.

heryone has come to expect so much of

these lines, yet the general public openly erii=

cizes thir visual impact. Power generation and

consumption ace recognizably important and

the public i not a critical of their structures,

Since transmission lines lie in the grey area

fag 2015 [Tanai & Ostrton Wnt

between these two spheres, they are easier

targets for criticism,

Aesthetic Considerations

‘When consumers cannot readily under-

stand the function of complex systems, the

general acsthetic of design becomes onc of

fonimpact: make it smaller, make it easier,

make it integrated, make it go away or put it

somenbere else. Today, uilties pursue the

typical transmission project with this acs-

iets of nominpect sometimes 40° inked

‘extremes — poles camouflaged:

foliage spring to mind

‘The aesthetic has not always been resigned

to nonimpact. Some approaches sought to ac-

centuate the imprint of utility structures on

the built environment A century ago, the

troduction of generally available electricity,

and the transmission system that brought it

to the home, was recognized and celebrated

by those hacky enough to be connected to the

rid. The transmission structure was a symm

bot of progress and possibility — literally,

power to the people.

Tin some instances, the dialog about the aesthetic impact

cn the built environment can overwhelm the technical and

economic considerations of project. Take for example the

San Francisco-Oakland Bay Bridge project, which a been

called a lanclmark beset by problems. In a similar fashion,

process in power delivery ean focus more on sting, aes

thetic impact and public acceptance than on how the line re-

Jates to the power grid reliability or performs electrically. But

at the end of the day, there isa lasting imprint on the land-

scape with every insalled mile of transmission line and the

coniferous

Form and Function

Power lines inherently take up aerial space and traverse

‘many linear miles o accomplish their purpose in the grid.

Along the way, they cross many properties and geographical

features while maintaining the required electrical clearances

for physical operation and. public safety. These basic func-

tional constraints are significant, and they dominate the size

and scale of an overall project. From a visual perspective, the

public encounters. transmission line in two primary modes,

cither as a viewable line segment or as individual structures,

Depending on the design execution, the line segment and

its repetition can be distracting and busy, or natural and even

‘graceful, A skillful line designer pays attention to height, col

fr, span length, structure position, community identity and

visual repetition of each line segment. Likewise, the design of

individual structures should include aesthetic considerations

based on architecture when setting the scale, proportion,

form and taper of the different structural components.

‘Traditional transmission structure design must address

‘This one-of-akind structure towers over the interstate Highway 4 intersection at the

entrance of Walt Disney World theme park in Orlando, Florida “Mickey” welcomes,

Visitors from all ever the werld with is iconic shape dominating the sk.

certain realities wo satiiy the laws of physics. Material and

‘manufacturing technologies have grown up with the in-

dustry, and there ate now many combinations of structure

types from which to alee for each project. Ax voltage levels

increase, so do structure sizes, to the point that structural

‘options become mor limited.

Historically, there have been two primary types of high-

volnge tranmission stractres: tubular poles and latce

towers. In terms of form, traditional poles resold, stra

vertical elements with multiple horizontakarm elevations in-

tcrscting column, Traditional towers arc airy tapered bod

ics with lacing elements throughout and a series of pointed

arm elevations attached along the superstrucire

‘While remaining in the realm of traditional design, in-

provements can be realized by applying basie architectural

Concepts to prevent poor aesthetic designs that result in ds-

Proportionate, uncomfortable and unnecessarily awkward

structures, Secondevel aesthetic enhancements ako can be

‘made vo traditional structure, with features such as special

coatings or appendages influencing the appearance without

substantially altering the core clement of standard structural

design procedures

Landmark Structures

‘There ate also out-otthe-box approaches, frely applying

architectural concepts that push the limits of engineering

and construction as well as operational reliability and cost

effectiveness. These solutions often change the equation with

regard (0 orientation or total number of elements, or they

‘convey meaning with the overall shape ofthe structure. Form,

space, order, color and lighting also may be used unconven-

tionally to produce a signature structure deployed strategi-

Tannin &DibtonWa Aut 2018

“The Viherindia tower was introduced in 2001, when Studio Nurmesniem! designed a

TLO-KV structure made of laminated timber and laticed bridge. The aesthetically designed

ladders follow the eentour ofthe laminated column

calvin the public view. The ute of innortve Som of rananinon structure as

Been wh he Industry for many year

The Micey Mouse siructare exemplify this approach, This 1540 (Ben),

2020 sebeupporing aroctre was comminoned ia 1995 tote ino at ex

3 tranumiaion Boe for anew sutaon to weve Wak Disney Word Resor in

us.

Cenhininy soe tadonal 1d, tenes pat hase, tie oi

plate neck and otindncion beat seciangulaefubig bear into a singe abe

Sy landmark srctte required careful consideration of aesthetic, tructral, manu

rater factoring, coating rangporation and conarocion factors The renuing shape is

the unitakabe age ofthe woes mont four mae

Another example isthe scaled Viberlandia Tower located at large arening

nae ctf at, Finland, wich het orn 400,00 visors analy.

"The Vian pelo in Fld, ha altace slat of aenin, Thi column

tasathreaded barcoveredinshminunranodied panel The entre pole heal

shaped and ilminated at night wth LED lights, This Mle tndeae pole wat

treed in 007 hgh 0m (164) and stunk made of gland sel

Successful Execution

As illustrated by these examples, successful aesthetic execution occurs when

thoughtful attention is given tothe visual impact of individual structures, structural

‘elements or specife line segments relative o the environmental context in which

they are being added, Pure structural and line design considerations are usilitarian

in nature. Considering aesthetic factors draws from architectural concepts, adding

the influence of visual impact to the design process. To the degree that designers

apply appropriate aesthetic treatment, transmision structure projects can exhibit

responsibilty and earn their place in the built environment. 1D

Mike Khavari received a BSCE degree from the University of Texas at Arlington in

1979, and has more than 30 years of experience in the design and analysis of new

‘and existing latice- and tubular-steel structures.

Ken Sharpless receved a BS degree in architectural engineering from the University

(of Texas at Austin in 1986. His career has spanned multiple facets of the utility, struc-

tural and manufacturing engineering fields,

‘August 2015 | Tansmisson& Distribution Wola

Sediver

m2 tae Pio

Zé

Visit us at ETS Conference - Booth #401

Branson, Missouri - September 27 to October 1

to a utility near you.

ness you have been living undera rock for the last

few years, you have no doubt figured out that we

are in the midst of a “drone revolution.” It seems

these days, everywhere you turn, the technology

for unmanned aerial vehicles or systems (UAV or UAS) is

pushing its way into the mainstream of our society.

‘Amazon, Google and Facebook are brands recognized

around the globe, and they are all becoming heavily invest-

ced in drones. Nov that the Federal As

(FAA) has ereated a pathway to legali

‘even more drones are taking to the skies. The number of in-

dustzies capitalizing on this new technology is growing, and

the list of potential applications for UAS appears to be limite

less. Whether you are a small startup or a multibllion-dollar

enterprise, you cannot afford to ignore the drone movement,

‘The idea of having a prckage delivered to your doorstep

via UAS seems like science fiction, but itis actualy closer to

reality than you may think.

on Administration

Wind farms provde an idesl environment for 2 maneuverable drone to perform inspections and take high-resolution photographs.

The Drone Generation

Unmanned drones are coming

By Grant T. Leaverton, Advanced Aerial Inspection Resources

Tn 2013, Amazon announced that testing was underway at

a secret facility in Canada for its UAS delivery service, Prime

Air. The firm was recently granted permission by the FAA to

begin testing in the United States. Delivery via drone could

be just around the corner:

‘The film industry is also making use of this technology

for evermore-captivating aerial footage for their blockbuster

‘movies. Even farmers can save big on labor and material costs

by deploying UAS out in their Felds. Imagine not needing

to spray entire fields with pesticides or fertilizers. Now they

‘can monitor individual plants among millions ina field and

precisely target which ones need attention using the aerial

imagery provided by UAS. The reduction of wasted materi-

als will be enormous, and the effect on their bottom line is

undeniable,

Agriculture, security, mining, real estate, and search and

rescue represent just a few of the many industries primed to

take advantage of the value of these unmanned systems.

Fey nee rene otter

Utility Drones

But forall of us electrical tility geeks,

there's an obvions question: Does this teeh-

nology have a place in the realm of utility

‘operation and maintenance (O&M)? The

answer is unequivocally yes!

UAS technology is still very much in

its infancy, but iis already being applied

in various forms for utility companies. In-

spections on overhead lines, substations

and generation facilities are well within the

equip coerret ont tiesitc

analysis on coal piles, mapping and survey

ing of rights-ofway, and security are also

being considered as viable applications. If

you thinkabout the currentstate ofthe ut

ity infrastructure in the US., the need for

more affordable inspection methods has

never been more apparent. The US. elec

tical grid i critical for the functioning of

a civil society. Is reliability emainsa top concern for govern:

ment agencies as wells for asset neners and operators.

Unfortunately, many transmission structures have either

reached or passed their expected design life. Atthis advanced

age, the risk of catastrophic failure increases significantly,

ing the structure.

and replacing all assets, once they hit chis threshold, is sim-

ply not an option. Unexpected failures and outages can have

Drones can be brought quickly to the structure in question with

‘minimum planning and preparation.

Drones can provide faster and safer close-up photography than manned fight o climb

a tremendous impact on the community, both financially

and from the standpoint of safety. Conditional assessment of

these assets is always the first step in upgrading the system

and that is where UAS are ready to hit the stage.

Smarter Drones

‘One of the many attractive features of UASis the flexibility

and versatility they possess in terms of the various payloads

they can carry. Anything from high-resolution digital and

thermal cameras, to Light Detection and Ranging (LiDAR)

and geographic information system (CIS) sensorsare now ca

able of being equipped onto a UAS platform. The extreme

clarity of close-up photography of a tower could showan engi-

reer how badly a weld is cracked or how much corrosion has

built up on hardware attachments or insulators.

Drones equipped with forwarddooking infrared (FLIR)

orultraviolet sensors can detect hot spots or corona discharge

fon conductors and insulators, signaling a potential defect or

weakness in the component, LiDAR ean be integrated with

drones to survey a proposed rightofway or monitor en-

croachment by vegetation. And this is just the tip of the iee-

berg in terms of potential uses for utilities,

‘The next phase of UAS technology will employ “smarter”

machines that can fly autonomously. They will sense and

avoid other objects in their path, recognize features or com=

ponents through complex software algorithms

situational awareness, This advanced technology will be able

to faster calculated decision making, such as initiating a fo-

cused inspection, issuing a work order for repairs, or pethaps

someday executing a repair on its own,

‘These notions may sound absurd, but just a decade ago,

the concept of selfdriving cars seemed only possible in the

movies. Now Google is testing a fully autonomous car that

it plans to make available to the public consumer within the

next five years. Flying robots built for utility O&M can't be

too far behind

Taisen & itn Wa Aut 2018

be 4,

Drones can get int tight spaces safely without outages and clearances

‘Of course, much of the allure created by UAS today re-

volves around its “wow factor” asthe newest trend in amateur

aviation. However, the truth is that once the enamored en=

thusiast grows tired of this shiny new toy and moves on to

the next big breakthrough in high-tech gadgetry, the funda-

‘mental value proposition of unmanned systems offered up to

industry will

Safety and comt are two of the most significant drivers in

any business, and that is especially true for utility O&M. Many

industrial work areas are hazardous in nature, While we ean

{ry to mitigate the risks as best we can, the truth is that accie

dlnts will always happen. Working on energized high-voltage

‘transmission lines, sometimes hundreds of feet up in the air,

‘can make the consequences of a mistake turn deadly. Ac-

cording to the Bureat of Labor Statistics, 15 linemen were

"No spot is unaccessible for drone inspections and phatograpy.

fatally injured in 2018 as a result of “exposure

to harmful substances ot environments” Un-

_manned systems have the potential to greatly

reduce the amount of risk exposure placed

upon the operational workforce. The value of

even one human life saved as a result of this

new technology is priceless.

Lifesaving Drones

While the enhancements to safety are un-

eniable, the cost-effective mature of UAS

becoming more apparent, as well. Like any

technology, as it matures, the associated

costs decline. More players are jumping into

the market with new innovations, making

the cost of application for utilities more af-

fordable. Couple this fact with the efficiency

gains achieved through the use of UAS and

the overal cst

tive nature of unmanned

systems becomes clear

Controlling labor expense, eliminating the need for cost-

prohibitive cranes or fullsize aircraft, and reducing asc

downtime and outages are all by-products of this technology

‘that go straight to a line owner's bottom line. It is hard to ar~

‘gue againsta movement where the tag lie is “Saving lives and

‘cutting cost!” It really is a no-brainer for the industry. This

is why the FAA, under pressure from Congress, has finally

started to loosen its death grip on commercial operations.

‘Since 2007, the FAA effectively banned the use ofall con

mercial UAS operation. The decision confounded many ince

amateurs and enthusiast could go out and fly the exact same

aircraft for fun without any regulation at all. The agency de-

cided to take an all-encompassing approach to regulating

this neve technology. The only problem with this approach

‘was that rules governing a Global Hawk or MQ9 Reaper don't

exactly mesh well with a Selb (234g) remote-controlled he-

licopter armed with a GoPro camera. Thankfully, the FAA

recognized this dilemma and began carving out special regu-

Iations for smaller UAS weighing less than 55 Ib (25 kg)

Ii the last year, the FAA has approved more than 700 com-

‘mercial entities to begin UAS operations under strict opera

ing guidelines, which means that U.S. airspace is finally open

for business. And that is good news for everyone, especially

utilities, Tow

Grant Leaverton joined Advanced Aerial Inspection Resources

in August 2013 to help lead an initiative centered around the

development and integration of unmanned systems into the

realm of infrastructure asset inspection, With a background in

utility structures manufacturing, he was drawn to the opportu

nity to work within a new and burgeoning technology renais

sence related to unmanned aerial systems (UAS) and their

particular relevance to utility transmission and distribution

‘operational challenges. Leaverton continues to work towards @

‘broad integration of UAS within 2 variety of key infrastructure-

and energy-related fields,

Fe ee 2s rere ost ne

FALCON STEEL

Cie eet)

Cee UCR ured

Cems cette

Eee}

BIGGER. BETTER. STRONGER. YOUR ONE STOP SHO!

Falcon Steel Company is a leading provider for power delivery structures.

We design and manufacture a full ine of substation steel structures,

transmission steel pole structures and lattice steel transmission towers.

817.581.9500 | falconsteel.com | ysales@falconsteel.com

By Don Cannon, Burns & McDonnell

18 2008, the Public Utility Commission of Texas (PUCT)

‘established a program to enhance the transmission sys-

tem and to encourage the continued development of

wind energy resources in West Texas. The Competitive

than USS5.9 billion in transmis

‘The PUCT selected Gross Texas Tr

‘With 235 miles (378 km) of new transmission lines to rou

design and construct — not to mention a SA5:RV switch

station and a 345-RV series ¢

had a tremendous opportunity and several extraordinary

challenges on its plate. CTT selected Burns & McDonnell to

perform routing and engineering design forthe transmission

They season esa sna of esy access However, when the rai come, water ils the erbed ang changes he clearances between

River Crossing

Spanning a river while dodging

FAA restrictions is a towering achievement.

lines as well as EPC construction of the switching and series

‘compensation stations,

‘The project team started from a blank slate as it developed

practices and designs, including conductors, hardware, load-

ia, structures and foundations. Any major

ing eri

taking is bound to face hurdles, and the C

Tines were no exception. Among those challenges we

very long spans to clear pivot irrigation systems, canyons and

stream crossings. But by far, the biggest of these challenges

‘was the 0.5-mile (0.8-km) crossing of the Prairie Dog Town

Fork ofthe Red River

Defining the Challenge

‘This crossing would be roughly parallel to an older wood

Heframe transmission line that included two H-frames con

Fey nc rene ttn ne

structed in the riverbed, so placing new structures in the

river bed was considered. However, there were wo main

challenges. The first was the potential for poor soil condi=

tions and the subsequent challenge of constructing foun-

dations and structures at this location, That would not be

easy, but undoubtedly it could be accomplished. The sec-

fond challenge was getting needed permits to place these

structures in the riverbed. After some discussion with the

regulatory authorities that controlled the river, CTT decid

fed to take that option off the table. Basically, the authori-

ties didn't want structures in the riverbed, and getting the

iacoctierypparaalls soul eafiresenta refer ieilcoge seal

potentially cause schedule delays.

Since it was thus necessary to span the river, the team

selected the best locations for structures on each side ofthe

river and began designing the section. The resulting clear

span between crossing towers was approximately 2,400 ft

(732 m). The team quickly discovered that spanning the

river with the aluminum conductor steel-supported (ACS)

Falcon conductors chosen for the majority of the project,

would require increasing the height of both crossing tow-

ers to well over 200 ft (61 m), which would lead to Federal

Aviation Administration (FAA) permitting and lighting re

jrements. While this was certainly doable, the Burns &

‘MeDonnell team began to look at options that would spare

CTT from the additional time and expense of that process

and those requirements,

‘The other obvious solution was to reduce the conductor

sag in this crossing span sufficiently to maintain structure

height requirements of less than 200 ft. ‘The team inves-

tigated three high-temperature, low-sag conductors that

‘might accomplish this: ACSS/HS285, aluminum conduc

tor composite core (ACCC) and alu

minum conductor composite-rein-

forced (ACCR).

‘The Burns & McDonnell team

contacted the conductor manufae-

turers associated with each of these

‘options to make sure it selected

the most appropriate conductor

for its electrical requirements and

to obtain the correct wire files for

PLS-CADD modeling. Then the

engineers completed crossing: span

designs for each conductor to deter-

mine the structure height require-

ments to achieve the desired clear

ance. Ultimately, this would guide

the selection of the conductor for

the river crossing.

Comparing the Candidates

‘To provide a point of reference,

consider the ACSS Falcon conduc-

tor used for the majority of the

transmission line. To achieve the ageable its.

The towers were installed in sections, allowing the efficient use of crews, equipment and man-

Spanning 2,400 ft require structures designed for the task and con-

‘ductors that could reduce the sag to an acceptable level

Tnnisin itn Wa Aut 2038

Minor changes and minimal adjustments were needed tothe hard

sezombioe fo install the ACCR Pecos conductor

desired clearance, towers with aboveground heights up to

235 ft (72 m) were needed. This clearly would not be suffi-

cient to avoid FAA involvement,

‘The ACSS/HS285 conductor is a traditional ACSS con-

ductor but with a higherstrength steel core to allow for high-

er tensions. To to achieve the desired clearance, towers with

aboveground heights up to 205 ft (62 m) would be needed,

nearly sufficient to achieve the goal of remaining below the

height that would tigger FAA requirements but not quite

‘good enough.

‘The ACCC conductor is similar to ACSS in that it has an-

nealed aluminum strands,

but with a carbon/glass

‘composite core. For this con-

‘ductor, an “ACCC Lapwing”

was used because a Falcon

equivalent ACCC conduc-

tor was not available at the

time, To achieve the de-

sired clearance, towers with

aboveground heights up to

210% (64m), which was even

taller than what would be re-

‘quired for the ACSS/HS285

conductor, were needed 10

withstand heavy ice loads.

Finally, the ACCR con-

ductor also uses composite

technology, but with an ale

minum composite core and

aluminum zirconium outer

strands, The ACGR Pecos

‘conductor achieved the de-

sired clearance with towers

measuring 185 ft (66 m) of

aboveground height, which

was well below the threshold chat would tigger addi-

tional FAA requirements.

And the Results Were

Based on these comparisons, CTT made the deci-

sion to use the ACCR Pecos conductor forthe crossing

span and one back span toa deadend tower on each side

of the river: Revised load trees for the crossing towers

‘were developed, allowing the tower manufacturer to de-

sign special river crossing structures for the additional

loads. These river crossing tangent structures essen-

tially ended up being the original lattice tangent tower

designs with some selected member changes. The dead-

ends were strengthened versions of the standard dead-

cnds to support the inereased tensions. Minor changes

to hardware assemblies were also made for this section

to support the ACCR conductors.

‘These towers, assemblies and conductor were in-

stalled successfully, with minimal adjustments to the

construction methods used to install the rest of the line.

With the river crossed and without needing to involve the

FAA, the team could turn its attention to other challenges on

‘what proved to be a successful projet that was completed on

schedule and under budget. TW

‘Don Cannom isthe transmission department manager for Burns

‘& McDonnell in Houston, Texas, U.S. A member of ASCE and

IEEE, he will be presenting more extensively on this project at

the Electrical Transmission & Substation Structures Conference

in September. He has a BSCE degree and a MSCE degree from

the University of Tennessee.

Fee nc 2 rene stn

best transmis

in the industry.

Cr rr PA AY ALE id enol a Kelly Ln. Houston, TX 77066

ASCE Codes and Standards

By Michael Miller, ASCE-Electrical Transmission Structures

waren cons ihe ae

C= oy the bok, They amie

ie ate ear eer een

Recess pened eesti

coeur ees

He a ee eae

fee es persian

Aree eyo

neces cee!

Indu mama of pace (oP wa

Eel eae eee eal!

aleeasaiat

ieee cameo Rescate

iererre erses

tepid a ad sta,

ea yao ue pee ate

i asa te Sap eee

Dt nal earl por oleae cone clos

2) aga ohich cn and elo ies

Gaus haber oe sestoaterioc ie ween!

Bete eee Se aa

engineer's everyday working life.

Thr America Sct of igi (ASCE Mo and

sandr fe tom oer cles the inary. Tay te

feeiges ie na ees ee

thd ASCE mente eoced by ASCE whe commits

eet ses cies Eada 2s eer

Ee praises eee re aie

EL apap pate O aaben cone

ete ary asses adalng caanuetieg

Ga aoniece tat laa mame eera Oe

espa ne Calirs

The flowing ASCE MOP and sandal re nu

Peerless

eas

ASCE Culdines fr Bletcal Trasisin Line

Suc Loading Tas MoP pres quan ont

pepacseie einen: meaambioee Ga

Sere ee

peered eee ieee eae

fom the Naa tn of Saad and Technology ot

feplncelb ASCE aekocion wed AS

sos harohd yal atts temp

fap ese see

TESCETS Suton Srcture Design Guide. This

fal pees ae eal gdp dc a

ites ea Resa lame

dom Tisdocundeies loons pec stony

fear eens asco ene

iment chad obs pushin 218.

of a co0

Bi ‘august 2015 | TWansmisson & Distribution Worl

‘* ASCE-104 Recommended Practice for Fi-

>ber-Reinforced Polymer Products of Overhead

Utility Line Structures. Non-steel, non-wood

structure technologies will continue to evolve

and improve, resulting in lightweight, high-

strength fiber-reinforced polymer materials

for the industry, Scheduled to be published

in 2016, this revised pre-standard discusses

design considerations, criteria and suggested

puidelines for performance-based designs.

'*ASCE-To Be Determined (TBD) Prac-

tice for Wood Pole Structures for Electrical

ion Lines. This brand-new docu-

‘ment, currently being developed, provides

design information specific to wood poles. The wind blows

and ice accumulates on a transmission line the same as on

a distribution line, producing the same load; therefore, this

design guide can be used for any wood pole line. This MoP is

scheduled to be published in 2017,

‘SASCE-TBD Aesthetic Design of Transmission Line

Structures, Currently being developed, this new ASCE com-

‘mittee report will atempt to address the aesthetics of trans-

mission structures by providing options that can be used in

all structure types. While aesthetics are subjective, certain

features can be used to enhance the aesthetics of structures

yet mect all applicable loading and functionality. This docu-

‘ment is scheduled to be published in 2016,

‘* ASCE-10 Design of Latticed Steel Transmission Struc

tures, Lattice-steel transmission structures have been used

for the past 100 years and are stll going strong. The newest

version includes guidance on the evaluation of existing tow-

crs for upgrades or re-rating, and provides information on

redundant member design. ASCE-10-15 is now available.

* ASCE-48 Design of Steel Transmission Pole Structures

‘Tubular-stect poles have been used for line support structures

since the 1960s and are now commonly used throughout

North America. This revision incorporates 48 change pro-

potals affecting 68 different sections of the document and is

scheduled to be published in 2016.

‘These efforts reflect the increased interest and activity in

the industry and are a sign of a healthy, vibrant transmission

Tine engineering community for years come, TDA

‘Trans

‘Michaet D. Miller is vice president of engineering at SAE Towers

Jn Houston, Texas, U.S. He is chair of the American Society of

Civil Engineers’ Electrical Transmission Structures committee.

He is a registered professional engineer.

Ezitor's note: Vist worw.asce.org/templates/publications-book-

detail. aspx?i¢=7094 to learn about the standards and MoP.

rt

an a la

Sabre-FWT)

Two Great Companies.

One Powerful Combination.

Building on the success of Sabre and FWT, the new

Sabre-FWT delivers exceptional value. Our combined

capabilities will lower your supply chain tisk wilh

increased capacity in engineering, customer service and

manufacturing. Contact us today to see how together

we can enhance your customer experience.

NMA Ueno Rm]

fat en

Transmission « Distribution + Foundation « Storm Response

PLH Group entities deliver integrated construction and Pp L H

maintenance solutions withthe expertise, resources and experience soup

to perform construction services for major utilities, regional GROUP

cooperatives, municipalities and renewable energy developers.

plhgroupinc.com

214.272.0500

PLH Group -Electric Power Subsidiaries

Potrebbero piacerti anche

- Criteria For The Design of Composite Slabs PDFDocumento8 pagineCriteria For The Design of Composite Slabs PDFakhileshgojeNessuna valutazione finora

- CFT Design Guide March 2014Documento44 pagineCFT Design Guide March 2014Juan Castillo100% (2)

- Mechanistic Insights Into The Durability of Ancient Roman ConcreteDocumento13 pagineMechanistic Insights Into The Durability of Ancient Roman ConcretePaulaNessuna valutazione finora

- European School for Advanced Studies In Reduction of Seismic Risk Myths and FallaciesDocumento98 pagineEuropean School for Advanced Studies In Reduction of Seismic Risk Myths and FallaciesRoberto UrrutiaNessuna valutazione finora

- Free FEM Course Civil Exercise: Beam On Elastic Springs: IcaeecDocumento19 pagineFree FEM Course Civil Exercise: Beam On Elastic Springs: IcaeecDanielRoblesTorresNessuna valutazione finora

- Two Dimensional TrussDocumento2 pagineTwo Dimensional Trussgreat2007Nessuna valutazione finora

- Two Dimensional TrussDocumento2 pagineTwo Dimensional Trussgreat2007Nessuna valutazione finora

- Two Dimensional TrussDocumento2 pagineTwo Dimensional Trussgreat2007Nessuna valutazione finora

- S70 - FlexiboatDocumento1 paginaS70 - FlexiboatPaulaNessuna valutazione finora

- Stability Publications FlexiFloatDocumento19 pagineStability Publications FlexiFloatPaulaNessuna valutazione finora

- Modular C5 FloatsDocumento2 pagineModular C5 FloatsPaulaNessuna valutazione finora

- Stability Publications FlexiFloatDocumento19 pagineStability Publications FlexiFloatPaulaNessuna valutazione finora

- Technical Bulletin No. 1: Basic Formulas of Static StabilityDocumento8 pagineTechnical Bulletin No. 1: Basic Formulas of Static StabilityPaulaNessuna valutazione finora

- Beam Tutorial 12 PDFDocumento20 pagineBeam Tutorial 12 PDFAnand ShahNessuna valutazione finora

- Deck Cleat Working DrawingDocumento1 paginaDeck Cleat Working DrawingPaulaNessuna valutazione finora

- Mapa Hidrografico CORFO 1971Documento19 pagineMapa Hidrografico CORFO 1971PaulaNessuna valutazione finora

- Estructuras de Protección Costera - Nota Técnica N°2Documento8 pagineEstructuras de Protección Costera - Nota Técnica N°2PaulaNessuna valutazione finora

- Second Edition International Code Council 2006Documento548 pagineSecond Edition International Code Council 2006ElgueVen82% (11)

- Preparing Your Computer For LFS101xDocumento16 paginePreparing Your Computer For LFS101xAnish RaoNessuna valutazione finora

- Info LinuxDocumento1 paginaInfo LinuxPaulaNessuna valutazione finora

- AWC WCD1 ConventionalWoodFrame ViewOnly 0107 PDFDocumento55 pagineAWC WCD1 ConventionalWoodFrame ViewOnly 0107 PDFjuan pringNessuna valutazione finora

- Hilti Instruction-for-use-HIT-MM-PLUS-Instruction-for-use-PUB-5204384-000 PDFDocumento64 pagineHilti Instruction-for-use-HIT-MM-PLUS-Instruction-for-use-PUB-5204384-000 PDFcemadaroNessuna valutazione finora

- Nocturne in B Flat Minor, Op. 9 No. 1Documento4 pagineNocturne in B Flat Minor, Op. 9 No. 1PaulaNessuna valutazione finora

- Semana 2 PDFDocumento1 paginaSemana 2 PDFPaulaNessuna valutazione finora

- Linux Editores de Texto - IntroducciónDocumento7 pagineLinux Editores de Texto - IntroducciónPaulaNessuna valutazione finora

- Estructuras de Protección Costera - Nota Técnica N°3Documento2 pagineEstructuras de Protección Costera - Nota Técnica N°3PaulaNessuna valutazione finora

- Bridge Design Eurocodes Worked ExamplesDocumento438 pagineBridge Design Eurocodes Worked Examplespradeepjoshi007100% (4)

- Second Edition International Code Council 2006Documento548 pagineSecond Edition International Code Council 2006ElgueVen82% (11)

- Enciclopedia SismicaDocumento3.996 pagineEnciclopedia SismicaPaula100% (2)

- Estructuras de Protección CosterasDocumento6 pagineEstructuras de Protección CosterasPaulaNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)