Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Economiser

Caricato da

EslCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Economiser

Caricato da

EslCopyright:

Formati disponibili

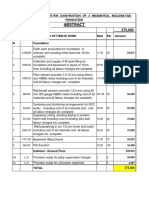

SHEET 1 OF 4

DESIGN CALCULATION FOR

MAKER'S No. EC

TYPE OF BOILER

:ECONOMISER COIL

DESIGN CODE

: IBR 1950

TOTAL HEATING SURFACE : 0.3835 sq.m

AREA

DESCRIPTION

ECONOMISER COIL

PREPARED

TEMP. C

Pr. Kg/cm

180.00

17.00

CHECKED

APPROVED & DATE

NAME :

NAME :

NAME :

SIGN:

SIGN :

SIGN :

DATE

SHEET 2 OF 4

THICKNESS CALCULATION FOR ECONOMISER COILS : (IBR 338)

Reference Drawing No.: EC-00-A4-001/00

Material size(Dia)=

Material Spec.

25 x 1.6

mm

SA 210 Gr.A1

f x (t - c)

WP =

WP x D

---------------

Eqn.87

----------------

t=

D-t+c

2 x f - WP

Where,

2

WP = Working Pressure in Kg/cm =

17.00

Kg/cm

t = Min. thickness required in mm

D = External Dia of tube =

25

mm

Allow stress for material SA 210 Gr.A1 as per ASME section - II Part f=

D at metal working temp. 180 C =

2

c = (for working pressure below 70 Kg/cm ) =

2

1203.27 Kg/cm

mm

17 x 25

t=

--------------------

+0

2 x 1203.27 - 17

=

0.18

mm

= Nom.Thickness + Neg.Tolerance (

0.00

%)

= 0.18 + 0

=

0.18

mm

Min.Thickness Reqd. =

Provided Thickness t, =

0.18 mm

1.60 mm

Working Pressure Calculation for provided thickness of tube.

Min.Thickness Provd. , t

=

=

=

Nom.Thickness - Neg. Tolerance (0.00%)

1.60

- 0.00

1.60

mm

2 x 1203.27 x (1.6 - 0)

WP =

--------------------------------25 - 1.6 + 0

2

164.55 Kg/cm >

2

17.00 Kg/cm

+c

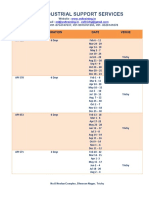

SHEET 3 OF 4

THICKNESS CALCULATION FOR ECONOMISER BEND COILS : (IBR 338)

Reference Drawing No.: EC-00-A4-001/00

Matl. size(DiaxThk)

Material Spec.

25

1.6

mm

Matl. Temp.

SA 210 GR. A1

180

2 x f x (t - c)

WP =

WP x D

-----------

Eqn.87

--------------

t=

D-t+c

+c

2 x f - WP

Where,

2

WP = Working Pressure in Kg/cm

17.00

t = Min. thickness required in mm

D = External Dia of tube =

25 mm

f = Allow stress for material SA 210 GR. A1 as per ASME section - II Part -D

at metal working temp. 180 C =

2

c = (for working pressure above 70 Kg/cm )

1203.27 Kg/cm

mm

17 x 25

t = -------------------- + 0.75

2 x 1203.27 - 17

= 0.18

mm

= Nom.Thickness + Neg.Tolerance (0%)

= 0.18 +

0

= Nom.Thickness + Thin. Allowance (12.5%)

= 0.18

+ 0.0222

= 0.20 mm

Min.Thickness Reqd.

Provided Thickness

0.20

mm

t, =

1.6

mm

Neg. Tol.

Thin. Allow

Working Pressure Calculation for provided thickness of tube.

Min.Thickness Provided , t

= Nom.Thickness - Neg. Tolerance (0%)

=

1.60

0.00

= Nom.Thickness - Thinnin. Allowance (12.5%)

=

1.60

1.40

0.2

2 x 1203.27 x (1.4 - 0)

WP =

-----------------------25 - 1.4 + 0

142.76

Kg/cm 2 >

17.00

Kg/cm 2

0

12.5

SHEET 4 OF 4

DRAWING LIST

MAKER'S No. SHC

S.No

1

Drawing No.

EC-00-A4-001/00

Description

Economiser Coil

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Proposed Construction of Commercial Complex Building at Sipcot, Kangaikondan, Tirunelveli DistrictDocumento1 paginaProposed Construction of Commercial Complex Building at Sipcot, Kangaikondan, Tirunelveli DistrictEslNessuna valutazione finora

- Reimbursement Form: Patient Information 1Documento1 paginaReimbursement Form: Patient Information 1EslNessuna valutazione finora

- Due Date Telephone Number Amount Payable: Summary of Charges Usage History (6 Months)Documento3 pagineDue Date Telephone Number Amount Payable: Summary of Charges Usage History (6 Months)EslNessuna valutazione finora

- Proposed Construction of Commercial Complex Building at Sipcot, Kangaikondan, Tirunelveli DistrictDocumento1 paginaProposed Construction of Commercial Complex Building at Sipcot, Kangaikondan, Tirunelveli DistrictEslNessuna valutazione finora

- Proposed Construction of Commercial Complex Building at Sipcot, Kangaikondan, Tirunelveli DistrictDocumento1 paginaProposed Construction of Commercial Complex Building at Sipcot, Kangaikondan, Tirunelveli DistrictEslNessuna valutazione finora

- SL. No QTY Rate Per Amount A Foundation: Owner: MRDocumento1 paginaSL. No QTY Rate Per Amount A Foundation: Owner: MREslNessuna valutazione finora

- Proposed Construction of Commercial Complex Building at Sipcot, Kangaikondan, Tirunelveli DistrictDocumento1 paginaProposed Construction of Commercial Complex Building at Sipcot, Kangaikondan, Tirunelveli DistrictEslNessuna valutazione finora

- Summary ISO TR 15608 Metallic Materials Grouping SystemDocumento4 pagineSummary ISO TR 15608 Metallic Materials Grouping SystemV SwamiNessuna valutazione finora

- Codes Standards RegulationsDocumento11 pagineCodes Standards RegulationsEslNessuna valutazione finora

- English1 June 2012 PDFDocumento7 pagineEnglish1 June 2012 PDFEslNessuna valutazione finora

- Resume 1Documento2 pagineResume 1EslNessuna valutazione finora

- 2Documento2 pagine2EslNessuna valutazione finora

- Super Heater CoilDocumento4 pagineSuper Heater CoilEslNessuna valutazione finora

- Welding 2 PDFDocumento7 pagineWelding 2 PDFEslNessuna valutazione finora

- Resume: Qualification Name of The Institute Year of Passing Percentage of MarksDocumento2 pagineResume: Qualification Name of The Institute Year of Passing Percentage of MarksEslNessuna valutazione finora

- ESL - API 2017 ScheduleDocumento2 pagineESL - API 2017 ScheduleEslNessuna valutazione finora

- ESL - API 2017 Schedule PDFDocumento2 pagineESL - API 2017 Schedule PDFEslNessuna valutazione finora

- ASNT Level 3Documento8 pagineASNT Level 3Indigo Wave0% (2)

- Heat FluxDocumento8 pagineHeat FluxEslNessuna valutazione finora

- 2012 04 SSLC English Second Paper April 2011 12 by Rktuitioncentre Blogspot inDocumento8 pagine2012 04 SSLC English Second Paper April 2011 12 by Rktuitioncentre Blogspot inEslNessuna valutazione finora

- Questions Book NDTDocumento63 pagineQuestions Book NDTEsl100% (2)

- WPS, PQR, WPQ PDFDocumento2 pagineWPS, PQR, WPQ PDFEsl100% (1)

- Questions On Section IxDocumento22 pagineQuestions On Section IxNasir JavedNessuna valutazione finora

- Plus2 - English2 - Mar2010Documento8 paginePlus2 - English2 - Mar2010EslNessuna valutazione finora

- Einstein II TFTDocumento2 pagineEinstein II TFTprv142Nessuna valutazione finora

- English II Paper Class 10Documento21 pagineEnglish II Paper Class 10Surya Prakash100% (1)

- SSLC English Second Paper Oct 2012Documento8 pagineSSLC English Second Paper Oct 2012EslNessuna valutazione finora

- 2012 12 HF 10th Eng12 KeyDocumento3 pagine2012 12 HF 10th Eng12 KeyEslNessuna valutazione finora

- 10th April 2014 English 2nd PaperDocumento8 pagine10th April 2014 English 2nd PaperEslNessuna valutazione finora

- Metal Welding - Types and ProcessesDocumento4 pagineMetal Welding - Types and ProcessesuismechprojectNessuna valutazione finora