Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Need of Experimental Studies On Variation of Additives On Basalt Fiber Fly Ash Concrete

Caricato da

Satyen RamaniTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Need of Experimental Studies On Variation of Additives On Basalt Fiber Fly Ash Concrete

Caricato da

Satyen RamaniCopyright:

Formati disponibili

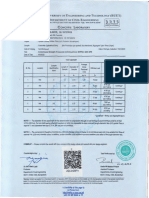

International Journal of Futuristic Trends in Engineering and Technology

ISSN: 2348-5264 (Print), ISSN: 2348-4071 (Online)

Vol. 1 (10), 2014

Need of Experimental Studies on Variation of Additives

on Basalt Fiber Fly Ash Concrete

(Paper ID: 10ET30112014016)

Tushar H. Kaswala

Prof. Satyen Ramani

M.E. Student, Civil Engineering Department

SAL Institute of Technology & Engineering Research

Ahmedabad, Gujarat, India

tusharkaswala@gmail.com

Civil Engineering Department

SAL Institute of Technology & Engineering Research

Ahmedabad, Gujarat, India

satyen.civil.engg@gmail.com

Abstract : Construction Industry is always concerning to find new

and better materials for improvement of properties of concrete to

manufacture new or improved products. Concrete possesses very low

tensile strength, low resistance to cracking and also low ductility.

Fiber reinforced concrete is the most widely used concept in

construction industry. Basalt continuous filaments are produced from

parent basalt rocks by melting and extrusion process. Basalt fibers are

non toxic, alkali resistant and also have good thermal properties. This

study is a trial of giving some highlights and works done on the use

of basalt fibers to make improved concrete.

Keywords: Basalt fiber fly ash concrete, mechanical properties,

alkaline water, basalt fiber, lime water

I. INTRODUCTION

Conventional concrete is the extremely used material but there are

numerous drawbacks such as very less tensile strength, nature of

brittle failure, low crack resistance, etc. Hence the fiber reinforced

concretes used generally in present scenario to achieve improved

properties against conventional concrete. The fibers used in

construction industry are like Glass fibers, carbon fibers, steel fibers,

aramid fibers, basalt fibers, etc.

Basalt fibers are the mainly harmless to environment and it is natural

material, i.e. volcanic rocks. Basalt is a volcanic rock which is the

condensed form of volcanoes or volcanic lava and from this volcanic

lava, by extrusion process, continuous filaments of fibers are

generated and then the fibers are chopped in various lengths as per

requirement and use. Basalt fibers have a lower density than

compared to steel and hence the use of fibers makes the concrete

lighter and durable. Basalt fibers are non combustible and explosion

proof and also in coming contact with other chemicals they produce

no chemical reaction which is harmful to health or environment.

Hence, it can be concluded that use of basalt fiber in concrete

produces an eco friendly and durable concrete.

In India, basalt rock originates in too much area and hence the fiber

becomes cheaper than other fiber like carbon fiber and glass fiber. It

has some excellent properties like thermal insulation and sound

insulation, non flammable, non corrosive, etc. The moisture content

of basalt fiber is very less i.e. less than 1%. The usage of fiber can be

done either as a filament or staple fibers. The fibers can be added

either as a percentage of total volume of composite or added as a

weight of cement.

2)

II. LITERATURE REVIEW

1)

Experimental design analysis of ultra fine fly ash, lime water,

and basalt fiber in mix proportion of high volume fly ash

concrete- Mochamad Solikin, Sujeeva Setunge

and

Akshar Publication 2014

54

Indubhushan Patnaikuni : This research was based on the

analysis of three factors in mix proportion of high volume fly

ash concrete to produce high strength concrete. Compressive

strength of cylinders was tested at 28 days and 56 days. Three

factors taken were Raw fly ash (Class-F) and ultra fine fly ash

(UFFA), Tap water and lime water and Conventional concrete

and basalt fiber concrete which was used in whole research

work. Each factor was taken as per two levels i.e. low and high.

The grade of concrete was 80 Mpa. The content of basalt fiber

taken was 1% of total concrete volume. 3 grams of hydrated

lime powder was dissolved in 1 liter tap water. The water binder

ratio was taken 0.3. The combinations taken was (1) UFFA with

out basalt fiber and using tap water (2) UFFA with basalt fiber

and using lime water (3) Raw fly ash with basalt fiber using tap

water (4) Raw fly ash without basalt fiber using lime water.

Compressive strength of combinations (1), (2), (3) & (4) was

70.90, 73.78, 52.97, 66.69 in Mpa respectively at 28 days. At 56

days it was 74.72, 78.84, 57.23, 71.97 for combinations (1), (2),

(3) & (4) respectively. At 28 days all the combinations did not

meet the designed strength 80 Mpa while at 56 days

combination (2) had met nearly the designed strength. Also

verification of mix proportion was done by mixes (A) UFFA

without basalt fiber using lime water & (B) Normal cement

without basalt fiber using tap water. Both mixes satisfied the

mix design of 80 Mpa at 28 days. It was concluded that the use

of basalt fiber decreases the compressive strength of concrete

and lime water increases the compressive strength of high

volume UFFA concrete with compared to normal concrete at the

age of concrete at 28 days and beyond. Also concluded that lime

water gives better reaction to the silica in fly ash compared with

hydrated lime, while basalt fiber decreases compressive

strength.

Effect of basalt fiber on mechanical properties of concrete

containing fly ash and metakaolin- Elba Helen George, B.

Bhuvaneshwari2, G. S. Palani, P. Eapen Sakaria, Nagesh R. Iyer

: In this research, the mechanical properties of M-50 grade of

concrete with and without basalt fibers were tested. Fly ash

(Class-F) and metakaolin was added 2.5% by weight of cement

and added as an admixture. The basalt fiber taken was fixed 1%

of the total mass of concrete. Fibers used in this study had length

of 12 mm and diameter of 13 m. The compressive strength

without fiber and with fiber was 53.61 Mpa and 52.65 Mpa at 28

days respectively. Which shows that the compressive strength

decreased when used fibers. Four point bending method was

adopted for flexural strength. The split tensile and flexural

strength without fiber was 3.21 & 4.05 and with fiber was 4.53

& 6.06 in Mpa. Workability of the mix was reduced due to the

http://www.ijftet.wix.com/research

International Journal of Futuristic Trends in Engineering and Technology

ISSN: 2348-5264 (Print), ISSN: 2348-4071 (Online)

Vol. 1 (10), 2014

3)

4)

5)

addition of basalt fibers. Hence, basalt fibers improved split

tensile and flexural strength but decreased compressive strength.

An experimental study on the effectiveness of chopped basalt

fiber on the fresh and hardened properties of high strength

concrete- Ali Elheber Ahmed Elshekh, Nasir Shafiq, Muhd

Fadhil Nuruddin, Ahmed Fathi and Fareed Ahmed Memom : In

this paper, fresh and hardened properties of basalt fiber concrete

were investigated. Two mixes were made, in which one mix was

made with 100% cement and another mix was made with 80%

cement and 20% fly ash (Class-F). Fiber content taken was 0,

0.25, 0.75, 1, 2 and 3% by weight of binder material. The fibers

used had length of 25 mm and diameter of 18 m. Readings for

compressive strength were taken at 3, 7, 28, 56 & 90 days

respectively and for splitting tensile & flexural strength it was

taken at 28 and 90 days. It was concluded that the time of

mixing was increased as an increased content of fiber. The

workability of HSC was decreased when increased fiber content.

The loss of the workability was potentially substituted when

used 20% cement replaced by fly ash. No aggregate segregation

was observed and the mix was fully homogeneous. Fiber

percentage 0.25, 0.50 & 0.75 respectively showed a little effect

on the slump of two group mixes (Without fiber and with fiber).

It was also concluded that compressive strength was reduced

with increased fiber. Tensile strength was increased when

increased with fiber content. When fibers were 1%, 2% & 3%

used with the mix contained 100% OPC HSC the splitting

tensile strength was found 10%, 18% and 20% increased and

when used with the mix contained 80% cement and 20% fly ash

it was found 15%, 25% & 28% increased at 90 days. Toughness

and ductility were also improved. Also, tensile to compressive

strength and flexural to compressive strength ratio were

observed and found to continuous increment with increased fiber

content.

Compressive behavior of basalt fiber reinforced compositeSmriti Raj : In this study the compressive strength, slump value,

average density test, stress strain behavior and failure mode was

studied with using basalt fiber reinforced composite and normal

concrete. The concrete grade was M-50. The fibers taken were

0, 0.3, 0.5, 1 & 2% of the total volume of mixture. The length of

fibers was 23 mm and diameter was 16 m. Composite mix

contained cement, fly ash (class F), silica fume, quartz powder,

ennore sand. It was concluded that slump value was decreased

with increased fiber content. Increased in density by adding

fibers. The compressive strength without fiber was 58 Mpa

whereas with fiber percentage of 0.3, 0.5 and 2, the strength

increment varied between 11% to 12%. The maximum

compressive strength achieved was 65.86 Mpa at the 0.5% of

fiber dosage. Modulus of elasticity value without and with fibers

was 20 Gpa & 34 Gpa respectively. Failure of composite mix

was found brittle. Optimal volume fraction defined was 0.5%

which showed 12% increased in compressive strength.

Performance of basalt fiber in concrete- Gorde Pravin Jaysing,

Deepa A. Joshi : This study was done to investigate the effect of

different proportion of fiber on concrete and the optimum

dosage of fiber was found. Basalt fibers used were 0, 0.25, 0.50,

0.75% and the grade of concrete was M-40. Fly ash (F-class)

was used. 15% of cement was replaced by fly ash. Mechanical

properties were investigated in this study. Compressive strength

with fiber amount 0%, 0.25%, 0.50% & 0.75% was 49.98,

63.51, 56.64 & 47.93 in Mpa respectively at 28 days. Splitting

tensile strength with fiber amount 0%, 0.25%, 0.50% & 0.75%

Akshar Publication 2014

was 4.565, 5.700, 5.640 & 5.205 in Mpa respectively at 28 days.

Flexural strength with fiber amount 0%, 0.25%, 0.50% & 0.75%

was 4.3, 6.3, 5.8 & 5.16 in Mpa respectively at 28 days.

Optimum percentage of basalt fiber found was 0.25%. It was

concluded that performance of concrete was higher at 0.25% and

then it gets decreased slowly.

6) Study on the compressive and split tensile strength properties

of basalt fiber concrete members- Arivalagan. S : In this study

the compressive strength and splitting tensile strength was

carried out for concrete grade M-20 & M-30 without fiber and

with fiber. The test was done at 7, 14 and 28 days respectively.

Basalt fiber concrete had gain compressive strength 20% - 24%

more of both grades with compared to controlled concrete at 7

days, 19% - 29% more at 14 days and 23% - 25% more at 28

days. Splitting tensile strength of basalt fiber concrete was 35%

and 25% more than controlled concrete for M-20 and M-30

respectively at 7 days, 39% and 45% more than controlled

concrete for M-20 and M-30 respectively at 14 days, 37% and

47% more than controlled concrete for M-20 and M-30

respectively at 28 days. It was concluded that all cylinders

showed a good ductile behavior. The strength difference

between basalt fiber concrete and normal concrete became high

distinct in the beginning age of curing. The final compressive

strength and tensile strength was 120% and 123% more than

controlled concrete for M-20 and M-30 respectively at 28 days

& 123% and 125% more than controlled concrete for M-20 and

M-30 respectively at 28 days.

7) Thermal and mechanical properties of basalt fiber reinforced

concrete- Tumadhir M., Borhan : The thermal and mechanical

properties of basalt fiber reinforced concrete were investigated

in this study. Basalt fiber volume fractions used were 0.1, 0.2,

0.3 and 0.5 % by total mix volume. Compressive strength,

splitting tensile strength and heat transfer properties were

studied in the research work. The fiber used had length of 25.4

mm and diameter of 13 m and concrete grade was M-35. The

water binder ratio was kept 0.55. The compressive test was done

at 7, 28 and 90 days respectively. Tensile strength test was done

at 28 days. It was concluded that the compressive strength was

increased with increase of fiber till 0.3% and then it was slightly

decreased when fiber increased above 0.3%. The compressive

strength was reduced 12% at 0.5% of fiber content. There was

slight increase in splitting tensile strength with increase of fiber

till 0.3% then it was decreased with 0.5% basalt fiber. The

modulus of elasticity value was increased with the increase of

fiber content till 0.3% then it decreased when 0.5% fibers were

used. When fiber content was increased the thermal conductivity

decreased at all temperature levels.

III. CONCLUSION

1)

2)

3)

4)

55

The workability of concrete becomes lower as the increment of

fiber content in the concrete mix.

The compressive strength of concrete becomes lower with

compared to controlled concrete when increase of fiber content

while in some studies it is showed that the compressive strength

increases with some percentage of fiber but after that it

decreases.

The splitting tensile strength and flexural strength increases as

the increase of fiber content.

Lime water increases the compressive strength of concrete as it

gives better reaction to the silica in fly ash compared with

hydrated lime.

http://www.ijftet.wix.com/research

International Journal of Futuristic Trends in Engineering and Technology

ISSN: 2348-5264 (Print), ISSN: 2348-4071 (Online)

Vol. 1 (10), 2014

5)

6)

As per done pilot study, by trial and error method and also by

suggested in research paper it is found that the optimum dosage

of the basalt fiber is 0.25% added by weight of cement. The

study was done by taking 0.25%, 0.50%, 0.75% and 1%.

The compressive strength of basalt fiber concrete increases at

later stage when fly ash is partially replaced with cement and

also lime water as mixing water increases the compressive

strength at later stage when using fly ash.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

Mochamad Solikin, Sujeeva Setunge and Indubhushan Patnaikuni,

Experimental design analysis of ultra fine fly ash, lime water, and

basalt fiber in mix proportion of high volume fly ash concrete,

Pertanika j. science & Technology 21(2): 589 600 (2013).

Elba Helen George, B. Bhuvaneshwari2, G. S. Palani, P. Eapen Sakaria,

Nagesh R. Iyer, Effect of basalt fiber on mechanical properties of

concrete containing fly ash and metakaolin, International Journal of

Innovative Research in Science, Engineering and Technology, volume 3,

special issue 5, July 2014.

Ali Elheber Ahmed Elshekh, Nasir Shafiq, Muhd Fadhil Nuruddin,

Ahmed Fathi and Fareed Ahmed Memom, An experimental study on

the effectiveness of chopped basalt fiber on the fresh and hardened

properties of high strength concrete, Research journal of applied

sciences, engineering and technology 7(16): 3304-3311,2014.

Smriti Raj, Compressive behavior of basalt fiber reinforced

composite, International journal of structural analysis and design,

Volume 1: issue 1.

Gorde Pravin Jaysing, Deepa A. Joshi, Performance of basalt fiber in

concrete, International journal of Science and research, Volume 3 Issue

5, May 2014.

Arivalagan. S, Study on the compressive and split tensile strength

properties of basalt fiber concrete members, Global Journal of

Researches in Engineering Civil and Structural Engineering, volume 12:

Issue 4 version 1, 2012.

Tumadhir M., Borhan, Thermal and mechanical properties of basalt

fiber reinforced concrete, World Academy of Science, Engineering and

Technology, vol: 7, 2013.

Kunal Singha, A short review on basalt fiber, International Journal of

Textile Science 2012, 1(4): 19-28.

Akshar Publication 2014

56

http://www.ijftet.wix.com/research

Potrebbero piacerti anche

- RRLDocumento13 pagineRRLAngelineAlinsodNessuna valutazione finora

- "Study of Natural Fibers As An Admixture For Concrete Mix Design" (Chapter 2)Documento9 pagine"Study of Natural Fibers As An Admixture For Concrete Mix Design" (Chapter 2)JOHN FHILIP ORIT100% (4)

- Sheep Wool ConcreteDocumento10 pagineSheep Wool Concretesharin vargheseNessuna valutazione finora

- 2015 A Study On Strength Properties of Hybrid Fiber Reinforced PDFDocumento5 pagine2015 A Study On Strength Properties of Hybrid Fiber Reinforced PDFSrikanth KonikiNessuna valutazione finora

- Effect of Recycled Aggregate and Glass Fiber on ConcreteDocumento22 pagineEffect of Recycled Aggregate and Glass Fiber on ConcreteSuresh KomurajuNessuna valutazione finora

- Study On Durability of Natural Fibre Concrete Composites Using Mechanical Strength and Microstructural PropertiesDocumento11 pagineStudy On Durability of Natural Fibre Concrete Composites Using Mechanical Strength and Microstructural PropertiessfsdffedsNessuna valutazione finora

- Tiwari 2020 IOP Conf. Ser. Mater. Sci. Eng. 961 012009Documento14 pagineTiwari 2020 IOP Conf. Ser. Mater. Sci. Eng. 961 012009Muhammad AwaisNessuna valutazione finora

- Mechanical and Physcial Properties of Fibre Cement Board PDFDocumento5 pagineMechanical and Physcial Properties of Fibre Cement Board PDFanhnguyenhaiNessuna valutazione finora

- Behaviour of Concrete Utilizing AR Glass Fibre As A Partial Replacement of CementDocumento5 pagineBehaviour of Concrete Utilizing AR Glass Fibre As A Partial Replacement of CementdarshanNessuna valutazione finora

- AFBAD2A10971Documento10 pagineAFBAD2A10971Samuel NkereuwemNessuna valutazione finora

- 1 s2.0 S2214509522003795 MainDocumento11 pagine1 s2.0 S2214509522003795 MainahmadNessuna valutazione finora

- Flexural Behavior of Reinforced Concrete Beam Using Abaca FiberDocumento10 pagineFlexural Behavior of Reinforced Concrete Beam Using Abaca FiberEngebrahim atallaNessuna valutazione finora

- REFERENCEDocumento4 pagineREFERENCES19M082 KRITHIK ANessuna valutazione finora

- Coconut Fiber in Concrete To Enhance Its Strength and Making Lightweight ConcreteDocumento5 pagineCoconut Fiber in Concrete To Enhance Its Strength and Making Lightweight ConcreteIndrawan Soleh PutraNessuna valutazione finora

- Comparing strength properties of coir and jute fiber reinforced concreteDocumento6 pagineComparing strength properties of coir and jute fiber reinforced concreteBenharzallah KrobbaNessuna valutazione finora

- Experimental Study On Hybrid Fiber Reinforced Concrete - A ReviewDocumento12 pagineExperimental Study On Hybrid Fiber Reinforced Concrete - A ReviewJames AugustineNessuna valutazione finora

- Acikel - 2011 - The Use of Miscanthus (Giganteus) As A Plant FiberDocumento8 pagineAcikel - 2011 - The Use of Miscanthus (Giganteus) As A Plant FibersalvadorNessuna valutazione finora

- Review On Fiber Reinforced ConcreteDocumento12 pagineReview On Fiber Reinforced ConcreteJames Augustine100% (1)

- Structural Behaviour of Fibrous Concrete Using Polypropylene FibresDocumento4 pagineStructural Behaviour of Fibrous Concrete Using Polypropylene FibresPatricia ClarkNessuna valutazione finora

- Vol 7 2 2 GJCRDocumento2 pagineVol 7 2 2 GJCRR HarshavardhanaNessuna valutazione finora

- Study On Durability of Natural Fibre Concrete Composites Using Mechanical Strength and Microstructural PropertiesDocumento11 pagineStudy On Durability of Natural Fibre Concrete Composites Using Mechanical Strength and Microstructural PropertiesdivakarNessuna valutazione finora

- A Study On Strength of Concrete by PartiDocumento9 pagineA Study On Strength of Concrete by Partijobcustodio54Nessuna valutazione finora

- Temperature Variation On SurfaDocumento7 pagineTemperature Variation On SurfaYathish YathiNessuna valutazione finora

- Mini Project DocumentDocumento26 pagineMini Project Document17-597 Sravani PanugantiNessuna valutazione finora

- CTRG2015 Submission 463Documento12 pagineCTRG2015 Submission 463Sri RamyaNessuna valutazione finora

- Optimum Fly Ash and Fiber Content For M20 Grade ConcreteDocumento5 pagineOptimum Fly Ash and Fiber Content For M20 Grade ConcreteIJMER0% (1)

- Suri AbstractDocumento1 paginaSuri AbstractKhaleelNessuna valutazione finora

- Kajian Pengaruh .. Kuat Tarik Beton Mudji Suhardiman Kajian Pengaruh Penambahan Serat Bambu Ori Terhadap Kuat Tekan Dan Kuat Tarik BetonDocumento26 pagineKajian Pengaruh .. Kuat Tarik Beton Mudji Suhardiman Kajian Pengaruh Penambahan Serat Bambu Ori Terhadap Kuat Tekan Dan Kuat Tarik BetonDhani de JaneiroNessuna valutazione finora

- Experimental Study On Human Hair As Fiber Reinforced ConcreteDocumento5 pagineExperimental Study On Human Hair As Fiber Reinforced ConcreteYogendra PatilNessuna valutazione finora

- Properties of fiber-cement composites with selected fibers and cellulose pulpDocumento11 pagineProperties of fiber-cement composites with selected fibers and cellulose pulpDgek LondonNessuna valutazione finora

- Effect of Fiber Orientation On Mechanical Properties of Sisal Fiber Reinforced Epoxy CompositesDocumento6 pagineEffect of Fiber Orientation On Mechanical Properties of Sisal Fiber Reinforced Epoxy CompositeskumareshNessuna valutazione finora

- Akhil ProDocumento100 pagineAkhil ProNI KH ILNessuna valutazione finora

- 02 Mechanical Strength of Coconut Fiber Reinforced Concrete - ScienceDirectDocumento6 pagine02 Mechanical Strength of Coconut Fiber Reinforced Concrete - ScienceDirectilyushi 20 014Nessuna valutazione finora

- tmp4D96 TMPDocumento5 paginetmp4D96 TMPFrontiersNessuna valutazione finora

- 2000 Words PDFDocumento5 pagine2000 Words PDFshoaibNessuna valutazione finora

- Ingris Panjang Serat GoniDocumento6 pagineIngris Panjang Serat GoniWardahNessuna valutazione finora

- Development and Characterization of Sisal Fiber and Wood Dust Reinforced Polymeric CompositesDocumento11 pagineDevelopment and Characterization of Sisal Fiber and Wood Dust Reinforced Polymeric CompositesGosa GutaNessuna valutazione finora

- Utilization of Bamboo Fiber As A Component Material in ConcreteDocumento9 pagineUtilization of Bamboo Fiber As A Component Material in ConcreteJemma AbadianoNessuna valutazione finora

- Study On The Effect of Coir Fibre in The Bituminous Concrete MixDocumento5 pagineStudy On The Effect of Coir Fibre in The Bituminous Concrete MixIJSTENessuna valutazione finora

- 2010 - Ultra High Strength Fiber Reinforced Concrete Using Aramid Fiber PDFDocumento6 pagine2010 - Ultra High Strength Fiber Reinforced Concrete Using Aramid Fiber PDFMonica Natalia Gavilanez RiveraNessuna valutazione finora

- International Journal of Engineering Research and DevelopmentDocumento4 pagineInternational Journal of Engineering Research and DevelopmentIJERDNessuna valutazione finora

- 1375-RUGC Manuscript-4763-1-10-20200425Documento6 pagine1375-RUGC Manuscript-4763-1-10-20200425Brinsi AnwerNessuna valutazione finora

- Cast-in-Place Cellulose Fiber-Reinforced Cement Paste, Mortar, and ConcreteDocumento9 pagineCast-in-Place Cellulose Fiber-Reinforced Cement Paste, Mortar, and ConcreteFlavio RojasNessuna valutazione finora

- Fiber Reinforced ConcreteDocumento5 pagineFiber Reinforced ConcreteJournalNX - a Multidisciplinary Peer Reviewed JournalNessuna valutazione finora

- Investigation of Mechanical Properties of Sisal Epoxy Hybrid CompositesDocumento7 pagineInvestigation of Mechanical Properties of Sisal Epoxy Hybrid CompositesYuvaraj RajuNessuna valutazione finora

- An Experimental and Characteristic Study of Abaca Fiber ConcreteDocumento10 pagineAn Experimental and Characteristic Study of Abaca Fiber ConcreteAika LorenNessuna valutazione finora

- Characterization of Properties of Epoxy Sisal / Glass Fiber Reinforced Hybrid CompositeDocumento7 pagineCharacterization of Properties of Epoxy Sisal / Glass Fiber Reinforced Hybrid CompositeMr. K.S. Raghul Asst Prof MECHNessuna valutazione finora

- Delta ConcreteDocumento7 pagineDelta ConcreteHari AppathuraiNessuna valutazione finora

- Emmy Dyah-Pengaruh Panjang Serat Dan Fraksi Volume Terhadap KekuatanDocumento13 pagineEmmy Dyah-Pengaruh Panjang Serat Dan Fraksi Volume Terhadap KekuatanShofiuddinNessuna valutazione finora

- Recron FibresDocumento12 pagineRecron FibresAnonymous kRIjqBLk100% (1)

- Lit Survey & RefDocumento10 pagineLit Survey & RefAnand KumarNessuna valutazione finora

- Experimental Study On Human Hair Fiber Reinforced Concrete With Partial Replacement of Cement by GgbfsDocumento11 pagineExperimental Study On Human Hair Fiber Reinforced Concrete With Partial Replacement of Cement by GgbfsmohanNessuna valutazione finora

- Effect of Fiber Length and Chemical Treatment On Wear Rate of The Natural Reinforced PolymerDocumento7 pagineEffect of Fiber Length and Chemical Treatment On Wear Rate of The Natural Reinforced PolymerWafaa MahdiNessuna valutazione finora

- Fabrication of Natural Composite Fiber and Study of Its Properties Shubham Sharma, Ashish Srivastava, Abhishek KumarDocumento12 pagineFabrication of Natural Composite Fiber and Study of Its Properties Shubham Sharma, Ashish Srivastava, Abhishek KumarPrince Ghosh EponNessuna valutazione finora

- Experimental Investigation On Bendable Concrete Using Natural and Artificial Fibres (Jute and Nylon)Documento5 pagineExperimental Investigation On Bendable Concrete Using Natural and Artificial Fibres (Jute and Nylon)anon_884442402Nessuna valutazione finora

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessDa EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNessuna valutazione finora

- Biomimetic Principles and Design of Advanced Engineering MaterialsDa EverandBiomimetic Principles and Design of Advanced Engineering MaterialsNessuna valutazione finora

- Handbook of Composites from Renewable Materials, Design and ManufacturingDa EverandHandbook of Composites from Renewable Materials, Design and ManufacturingNessuna valutazione finora

- Pulp and Paper Industry: Nanotechnology in Forest IndustryDa EverandPulp and Paper Industry: Nanotechnology in Forest IndustryValutazione: 5 su 5 stelle5/5 (1)

- Office Plan ModelDocumento1 paginaOffice Plan ModelSatyen RamaniNessuna valutazione finora

- El Sheikh2001Documento13 pagineEl Sheikh2001Satyen RamaniNessuna valutazione finora

- Kacheri PaddhatiDocumento14 pagineKacheri PaddhatiSatyen RamaniNessuna valutazione finora

- Low Cost Housing Technical ManualDocumento52 pagineLow Cost Housing Technical ManualAbiy KebereNessuna valutazione finora

- r0 St-01 Parking Shed Details Dt310319 BWDocumento1 paginar0 St-01 Parking Shed Details Dt310319 BWSatyen RamaniNessuna valutazione finora

- Chap 6Documento29 pagineChap 6mayarayNessuna valutazione finora

- Guidelines For Instrumentation of Large Dams PDFDocumento198 pagineGuidelines For Instrumentation of Large Dams PDFSatyen RamaniNessuna valutazione finora

- Conceptual Design and Reliability of Long Span StructuresDocumento13 pagineConceptual Design and Reliability of Long Span StructuresMuhd YazidNessuna valutazione finora

- Concre - IS Code On Prefabricated ConcreteDocumento28 pagineConcre - IS Code On Prefabricated Concretenimm1962100% (1)

- MMSA (Curved Beam)Documento18 pagineMMSA (Curved Beam)Satyen RamaniNessuna valutazione finora

- Transcript For Satyen Dahyalal Ramani: Course Delivery Type LU Completion Date (S)Documento1 paginaTranscript For Satyen Dahyalal Ramani: Course Delivery Type LU Completion Date (S)Satyen RamaniNessuna valutazione finora

- Report PrintingDocumento1 paginaReport PrintingSatyen RamaniNessuna valutazione finora

- Chapter 7 Moment Distribution MethodDocumento12 pagineChapter 7 Moment Distribution MethodSatyen Ramani100% (1)

- Application of CFD For Determination of Pressure Coefficients Using Ansys Flotran by Satyen Ramani PDFDocumento12 pagineApplication of CFD For Determination of Pressure Coefficients Using Ansys Flotran by Satyen Ramani PDFSatyen RamaniNessuna valutazione finora

- IJIRSET Paper 2 PDFDocumento9 pagineIJIRSET Paper 2 PDFSatyen RamaniNessuna valutazione finora

- Finite Element Analysis of Navier-Stokes EquationsDocumento28 pagineFinite Element Analysis of Navier-Stokes EquationsSatyen RamaniNessuna valutazione finora

- Parametric Study To Understand Pressure Distribution Around Differential Height Structure Ijariie1651Documento15 pagineParametric Study To Understand Pressure Distribution Around Differential Height Structure Ijariie1651Satyen RamaniNessuna valutazione finora

- HOSPITAL - Tiebeam LVL STAAD PlanA3Documento1 paginaHOSPITAL - Tiebeam LVL STAAD PlanA3Satyen RamaniNessuna valutazione finora

- RCC - Properties of Steel and ConcreteDocumento17 pagineRCC - Properties of Steel and Concretenitishpathak79Nessuna valutazione finora

- Wa0009Documento45 pagineWa0009Victor OmotoriogunNessuna valutazione finora

- Yojin Myanmar Cement Co CEM-I 42.5 N Class Test ReportDocumento1 paginaYojin Myanmar Cement Co CEM-I 42.5 N Class Test ReportAung Naing Latt Aung100% (1)

- Giatec iCOR DS 18v2Documento2 pagineGiatec iCOR DS 18v2SyedZain1993Nessuna valutazione finora

- Virtual CemTrans Proceedings 16 June 2020 PDFDocumento94 pagineVirtual CemTrans Proceedings 16 June 2020 PDFStockKingNessuna valutazione finora

- Experimental Research On The Behaviour of High Frequency Fatigue in ConcreteDocumento10 pagineExperimental Research On The Behaviour of High Frequency Fatigue in Concreteming_zhu10Nessuna valutazione finora

- ElepahatShield BrocureDocumento11 pagineElepahatShield BrocureBinoy KaladiNessuna valutazione finora

- FM5-490 (92) (3) Engineer Diving OperationsDocumento38 pagineFM5-490 (92) (3) Engineer Diving OperationsJune Carlo Sumile100% (1)

- Presentation FRPDocumento35 paginePresentation FRPANKESH SHRIVASTAVANessuna valutazione finora

- QC02001 BRC DRW SDW STR 06 Fe1 80203Documento1 paginaQC02001 BRC DRW SDW STR 06 Fe1 80203hbfbfkbf100% (1)

- Bill of Quantity Name of Work-Septic Tank (29'-0"x8'-0"x7'-0")Documento36 pagineBill of Quantity Name of Work-Septic Tank (29'-0"x8'-0"x7'-0")Khin Thu Zar HtayNessuna valutazione finora

- Effects of Aluminum Dross Partial Replacement of Cement and Curing Media On ConcreteDocumento7 pagineEffects of Aluminum Dross Partial Replacement of Cement and Curing Media On ConcreteAtinukeNessuna valutazione finora

- Eq 1Documento4 pagineEq 1jppblckmnNessuna valutazione finora

- Schedule of Rates for Construction WorksDocumento157 pagineSchedule of Rates for Construction WorksRinpal67% (3)

- Application & Analysis of Banana Stem Fibre Use As Construction MaterialDocumento12 pagineApplication & Analysis of Banana Stem Fibre Use As Construction MaterialEditor IJTSRDNessuna valutazione finora

- Bridge Design - Sample QuestionsDocumento23 pagineBridge Design - Sample QuestionsSena KenaNessuna valutazione finora

- Analysis of Construction Rates for Fiscal Year 2074/075Documento45 pagineAnalysis of Construction Rates for Fiscal Year 2074/075Laxu KhanalNessuna valutazione finora

- Project Management: Mid-Term AssignmentDocumento15 pagineProject Management: Mid-Term Assignmentnuman ejazNessuna valutazione finora

- Con Stru Ctio N: Sikacrete - Gunit 105Documento3 pagineCon Stru Ctio N: Sikacrete - Gunit 105Jamsheed Ap KadangodNessuna valutazione finora

- BC MOT Supplement To CHBDCDocumento138 pagineBC MOT Supplement To CHBDCtrulyvirgoNessuna valutazione finora

- 0116 202006081032 PDFDocumento4 pagine0116 202006081032 PDFPatrickNessuna valutazione finora

- Dcs 2 Sessional PaperDocumento2 pagineDcs 2 Sessional Papermaniram7Nessuna valutazione finora

- Fondu PDFDocumento2 pagineFondu PDFbaselNessuna valutazione finora

- Wiremesh InstallationDocumento3 pagineWiremesh InstallationFitriansyah Adi Putra IrwanNessuna valutazione finora

- Splash Works Water Parks Core Test Report PDFDocumento1 paginaSplash Works Water Parks Core Test Report PDFJahid HasanNessuna valutazione finora

- Thioflex 600 Sealant Technical Data SheetDocumento5 pagineThioflex 600 Sealant Technical Data Sheetalbukharir100% (1)

- Fly Ash TechdataDocumento2 pagineFly Ash TechdataNamrata SapkalNessuna valutazione finora

- Brick TiesDocumento15 pagineBrick TiesengrfarhanAAANessuna valutazione finora

- 2013 Hilti Hit-Hy 200 With His - (R) NDocumento4 pagine2013 Hilti Hit-Hy 200 With His - (R) NDifa LiuNessuna valutazione finora

- The Brownstone Guide: Maintenance & Repair Facts For Historic Property OwnersDocumento12 pagineThe Brownstone Guide: Maintenance & Repair Facts For Historic Property OwnerspajinaNessuna valutazione finora

- Moc IiDocumento9 pagineMoc IiVikram Rao100% (1)