Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Heat Calcultion

Caricato da

Dgk RajuTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Heat Calcultion

Caricato da

Dgk RajuCopyright:

Formati disponibili

Page :1/4

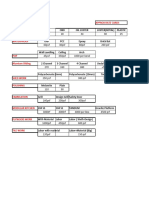

UNIT-3 : HEAT BALANCE CALCULATION

: 9/8/2008

: KILN

: PROCESS DEPT

Date

Section

Calculations by

PLANT CAPACITY TPD :

AMB. TEMPERATURE (OC) :

DOSING AIR :

TEMPERATURE (OC) :

34

VOLUME (NM /KG) :

3500

29

PRIMARY AIR :

TEMPERATURE (OC) :

33

CLINKER COMPOSITION :

% SiO2 :

22.38

% Al2O3 :

5.47

RADIATION LOSSES (kcal/Kg CLINKER):

% Fe2O3 :

4.20

64.89

1.19

KILN SHELL:

PREHEATER :

COOLER SIDE :

% CaO :

% MgO :

VOLUME (NM /KG) :

0.056

TEMPERATURE (OC) :

295

BYPASS :

VOLUME (NM3/KG) :

1.56

VOLUME AT KILN INLET (NM3/KG) :

DUST LOAD (gms/NM ) :

50

% BYPASS CONSIDERED :

RAW MEAL :

AMOUNT (Kg/Kg of CLINKER) :

GAS TEMP. AT KILN INLET ( C) :

DUST LOAD (gms/NM3) :

1.6

TEMPERATURE ( C) :

60

MOISTURE (%) :

0.5

204

TEMPERATURE (OC) :

VOLUME (NM /KG) :

3

239

0.970

TEMPERATURE (OC) :

VOLUME (NM /KG) :

3

3.18

4.95

6. HEAT CARRIED BY CLINKER :

7. RADIATION LOSSES :

8. HEAT CARRIED BY BYPASS GAS :

HEAT CARRIED BY BYPASS DUST :

DECARBONISATION LOSS :

35.97

70.405

0.00

0.00

0.00

TOTAL HEAT OUTPUT (KCAL/Kg CLINKER) :

743.12

5.20

0.38

SP. HEAT OF RAW MEAL (KCAL/Kg) :

0.320

0.311

0.214

3. HEAT FROM PRIMARY AIR :

4. HEAT FROM RAW MEAL :

5. HEAT FROM FUEL :

0.23

13.71

723.61

SP. HEAT OF KILN DUST (KCAL/Kg) :

0.231

SP. HEAT OF CLINKER (KCAL/Kg) :

0.195

0.209

0.323

TOTAL HEAT INPUT (KCAL/Kg CLINKER) :

743.12

SP. HEAT OF COOLER EXH. GAS (KCAL/NM3) :

SP. HEAT OF DUST AT KILN INLET (KCAL/Kg) :

COOLING AIR :

68.04

4. HEAT CARRIED BY PH EXHAUST GAS DUST :

1. HEAT FROM COOLING AIR :

2. HEAT FROM DOSING AIR :

SP. HEAT OF DOSING AIR (KCAL/NM3) :

COOLER EXHAUST GAS :

3. HEAT CARRIED BY COOLER EXHAUST GAS :

0.310

0.352

SP. HEAT OF PH. EXHAUST GAS (KCAL/NM3) :

TEMPERATURE (OC) :

151.21

HEAT INPUT (KCAL/Kg CLINKER) :

SP. HEAT OF AMBIENT AIR (KCAL/NM3) :

CLINKER :

409.37

2. HEAT CARRIED BY PH EXHAUST GAS :

0.00

0

1. HEAT FOR CLINKERISATION :

5. HEAT FOR MOISTURE EVAPORATION :

29.655

29.994

10.756

PH EXHAUST GAS :

HEAT OUTPUT (KCAL/Kg CLINKER) :

0.088

SP. HEAT OF GAS AT KILN INLET(KCAL/NM3) :

29

1.86

Calculation by: B.Ravindran

UNIT-3 : HEAT BALANCE CALCULATION

Note: Raw Meal to Clinker Factor = 1.60 kg / kg clinker.

Calculation by: B.Ravindran

Page :2/4

Page :3/4

UNIT-3 : HEAT BALANCE CALCULATION

PH EXHAUST GAS :

RAW MEAL :

CLK. TEMPERATURE (OC) :

TEMPERATURE ( C) :

295

Kg/Kg of CLINKER :

1.6

COOLER EXHAUST GAS :

VOLUME (NM /KG) :

1.56

TEMPERATURE ( C) :

60

TEMPERATURE ( C) :

DUST LOAD (gms/NM3) :

50

MOISTURE (%) :

0.5

VOLUME (NM3/KG) :

HEAT OUTPUT KCAL/ Kg CLINKER

204

COOLING AIR :

TEMPERATURE (OC) :

29

239

VOLUME (NM /KG) :

1.86

0.97

DATE:

9/8/2008

HEAT INPUT KCAL/ Kg CLINKER

Clinkerisation

55.09%

409.37

20.35%

PH Exhaust gas

151.21

Sensible heat cooling air

5.20

0.70%

Sensible heat dosing air

Cooler Exhaust gas

9.16%

0.43%

0.67%

0.38

0.05%

68.04

PH Exhaust dust

PLANT CAPACITY

Sensible heat primary air

3.18

3500 TPD

0.23

0.03%

Moisture

AMB. TEMP.

4.95

29 OC

Sensible heat raw meal

13.71

1.84%

FUEL

723.61

97.37%

Exit clinker

4.84%

35.97

Radiation losses

9.47%

70.405

0.00%

By pass losses

0.00

743.12

TOTAL HEAT INPUT (KCAL/Kg CLINKER) :

Calculation by: B.Ravindran

743.12

UNIT-3 : HEAT BALANCE CALCULATION

Calculation by: B.Ravindran

Page :4/4

Potrebbero piacerti anche

- Cooler EfficiencyDocumento58 pagineCooler Efficiencyayaskant75100150% (2)

- Heat Balance-1Documento85 pagineHeat Balance-1Ravi sharmaNessuna valutazione finora

- Heat Calculation by SG.Documento26 pagineHeat Calculation by SG.TIRIANTO0% (2)

- 3500TPD Cement Plant Heat BalanceDocumento2 pagine3500TPD Cement Plant Heat BalanceIrshad HussainNessuna valutazione finora

- Pheater Heat BalanceDocumento2 paginePheater Heat BalanceRaji SuriNessuna valutazione finora

- Kiln Pre Heater Fan Power CalculationDocumento4 pagineKiln Pre Heater Fan Power CalculationVijay Bhan67% (3)

- Calculating hot gas requirements for coal dryingDocumento2 pagineCalculating hot gas requirements for coal dryingJoko Dewoto0% (1)

- Kiln Rotation Procedure Guide for Firing CeramicsDocumento1 paginaKiln Rotation Procedure Guide for Firing CeramicsVijay BhanNessuna valutazione finora

- Heat Balance CalculationsDocumento29 pagineHeat Balance CalculationsGuillermo Càceres100% (1)

- Bestway Cement Limited heat balance and WHR analysisDocumento4 pagineBestway Cement Limited heat balance and WHR analysisKiran Veerubhotla100% (1)

- Bag Filter Selector: Filter Type: C (For This Type of Filter Contact Area Genovese)Documento8 pagineBag Filter Selector: Filter Type: C (For This Type of Filter Contact Area Genovese)Ashish GulabaniNessuna valutazione finora

- Calculation of CO2 Gas Requirement For Coal Bin InterisationDocumento2 pagineCalculation of CO2 Gas Requirement For Coal Bin Interisationvvijaybhan100% (1)

- Fuel Analysis CalculationDocumento2 pagineFuel Analysis CalculationRamachandran Venkatesh100% (1)

- Heat & Mass Equation For CementDocumento99 pagineHeat & Mass Equation For Cementamit100% (1)

- Conversion Factor For NOx and SOx CalculationsDocumento2 pagineConversion Factor For NOx and SOx CalculationsvvijaybhanNessuna valutazione finora

- Fan Eff Calculation'Documento119 pagineFan Eff Calculation'Durga Prasad100% (1)

- Bag Filter Flow RateDocumento1 paginaBag Filter Flow RatemorlsNessuna valutazione finora

- Combustion Air Fan CalculationDocumento2 pagineCombustion Air Fan CalculationVijay BhanNessuna valutazione finora

- Cooler CalculationDocumento3 pagineCooler Calculationmohanprocess24Nessuna valutazione finora

- Cooler Air Flow Vs Kiln FeedDocumento2 pagineCooler Air Flow Vs Kiln FeedBùi Hắc HảiNessuna valutazione finora

- Bag FilterDocumento27 pagineBag FiltermkpqNessuna valutazione finora

- Kiln Audit H&M Balance Calculation 2012Documento24 pagineKiln Audit H&M Balance Calculation 2012Anonymous 3ESYcrKP100% (7)

- The Cement Grinding Office: Home About Us Services Mining AreaDocumento3 pagineThe Cement Grinding Office: Home About Us Services Mining AreaVisnu SankarNessuna valutazione finora

- HT-2.2 RMR Heat Belance 5 Stage T17 M7,9Documento1 paginaHT-2.2 RMR Heat Belance 5 Stage T17 M7,9GiequatNessuna valutazione finora

- Mod 8-Application of Heat and Mass BalancesDocumento218 pagineMod 8-Application of Heat and Mass BalancesTamer Fathy100% (3)

- FANPOWDocumento3 pagineFANPOWElwathig BakhietNessuna valutazione finora

- Heat Balance Template LM 53 3+3Documento11 pagineHeat Balance Template LM 53 3+3Sai Sricharan Reddy100% (3)

- Mass BalanceDocumento2 pagineMass BalanceElwathig Bakhiet100% (1)

- Coolheat1 AmericanDocumento103 pagineCoolheat1 AmericanPrabhakar Reddy PeramNessuna valutazione finora

- Coal CombustionDocumento3 pagineCoal CombustionRahul ChandrawarNessuna valutazione finora

- Cement manufacturing technologies for energy efficiency and emission reductionDocumento22 pagineCement manufacturing technologies for energy efficiency and emission reductionnecdetdalgicNessuna valutazione finora

- H&M CalculationsDocumento14 pagineH&M CalculationsNITINNessuna valutazione finora

- Rajashree Cements Line-III Clinker Cooler Project Data 2005Documento10 pagineRajashree Cements Line-III Clinker Cooler Project Data 2005Irfan AhmedNessuna valutazione finora

- Typical Cement Mill Bag Filter Capital Cost CamparisonDocumento1 paginaTypical Cement Mill Bag Filter Capital Cost CamparisonKenny RuizNessuna valutazione finora

- AFR Profile 2003 GuidelinesDocumento13 pagineAFR Profile 2003 Guidelinesshani5573Nessuna valutazione finora

- Clinker CoolersDocumento74 pagineClinker Coolersemad sabri80% (5)

- MASS BALANCE SUMMARYDocumento51 pagineMASS BALANCE SUMMARYirfan100% (1)

- Krupp Industries India Ltd design calculation manualDocumento24 pagineKrupp Industries India Ltd design calculation manualMohsen Ardestani100% (4)

- Clinker Plant Airflow and Fan Efficiency MeasurementDocumento109 pagineClinker Plant Airflow and Fan Efficiency MeasurementSantanu PachhalNessuna valutazione finora

- Bag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFDocumento14 pagineBag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFRICARDOALEXBORGES100% (2)

- By-Pass Calculation Method - DocbDocumento2 pagineBy-Pass Calculation Method - DocbElwathig BakhietNessuna valutazione finora

- Fabric Filter Design VariablesDocumento14 pagineFabric Filter Design VariablesElumalai Srinivasan100% (1)

- Cooler BalanceDocumento16 pagineCooler BalanceIrfan Ahmed100% (1)

- Heat & Mass BalanceDocumento2 pagineHeat & Mass Balancesneha_21100% (1)

- Design Criteria For PH & PCDocumento6 pagineDesign Criteria For PH & PCtricky777Nessuna valutazione finora

- WHR Calculation For Cement KilnDocumento11 pagineWHR Calculation For Cement KilnHieu DuongNessuna valutazione finora

- Material Residence Time in KilnDocumento2 pagineMaterial Residence Time in KilnVijay Bhan100% (2)

- Pulse Jet Bag Filters PDFDocumento12 paginePulse Jet Bag Filters PDFPetros IosifidisNessuna valutazione finora

- Overall Heat Balance - 11.08.2008Documento8 pagineOverall Heat Balance - 11.08.2008Tamer FathyNessuna valutazione finora

- Line I Heat BalanceDocumento60 pagineLine I Heat Balancehmaza shakeelNessuna valutazione finora

- Cement Kiln Pyro BalanceDocumento45 pagineCement Kiln Pyro BalanceirfanNessuna valutazione finora

- Unit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTDocumento2 pagineUnit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTjoe_kudoNessuna valutazione finora

- Heat balance calculation breakdownDocumento2 pagineHeat balance calculation breakdownsalahromdhani89Nessuna valutazione finora

- Unit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTDocumento2 pagineUnit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTAnil KumarNessuna valutazione finora

- Unit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTDocumento2 pagineUnit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTHusni BasharudinNessuna valutazione finora

- Unit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTDocumento2 pagineUnit-3: Heat Balance Calculation: 9/8/2008 Section: Calculations By: PROCESS DEPTPradeepNessuna valutazione finora

- Heat Balance For Kiln: D.GokhaleDocumento4 pagineHeat Balance For Kiln: D.GokhaleAMRITLAL PRAJAPATINessuna valutazione finora

- Heat Balance For Kiln: Jasveer SinghDocumento4 pagineHeat Balance For Kiln: Jasveer SinghAlok RanjanNessuna valutazione finora

- Binani Cement kiln process diagram analysisDocumento99 pagineBinani Cement kiln process diagram analysissaji kumar100% (5)

- Mod 6Documento49 pagineMod 6mkpq100% (1)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 2013-09-03 131913 63Documento8 pagine2013-09-03 131913 63Dgk RajuNessuna valutazione finora

- Material Data Sheets For Piping: 1 ForewordDocumento50 pagineMaterial Data Sheets For Piping: 1 ForewordhsdeNessuna valutazione finora

- EspDocumento1 paginaEspDgk RajuNessuna valutazione finora

- 03aup Clinker Storage Systems GB Brochure PDFDocumento12 pagine03aup Clinker Storage Systems GB Brochure PDFDgk RajuNessuna valutazione finora

- New Steel Silo For Irish CementDocumento3 pagineNew Steel Silo For Irish CementDgk RajuNessuna valutazione finora

- Corrosion AllowanceDocumento35 pagineCorrosion AllowanceReni Mutiara Sari50% (2)

- TARCE Vol.5 No.2 July December 2016 PG.27 33Documento7 pagineTARCE Vol.5 No.2 July December 2016 PG.27 33Dgk RajuNessuna valutazione finora

- Specifications For Stainless SteelDocumento12 pagineSpecifications For Stainless Steelzyx26100% (2)

- 148 160Documento13 pagine148 160Dgk RajuNessuna valutazione finora

- 148 160Documento13 pagine148 160Dgk RajuNessuna valutazione finora

- Belt Bucket Elevatros Techno - Commercial Comparision StatementDocumento13 pagineBelt Bucket Elevatros Techno - Commercial Comparision StatementDgk RajuNessuna valutazione finora

- Lathe Machine SpecificationDocumento2 pagineLathe Machine SpecificationDgk RajuNessuna valutazione finora

- 9 Information Series Casting of Stainless SteelDocumento6 pagine9 Information Series Casting of Stainless SteelDgk RajuNessuna valutazione finora

- StatementDocumento12 pagineStatementDgk RajuNessuna valutazione finora

- BSNL Land Line Bill Payment RecieptDocumento1 paginaBSNL Land Line Bill Payment RecieptDgk RajuNessuna valutazione finora

- Payment Response FLIPKARTDocumento1 paginaPayment Response FLIPKARTDgk RajuNessuna valutazione finora

- 4 EemsDocumento87 pagine4 EemsDgk RajuNessuna valutazione finora

- Proposal For Reducing Emissions of Sox in Cement Plants: December 2014Documento5 pagineProposal For Reducing Emissions of Sox in Cement Plants: December 2014Dgk RajuNessuna valutazione finora

- Esp'S Technical Data of Kcs & I LTD.: Kakatiya Cement Sugar & Industries LTDDocumento1 paginaEsp'S Technical Data of Kcs & I LTD.: Kakatiya Cement Sugar & Industries LTDDgk RajuNessuna valutazione finora

- Cooler CIS & Grate Plates PDFDocumento1 paginaCooler CIS & Grate Plates PDFDgk RajuNessuna valutazione finora

- Cement Co-Processing GazetteDocumento7 pagineCement Co-Processing GazetteKrishna SrikanthNessuna valutazione finora

- Packing House Up Dated Flow Sheet-ModelDocumento1 paginaPacking House Up Dated Flow Sheet-ModelDgk RajuNessuna valutazione finora

- Chimney ExtensionDocumento1 paginaChimney ExtensionDgk RajuNessuna valutazione finora

- Raw Mill FlowsDocumento2 pagineRaw Mill FlowsDgk RajuNessuna valutazione finora

- BLENDING AND STORAGE UP DATED-Model PDFDocumento1 paginaBLENDING AND STORAGE UP DATED-Model PDFDgk RajuNessuna valutazione finora

- VibrationDocumento1 paginaVibrationDgk RajuNessuna valutazione finora

- PHE Excel Sheet (Data)Documento2 paginePHE Excel Sheet (Data)Dgk RajuNessuna valutazione finora

- Life Time Calendar-2017Documento1 paginaLife Time Calendar-2017Dgk RajuNessuna valutazione finora

- Fishing in Drilling OperationsDocumento19 pagineFishing in Drilling Operationsmts1234100% (1)

- 2010 Proportional CatalogDocumento16 pagine2010 Proportional CatalogjondesousaNessuna valutazione finora

- Coaxial Cables: Section VDocumento6 pagineCoaxial Cables: Section VFrancisco CamposNessuna valutazione finora

- Motorized Butterfly Valve With Actuator JJ (WAFN3 - MSEENR)Documento10 pagineMotorized Butterfly Valve With Actuator JJ (WAFN3 - MSEENR)hvacvn1984Nessuna valutazione finora

- Chemistry Unit 3B NotesDocumento13 pagineChemistry Unit 3B NotesShuchi HossainNessuna valutazione finora

- Periodic Table Labeled GroupsDocumento1 paginaPeriodic Table Labeled GroupsNikFenningÂûNessuna valutazione finora

- Bbe ProductDocumento9 pagineBbe Productbackkomster6439Nessuna valutazione finora

- MSS SP-44-2016 Steel Pipeline FlangesDocumento52 pagineMSS SP-44-2016 Steel Pipeline Flangesarnoldbatista55100% (2)

- Effects of Doping Yb3 - La3 - Ti4 - Hf4 - Ce4 Cations On - 2019 - Journal of ADocumento13 pagineEffects of Doping Yb3 - La3 - Ti4 - Hf4 - Ce4 Cations On - 2019 - Journal of Ahk esatonNessuna valutazione finora

- Evaluation of Steam Jet EjectorsDocumento11 pagineEvaluation of Steam Jet EjectorsRajeh Somrani100% (3)

- Internship ReportDocumento31 pagineInternship ReportShashidhara AENessuna valutazione finora

- Membrane Technology: Reverse Osmosis Ultrafiltration MicrofiltrationDocumento66 pagineMembrane Technology: Reverse Osmosis Ultrafiltration MicrofiltrationShivani MunishwarNessuna valutazione finora

- Turbocharger Service InstructionsDocumento4 pagineTurbocharger Service Instructionskarol1177Nessuna valutazione finora

- Rohm & Haas Amberlite IRN 150 LDocumento2 pagineRohm & Haas Amberlite IRN 150 LMuhammad ImranNessuna valutazione finora

- Dow Corning 3145 RTV Adhesive-SealantDocumento8 pagineDow Corning 3145 RTV Adhesive-SealantEdgarNessuna valutazione finora

- Indian Oil's Petrochemical Initiatives at Paradip & Downstream OpportunitiesDocumento26 pagineIndian Oil's Petrochemical Initiatives at Paradip & Downstream Opportunitiesabhishek chowdhuryNessuna valutazione finora

- Pop-up and Starter Fertilizers for Corn: Rates, Placement and Nutrient RemovalDocumento5 paginePop-up and Starter Fertilizers for Corn: Rates, Placement and Nutrient RemovaluserNessuna valutazione finora

- Rate CardDocumento6 pagineRate CardRavi SrivastavaNessuna valutazione finora

- 2009 - Turner, J. W. - Death of A Child From Topical DiphenhydramineDocumento2 pagine2009 - Turner, J. W. - Death of A Child From Topical DiphenhydramineMaria KandelaNessuna valutazione finora

- Phase I document covers states of matter basicsDocumento41 paginePhase I document covers states of matter basicsdivakarsNessuna valutazione finora

- Preparing Meds From Ampules and VialsDocumento7 paginePreparing Meds From Ampules and VialsZyra ObedencioNessuna valutazione finora

- Activated CarbonDocumento34 pagineActivated CarbonSanjeeva YedavalliNessuna valutazione finora

- DPP 20220411175616686155Documento52 pagineDPP 20220411175616686155Ronit NigamNessuna valutazione finora

- Studies On Degradation of Synthetic Polymer Nylon 6 by FungusDocumento8 pagineStudies On Degradation of Synthetic Polymer Nylon 6 by FungusTiten PinastiNessuna valutazione finora

- Corrosion PDFDocumento51 pagineCorrosion PDFSuryansh SinghNessuna valutazione finora

- Unit 7 - Week 4: Assignment 4Documento3 pagineUnit 7 - Week 4: Assignment 4Ananda VijayasarathyNessuna valutazione finora

- Regular chimney inspections extend plant operationsDocumento6 pagineRegular chimney inspections extend plant operationstecvidyaNessuna valutazione finora

- Name: Ridus Haroon Roll No: 21-10884 Course: Commercialization of Biotechnology Course Code: BIOT305 Section: A Instructor: Z. MehmoodDocumento8 pagineName: Ridus Haroon Roll No: 21-10884 Course: Commercialization of Biotechnology Course Code: BIOT305 Section: A Instructor: Z. MehmoodAreeba KhanNessuna valutazione finora

- 1 MergedDocumento8 pagine1 MergedNo NameNessuna valutazione finora

- Coway water purifiers product collectionDocumento10 pagineCoway water purifiers product collectionSyida NaufalNessuna valutazione finora