Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BSP Technical Handbook

Caricato da

Vincent0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

178 visualizzazioni43 pagineBSP Fabric Technical Handbook - Wire Mesh

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoBSP Fabric Technical Handbook - Wire Mesh

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

178 visualizzazioni43 pagineBSP Technical Handbook

Caricato da

VincentBSP Fabric Technical Handbook - Wire Mesh

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 43

Technical Handbook

Contents

1. Specification & Material Properties

—®

at Specifications 4

1.2 Characteristic Strength 4

13° Weld 4

14 Ribbed Fabric 5

15 Rust 5

2. Fabric

24 Standard Fabric

o

6-7

22 Special Fabric 8-11

23 Twin Wire Fabric 12

24 Staggered Fabric 19-14

* Basis of Staggered Fabric - Curtailment of Bars 5

* Applications of Staggered Fabric 16

25 — Engineered Fabric 7

** Applications of Engineered Fabric 18

4, Building Code Requirement

41 Bend 20

42 Anchorage 20

43 Laps 21

4.4 Anchorage of fabric used as links ral

4.5 — Spacing of Renforcement 22

4.8 Minimum Reinforcement in slab 22

4.7 Deflection ‘ 22

5. Design

5.1 Subsiitution of Steel Reinforcement 23-24

5.2 Design 25

+ One way stab 25-34

+ Two way stab 25-34

* Flat slab 25-34

+ Pad Footing 35-37

5.3 Shear Wall Fabric Detailing Example 38-39

6. Non-suspended Slabs and Pavements on the Ground _

* Crack Control 40

Technical

Brisk Steel Products Sdn Bhd

Handbook

Brisk Steel Products Sdn Bhd (BSP) was incorporated in 1980. BSI

a subsidiary of the

listed Southern Stee! Bethad, and is the leading stee! fabric manufacturer in the country with

its production plants strategically located in Klang, Prai and Pasir Gudang,

Equipped with electronically controlled welding machines with distinctive welding features,

the company has broadened its fabric types into Engineered Fabric in addition to the conventional

standard fabric.

‘As one of the largest specialist fabric producer, BSP is a leader in innovation and development

in ts fields of specialization.

Disclaimer

itis desired to make clear that whist Brisk Stee! Products Sdn Bhd does the best to ensure that any advice,

recommendation or information i may give is accurate, no lability or responsibilty of any Kind (including lablity for

rnagigence) is acoapted by the company, is servants or agents inthis respect.

Technical Handbook

Preface

‘Welded wire fabric is a prefabricated sheet consisting of a series of high-strength wires welded

together in square or rectangular grids.

The smaller diameter, more closely spaced wires of welded wire fabric have proven to provide

more uniform stress distribution and more effective crack control in slabs and walls as compared

to larger-diameter rebars. The wide range of wire sizes and spacing available makés it possible

to furnish almost exactly the cross-sectional steel area required.

‘The ease and speed with which welded fabric can be handled and installed considerably

reduces placing time and consequently reduces the cost of the installed reinforcement.

Reduced construction time is of particular benefit to the owner allowing earlier occupancy of

the structure, hence reducing total construction cost.

This manual provides welded wire fabric product information, material specification, design

‘and dealing requirements, and various tables and design aids for design engineers and those

Involved in the construction of reinforced conerete structures.

Technical Handbook

1.Specification & Material

Properties

1.1 Specification

‘The Standards & Industrial Research Institute of Malaysia (SIRIM) publishes specifications for steel wire and

welded steel fabric.

‘The appropriate Malaysian and also British Standards are given in following table :-

Standard Title

Ms 144: 2001 ‘Specification for Cold Reduced Mild Steel Wire For the Reinforcement of Conorete

BS 4482 : 1988

Ms 145. : 2001 Specification for Welded Stee! Fabric For the Reinforcement of Concrete

BS 4483 : 1998

1.2 Characteristic Strength

MS 144 and MS 145 stipulate the minimum requirement for characteristic yield strength of welded fabric

Grade Min. characteristic strength

Nimm2

485

500

1.3 Weld

Welded stee! fabric is manufactured with automatic welding machines, where wires are welded together in

square or rectangular grids.

‘The weld is formed by a controlled combination of pressure, intensity and duration of electric current to

develop a fusion of the wires.

Welded steel fabric utilizes welded intersections for bond and anchorage.

Technical Handbook

1.4 Ribbed Fabric

Ribbed Fabric has been widely used as reinforcement for concrete structures in Malaysia and many developed

countries.

‘Advantages of ribbed fabric are

+ higher bond and anchorage characteristics ofits ribbed wire

ribbed wite is cold-rolled produced - the rolling process give rise to uniform plastic flow in the material

‘The results - more consistent properties and better ductility

‘+ crack widths in concrete elements are controlled to the

through bond effect of ribbed wire as compared to plain wire.

:

eee

1um because force is well distributed

) 1.5 RUST

BS 8110 Clause 7.4 Surface Condition states

“Reinforcement should not be surrounded by concrete unless its free from mud, oll, paint, retarders, loose

rust, loose mill scale, snow, ice, grease or any other substance which can be shown to affect adversely the

steel or concrete chemically, or reduce the bond. Normal handling prior to embedment in the concrete is

usually sufficient for the removal of loose rust and scale from reinforcement."

Loose rust is removed during handling and shaking of reinforcement. It is not advisable to strike the

reinforcement.

Any surface rust which remains on the fabric is not harmful and will increase the bond and anchorage

Properties of fabric. Wire brushing is unnecessary and may reduce the bond on plain steel wire.

Technical Handbook

2.Fabric

© 2. Standard Fabric

The preferred fabrics are categorised as follows:

Tyee A square fabric - 200 x 200 mm spacing

Type B rectangular fabric - 100 mm main wire spacing

200 mm cross wire spacing

Typec long fabri - 100 mm main wire spacing

4400 mm cross wire spacing

‘pe D small square fabric- 100 x 100 mm spacing

BSP Standard Fabrics are shown in Table 2.1. Standard fabrics could be selected from this table.

+ [Example]

area of steel requited

a slab design specify B10

main direction 769 mm*im 785 mm"/m

192 mm‘im 252 mmm,

“from BSP Standard Fabric Table 2.1, select fabric B10.

Table 2.1 BSP Standard Fabric

SQUARE FABRIC

An3 664 664 13 13 200 200 10.43

ar 566 566 2 12 200 200 889

At 478 475 1 1 200 200 746

Ato 393 999 10 10 200 200 16

Ag 318 318 8 8 200 200 4.99

AB 252 252 8 8 200 200 3.95

AT 193 193 7 7 200 200 3.02

AG 142 142 6 6 200 200 222

AS 98 98 5 5 200 200 154

013 1927 1327 13 13 100 100 20.86

or 1131 1131 2 12 100 100 1278

bit 950 950 " 1" 100 100 1491

D10 785 785 10 10 100 4100 1282

be 636 636 9 9 100 100

be 503 503 8 8 100 100

D7 385 385 7 7 100 100

Ds 283 283 6 6 100 100

Ds 196 196 5 5 100 100

RECTANGULAR FABRIC _ 2 S

B13 1928 399 13 10 100 200 13.50

B12 1131 252 2 8 100 200 10.90

Bit 950 252 " 8 100 200 9.43

B10 735 252 10 8 100 200 and

Bo 636 252 8 8 100 200 697

Ba 503 252 8 8 100 200 593

87 385 193 i 7 100 200 453

BS 283 193 6 7 100 200 “373

BS 196 193 5 7 100 200 3.05

cr 1131 128 12 8 100 400 987

on 950 128 " 8 100 400 44

cro 785 n 10 6 100 400 6.72

ce 635 7 8 6 100 400 5.55

ce 503 49 8 8 100 400 434

c7 385 43 7 5 100 400 341

| ce 283 49 6 5 100 400 261

Teennicat Handbook

2.2 Special Fabric

BSP Special Fabric offers designer a wider range of fabric selection to match closely to area of steel required

in design, hence provides a more economical solution,

BSP Special Fabri

standard fabric table.

give the combinations of wire diameter and spacing which are not in the range of

Most commonly used Special Fabrics are tabulated in Table 2.2, Table 2.3 and Table 2.4

Notation for special fabric :

spacing code - Main wire diameter / Cross wire diameter

spacing code Wire spacing ( mm)

Main Cross

A 200 200

B 100 200

D 100 100

{for example: B 8/7 denotes special fabric of

* diameter 8mm wire at 100 mm spacing (main direction.)

+ diameter 7mm wire at 200 mm spacing (cross direction.)

Where standard fabric could not provide an economical design, the designer should specify special fabric.

How to select Special Fabric

* Using similar example as in Section 2.1 (Standard Fabric)

area of steo! required in a slab design B10 e107

main direction (mm/m) 769 785 785

distribution direction (mm/m) 192 252 192

designer should specity B10/7 (7.68 kg/m?) from Table 2.4, which is more economical than B10

(8.14 kgim?).

Technical Handbook

Table 2.2 Special Fabric - A series

© SQUARE FABRIC

[ane [es] sss [me |e] a0] ao 388

{ ANII1 664 475 13 " 200 200 8.94

| ww | ose | ae | cs | | 20 | am 3c. |

wap | cet | oe | we |e | am | am mm

woe | ee | as | a | 8 | 2m | 200 ze

aon | ses | as | te | a | 200 | 200 sar

wana | ses | os | 2 | wo | ao | 200 753

| wan | sas | aw | | 0 | 200 | 200 | me

| wae | ss | at | oe | 8 | om | ooo 342

| war | sas | me | tz | 7 | mo | 200 395

| amo | as) owe | ot | | ao | aon sa

ann | as | ow | on | 9 | 20 | mo | eas

ave | as | oan | ot | 8 | oe | oo 57

| om | as fw | on | | a | amo 524

| ome | as foam | on | 8 | oo | amo so4

mae | oo | or | w | 0 | 200 | 200 ss

moe | ox | an | i | 5 | oo | 20 508

wo7 | ov | we’ | w | 7 | am | am | 400

| moe fw | es | ow | 8 | om | oo “0

soe | ow | on | 0 | @ | am | am san

| ASIT 318 192, 9 7 200 200 ag

soe | ow | a | ce | 6 | am | am ast

| nar | at | ee | 8 | 7 | om | om suo

ee 3.08

| we | we | mt | 7 | 6 | a | 200 ace

Technical Handbook

Table 2.3 Special Fabric - D series

re Diam

(mm)

‘SMALL SQUARE FABRIC

oie | wer | nar |v 2 | 100 | 100 98

Diaitt 1327 | 950 | 13 it 10 | 100 1789

piano | tar | 7s] 0 | 10 | 100 1689

Drae ter | x6 | 13 9 ro | 100 1542

Disi8 wer | 03 | 13 8 100 | 100 sr

pian nat | es |e i 10 | 100 1695

vino | war | 75 | te 1% | 10 | 100 1505

oi20 nar | ee | 2 9 10 | 100 1288

pias nat | soa |e 8 100 | 100 1283

pier nat | a5 | 2 7 10 | 100 niet

ono wo | 7s | on w | 10 | 100 1368

Divi so | cs | ot Q 10 | 100 1246

one eso | 50g 1 8 10 | 100 tat

p17 so | 965 i 7 10 | 100 1043

owe so | am | it 6 100 | 100 968

108 7s | ee | wo ° 10 | 100 17

Dios mes | soo | 1 8 100 | 100 0.12

pio 7s | 0 | 0 7 10 | 100 918

Dro ms | zo | 10 6 10 | 100 839

bee eos | 509 8 8 to | 100 ao

a7 e3s | 38s 8 7 roo | 100 a0

ae cas | 28s ° 6 10 | 100 722

a7 soa | 38s 8 7 to | 100 eer

Dave sos | 289 8 8 10 | 100 ear

| ore ass | ass 7 6 10 | 100 524

Technical Handbook

Table 2.4 Special Fabric - B series

pists | wor | os | i | ® | wo | 200 1864

siz | sor | ses | te | 2 | 100 | 200 user

sian | azar | as | | on | 00 | 20 1416

sisio | wor | a | 1s | 1 | 10 | 200 1351

piso | tr | oe | as | 9 | wo | 200 1292

(erane | or | ses | 12 |e | 100 | 200 1992 |

ain =| nor | as | vz | on | 100 | 200 re

sino | wat | om | 2 | 1 | 100 | 200 97

pio | nat | oe | 2 | 2 | 10 | 200 noe

BI2Z7 1131 192 12 7 100 200 10390 |

|

awn | 950 | as | om | or | 100 | 200 ‘20

anno | 90 | om | | 1 | 100 | 200 1055

ae | 00 | ow | 1 9 | 10 | 200 99

an7 | a0 | we | on 7 | 1 | 200 ase

aie | oso | ua | 6 | 10 | 200 as7

sor | 75 | a | w | 1 | 100 | 200 025

swe | 75 | ow | wo | 9 | 100 | 200 67

aor | 7s | we’ | wo | 7 | 0 | 200 703

soe | 7s | wm | wo | 6 | so | 200 728

899 os | ow | 9 s | 10 | 200 749

897 cs | w2 | 9 wo | 200 est

396 m | 8 6 | 1 | 200 en

837 so | i | e 7 | 10 | 200 sao |

336 so | m | s e | 1 | 20 5.08

876 ws | mw | 7 6 | wo | 200 ans

er mo | m | 6 6 | 1 | 200 a8

n

Technical Handbook

2.3 Twin Wire Fabric

‘Twin Wire Fabric consists of two main wires placed side by side welded to single cross wire. This fabric

configuration gives 4 larger cross sectional area of main steel

Common main wires spacing are 100mm, 150mm and 200mm. Other spacings are also possible. To specify

‘Twin Wire Fabric, the designer may consult BSP Technical Department for advice.

‘Twin Wire Fabric can be used in raft foundation, basement slabs, flat slab, etc.

Notation for Twin Wire Fabric:

In the example shown below, fabric B8 (2) /9 denotes:

* Two mm wires at 100mm main spacing,

* One Smm wire at 200mm cross spacing.

+ Bidenotes spacing code of 100mm (main), 200mm (cross)

* 2) denotes twin wire

us Baee

e Ls pacerre

| ‘MAIN DRAIN (TYPE_D

com |

prt ice |

fe tue VOR | ER

eae

|

leae] | a

nal =

| eee] Oe ea]

em] aan

Technical Handbook

» 2.4 Staggered Fabric

A

fond zone middle zone end zone

In Staggered Fabric, main wires are arranged alternately in staggered manner.

wil give 100% area of steel at the middle zone of the sheet and 50%

arrangement of wires

area of steel at both ends.

‘Staggered fabric is cost effective due to the following reasons

it offer great steel savings as its steel cross section area could be arranged in zone corresponding to

the zone of force direction.

* curtailment of reinforcement can be readily manufactured in factory.

one-layer large surface reinforcenent sheet could be used instead of having two layer of standard

fabric to achieve curtailment patter. Placing speed is much faster.

element of Staggered Fabric

Line Wire Single and/ or double wires.

Mixture of long and short wires

Could be of different diameter.

Diameter - 6 to 13 mm

Cross Wire Only single wire. Same diameter.

Diameter - 6 to 13 mm

Fabric length up to 12m. (Longer fabric is available upon request)

Fabric width Up to 2.4 m (Wider fabric is available upon request)

413

14

Staggered Fabric

Technical Handbook

Staggered Fabric could be defined numerically according to fabric notation.

Notations for Staggered Fabric:

for Standard Fabric

Standard Fabric Reference - Staggered Length

10 - 500

denotes :

410 mm main wire at 200mm spacing

410 mm cross wire at 200mm spacing

500 mm staggered length at both ends

for Special Fabric

Special Fabric Reference - Staggered Length

BaT-425

denotes :

8 mm main wire at 100mm spacing (at middie)

7 mm cross wire at 200mm spacing

425 mm staggered length at both ends

‘The suffix (number) after fabric reference denotes staggered length at both ends and must be specified.

Technical Handbook

Basis of Staggered Fabri

‘The reinforcement designed to resist the maximum bending moment in a member can often be reduced over

the regions where the moments are smaller. This is achieved by curtailing some of the bars at appropriate

points. The rules governing curtailment of bars are stated in Clause 3.12.9 of BS8110.

‘The general rule is that ina flexural member every bar should extend beyond the point at which itis no longer

required for a distance at least equal to the greater of

* the effective depth of the member, or

. 12 times the bar size.

However , The codes also gives simpitied rules for curtalment of reinforcement for beams and slabs in clause

8.12.10. and 3.12,10.8. See figure below.

| ous

| [Pres

san, pore |

ete L.. 4

Technical Handdook

Applications of Staggered Fabric

‘Staggered Fabric could be used with considerable steel savings in

top steel over support beam in slabs

RC U-Drain and culvert

‘Typical Section of B.C. Drain ‘Typical U-Bend Staggered Mesh

‘Top steel over support beam

Technical Handbdook

_) 2.5 Engineered Fabric

Engineered Fabric is specially configured to suit certain specific design requirements. Engineered Fabric

could not be defined with fabric notation. Each sheet requires a fabric configuration dt

Engineered Fabric in single or double wires are illustrated below.

. Examples of

With these special fabric configurations, a more economical design could be produced.

‘The designer may consult BSP Technical Department for advice.

|

Dra |

MESH 160-RE 12/8 (5080 X 0.94)

WEIGHT/ SHEET - 34.07 KG

Engineered Fabric Configuration Drawing

18

Applications of Engineered Fabric

Tochnicat

Handbook

Engineered Fabric could be used with considerable steel savings in almost any reinforced concrete structures,

such as’

R.C.U-Drain

top steel over drop panel in flat slab

prefabricated cages:

raft foundation

a aes

t

4

v

ecb LE

Technical Hanandook

3. Bar - Mat

Bar Mats are prefabricated steel sheets consisting of a series of HIGH YIELD BAR welded together with

small diameter cross WIRE.

‘The cross wires are purely carrier wires used to form a rigid assembly and are spaced typically at 1000 mm

centre to centre. The exact spacing varies according to design requirements.

if main steels are needed in both directions, bar mats can be laid at 90 degree to each other. See figure

below.

‘The use of scheduled or detailed types of mats can offer further economies in material quantities. Bar mats

can usually be placed by two people, without using crane.

element of Bar - Mat

Main Bar single high yield bar.

Could be of different diameter.

Diameter - 16 to 25mm

Cross Wire used as cartier wire (non - structural)

Diameter - 6 to 10mm

Length up to 12m. (longer mat is available upon request).

Width up to 2.4m (wider mat is available upon request)

Length

‘ofmain bare

Longth of

Carer wie

100 tel 1 100

i

‘Typical bar mat layout in slabs.

Technical Hangnook

4. Building Code Requirements

in relation to Welded Steel Fabric

PROVISION BS 8110

Clauses

4.1 Bend anze2e

End anchorage in the form of hooks and bends should only be used to meet specific

design requirements.

Typical bends

unm WIRE

cross wine

Single Bend Double Bend

| 4.2 Anchorage 3.128

Table 3.29 |

The force in a reinforcement bar at a section can only develop ifthe bar has, on either

side of the section an appropriate embedment length of anchorage

Values for anchorage lengths are given in table 3.29 as multiples of bar size.

Generally, two welds are sufficient for welded fabric.

20

Technical Handbook

PROVISION

BS 8110 ©

Clauses

4.3 Laps 3.12.8.18,

Table 3.29

‘Tension laps 8128.15

‘Tension lap length should be at least equal to the design tension anchorage length

necessary to develop the required stress in the reinforcement.

Compression laps

The length should be at least 25% more than the compression anchorage length.

In the detailing of stee! fabric, two cross welds are provided to transfer the stresses.

In sidelaps of one-way slabs, half yield strength laps with overlap of only one cross |

weld are acceptable. This is commonly used in top (negative) reinforcement.

Full yield strength lap should always be provided when lap length is not specified,

evan 4

tet |

|

full yea strength tp hal yield strength laps

| 4.4 Anchorage of fabric used as links

A Link may be considered to be fully anchored when it has within the length of the | I

anchorage, elther two welded transverse (cross) wires or a single welded wire of a |

size not less than 1.4 times the size of the wire being anchored,

22

Technical

PROVISION

4.5 Spacing of reinforcement

The code recommends minimum distances between bars to avoid congestion of

reinforcement and the consequent difficulties in properly placing and compacting

concrete. The minimum clear distance between bars should not be less than (hagg

+5 :mm) or the diameter of the bar, where hag is the maximum size of the coarse

aggregate.

For maximum spacing requirements in slabs, the clear distance between bars should

not exceed the lesser of 3d or 750 mm,

4.6 Minimum reinforcement in slabs

Sufficient reinforcement should be provided to control cracks in the concrete.

The minimum steel requirements are specified in Table 3.27 :

a) forfy=250 0.24% of gross concrete area

b) —_forfy= 480 or higher 0.13% of gross concrete area

4.7 Deflection

Deflection is considered as a serviceability limit state. BS 8110 Part II deals with

serviceability calculations in details. However, instead of working on the actual

detlection, the code allows the checking of ratio of the effective span’ effective depth

(Ud ratio) by deemed-to-satisfy provi

Table 3.10 gives the basic effective span/ effective depth ratio and where appropriate

the value should be modified by using values from tables 3.11 and 3.12

In general, the higher the stress in the steel, the higher the deflection. Compared to

usage of high yield bars, fy = 460 N/mm2, steel fabric (because of fy = 485 N/mm?)

gives higher deflection, in the region of 2.5% to 5% higher.

Hand

BS 8110

Clauses

3.42.44

3.12112

3.125

Table 3.27

Table 3.10

Table 3.11

Table 3.12

book

DO

5. Design

Technical Handbook

) 5.1 Substitution of Steel Reinforcement

BSP Fabric could substitute conventional steel bars in structural concrete members because the structural

analysis and design is in accordance with standard code of practice such as BS 8110. However, the main

differences are:

+ the steel yield stress fy for steel fabric is usually 485 Nimm2 as compared to 250 N/mm2 for mild stee!

bars and 460 N/mm for high yield bars.

‘+ serviceability limit state because of higher yield stress used in fabric design

Conversion Formula

To find equivalent fabric area, the general conversion formula is:

Asreq area of steel bar required in design (mm2/m)

A fabric = At

ee ‘yar yield strength of steel bar in design

(.9.250 Nimm2 for mid steel bars,

+460 Nim fr High Yield bars)

‘yteoie yield strength of fabric (eg. 485 Nimm2)

| mild steel bar (fy=250 Nimm?) high yield bar (fy=460 Nimm?)

460

A fabric

For easy reference, conversions of common bar diameter and spacing are tabulated in Table 5.1 and 5.2

Suitable fabric reference could be selected from fabric table based on converted equivalent steel area.

23

Technical Handbook

bar sizo | a

100 1251801750025 2507300

RIO CE ne

fabric 4059242701080 6218S

Ria bar 1131-905. ~=«754~=~=C«AS*«CSSC*«COSSC*«SSSCTSSC*C«T

fabric 5834689893339 33th

Rie bar 201 1608 ~—~+1340~«1T49~=~«SNO0S~=~=~«COSCSC*COSSCSCSSCSC«CW TON

fabri__ 1038629812518 1S 3778S

20 bar 31422513 20941795 1571 1206 1257 1142 1047

fabric 1619 1296 = 1080-92510

Table 5.2 Equivalent steel area for High Yield Bars (

Pere Spaci

100125180175 225 250275300

To a a a me StS

fabric 745 596497426 sai 208 at 2a

Te a 50s 452~~*~C«SCSCST

fabric 1073858715613. a7 429390358 |

Tie bar 201 1608 ——~«1940~—~—~«1149 Boe 804—~SCBTSC TO,

fabric __1907__1526__1271__+1090 gas 763683636

T20 bar 3142-2513 2094 1795 1398 1257 11421047

fabric 2080238419 1

3324192108499

‘Note:Cross sectional area in mm2im width. Numbers shown in bold are equivalont area in fabric.

[example

main distribution

reinforcement bar specified 716-250 T10-300

* area of steel (mm?) 804 262

+ equivalent area in fabric- (Table 5.2) 763 288

* select B10 (Table 2.1) 785 251

“The designer could spectty fabric B10 selected from Table 2.1

‘Altematively, corwersion formula could be used

24

» 5.2 Design

* One-way Spanning Solid Slab

The code states in Clause 9.5.2.4 that where the spans of the slab are approximately equal and

conditions set out in Clause 3.5.2.3 of BS 8110 : 1997 are met, the moments and Shears in continuous

one-way spanning slab may be calculated using the coefficients given in Table 3.12.

The curtailment of reinforcement designed in accordance with Table 3.12 may be carried out in

accordance with provision of 3.12.10.8 and Fig. 3.25 of the code.

‘The design of one-way spanning slab by using coefficients in Table 3.12 of BS 811

in Example 5.1

* Two-way Spanning Solid Slab

The design method adopted by BSP for two-way spanning slab is based on BS 8110: 1997 section

3.5.3. The bending moments and shear force coefficients are given in Table 3.14 and Table 3.15 of

the code respectively

The reinforcement is to be detailed in accordance with the simplified rules for curtailment of bars in

slabs given in section 3.12.10.3 and shown in Fig. 3.25 of the code.

‘The design of two-way spanning slab by using coefficients in Table 3.14 and 3.15 of BS 8110 : 1997

is ilustrated in Example 5.2.

* Flat Slabs

‘The flat slab is defined in BS 8110 : 1997 Clause 1.3.2.1 as a slab with or without drops, supported

generally without beams by columns with or without column heads.

‘The design of flat slab is covered in BS 8110 : 1997, section 3.7. The slab reinforcement is designed

to resist moment derived from Tables 3.12 and 3.18 of the code. Reinforcement can be detailed in

accordance with the simplified rules given in Clause 3.12.10.3 and Fig.3.25 of the code.

The design of internal panel by using simplified method as stated in Clause 3.7.2.7 of the code is

illustrated in Example 5.3.

‘technical Hanedook

Technical Handbook

Example : 5.1

| PRINTED ON 2 13-Jun-03

| DISKETTE/FILENAME

| Example

| a) Fy, STEEL = 485 Nimm?

' 'b) CONCRETE GRADE = 25 Nim?

| cover-sorrom 18mm |

| TOP 15 mm |

| |GRID LINE

| [SLAB NO st

PLOAOING™ |

rickNess nr 1a |

JFINISHES, (kN/m?) 1,00

|PARTITION, (kNim? ) 1,00

| |eaD Loa, (wm?) 5.00 |

|IMPOSED LOAD, (kNim?) 3.00 }

40.44. 6LL ain) 1180 |

lewority im) 1000

|WIDTH, Lx (m) 4.00 |

tx 250 |

err ocr. o-80T70M 10s

(mm) TOP 40s

|8.M COEFF/B. MOMENT Coefi__kNm_| Coe kNm | Coeff kNm | Coeff __kNm |

WMecootins® one | crs tae |

| +My 0.000 0.00] |

mw | 0008 1624 |

My 0.000 0.00] |

[AREA OF STEEL mati, REQD prov | REQD PROV | REQD PROV | REQD PROV |

Min Asto.19%6BH 163 \

| Jastap.m0.95« +a 312509] |

asd) oy 0 2a

| x | et 3a |

| ever ARM. Ay o 166) = |

|

| [Gace DertecTOn BS SiO TABLESIO |

Serice Stress Ninn 700

|MIBD? 1.28 |

Mex, Factor 101

| Atiowabie span, m 438

| [bertection ok.

BSP PROVIDED |

‘BOTTOM Xenis 22

vans

ror Kas ator

ans 295

Notes: Axdy denotes dia, x mm main wite@200em spacing de and dia. ymm cross wre@200mm spacing oe

B nly denotes cia. xmm main wire@100mm spacing cle and gia. y mm cross wire@200mm spacing cle

DA wy denotes dia. xmm main wire@ 100mm spacing cle anc dia. y mm eross wire@100mm spacing cle

26

Handdook

Technical

Ly=10000

SECTION A-A

Example : 5.2

Hange

PRINTED ON Jun 13, 03

DISKETTE/FILENAME

PROJECT Example

9) Fy STEEL, = 485 Nimm2

D)CONCRETEGRADE = = «25 Nimm2

COVER-BOTTOM = 18mm

Top = 8mm

[eri une

[SLAB NO.

LOADING?

[THICKNESS\h (mm) 108

FINISHES, owim2) 100

JPARTITION, (ktuen2) 4.00

JOEAD LOAD, (kNIm2 ) 5.00

IMPOSED LOAD, (kNim2 ) 3.00

4. 40L+1.6LLw (kn) 4180

JLENGTH.Ly (m) 6.00

lwioTe.Lx(m) 400

Lyx 150

|EFF DEPTH 0-BoTTOM 108

(mm TOP 105

[EM COEFFI MOMENT ‘Goat iim | Coott kim | Cooft iim | Coeff im

Jesse 7

ee

avy | 9028 529]

mx | 0058 1095]

-wy | 0037 al

JAREA OF STEEL main REQD PROV | REGD PROV | REGD PROV | REGD PROV.

Min et. 0-13%66H 16

Ast=B. (0 85x he a7 189i

4851.20) shy 27133]

~ 238 252 rr

La=Lever ARM Ay 12168 =

[HECK DEFLECTION BS SIOTABLE S10

Service Stress,Nimm2 2

lwe02 o74

Mod, Factor 147

JAlowable span, m 402

DEFLECTION OK

jasP PROVIDED

“BOTTOM Xeie ar

Y aie

sT0P Kans aa

Y avis 265

Notes A xy denotes da, x mm main wre@20Gmm spacing oe and da. y mm otoss wre@200nm epacing ce

Buy denetes dia xm main wiro@!00mm epacing cle and da. y mm cross wire@200mim spacing cle

DA wy denotes di, x mm main wire@100%mm spacing cl and da. y mm cross wire@@’ 100mm spacing cle

Technical Handbook

®

y= 6000

Section A-A

Section 8-8

30

Example

Example given below is for illustration purpose oniy.

FLAT SLAB DESIGN - INTERNAL PANEL,

Column with, Ly 600 mm

Drop panel width = 2660 mm

Panel length, 8000 mm

Panel length, Ly 8000 mm

Concrete grade, t,, 30 Nimme

Stee! Yield strength , 485 Nimm?

Conerete cover = 25 mm

Slab thickness, h = 250 mm

Drop pane thickness 200 mm

Effective depth at drop 410 mm

Effective depth at slab = 240 mm

Loading :

Dead load = 6.59 kNim2

Fishes 1.00 kNim?

Parton 0.00 kim?

Imposed load 5.00 kNim2

Uttmate design load, n 18.54 kNim?

Loe = 2680 mm

From Table 3.12, BSB110: 1097

Firs Interior Support,

Moment, M . 753.59 kNm

CConier of Interor Span

Moment, M 552.00 kNm

Interior Support,

Moment, M . 52.00 kNm

Distribution of design moment, able 8.18, BS8110 : 1997

CENTER OF INTERIOR SPAN

Moment, M 552,00 kNm

With of column stip - 2660 mm

Widta of middle strip 5340 mm

Proportion of moment = 0.60

taken by middle strip

Proportion of moment

= 040

taken by column strip

Middle strip positive moment 33162 kNm

Column strip positive moment 220.39 kNm

Technical

Bars dia

Handbook

10mm

4900 mm

Continue

For Middle Strip:

Moment, M

K=Mibd#t,,

Z= of0'54(0.25-K00.9)"2)

0.84

Use z

As = M0.95,z =

Ag min (0-1801/100)

Provide 2 layer of D10, As

For Column Strip:

Moment, Mt

K=Mibg,,

Z = d[0.5+(0.25-K00.9)!]

o.986

Usez

As = M0.981,z E

Provide 1 layer of D11, AS

INTERIOR SUPPORT

Moment,

Width of column strip

Width of middle strip

Proportion of moment

taken by middle strip

Proportion of moment

taken by column stip

Middle strip negative moment

Column strip negative moment

For Middle Strip:

Moment, M

K= Mba,

Z = dl0.5+(0.25-Ki0.9)"2]

095d

Use z

As = M0.9512

Provide 1 layer of 010, As

For Column Strip:

Moment, M

331.62 kNm

0.0469

198.41 mm

199.50 mm

198.41 mm,

3628 mm?

679 mm? /m

325 mm? /m

1870 mm? /m

220,39 kNm

0.0628

194.20 mm,

199.50 mm,

194.20 mm,

2463 mm?

1928 min? im.

950 mm2 fm

1552.00 kNm

2860 mm

5340 mm

0.33

067

184.23 KNm

36777 kNm

184.23 kNm

0.0261

203.73 mm

199.50 mm

199.50 mm,

2004 mm?

375 mm? /m

393 mm? /m

96777 kNm

0274

39710 mm

389.50 mm

389.50 mm

2049 mm?

770 mmr? jm

Technical

Hangs

4000 mim

Technical Handbook

Continue

siavacrnsiarnnanana|

Two third ofthe rilorcoment should be placed win canter half ofthe column stip. (Clause 2.73.1) |

218 As 1366 mm?

4027 min? fm

Provide 2layer of D9,As = 4272 mm? /m

PUNCHING SHEAR CHECK

‘Atcolurmn head

Perimeter, u = 2400 mm

Shear, V = 1180.07 kN

‘To allow forthe effects of moment transfer, Vis increased by 15%, (Clause 3.76.2)

Effective shear, Ver = 1957.08 kN

Shear stress, = 138 Nimme

<__ lesser of 0.8(f,)"? or 5 Nimm? oK

For fist etical perimeter 15d trom column face.

Perimeter, 7320 mm

Shear, V 1124.65 kN.

Effective shear, Vey 1293.35 KN

Shear stress, Vv 043 Nimm?

Concrete stress, Ve 0.48 Nimme > 0.43.Nimm? OK

At drop panel:

Perimeter, w = 10640 mm

Shear, V = 1055.55 kN

Effective shear, Voq 1213.88 kN

Shear stress, V 0.54 Nimm?

< lesser of 0.8(f)"# or 5 Nim? ok

For first ertcal perimeter 15d from edge of drop panel.

Perimeter, u 49160 mm

Shear, V 986.04 KN

Effective shear, Veg 1133.94 kN

Shear stress, ¥ 0.41 Nim?

Concrete sires, Vv 0.67 Nimm? > 0.41 Nim? OK

DEFLECTION

‘The calculation are made for the middle strip using total moment at mid span and the average of column and

middie strip tension stoo!

‘Span moment, M

552.00 kn |

Mpg 156

AAs, req, £803 mm? fm

As, prov = 1260 mm? /m

Service stress, f, 205.97 Nimm? |

Modification factor = 147 < 20 OK

From Table 3.9,BS 8110 : 1997

Basic Lid = 26

Limiting Lid 38.13 |

Actual Lid = 38.10 < 38.13 OK

SET

Technical Handbook

ont

JA _ peace _A

T

on

ove

UB | oat | o ante See ot || of | Bl

to jes)

BOTTOM FABRIC |

a | ae |

UA. ! ae wo || ae - |

soe Se

1B a 7 "0

|e = — |

| mn ra eae

at ail oa

L—

TOP FABRIC

ue 0%

Section 8-8

‘peehnical Handbook

© Pad Footing Design

‘The design of pad footings is covered in BS 8110 : 1997, section 3.11 Bases. The size of a foundation bearing

directly on the ground depends on the safe bearing pressure of the soil, which is taken to mean the bearing

pressure that can be imposed without causing excessive settlement. In general, site load tests and laboratory

tests on soil samples should be carried out to determine soil properties for foundation design.

‘The design loading to be considered when calculating the base areas should be those apply tothe serviceability

limit state whereas

the design to determine the structural strength of the bases, that is the thickness of

the bases and the areas of reinforcement, should be based on the loading and the resultant ground pressures

corresponding to the ultimate limit state.

Assumptions to be used in the design of pad footings are set out in Section 3.11.2 of the code.

‘The design of axially loaded base in illustrated in Example 5.4.

ee

®

@

ol

Example

Technical

Bars dia

Effective depth,

Handbook

10 mm

450 mm,

213 of the required reinforcement should be placed within a cistance 1.5d each from the face of column, (Clause 8.11.2)

DESIGN OF AXIALLY LOADED PAD FOOTING (BS 8110 : 1997)

Column dimension, Cy 0.40 m

Column dimension, Cy = 0.30 m

Dead load, Gk 800 kN

Imposed load, Ok 300 kN

Alloweble scil bearing capacity = 200 kNim?

Concrete cover, ¢ = 40 mm

Concrete grade, f, 35 Nimme

‘Steel Yield strength, 485 Nim?

Assume seltweight of footing 77 KN

Total service load 197 KN

‘Area required 5.89 m?

Base dimension adopted:

kk 250m

y 2.50 m

Thickness, h ‘500 mm

Utimate load, (14Gk + 160k) 1708 kN

Utimate pressure, n = 273.25 kNim?

Reinforcement Parallel to X-X Axis

Moment at column face, Mio = 876.57 kNm

K : 0.02125

z 498.11 mm

0.954 = 427.50 mm

Use z 42750 mm

As, req 1912 mm?

3C,/44ed4 = 128750 mm

ly = 1250 mm

> 80, /4+ 90/4

AAs, req = ‘772 mmetm

forcement Parallel to¥-Y Axis

Moment at column face, My 413.29 kN.

K 0.02382

z 498.02 mm

42750 mm

42750 mm

2098 mm?

4312.50 mm

Nex 1250 mm,

36, /4 + 904

Reinforcement should be uniformly distributed over Ioy. (Clause 8.13.2)

As, req = 1839 mméim

Provide mesh type: on

Asx = 950 mm&im

Asy = 950 mm®im

Continue

‘Shear Parallel to X-X Axis

Shear force, Vix

Shear stress, v =

Concrete stress, v,

‘Shear Parallel to ¥-¥ Axis

Shear force, Vyy

Shear stress, v

Concrete stress, v,

Punching Shear Check

‘At column face:

Perimeter, u

Shear force, V

Shear stress, v

444,03 KN.

0.39 Nimmé

0.42 Nim?

(0.99 Nimm?

409.87 kN

(0.96 Nimm2

0.42 Nim?

0.38 Nim?

1400 mm

1675.01 kN,

2.66 Nim?

lesser of 0.8(f,)° or § Nima?

For first crtical perimeter 15d from the column face:

Perimeter, u =

‘Shear force, V

‘Shear stress, v

‘6800 mm

918.80 kN.

0.30 Nimm2

le Nim?

on

fe

2500

+2 ____,

Section yy

0K

ok

oK

OK

Handbook

37)

Technical Handbook

5.3. Shear Wall - Fabric Detailing Example

at

act

SECTION 6-6

/ATION_OF Ws

Technical Handbook

ae

| gm

my | A 5

7 7 Vet T\7 V7 g

MY V/ VV 5

PN [pel] eV Se

" Zhe P\/ H

N K

‘on “apr \\r0-10| er || nome] u

a 4

wri,

ot

Ce

Es

re

=

He

= [se = BRISK STEEL

“ELEVATION OF WALL 25 a TO aera PRODUCTS SDN. BHD.

ABAD OF tL & ae Rect’

oures ve | BSP/a7e Se

6.Non-suspended Slabs and

Pavements on the Ground

SP Fabric is ideal for use as reinforcement in concrete slabs on the ground. Care is needed in the design

of these stabs. The following factors must be considered:

1. Load size and frequency.

2. Soll type under the slabs.

3. Presence of ground water.

4. Provision for drainage of surface water,

For heavily loaded trucks and for highway pavements, the structural engineer should cary out design of

slab. Similarly for warehouses where loads are not uniform or loads are unusually heavy, specialist advioe is required.

Eau nhae een tou

} Application Soil Slab Thickness Location and

| mm BSP Fabric

| Domestic-cars and foot traffic dry and stable 4100 top BSP_AS_|

needs compaction of base 110 top BSP_A7

Light industrial and commercial | dry and stable 125 top BSP_A7

| esmail trucks needs compaction of base 150 top BSP _Aé

Ware houses and pavements for trucks _dry and stable 150 top BSP Ag

| need compaction of base 200 top BSP AS |

bottom BSP A7

Crack Control

BSP Fabric will control the spacing and size of cracks that develop in the concrete due to initial shrinkage,

teimperature changes and minor soll movement. The anchorage provided at each welded joint is able to keep

any conerete cracks small and closely spaced.

AAt joints in the stabs dowel bars should be placed in the centre of the slab so that the two adjacent slabs

do not move vertically out of position (see below) A typical dowel arrangement for slabs up to 125mm thick

would be 18mm diameter dowel bars 600mm long spaced at 250mm centres. For slabs 150mm to 200mm,

thick, 18mm diameter dowel bars 800mm long spaced at 200mm centres could be used.

Dowel bar in oes

‘0mm from

cope ot as top of slab

Grease or wrap one

‘ond of Dowel bar

‘Typical Dowel Bar Arrangement

Steel Bar/Wire Cross-Sectional Area

Cross Se

S

[125 [150 |

echnical Handbook

jctional Area in mmm at

mm

[17s [200 [225] 260 275] 300_|

4 )

4

i

eile

ali

lt

an

i

i

:

|

j

i

+ Lot 269 Lorong Perusshaon, 12 Prandtl Estate, 19600 Pra, Perang. + Tet 04-999 8286/77 Fax: 04-300 8255

+ PLO.00 Jalan Ket Zone 10, Pasir Gudng, 81700 Johor Bharu. + Tek: 07-251 7770/2 Fax: 07-254 7769

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- LED Catalog2020Documento61 pagineLED Catalog2020VincentNessuna valutazione finora

- Ytl Life 32Documento63 pagineYtl Life 32VincentNessuna valutazione finora

- Sunway Alishan Master BrochureDocumento15 pagineSunway Alishan Master BrochureVincentNessuna valutazione finora

- Vital Technical Sdn. BHD.: VT-268 / VT-268GGDocumento10 pagineVital Technical Sdn. BHD.: VT-268 / VT-268GGVincentNessuna valutazione finora

- VT-268/ VT-268GG PU Foam: Vital Technical Sdn. BHDDocumento2 pagineVT-268/ VT-268GG PU Foam: Vital Technical Sdn. BHDVincentNessuna valutazione finora

- Southern Marina Residences Brochure 23x32 FADocumento9 pagineSouthern Marina Residences Brochure 23x32 FAVincentNessuna valutazione finora

- LGG 2 OnlineDocumento52 pagineLGG 2 OnlineVincentNessuna valutazione finora

- LGG 1 OnlineDocumento48 pagineLGG 1 OnlineVincentNessuna valutazione finora

- Perniagaan Yik Sing SDN BHDDocumento12 paginePerniagaan Yik Sing SDN BHDVincentNessuna valutazione finora

- Langkawi UNESCO GlobalDocumento17 pagineLangkawi UNESCO GlobalVincentNessuna valutazione finora

- Gpk2011 Geopark Emagazine 160522Documento32 pagineGpk2011 Geopark Emagazine 160522VincentNessuna valutazione finora

- Application Guide For Masterflow Epoxy Grouts: Masterflow 618 Masterflow 628 Masterflow 648 Masterflow 678Documento14 pagineApplication Guide For Masterflow Epoxy Grouts: Masterflow 618 Masterflow 628 Masterflow 648 Masterflow 678VincentNessuna valutazione finora

- Smart Automation System For Your Dream LivingDocumento21 pagineSmart Automation System For Your Dream LivingVincentNessuna valutazione finora

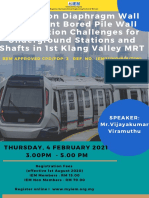

- WEBINAR - Diaphragm Wall and Secant Bored Pile Wall Construction Challenges For Underground Stations and Shafts in 1st Klang Valley MRTDocumento2 pagineWEBINAR - Diaphragm Wall and Secant Bored Pile Wall Construction Challenges For Underground Stations and Shafts in 1st Klang Valley MRTVincentNessuna valutazione finora

- Bored Piling Using Rotary Kelly Drilling KLCC Lot L&M, A New World Record in Bored Piling Has Probably Been Set Again in MalaysiaDocumento2 pagineBored Piling Using Rotary Kelly Drilling KLCC Lot L&M, A New World Record in Bored Piling Has Probably Been Set Again in MalaysiaVincentNessuna valutazione finora

- Delighting People With Smarter SolutionsDocumento14 pagineDelighting People With Smarter SolutionsVincentNessuna valutazione finora

- Half-Day Webinar On "Ground Improvement"Documento2 pagineHalf-Day Webinar On "Ground Improvement"VincentNessuna valutazione finora

- GETD 4febDocumento2 pagineGETD 4febVincentNessuna valutazione finora

- 2 Half-Days Webinar On Geotechnical Experience in 1st Klang Valley MRT ProjectDocumento3 pagine2 Half-Days Webinar On Geotechnical Experience in 1st Klang Valley MRT ProjectVincentNessuna valutazione finora

- Cement: GL BalDocumento68 pagineCement: GL BalVincentNessuna valutazione finora

- Webinar One Day Course On Project Schedule Management: Registration FormDocumento2 pagineWebinar One Day Course On Project Schedule Management: Registration FormVincentNessuna valutazione finora