Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Metric Fastener Data

Caricato da

David McCullaghCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Metric Fastener Data

Caricato da

David McCullaghCopyright:

Formati disponibili

notes:

a) Using coarse thread as standard

b) To give 60/70% thread engagement

c) To suit a 1.5D Helicoil

d) To allow 1.5D minimum thread engagement

e) To allow 1D minimum thread engagement

f) To allow for +/- 3mm casting variation plus repair by Helicoil

g) To allow for +/- 3mm casting variation plus repair by 'Tappex' type insert

h) From Shigley 'Mechanical Engineering Design' 1986 p293

i) Based on tightening to 70% of proof strength

j) Based a friction factor of 0.2

4.6

6.8

9.0

11.0

13.0

17.5

21.5

25.5

12

16

20

26

29

36

44

53

69

85

102

117

8

11

15

18

22

28

35

42

52

62

72

82

8.8

20

37

58

84

157

245

353

561

817

1121

1473

i)

Bolt preload (N) for grade 8.8

13

16

19

26

29

40

47

54

70

81

94

110

Area at Base of Thread (sq.mm)

14

18

22

28

30

42

48

56

72

86

104

118

3696

8400

15540

24360

35280

65940

102900

148260

235620

343140

470820

618660

Bolt torque (Nm) for Gr 12.9 - Copaslip/Moly

8

11

15

18

20

26

33

40

Bolt torque (Nm) for Gr 8.8 - Copaslip/Moly

6.4 3

8.4 4

10.5 4

13.0 5

17.0 6

21.0 6

25.0 8

31.0 10

j)

Bolt torque (Nm) for grade 12.9

17

23

28

35

45

50

60

68

j)

Bolt torque (Nm) for grade 8.8

0.8

1.6

1.6

2.0

2.5

3.0

3.0

4.0

4.5

6.0

Open Jaw Spanner Radius

4.3

6.4

8.4

10.5

13.0

17.0

21.0

25.0

31.0

37.0

Caphead Screw Counterbore Depth

9.0

12.5

16.6

21.0

24.0

30.0

37.0

44.0

56.0

66.0

Caphead Screw Counterbore Dia

3

5

6

8

10

14

17

19

22

27

Hardened Washer to DIN 6340 Thickness

4

6

8

10

12

16

20

24

30

36

42

48

Hardened Washer to DIN 6340 Min ID

7

10

13

16

18

24

30

36

45

54

Ring Spanner Diameter

3.0

4.2

5.7

7.2

8.2

10.2

13.2

15.2

19.3

23.3

26.3

30.3

Socket Diameter

3.2

5

6.5

8

10

13

16

19

24

29

34

38

45

48

95 105 51

105 116 58

11.5

15.0

19.6

21.9

27.7

34.6

41.6

53.1

63.5

75.1

86.6

h)

Spotface Diameter

7

10

13

17

19

24

30

36

46

55

65

75

85

90

Hardened Washer to DIN 6340 Max OD

15

21

25

31

35

44

55

66

80

94

109

123

Standard Washer Thickness

18

24

29

36

41

51

61

73

89

111

129

145

Standard Washer ID

Boss Depth (Steel)

16

20.5

25

30

34

43

52

61.5

75

88

101

115

132

140

149

165

Standard Washer OD

Boss Depth (Cast Iron & Aluminium)

15

19

23

28

30

36

44

51

63

74

86

100

111

117

123

133

Caphead Screw Hex Drive A/F

Boss Diameter (Aluminium)

5

8

10

12

14

19

24

29

36

43

50

58

Caphead Screw Head Thickness

Boss Diameter (Cast Iron & Steel)

8

11

14

17

20

26

31

36

45

60

70

80

9.5

13.5

17.5

21.0

24.5

31.0

l)

Caphead Screw Head Diameter

f)

Hexagon Bolt Head Thickness

f)

Nut Thickness

g)

Hexagon A/C

f)

Hexagon A/F

e)

Thread Depth Steel

9

13

16

20

23

29

37

44

54

63

73

83

d)

Thread Depth Cast Iron

10

13

17

20

24

30

36

42

52

68

79

90

c)

Drill Depth (Aluminium)

12

16

20

25

29

36

43

51

63

80

93

105

Drill Depth (Steel)

4.5

6.8

9.0

11.0

14.0

18.0

22.0

26.0

33.0

39.0

45.0

52.0

Absolute minimum drill depth (cast iron)

Drill Depth (Cast Iron)

4.10

6.20

8.30

10.30

12.40

14.40

20.50

24.75

30.50

36.50

Clearance Drill

3.40

5.20

7.00

8.80

10.60

14.50

18.00

21.75

27.25

33.00

38.50

44.00

k)

Tapping Drill for Aluminium - Helicoil

Thread

Diameter and

Pitch

M 4 x 0.7

M6 x 1

M 8 x 1.25

M 10 x 1.5

M 12 x 1.75

M 16 x 2

M 20 x 2.5

M 24 x 3

M 30 x 3.5

M 36 x 4

M 42 x 4.5

M 48 x 5

M 56 x 5.5

M 60 x 5.5

M 64 x 6

M 72 x 6

Tapping Drill Steel & Cast Iron

a)

Bolt preload (N) for grade 12.9

Standard Fastener Data Sheet

issue G July 07

i)

5975

13580

25123

39382

57036

106603

166355

239687

380919

554743

761159

###

3

10

25

49

85

211

412

712

1414

2471

3955

5939

5

16

40

79

137

341

665

1150

2286

3994

6394

9602

2

7

17

34

59

148

288

498

990

1729

2768

4157

3

11

28

55

96

239

466

805

1600

2796

4476

6721

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Manual Partes SD116-TFDocumento402 pagineManual Partes SD116-TFAntonio Carrion50% (2)

- Manual - Coriant 8615 Smart RouterDocumento46 pagineManual - Coriant 8615 Smart RouterFabricio FigueiredoNessuna valutazione finora

- (Bookflare - Net) - Cloud Computing Simply in Depth by Ajit Singh PDFDocumento135 pagine(Bookflare - Net) - Cloud Computing Simply in Depth by Ajit Singh PDFHaftamu Hailu100% (1)

- Template Invoice PartsDocumento1 paginaTemplate Invoice PartsDavid McCullaghNessuna valutazione finora

- Technomot Design PhilosophyDocumento1 paginaTechnomot Design PhilosophyDavid McCullaghNessuna valutazione finora

- Short TM PresentationDocumento10 pagineShort TM PresentationDavid McCullaghNessuna valutazione finora

- Technomot Brochure 2010Documento12 pagineTechnomot Brochure 2010David McCullaghNessuna valutazione finora

- Spike's Universal TruthsDocumento2 pagineSpike's Universal TruthsDavid McCullaghNessuna valutazione finora

- Describe The LaptopDocumento5 pagineDescribe The LaptopRowan SapladNessuna valutazione finora

- A1 PricelistDocumento9 pagineA1 PricelistIveta NikolovaNessuna valutazione finora

- HMI and PLC Connecting GuideDocumento392 pagineHMI and PLC Connecting GuideThiago AbraaoNessuna valutazione finora

- ETC Console Shortcut Keys: Eos Family v2.4.0Documento2 pagineETC Console Shortcut Keys: Eos Family v2.4.0Nicholas CulmoneNessuna valutazione finora

- (AiboHack - Boneyard) RoboSapien V2 GutsDocumento3 pagine(AiboHack - Boneyard) RoboSapien V2 GutsRICHARDNessuna valutazione finora

- 1.1 Computer TerminologyDocumento7 pagine1.1 Computer TerminologyEver MontoyaNessuna valutazione finora

- Writing Space: The Computer, Hypertext, and The History of Writing Jay David BolterDocumento9 pagineWriting Space: The Computer, Hypertext, and The History of Writing Jay David BolterVinaya BhaskaranNessuna valutazione finora

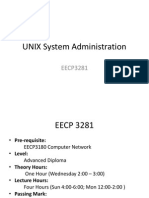

- EECP3281 Course IntroductionDocumento20 pagineEECP3281 Course IntroductionmichaeldalisayNessuna valutazione finora

- Bdx33B Bdx33C Bdx34B Bdx34C: Complementary Silicon Power Darlington TransistorsDocumento5 pagineBdx33B Bdx33C Bdx34B Bdx34C: Complementary Silicon Power Darlington TransistorsJavier BendekNessuna valutazione finora

- OSI Model LayersDocumento3 pagineOSI Model LayersKate ResusNessuna valutazione finora

- India Structured Cabling Edition 2world Market For Cabling 2017r2016 (Sample)Documento5 pagineIndia Structured Cabling Edition 2world Market For Cabling 2017r2016 (Sample)federicosanchezNessuna valutazione finora

- MX Data SheetsDocumento14 pagineMX Data Sheetssatriam riawanNessuna valutazione finora

- Java 8 - GC CheatsheetDocumento1 paginaJava 8 - GC CheatsheetIván ColetoNessuna valutazione finora

- Invoice OD110503281128278000 PDFDocumento1 paginaInvoice OD110503281128278000 PDFSandeep KumarNessuna valutazione finora

- A) B) C) D) : Part A: Review Questions (40 Points) I. Mcqs (10 Points)Documento21 pagineA) B) C) D) : Part A: Review Questions (40 Points) I. Mcqs (10 Points)khalil alhatab83% (6)

- 1188CK ExampleDocumento2 pagine1188CK ExampleYurii ChinovNessuna valutazione finora

- Atomic Radii LabDocumento3 pagineAtomic Radii LabRobert LeiNessuna valutazione finora

- ISC 2007 Computer Science Paper 1 TheoryDocumento6 pagineISC 2007 Computer Science Paper 1 TheoryShadowerNessuna valutazione finora

- Nursing InformaticsDocumento14 pagineNursing InformaticsAve Meri Noreen PizonNessuna valutazione finora

- MW 04/08/2013 - RELEASED ON ECO: 500007751: Maximum Weight Capacity 75 LBS. 34.1 KGSDocumento2 pagineMW 04/08/2013 - RELEASED ON ECO: 500007751: Maximum Weight Capacity 75 LBS. 34.1 KGSJesus Daniel Diaz de Guzman DiazNessuna valutazione finora

- 131-Government School of Mines: 'Diploma Store"Documento7 pagine131-Government School of Mines: 'Diploma Store"diploma storeNessuna valutazione finora

- Catalogo FESTOONDocumento68 pagineCatalogo FESTOONmaciasrobNessuna valutazione finora

- 96x96mm Ac 3phase Ammeter VoltmeterDocumento4 pagine96x96mm Ac 3phase Ammeter VoltmeterMohan KNessuna valutazione finora

- Goodrive10 Series Mini VFD - V2.5Documento109 pagineGoodrive10 Series Mini VFD - V2.5Aung MhNessuna valutazione finora

- ASDA-A2 400V - 0.75kW-7.5kW - Launch AnnouncementDocumento27 pagineASDA-A2 400V - 0.75kW-7.5kW - Launch AnnouncementfilicioNessuna valutazione finora

- JBASE ToolsDocumento88 pagineJBASE ToolsGirish0% (1)

- Lab 8 - Virtualization Using VMWare WorkstationDocumento4 pagineLab 8 - Virtualization Using VMWare WorkstationraytamsNessuna valutazione finora