Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

The Centrifugal Pump Curve Will Move To The Point of Shut Off Head

Caricato da

Pavani Nisansala Kulasekara0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

21 visualizzazioni1 paginaCentrifugal pumps

Titolo originale

The Centrifugal Pump Curve Will Move to the Point of Shut Off Head

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCentrifugal pumps

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

21 visualizzazioni1 paginaThe Centrifugal Pump Curve Will Move To The Point of Shut Off Head

Caricato da

Pavani Nisansala KulasekaraCentrifugal pumps

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

what would be the effect of keeping the delivery valve closed during the working of

the centrifugal pump?

The centrifugal pump curve will move to the point of shut off head. Where at this

point :

1. The capacity (Q) = 0

2. The head (H) = at max pressure

3. The Power consumption (kw) = at minimum

4. The impeller will be act same as the mixer to the fluid within the pump casing.

5. The electric energy will become kinetic and heat (the casing will be warm but not

making damage to the pump.

6. The NPSH required by the pump is at minimum.

So the best way to operate the centrifugal pump is to shut the discharge valve

(delivery valve) and then open it slowly until at the working pressure of the

pumping system owned.

Centrifugal Pump Protection Review

A centrifugal pump is dead-headed when it is operated with no flow through it, for example, with

a closed discharge valve or against a seated check valve. If the discharge valve is closed and

there is no other flow path available to the pump, the impeller will churn the same volume of

water as it rotates in the pump casing. This will increase the temperature of the liquid (due to

friction) in the pump casing to the point that it will flash to vapor. The vapor can interrupt the

cooling flow to the pump's packing and bearings, causing excessive wear and heat. If the pump is

run in this condition for a significant amount of time, it will become damaged.

When a centrifugal pump is installed in a system such that it may be subjected to periodic shutoff

head conditions, it is necessary to provide some means of pump protection. One method for

protecting the pump from running dead-headed is to provide a recirculation line from the pump

discharge line upstream of the discharge valve, back to the pump's supply source. The

recirculation line should be sized to allow enough flow through the pump to prevent overheating

and damage to the pump. Protection may also be accomplished by use of an automatic flow

control device.

Centrifugal pumps must also be protected from runout. Runout can lead to cavitation and can

also cause overheating of the pump's motor due to excessive currents. One method for ensuring

that there is always adequate flow resistance at the pump discharge to prevent excessive flow

through the pump is to place an orifice or a throttle valve immediately downstream of the pump

discharge. Properly designed piping systems are very important to protect from runout

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Deloitte Uk Mining and Metals DecarbonizationDocumento10 pagineDeloitte Uk Mining and Metals DecarbonizationfpreuscheNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- NSTP1 MODULE 3 Disaster Awareness Preparedness and ManagementDocumento16 pagineNSTP1 MODULE 3 Disaster Awareness Preparedness and Managementrenz dave100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Biology 2 Chapter 4Documento61 pagineBiology 2 Chapter 4Malas Nak TaipNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Superhero LifestyleDocumento9 pagineThe Superhero LifestyleDerp Blood0% (3)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Practice Problems Mat Bal With RXNDocumento4 paginePractice Problems Mat Bal With RXNRugi Vicente RubiNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- UK FreshTECH Jammer RecipeBook 0Documento24 pagineUK FreshTECH Jammer RecipeBook 0Temet NoscheNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Creamy and Thick Mushroom Soup: IngredientsDocumento8 pagineCreamy and Thick Mushroom Soup: IngredientsSheila Mae AramanNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Ainsworth, The One-Year-Old Task of The Strange SituationDocumento20 pagineAinsworth, The One-Year-Old Task of The Strange SituationliliaNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Wada Defending Cannabis BanDocumento18 pagineWada Defending Cannabis Banada UnknownNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Rotary Screw Gas: CompressorsDocumento2 pagineRotary Screw Gas: CompressorsLucas SilvestreNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Final Manuscript GROUP2Documento102 pagineFinal Manuscript GROUP222102279Nessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Sargent Catalog CutsDocumento60 pagineSargent Catalog CutssmroboNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Unit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesDocumento29 pagineUnit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesMark DemNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Data Performance 2Documento148 pagineData Performance 2Ibnu Abdillah MuhammadNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Quality Assurance Kamera GammaDocumento43 pagineQuality Assurance Kamera GammawiendaintanNessuna valutazione finora

- LWT - Food Science and Technology: A A B ADocumento6 pagineLWT - Food Science and Technology: A A B ACarlos BispoNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Wes Jackson PM PMP OhioDocumento10 pagineWes Jackson PM PMP Ohioraj jdsNessuna valutazione finora

- Quinta RuedaDocumento20 pagineQuinta RuedaArturo RengifoNessuna valutazione finora

- Lead Avr PDFDocumento9 pagineLead Avr PDFsiddharthNessuna valutazione finora

- Guidelines For Forensic Report Writing: Helping Trainees Understand Common PitfallsDocumento54 pagineGuidelines For Forensic Report Writing: Helping Trainees Understand Common PitfallsNorfolk Journal100% (1)

- MelatoninaDocumento32 pagineMelatoninaCodrut GeorgescuNessuna valutazione finora

- E3sconf 2F20187307002Documento4 pagineE3sconf 2F20187307002Nguyễn Thành VinhNessuna valutazione finora

- English Language Paper 1 - Answer KeyDocumento5 pagineEnglish Language Paper 1 - Answer Keybangtansone1997Nessuna valutazione finora

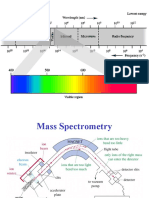

- Mass SpectrometryDocumento49 pagineMass SpectrometryUbaid ShabirNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- API 650 10th Edition ErrataDocumento6 pagineAPI 650 10th Edition ErrataJosé Ramón GutierrezNessuna valutazione finora

- Weekly Meal Prep GuideDocumento7 pagineWeekly Meal Prep Guideandrew.johnson3112Nessuna valutazione finora

- Optical Fiber Communication Unit 3 NotesDocumento33 pagineOptical Fiber Communication Unit 3 NotesEr SarbeshNessuna valutazione finora

- Capacitor BanksDocumento49 pagineCapacitor BanksAmal P RaviNessuna valutazione finora

- Wago PCB Terminal Blocks and Connectors Catalog 7Documento105 pagineWago PCB Terminal Blocks and Connectors Catalog 7alinupNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Erich FrommDocumento2 pagineErich FrommTina NavarroNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)