Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Handbook On Dos and Donts On Points and Crossings

Caricato da

Er Rajesh BuraTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Handbook On Dos and Donts On Points and Crossings

Caricato da

Er Rajesh BuraCopyright:

Formati disponibili

Camtech/2000/C/Track/Points and Crossings/1.

GOVERNMENT OF INDIA

MINISTRY OF RAILWAYS

DO's AND DON'Ts

ON

POINTS & CROSSINGS

CAMTECH/2000/C/Track/Points & Crossings/1.0

For Office Use only

March - 2000

Centre

for

Advanced

Maintenance

Excellence in Maintenance

TECHnology

Maharajpur, GWALIOR, 474 020

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

DOS AND DONTS

ON

POINTS AND CROSSING

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

PREFACE

In Indian Railways, points and

crossings constitute a very important

infrastructure of a Railway System.

This Dos and Dont handbook

on point and crossing has been

prepared for SE (P.Way) and his staff

up to P.Way mistry level, who is

directly responsible for maintenance

of points and crossings. This booklet

may used as a ready rekoner for

maintenance of point and crossings

includes switch portion, lead portion

and turn in curve etc.

This handbook does not

supercede any existing instruction

from Railway Board, IRPWM, RDSO

etc. except where necessary correction

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

slips intimating the required changes

are issued by Rly. Board/RDSO. Most

of data and information mentioned

here in are available in some form the

other in various books or other printed

matter.

I would also welcome any

suggestion

for

addition

and

improvements.

CAMTECH

Gwalior

Date : 30.04.2000

R.S.Dubey

Joint Director/Civil

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

CONTENT

Sr.

No.

Description

Page

No.

Preface

Contents

vii

Correction Slip

ix

General Instruction

Switch portion

Schedule of dimension

Crossings

10

Lead portion & turn in curve

12

Schedule of inspection.

15

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

ISSUE OF CORRECTION SLIPS

The correction slips to be issued in future for this

handbook will be numbered as follows:

Camtech/2000/C/Track/Points & Crossings/1.0 /CS

# XX date.....................

Where XX is the serial number of the concerned

correction slip (starting from 01 onwards).

CORRECTION SLIPS ISSUED

Sr.

No.

of

C.Slip

Date

of

issue

Page no. and

Item No.

modified

Dos and Donts on Points and Crossings

Remarks

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

DO's

General instruction for Points and

Crossings

1.

Points and Crossings should be laid

without the 1 in 20 cant.

2.

Organise

regular

cycle

of

maintenance covering all Points

and Crossings. Where large number

of Points and Crossings are being

maintained within a specific area

such as marshalling yards, large

layout of sidings, terminal stations

etc.

3.

Give correct clearance at the check

rail.

4.

Maintain cess low enough to permit

efficient drainage

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

5.

Ensure correct spacing of sleepers

according to the standard layout

drawings.

6.

Use of spherical washers/in CMS

crossings tapered washers shall

only be used at appropriate places

in a Points and Crossing assembly.

7.

Maintain uniform gauge at all

places in a Points and Crossings

except at a point just ahead of toe

of the switch where it will be

slightly slack (enough to house the

tip of tongue rail).

i.

ii.

8.

With SEA 0 - 20' : Nominal

gauge.

With SEA more than 0 - 20'

nominal gauge + 6 mm.

Properly secure the chairs and

fastenings and all other fittings.

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

9.

Maintain good condition of the

points and crossing assembly, and

alignment with the rest of the track

without kinks.

10.

It is desirable to weld stock and

lead joints on the Points and

Crossings assembly.

11.

Bring the rails to correct level and

alignment.

12.

Provide creep indicators near stock

joint if required.

13.

Make the road level same as track

at level crossings.

14.

Provide end fixed special timbers

as required.

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

15.

Provide sufficient anchors to arrest

creep.

16.

Provide adequate depth of ballast

cushion and permit efficient

drainage under point and crossing.

17.

Box anchoring of at least one rail

length a head of stock rail.

18.

Bring the location to correct level

and clear formation where rods and

wires run.

For Switch Portion

1.

Ensure the tongue rail rest

evenly on all the slide chairs.

2.

Ensure all the sleepers are

packed properly.

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

3.

4.

Tongue rail supports evenly

against distance blocks when in

closed position.

Adjust slight wide gauge at the

toe of switch, by providing

suitable steel packing between

the web of the stock rail and the

lug of the slide chair.

5.

Maintain

stretcher

bars

connected to the pull/drive rod

jointly by the Permanent Way

Staff and the Signalling Staff.

Other stretcher bar maintained

by Permanent Way Inspector.

6.

Lubricate the gauge face of

tongue rail. It will reduce wear

on switches.

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

7.

Provide correct amount of bend

to stock rail on the turn outside

at the theoretical toe of switch in

the straight switches. This bend

is not required in curved

switches having SEA 00 - 20' or

less.

8.

Examine the condition of stock

and tongue rail carefully.

9.

Provide adequate creep anchors

to arrest creep.

10.

Lay the permanent way at points

and crossings to correct gauge

so that switches fittings and

locks may be correctly put

together.

Go to index

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

11.

Fix gauge tie plate correctly at

all switches.

12.

Tighten all bolts on switches

except those at the heel of loose

heel type switches where the

first two bolts in the switch rail

should be finger tight and other

two in the lead rail spanner tight.

13.

Fix the slide chairs on timbers

by plate screws/ fang bolts.

14.

Replace tongue rail if

a. It is chipped/cracked over

small lengths aggregating of

200 mm. within a distance of

1000 mm from its toe.

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

b. It is badly twisted or bent,

and does not house properly

against the stock rail causing

a gap of 5 mm or more at the

toe.

c. The wear on tongue rail

exceeds the following limit.

Vertical wear Lateral Wear -

8 mm for 60 kg

5 mm for 52 kg

and 90 R

3 mm for 75 R

and 60 R

8 mm for 60 kg

6 mm for 52 kg

and 90 R

5 mm for 75 R

and 60 R.

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

(Measured at 13 to 15 mm below top

of stock rail)

15.

Correctly maintain the clearance

at the toe, heel of switch, at

check rail and wing rail within

the tolerance prescribe in the

schedule of dimensions and in

relevant drawings.

Schedule of Dimension

Sr.

No.

Description

Maximum clearance of

check rail opposite nose of

crossing or wing rail at

nose of xing.

Min. clearance of check rail

opposite nose of crossing

and at heel of switch rail.

Min. radius of curvature of

slip points, turn out or cross

over roads

B.G.

mm

(ft. inch)

48

(1 - 7/8")

M.G.

mm

(ft. inch)

44

(1 - ")

44

(1 -3/4")

41

(1 - 5/8")

218

(716')

116

(382')

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

Min. angle of ordinary

crossing

Diamond crossing not to be

flater than.

Min. length of tongue rail.

5

6

7

Minimum length of train

protection, point locking or

fouling treadle bar.

Min. clearance between toe

of open switch and stock

rail.

10

1 in 16

1 in 12

1 in 8.5

1 in 8.5

3660

(12'- 0")

12800

(42' 0")

2145

(9' 0")

12200

(40' 0")

Min. 95

(3.75")

89

(3.5")

For Crossings

1.

Trace if any damage to the nose of

crossing noticed which may be due

to tight gauge or due to excessive

clearance at the check rail.

2.

Maintain correct gauge and provide

tie plate under the nose of crossings

on layout of wooden sleepers.

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

11

3.

Maintain correct distance between

the throat and the nose in obtuse

crossings.

4.

In diamond crossings, obtuse

crossings should be laid square to

each other with respect to the

center line of the acute crossings.

5.

Maximum vertical wear on wing

rail or nose of crossing shall be 10

mm on straight edge, not from

initial

level

&

on

Rajdhani/Shatabdi root recondition

to be planed after wear of 6 mm for

built up crossing and 8 mm for

CMS crossing as a good

maintenance practice.

6.

Recondition/resurface by welding

of Crossings when required.

Go to index

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

12

7.

Use of wooden blocks added to the

contour of the underside of

sleepers, strengthens the support

and helps in better maintenance in

the case of steel trough sleepers

used in crossings. However steel

sleepers strengthened by providing

steel ribs on their under side, use of

wooden block is not required.

8.

Maintain correct gauge at the wing

rail and nose of crossing if gauge is

not exact it will damage to the nose

of crossing and wing rail.

For Lead Portion and Turn in

Curve

1.

Maintain correct lead and radii on

turnout according to the section of

the rail and the angle of crossing

used.

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

2.

3.

4.

5.

6.

13

The curve lead should be laid by

off-sets from the gauge face of the

straight track.

Mark the stations at 3 M. intervals

and versines checked and track

attended as necessary.

Record the versines of turn in

curves on loops recorded at stations

at 3 M intervals during the

inspection of points and crossings

to check the sharpness of the curve

and rectified as necessary.

Check the turn in curve for

condition

of

sleepers

and

fastenings.

Maintain uniform gauge over

turnouts.

DON'Ts

1.

Place any tool or metal object to

touch across two rails in the track

which may cause short circuiting.

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

14

2.

Use worn out and defective rails.

3.

Use steel tapes in track circuited

section.

4.

Infringe the standard dimension

during maintenance of points and

crossings.

5.

Pull back the rails in track circuit

areas without S&T staff where

signalling connections involved.

6.

Use junction fish plate at stock rail

joints or at the heel of crossing.

7.

Damage the track fittings like rail

bonding wires, lead wires to rails

bottom legs, jumper wires etc.

during track maintenance.

8.

Interfere

Dos and Donts on Points and Crossings

with

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

15

stretcher bars insulation for track

circuit purpose unless signal staff

are present.

9.

Allow deficiency of any fastening

and fittings.

10.

Allow bad alignment and kink in

the point and crossing assembly.

11.

Allow loose packing under the

sleepers of crossings and switches.

12.

Use defective sleeper under the

crossing and the switches.

Go to index

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

16

SCHEDULE OF INSPECTION OF

POINTS AND CROSSINGS

(a)

Permanent

Way

Inspectors

Inspections {Para 107(5)}The Permanent Way Inspector in

charge of the Section and his

assistant should carry out thorough

inspection of points and crossings

in passenger running lines once in 3

months and other lines once in six

months by rotation.

(b)

Assistant Engineers

{Para 124 (3)} -

Inspection

The Assistant Engineer should

inspect once a year all points and

crossings thoroughly on passenger

running lines and 10 percent of the

points and crossings on other lines.

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

(c)

17

Divisional Engineers Inspection The Divisional Engineer should

inspect at his discretion a certain

number of points and crossings

particularly in running lines and

those recommended for renewals.

The permanent way inspector shall

be responsible for the cleaning and

lubrication of slide chairs of all

hand operated points on their

sections.

*****

Go to index

Dos and Donts on Points and Crossings

March-2000

Camtech/2000/C/Track/Points and Crossings/1.0

18

OUR OBJECTIVE

To upgrade Maintenance

Technologies and Methodologies and

achieve improvement in

productivity and performance of all

Railway assets and manpower

which inter-alia would cover

Reliability, Availability, and

Utilisation.

If you have any suggestion & any specific

comments, please write to us :

Contact person :

Joint Director (Civil)

Postal Address :

Indian Railways,

Centre for Advanced

Maintenance Technology

Maharajpur, Gwalior

Pin Code 474 020

Phone

Fax

: (0751) - 470869, 470803

: (0751) - 470841

Dos and Donts on Points and Crossings

March-2000

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 4 Bedroom BoqDocumento13 pagine4 Bedroom BoqNana Barima100% (2)

- Lone Star Steel Casing DesignDocumento67 pagineLone Star Steel Casing DesignHoan Hoan100% (1)

- Thieken - Knee - ACL Reconstruction Rehab Protocol PDFDocumento4 pagineThieken - Knee - ACL Reconstruction Rehab Protocol PDFEr Rajesh BuraNessuna valutazione finora

- Stone India FDocumento2 pagineStone India FEr Rajesh Bura0% (1)

- 6.1 Tractors and Heavy Earth Moving MachineryDocumento16 pagine6.1 Tractors and Heavy Earth Moving MachineryEr Rajesh Bura100% (1)

- Tution ApplicationDocumento5 pagineTution ApplicationEr Rajesh BuraNessuna valutazione finora

- 401XL Crusher Machine ManualDocumento12 pagine401XL Crusher Machine ManualEr Rajesh BuraNessuna valutazione finora

- Guidelines & SpecificationsDocumento1 paginaGuidelines & SpecificationsEr Rajesh BuraNessuna valutazione finora

- Icf MD Spec 268 Issue 01 Rev00Documento6 pagineIcf MD Spec 268 Issue 01 Rev00Er Rajesh BuraNessuna valutazione finora

- Part 4 of Tender DocumentDocumento51 paginePart 4 of Tender DocumentEr Rajesh BuraNessuna valutazione finora

- (IRFCA) Brake Systems Used by IRDocumento4 pagine(IRFCA) Brake Systems Used by IREr Rajesh BuraNessuna valutazione finora

- (IRFCA) Indian Railways FAQ - Rolling Stock - IDocumento23 pagine(IRFCA) Indian Railways FAQ - Rolling Stock - IEr Rajesh BuraNessuna valutazione finora

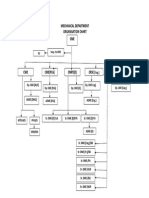

- Mechanical Department Organisation Chart CMEDocumento1 paginaMechanical Department Organisation Chart CMEEr Rajesh BuraNessuna valutazione finora

- CC Rakes 130814Documento2 pagineCC Rakes 130814Er Rajesh BuraNessuna valutazione finora

- K KH Lao OgkjDocumento12 pagineK KH Lao OgkjEr Rajesh BuraNessuna valutazione finora

- 1367482635621-Vacuum Air BrakeDocumento31 pagine1367482635621-Vacuum Air BrakeEr Rajesh BuraNessuna valutazione finora

- 1411306026400-Bit Bank - WorkshopDocumento93 pagine1411306026400-Bit Bank - WorkshopEr Rajesh BuraNessuna valutazione finora

- North Western Railway: Mechanical DepartmentDocumento1 paginaNorth Western Railway: Mechanical DepartmentEr Rajesh BuraNessuna valutazione finora

- MRRJ If'Pe Jsyos DK Kzy Izkpk Z) I Zos (KD Izf'K (K.K Dsunz) Vtesj La. M 377/Stc/Tentative/Plan Date: 10.11.2012Documento4 pagineMRRJ If'Pe Jsyos DK Kzy Izkpk Z) I Zos (KD Izf'K (K.K Dsunz) Vtesj La. M 377/Stc/Tentative/Plan Date: 10.11.2012Er Rajesh BuraNessuna valutazione finora

- At A GlanceDocumento1 paginaAt A GlanceEr Rajesh BuraNessuna valutazione finora

- Key StatisticsDocumento1 paginaKey StatisticsEr Rajesh BuraNessuna valutazione finora

- Straw Bale ConstructionDocumento33 pagineStraw Bale ConstructionDomenico BevilacquaNessuna valutazione finora

- Quotation Letter: Yours TrulyDocumento4 pagineQuotation Letter: Yours TrulyJonathan LatawanNessuna valutazione finora

- Technology For Electromagnetic Stirring of Aluminum Reverberatory FurnacesDocumento6 pagineTechnology For Electromagnetic Stirring of Aluminum Reverberatory FurnacesghndslNessuna valutazione finora

- Total 446 Acres 446: Project Break Up by Aristotle Balraj Type % AcresDocumento53 pagineTotal 446 Acres 446: Project Break Up by Aristotle Balraj Type % AcresRED 2K17Nessuna valutazione finora

- SIR Homeowners 04-21-11Documento2 pagineSIR Homeowners 04-21-11TimesreviewNessuna valutazione finora

- Steps: Factors in Estimating The Cost Concrete / MDocumento2 pagineSteps: Factors in Estimating The Cost Concrete / MIbrà ArshadNessuna valutazione finora

- Case Study Shanghai TowersDocumento1 paginaCase Study Shanghai TowersShinde ShubhamNessuna valutazione finora

- Yogesh Mishra PDFDocumento2 pagineYogesh Mishra PDFAlok Singh RajawatNessuna valutazione finora

- Truss Solutions For Curved RoofsDocumento3 pagineTruss Solutions For Curved RoofszamaxxNessuna valutazione finora

- Demu Fix - 12 eDocumento44 pagineDemu Fix - 12 emulti5torpeNessuna valutazione finora

- IJSDR190491Documento21 pagineIJSDR190491RohimNessuna valutazione finora

- Proceq Resipod PDFDocumento2 pagineProceq Resipod PDFLucky ZozagallaNessuna valutazione finora

- MEP805B MEP815B Engine Parts Manual TM 9 2815 259 24PDocumento121 pagineMEP805B MEP815B Engine Parts Manual TM 9 2815 259 24PIgor LNessuna valutazione finora

- Design of Trail Bridges: Sag Calculation D TypeDocumento4 pagineDesign of Trail Bridges: Sag Calculation D TypePramod RijalNessuna valutazione finora

- Checklist For Rain Water Harvesting DetailsDocumento2 pagineChecklist For Rain Water Harvesting DetailsRupesh KhandekarNessuna valutazione finora

- Buildings LandscapeDocumento62 pagineBuildings LandscapeAkash SrivastavaNessuna valutazione finora

- BOQ Fire DetailDocumento7 pagineBOQ Fire DetailDaudMuhammadNessuna valutazione finora

- FYP Presentation TemplateDocumento20 pagineFYP Presentation TemplateAliNessuna valutazione finora

- QIP-PDI-G.3 - Design Instruction For Standard Pipe Support SelectionDocumento1 paginaQIP-PDI-G.3 - Design Instruction For Standard Pipe Support Selectiondimas prasetyoNessuna valutazione finora

- Steel Construction - 2012 - Espion - The Vierendeel Bridges Over The Albert Canal Belgium Their Significance in TheDocumento6 pagineSteel Construction - 2012 - Espion - The Vierendeel Bridges Over The Albert Canal Belgium Their Significance in TheJoao SilvaNessuna valutazione finora

- Steel Design 9 Nov 2020 PDFDocumento1 paginaSteel Design 9 Nov 2020 PDFJustine Ejay MoscosaNessuna valutazione finora

- Submittal ExtractorDocumento2 pagineSubmittal ExtractorLuis Fernando Nordhausen MartinezNessuna valutazione finora

- DIN EN 50600 Question and AnswersDocumento2 pagineDIN EN 50600 Question and AnswersPercy GoitsemangNessuna valutazione finora

- Cmci Cmci: Epoxy Grout System For Equipment BasesDocumento2 pagineCmci Cmci: Epoxy Grout System For Equipment Basespravi3434Nessuna valutazione finora

- Pipe Wall Thickness ASME B31 3Documento116 paginePipe Wall Thickness ASME B31 3NicolaSavili100% (1)

- Taguibo Const. ExpensesDocumento31 pagineTaguibo Const. ExpensesEvangeline CasccaraNessuna valutazione finora

- IOM Haakon AHU 1Documento47 pagineIOM Haakon AHU 1Wesly ChavezNessuna valutazione finora

- METHOD STATEMENT FOR DEEP EXCXVATIONS-Subrahmanaya S MurthyDocumento8 pagineMETHOD STATEMENT FOR DEEP EXCXVATIONS-Subrahmanaya S MurthySikandar KhanNessuna valutazione finora