Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Needle Detector Calibration

Caricato da

ari sunCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Needle Detector Calibration

Caricato da

ari sunCopyright:

Formati disponibili

Global Quality Department

Valid for all brands in H&M group

November 2013

NEEDLE DETECTOR CALIBRATION

Factory Name: PT. DOOSAN JAYA SUKABUMI

Country: INDONESIA

Remarks: Needle detector must verify the calibration and accuracy every 2 hour. At the beginning

middle and end of a working period by using the 1.2 mm sphere ferrous cards to check machine

sensitively.

CROSS SECTION OF NEEDLE DETECTOR TUNNEL

TOP

CENTER

BOTTOM

A7

A4

A1

A8

A5

A2

A9

A6

A3

1. Switch on the machine and adjust sensitively level to less then 1.2 mm sphere.

2. Position the 1.2 mm sphere ferrous check card on to the conveyor belt at position A1, let the test card

pass through the search head.

3. The needle detection should be activated (alarming).

4. Repeat the procedure 1-3 with position the 1.2 mm sphere ferrous card on to the conveyor belt at position

A2 & A3.

5. The needle detection should be activated (alarming) also.

6. Test A1, A2 & A3 with 1.2 mm ferrous check card only. No garments or paper is allowed to put together

during testing.

7. Repeat the procedure 1-3 with position the 1.2 mm sphere ferrous check card on the stand and placed the

stand on to the conveyor belt at the position A4, A5, A6, A7, A8 & A9 end record.

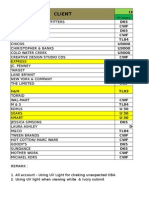

Operator

Signatur

e

Time

Buye

r

A1

A2

A3

A4

A5

A6

A7

A8

A9

07.30

09.30

11.30

12.30

14.30

15.30

07.30

09.30

11.30

12.30

14.30

15.30

07.30

09.30

11.30

12.30

14.30

15.30

07.30

09.30

11.30

12.30

14.30

15.30

07.30

09.30

11.30

12.30

14.30

15.30

07.30

09.30

11.30

12.30

14.30

15.30

Date

PSO

signature

Y- The needle detection activates (alarming) when 1.2mm ferrous check and pass through the

search head.

N - The needle detection inactivate (not alarming) when 1.2mm ferrous check and pass through the

search head.

Potrebbero piacerti anche

- SOP On Sewn Button & Snap Fastener Safety PDFDocumento58 pagineSOP On Sewn Button & Snap Fastener Safety PDFJuwel Rana85% (13)

- Swann n3960 Camera ManualDocumento4 pagineSwann n3960 Camera ManualEddie Lopez0% (3)

- Traffic Light System in Garment IndustryDocumento11 pagineTraffic Light System in Garment IndustryGopal Dixit0% (1)

- WOL-3 - Dragons of SpringDocumento341 pagineWOL-3 - Dragons of SpringRyan Hall100% (15)

- IQ TestDocumento6 pagineIQ TestReema Tomagtang50% (2)

- 11 Broken Needle Sharp Tool PolicyDocumento5 pagine11 Broken Needle Sharp Tool PolicyKamal SinghNessuna valutazione finora

- Button Attachment SOPDocumento22 pagineButton Attachment SOPratno wijaya89% (18)

- Sop ForDocumento8 pagineSop ForPalash75% (4)

- Needle Metal Contamination Control SOPDocumento16 pagineNeedle Metal Contamination Control SOPVishal Kumar80% (5)

- Button Pull Test Machine SOPDocumento1 paginaButton Pull Test Machine SOPTaufiq Ahmed100% (2)

- Standard Operating Procedures For Pre Final InspectionDocumento1 paginaStandard Operating Procedures For Pre Final InspectionSayed Aasim Jawaid100% (2)

- Title: Textile Testing and Quality AssuranceDocumento4 pagineTitle: Textile Testing and Quality AssuranceTauqeer Raza100% (2)

- Product Safety - CompressDocumento26 pagineProduct Safety - Compressari sun67% (3)

- Light Source All BuyerDocumento2 pagineLight Source All Buyerari sunNessuna valutazione finora

- Huawei Modem E960 UpgradeDocumento13 pagineHuawei Modem E960 Upgradebearking80Nessuna valutazione finora

- ENE KB9022 On LA-A342P ZIPS3Documento15 pagineENE KB9022 On LA-A342P ZIPS3Hassan FakhouryNessuna valutazione finora

- Needle Detector PolicyDocumento5 pagineNeedle Detector PolicyTaufiq Ahmed100% (1)

- Cutting Section SOPDocumento4 pagineCutting Section SOPsok daraNessuna valutazione finora

- Fabric Quality HandbookDocumento51 pagineFabric Quality HandbookMorshed MahamudNessuna valutazione finora

- Safety Policy For Garment 31-07Documento5 pagineSafety Policy For Garment 31-07S.M. Shariful Islam100% (1)

- DHU & Defective%Documento2 pagineDHU & Defective%Padmakar29Nessuna valutazione finora

- Garments AQLsDocumento1 paginaGarments AQLsRejaalNessuna valutazione finora

- Fabric RelaxationDocumento2 pagineFabric RelaxationNahid67% (3)

- Needle Policy.2Documento2 pagineNeedle Policy.2kabery100% (3)

- Needle and Metal Contamination Control PDFDocumento18 pagineNeedle and Metal Contamination Control PDFMohammed IshakNessuna valutazione finora

- Spreading and Cutting MachinaryDocumento21 pagineSpreading and Cutting Machinarypsyish100% (1)

- Industrial Sewing Machine Needles Replacement Policy - Auto GarmentDocumento4 pagineIndustrial Sewing Machine Needles Replacement Policy - Auto GarmentVarun MehrotraNessuna valutazione finora

- Cutting Section SOP: Fabrics Relaxation ProcedureDocumento1 paginaCutting Section SOP: Fabrics Relaxation ProcedureGAURAV SHARMA100% (1)

- Fabric Inspection ProcedureDocumento6 pagineFabric Inspection ProcedureMayan DynastyNessuna valutazione finora

- Snap SOP - 27 Feb 2022Documento38 pagineSnap SOP - 27 Feb 2022Suresh KumarNessuna valutazione finora

- Cutting and Spreading, Use of AutomationDocumento30 pagineCutting and Spreading, Use of AutomationAditi33% (3)

- Broken Needle Control ProtocolDocumento4 pagineBroken Needle Control ProtocolAsad MuhammadNessuna valutazione finora

- Cutting Standard Operating Procedure SOP EnglishDocumento2 pagineCutting Standard Operating Procedure SOP Englisharvindtiwari21Nessuna valutazione finora

- Preparatory Processes (Cutting Part 1) : Learn Apparel Merchandising Learn Fashion DesigningDocumento7 paginePreparatory Processes (Cutting Part 1) : Learn Apparel Merchandising Learn Fashion DesigningZaman ParvezNessuna valutazione finora

- Needle and Metal Contamination ControlDocumento18 pagineNeedle and Metal Contamination Controljahazi1100% (1)

- 20 Ways To Improve Productivity in Garment Production and Planning CapacityDocumento8 pagine20 Ways To Improve Productivity in Garment Production and Planning CapacityCucak RowoNessuna valutazione finora

- QCM - Quality Control in Garments Industry by SatexDocumento21 pagineQCM - Quality Control in Garments Industry by Satexsatex100% (1)

- Spme Assignment: Sewing Products Machinery and EquipmentDocumento29 pagineSpme Assignment: Sewing Products Machinery and EquipmentVishnu P RNessuna valutazione finora

- Snap & Popper Att ProcessDocumento25 pagineSnap & Popper Att ProcessprashantmithareNessuna valutazione finora

- Needle and Metal Contamination ControlDocumento18 pagineNeedle and Metal Contamination Controlaristian27Nessuna valutazione finora

- Finished Knitted & Jersey Fabric Specification: Fabric Supplier:Norba Comtex Ltd. Mill Reference:77534 SeasonDocumento3 pagineFinished Knitted & Jersey Fabric Specification: Fabric Supplier:Norba Comtex Ltd. Mill Reference:77534 SeasonMd Majharul IslamNessuna valutazione finora

- Sample Section:It Is The First Section Of: Garment Manufacturing ProcessDocumento6 pagineSample Section:It Is The First Section Of: Garment Manufacturing ProcesssantumysoreNessuna valutazione finora

- Fabric Relaxation SOPDocumento1 paginaFabric Relaxation SOPMd.Ahasan Ullah100% (1)

- Manual SpreadingDocumento4 pagineManual SpreadingarunkadveNessuna valutazione finora

- Word TSL FILEDocumento14 pagineWord TSL FILEKumbhar p.s.100% (1)

- Majumder Garments Limited: Standard Operating ProcedureDocumento3 pagineMajumder Garments Limited: Standard Operating ProcedureRanjit Roy100% (1)

- Process Flow Chart of Banswara Garment Kadaiya Unit AvinashDocumento23 pagineProcess Flow Chart of Banswara Garment Kadaiya Unit AvinashakashNessuna valutazione finora

- SM QA ChildrenswearDocumento58 pagineSM QA Childrenswearnaveenerotex100% (1)

- Case Study: Implementation of Poka Yoke in Textile IndustryDocumento11 pagineCase Study: Implementation of Poka Yoke in Textile IndustryJyoti RawalNessuna valutazione finora

- Iot & MMDocumento9 pagineIot & MMAnushkaNessuna valutazione finora

- Department of Fashion TechnologyDocumento22 pagineDepartment of Fashion TechnologyAbhishek YadavNessuna valutazione finora

- Metal PolicyDocumento27 pagineMetal PolicyalamtareqNessuna valutazione finora

- Pull Force Test of Buttons & AccessoriesDocumento3 paginePull Force Test of Buttons & AccessoriesjobaerNessuna valutazione finora

- Chittagong Fashion Specialised Textiles LTD.: Cad Room SopDocumento5 pagineChittagong Fashion Specialised Textiles LTD.: Cad Room SopTaufiq AhmedNessuna valutazione finora

- An Overview of Quality and Quality Control in Textile IndustryDocumento12 pagineAn Overview of Quality and Quality Control in Textile IndustryTasnif Mahmud100% (1)

- 3.1 Clothing Performance Requirements - March 22Documento60 pagine3.1 Clothing Performance Requirements - March 22Rohan KabirNessuna valutazione finora

- Technical Audit in Apparel IndustryDocumento7 pagineTechnical Audit in Apparel IndustryRongdhonu MasumNessuna valutazione finora

- Cutting SOPDocumento8 pagineCutting SOParvindtiwari21Nessuna valutazione finora

- Print DurabilityDocumento3 paginePrint DurabilityDoulat Ram100% (2)

- SOP Traffic LightDocumento2 pagineSOP Traffic LightDurbar Dasgupta100% (3)

- Sewing Quality SOP EnglishDocumento1 paginaSewing Quality SOP EnglishSayed Aasim ShahNessuna valutazione finora

- Etm 2 ManualDocumento13 pagineEtm 2 ManualMark K50% (2)

- Sealey SMS2008Documento3 pagineSealey SMS2008cabuloNessuna valutazione finora

- 02.needle Detector CalibrationDocumento1 pagina02.needle Detector CalibrationMuhammad Asad SaeedNessuna valutazione finora

- Id 168 en User Manual Sharp Edge Tester UnlockedDocumento6 pagineId 168 en User Manual Sharp Edge Tester UnlockedLourdes Fernandez MejiaNessuna valutazione finora

- 9-Point Testing ProcedureDocumento1 pagina9-Point Testing ProcedureJahangir Alam SohagNessuna valutazione finora

- Equipmen Machie CheckDocumento18 pagineEquipmen Machie Checkari sunNessuna valutazione finora

- Taggun Gunting PenserDocumento2 pagineTaggun Gunting Penserari sunNessuna valutazione finora

- Susi - Ben&BenDocumento10 pagineSusi - Ben&BenMarc Christian Paraan FernandezNessuna valutazione finora

- Behind The Screen - How Gays and Lesbians Shaped Hollywood, 1910-1969 Ipad Android KindleDocumento7.740 pagineBehind The Screen - How Gays and Lesbians Shaped Hollywood, 1910-1969 Ipad Android KindleRafael Der0% (3)

- 2010 Double Bass ExcerptsDocumento8 pagine2010 Double Bass ExcerptsSebastien SiroisNessuna valutazione finora

- Complex SentencesDocumento3 pagineComplex SentencesPilar Romero CandauNessuna valutazione finora

- Q4-PPT-PE10_Lesson 2 (Dance Forms Elements and Techniques)Documento28 pagineQ4-PPT-PE10_Lesson 2 (Dance Forms Elements and Techniques)Judy Ann FunitNessuna valutazione finora

- Gothic V RomanticDocumento10 pagineGothic V RomanticLucia InglesNessuna valutazione finora

- Peel 2 Self-TrainingDocumento101 paginePeel 2 Self-TrainingManolo EsperidesNessuna valutazione finora

- Tunday KababDocumento2 pagineTunday KababPresley ThomasNessuna valutazione finora

- Past Simple and Past ContinuousDocumento4 paginePast Simple and Past ContinuousRosa Sousa100% (1)

- 5 Yrs 5 Yrs 1 Yr 5 Yrs 1 Yr 1 Yr 1 Yrs 5 Yrs 1 Yr 5 Yrs 1 Yr 5 YrsDocumento2 pagine5 Yrs 5 Yrs 1 Yr 5 Yrs 1 Yr 1 Yr 1 Yrs 5 Yrs 1 Yr 5 Yrs 1 Yr 5 YrsMuhamad YusreyNessuna valutazione finora

- Subject Verb Agreement Exercise MCQ Questions 52Documento7 pagineSubject Verb Agreement Exercise MCQ Questions 52Parveen TaakNessuna valutazione finora

- Bali Dynasty Resort HotelDocumento25 pagineBali Dynasty Resort HotelSAKUNessuna valutazione finora

- Stunt Kites PDFDocumento94 pagineStunt Kites PDFJuan David100% (2)

- International Business PlanDocumento11 pagineInternational Business PlanBabi NgepetNessuna valutazione finora

- Winch ControlDocumento3 pagineWinch ControlABDUL GHAFOORNessuna valutazione finora

- Ethesis 1 PDFDocumento170 pagineEthesis 1 PDFRicardo A Martinez100% (1)

- Hi-Force Hydrostatic PDFDocumento6 pagineHi-Force Hydrostatic PDFWong Chung MengNessuna valutazione finora

- Cisco 3900 and Cisco 2900 Series RoutersDocumento31 pagineCisco 3900 and Cisco 2900 Series RoutersCassandra ShafferNessuna valutazione finora

- Abpc DisneyDocumento21 pagineAbpc DisneyMarielos PaauNessuna valutazione finora

- Characteristics of Middle English LiteratureDocumento2 pagineCharacteristics of Middle English Literature221670135Nessuna valutazione finora

- Blackout - ScriptDocumento9 pagineBlackout - Scriptapi-295129288Nessuna valutazione finora

- Pedal Powered Blender: Produced by Maya Pedal 2013Documento4 paginePedal Powered Blender: Produced by Maya Pedal 2013AnaNessuna valutazione finora

- Hangman Report1Documento10 pagineHangman Report1RenjithNessuna valutazione finora

- Chord ProgressionDocumento2 pagineChord Progressionsenonais nissaroub100% (1)

- Accessories: ADP45-MSTP-x: Quick Connect MS/TP AdaptersDocumento2 pagineAccessories: ADP45-MSTP-x: Quick Connect MS/TP AdaptersBMSNessuna valutazione finora