Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

GSPC PLQP

Caricato da

Anonymous rYZyQQot55Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

GSPC PLQP

Caricato da

Anonymous rYZyQQot55Copyright:

Formati disponibili

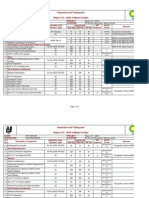

INSPECTION & TESTING REPORT OF CRANE ASSEMBLY

Project

OWNER

CONTRACTOR

VENDOR

PO NO

CRANE MODEL

MHN PROCESS PLATFORM & LQ PROJECT

ONGC

L&T

M/S RAINA ENGINERS,MUMBAI(ISO 9001 & API CERTIFIED)

OGSP/45000-60182/SRD, Dt. 23/10/2009

RE-25-12-50

ITEM

DESCRIPTION

BOOM LENGTH

: 42 M

DYNAMIC LIFT

RADIUS

STATIC LIFT

RADIUS

DECK CRANE FOR

PLQP

:

:

TAG NO

LOCATION

PLATFORM

12T AT 25M

12T AT 42M

: 114-CR-1010

: DDW1 WELLHEAD

CRANE PART NO : RE-12-25-42

CRANE SERIAL NO :

259

MANUFACTURER :

M/S. RAINA ENGINEERS

AT & POST : PATANSAI NAGOTHANE

TAL: ROHA, DIST : RAIGAD

MAHARASHTRA, INDIA.

SR.N

O

1.

2.

3.

DATE OF INSPECTION: 14/04/2012

REFERENCE DOCUMENTS :QAP NO

RE-GSPC-QA-01,Rev. 01

G.A. DRG.NO

1811120-7

API SPEC.

API 2C, 6th. Edition

1.SPEED TESTS:

1.1 MAIN HOIST:

S.N MOTIO

.

N

LOAD

(Tons

)

Distance

Load

Moved

(Meter)

Time

record

ed

Speed

(M/Min)

Avera

ge

time

Req.

Act.

5.446

21

22

Remar

ks

5.53

1.

MAIN

HOIST

12

2 Meter

5.47

5.34

Accepted

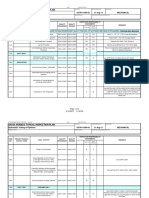

INSPECTION & TESTING REPORT OF CRANE ASSEMBLY

Project

OWNER

CONTRACTOR

VENDOR

PO NO

CRANE MODEL

MHN PROCESS PLATFORM & LQ PROJECT

ONGC

L&T

M/S RAINA ENGINERS,MUMBAI(ISO 9001 & API CERTIFIED)

OGSP/45000-60182/SRD, Dt. 23/10/2009

RE-25-12-50

1.2 AUX. HOIST:

S.

N.

MOTIO

N

LOAD

(Tons)

Distance

Load

Moved

(M)

AUX

HOIST

2M

1.

Time

record

ed

Averag

e time

1.31

1.38

1.35

1.346

Speed

(M/Min)

Act

Req.

.

76

89

Remar

ks

Accepte

d

1.3 SLEWING SPEED TEST:

RPM

Req.

Act.

S.N.

SLEW

MOTION

TIME

(Sec)

Revolutio

n

1.

SLEW LEFT

39

1.5

1.53

Accepted

2.

SLEW RIGHT

40

1.5

1.5

Accepted

Remarks

2. LOAD TESTS:

2.1 MAIN HOIST:

CRANE RADIUS

(MTRS)

STATIC RATED

LOAD (TONS)

ACTUAL LIFTED

LOAD (TONS)

REMARK

8.50

16.0

25.0

32.0

38.0

42.0

12

12

12

12

12

12

12

12

12

12

12

12

OK

OK

OK

OK

OK

OK

2.2 AUXILLIARY HOIST:

CRANE RADIUS

(MTRS)

RATED LOAD

(TONS)

ACTUAL LIFTED

LOAD (TONS)

REMARK

Minimum to

Maximum

OK

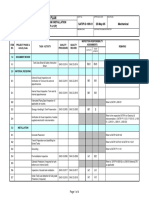

INSPECTION & TESTING REPORT OF CRANE ASSEMBLY

Project

OWNER

CONTRACTOR

VENDOR

PO NO

CRANE MODEL

MHN PROCESS PLATFORM & LQ PROJECT

ONGC

L&T

M/S RAINA ENGINERS,MUMBAI(ISO 9001 & API CERTIFIED)

OGSP/45000-60182/SRD, Dt. 23/10/2009

RE-25-12-50

2.3 OVER LOAD TEST:

Overload test with load 1.33 times of SWL i.e. 16MT at 25 meter radius

performed and found satisfactory.

3. FUNCTIONAL TESTS OF ELECTRICAL ACCESSORIES:

LIGHTS

Location

Remark

Flood light

Boom

O.K.

Air craft Light

Boom tip

O.K.

Air craft Light

Top of yoke

O.K.

Bulk head lights

Cabin

O.K.

Bulk Head lights

Walkway

O.K.

Bulk head lights

Engine room

O.K.

4. POWER PACK PARAMETRS:

S.

N.

PARAMETER CHECK

OBSERVATION

Flow (LPM)

1

2

3

4

5

6

7

8

9

REMARKS

Pressure(BAR

)

Main Pump

Main motor

Aux. pump

Aux. Motor

Slew Pump

Slew Motor

Luff Pump

Luff Motor

Taco hour meter

Running RPM

5.ACCESSORIES CHECK

S.N

1

TAG Description

Jib angle indicator functional check for

angle indication from minimum to

maximum angle

REMARK

VERIFIED & OK

INSPECTION & TESTING REPORT OF CRANE ASSEMBLY

Project

OWNER

CONTRACTOR

VENDOR

PO NO

CRANE MODEL

2

3

4

5

6

7

8

MHN PROCESS PLATFORM & LQ PROJECT

ONGC

L&T

M/S RAINA ENGINERS,MUMBAI(ISO 9001 & API CERTIFIED)

OGSP/45000-60182/SRD, Dt. 23/10/2009

RE-25-12-50

Boom Back stopper

VERIFIED & OK

Slew Lock

VERIFIED & OK

Luff pawl cylinder

VERIFIED & OK

EPU

VERIFIED & OK

Speed variation

VERIFIED & OK

Start & Stop

VERIFIED & OK

Wiper assembly

VERIFIED & OK

6. Manual and Controlled lowering of the load by stopping the prime mover is

checked for main and auxiliary hoist and found satisfactory.

7. Anti two blocks test for main & auxiliary hooks carried out and found

satisfactory.

8. Control Panel functional test indication alarms 7 shutdown checked &

found satisfactory.

9. Functional test of Pneumatic & Hydraulic starter carried out and found

satisfactory.

10. PAINTING:

10.1 FINAL DFT:

Sr. No.

1

2

3

4

5

6

7

8

9

10

CRANE

COMPONENTS

Crane Base

Yoke

Boom( Base section)

Boom ( Insert section)

Boom ( Top section)

Canopy

Boom Cat ladder

Bottom catwalk

Hammer head catwalk

Yoke catwalk

DFT

365

365

365

365

365

365

365

365

365

365

TO

TO

TO

TO

TO

TO

TO

TO

TO

TO

450

450

450

450

450

450

450

450

450

450

REMARK

Acceptable

Acceptable

Acceptable

Acceptable

Acceptable

Acceptable

Acceptable

Acceptable

Acceptable

Acceptable

10.2 HOLIDAY TEST:

Sr. No.

CRANE

REMARK

INSPECTION & TESTING REPORT OF CRANE ASSEMBLY

Project

OWNER

CONTRACTOR

VENDOR

PO NO

CRANE MODEL

1

2

3

4

5

6

7

8

9

10

MHN PROCESS PLATFORM & LQ PROJECT

ONGC

L&T

M/S RAINA ENGINERS,MUMBAI(ISO 9001 & API CERTIFIED)

OGSP/45000-60182/SRD, Dt. 23/10/2009

RE-25-12-50

COMPONENTS

Crane Base

Yoke

Boom( Base section)

Boom ( Insert section)

Boom ( Top section)

Canopy

Boom Cat ladder

Bottom catwalk

Hammer head catwalk

Yoke catwalk

Satisfactory

Satisfactory

Satisfactory

Satisfactory

Satisfactory

Satisfactory

Satisfactory

Satisfactory

Satisfactory

Satisfactory

10.3DIMENSIONAL CHECK:

S.N.

1

2

3

PARAMETERS

Base lug centre to Top

Sheave Pin Center

Total Boom length

Tail Radius

READINGS

REMARK

10006,10008

Accepted

42009,42012

5466,5467

Accepted

Accepted

7. NOISE LEVEL:

S.N.

1

2

3

Parameters

At 1 meter away

from engine

Inside cabin

At 1 meter away

from Crane on the

ground

READINGS( minimum 4)

REMARK

74 dB,77 dB, 76 dB, 75 dB

Accepted

72 dB,75 dB,73 dB,70 dB

Accepted

70 dB,73 dB,71 dB, 72 dB

Accepted

Based on above observation, the crane meets the requirements of PO and API 2C and released for

dispatch.

INSPECTED BY:

VERIFIED BY:

Potrebbero piacerti anche

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineDa EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineValutazione: 5 su 5 stelle5/5 (1)

- Msog-m1611-Qaqc-gp-002 - Code 2 - Itp Piping and StructuresDocumento5 pagineMsog-m1611-Qaqc-gp-002 - Code 2 - Itp Piping and StructuresMohd SaffririzalNessuna valutazione finora

- Legends: Quality Assurance PlanDocumento3 pagineLegends: Quality Assurance PlanShrikant KajaleNessuna valutazione finora

- FQP of Water Tank Power Mech 2Documento4 pagineFQP of Water Tank Power Mech 2Kumar Krishna MandalNessuna valutazione finora

- Test Forms For SSDocumento105 pagineTest Forms For SSRakesh Kumar75% (4)

- Albany Profile (GT) RevDocumento48 pagineAlbany Profile (GT) RevHeri SetyantoNessuna valutazione finora

- 50037-QA-PLN-002 Rev.0Documento13 pagine50037-QA-PLN-002 Rev.0seehari100% (3)

- A-Qac-Pro-730-38930 Rev ADocumento10 pagineA-Qac-Pro-730-38930 Rev ARamzi ZoghlamiNessuna valutazione finora

- Iocl Shut Down PresentationDocumento92 pagineIocl Shut Down Presentationsanjay4210% (1)

- Emergent Repairs To Riding Surace KM 3.6 - 4.8Documento6 pagineEmergent Repairs To Riding Surace KM 3.6 - 4.8venugopalchintaNessuna valutazione finora

- Itp - Rev eDocumento36 pagineItp - Rev ezaki_saddarNessuna valutazione finora

- Resume An Welding InspectorDocumento7 pagineResume An Welding InspectorspearboraNessuna valutazione finora

- Motor Testing and General Checks FormatDocumento4 pagineMotor Testing and General Checks FormatRaj Kiran77% (22)

- QAP For Conical StrainerDocumento2 pagineQAP For Conical StrainersatishchidrewarNessuna valutazione finora

- Resume: Voltech Engineers PVT LTDDocumento7 pagineResume: Voltech Engineers PVT LTDsarunkvpNessuna valutazione finora

- Lva1 App6891Documento11 pagineLva1 App6891ganeshram2305Nessuna valutazione finora

- Itp Mast TruckDocumento3 pagineItp Mast TruckArisNessuna valutazione finora

- Client: Phed, Rajasthan Contractor: NCC Limited Project: Sheet ofDocumento2 pagineClient: Phed, Rajasthan Contractor: NCC Limited Project: Sheet ofJacob B ChackoNessuna valutazione finora

- S-202A (Inspection and Testing Plan) Rev-0Documento6 pagineS-202A (Inspection and Testing Plan) Rev-0AliDadKhanNessuna valutazione finora

- 037-Procedure For Cleanliness PDFDocumento21 pagine037-Procedure For Cleanliness PDFKöksal PatanNessuna valutazione finora

- Bijukumar - CVDocumento8 pagineBijukumar - CVbijukumarNessuna valutazione finora

- Government of Andhra Pradesh Roads and Buildings DepartmentDocumento11 pagineGovernment of Andhra Pradesh Roads and Buildings DepartmentvenugopalchintaNessuna valutazione finora

- TBE Pumps CP 16Documento21 pagineTBE Pumps CP 16ivomNessuna valutazione finora

- SATIP-A-004-01 Rev 7Documento2 pagineSATIP-A-004-01 Rev 7Bebin Mathew100% (1)

- Data Sheet of Local Control StationsDocumento4 pagineData Sheet of Local Control StationsDharmenderSinghChoudharyNessuna valutazione finora

- FQP For Civil WorkDocumento15 pagineFQP For Civil WorkManoj ShahNessuna valutazione finora

- Technofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIDocumento9 pagineTechnofac: Welding Inspector CSWIP 3.1 Non Destructive Examination (NDE), ASNT Level-IIElankumaran PeriakaruppanNessuna valutazione finora

- 28 - Uninterrupted Power Supply (Ups)Documento8 pagine28 - Uninterrupted Power Supply (Ups)jigyeshNessuna valutazione finora

- 02 MechanicalDocumento44 pagine02 MechanicalSigit Bintan100% (1)

- Expansion ProcedureDocumento13 pagineExpansion ProcedureMani Tamil100% (1)

- 5657-Jawad Hanif CV TakreerDocumento6 pagine5657-Jawad Hanif CV TakreerkanchithalaiNessuna valutazione finora

- FQP - Civil NewDocumento13 pagineFQP - Civil NewVenkatesh MudragadaNessuna valutazione finora

- Capability Dl&tocument For Process Platforms PDFDocumento72 pagineCapability Dl&tocument For Process Platforms PDFSunil SinghNessuna valutazione finora

- QAP EWS & LIG Houses - AMC - R-0Documento6 pagineQAP EWS & LIG Houses - AMC - R-0Vijay SinghNessuna valutazione finora

- Mech Engg CVDocumento5 pagineMech Engg CVShams TabrezNessuna valutazione finora

- 19 Pre Hydro TestingDocumento5 pagine19 Pre Hydro TestingManoranjan sharmaNessuna valutazione finora

- APIINSPECTORDocumento10 pagineAPIINSPECTORdada khalandarNessuna valutazione finora

- CV & Certficate Merged.hDocumento28 pagineCV & Certficate Merged.hAjyal Union Ltd. Co.Nessuna valutazione finora

- Satr S 4001Documento1 paginaSatr S 4001mahdi_gNessuna valutazione finora

- Dry TR TestDocumento9 pagineDry TR Testamjaad100% (1)

- SRV Detaisl Awa Salawas PDFDocumento222 pagineSRV Detaisl Awa Salawas PDFdiwakarngm100% (1)

- Satip A 004 03Documento3 pagineSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- 00 ZA E 02018 Att2B-Test Pack Contents 00ADocumento30 pagine00 ZA E 02018 Att2B-Test Pack Contents 00AThamaraikani Mani100% (1)

- Satip G 005 01Documento2 pagineSatip G 005 01Anonymous 4e7GNjzGWNessuna valutazione finora

- Coupler Plate DP TestDocumento1 paginaCoupler Plate DP Testshindemitesh17Nessuna valutazione finora

- Ei-Xxx Gouri Sap#80001434 CVDocumento9 pagineEi-Xxx Gouri Sap#80001434 CVNimra RizwanNessuna valutazione finora

- Sharda Engineers & Constructions: Liquid Penetrant Test Inspection ReportDocumento2 pagineSharda Engineers & Constructions: Liquid Penetrant Test Inspection ReportAmol KhatateNessuna valutazione finora

- R As0007 Qa Proc 0744 - Fat Procedure Precoat - r0Documento42 pagineR As0007 Qa Proc 0744 - Fat Procedure Precoat - r0phamthaituyen100% (1)

- ITP For HRSG OperationDocumento5 pagineITP For HRSG Operationmister pogi0% (1)

- 1 SATIP-D-109-01 Shop Fab Storage Tank PDFDocumento4 pagine1 SATIP-D-109-01 Shop Fab Storage Tank PDFJithuJohnNessuna valutazione finora

- Inspection & Test PlanDocumento1 paginaInspection & Test PlanMelissa MurrayNessuna valutazione finora

- Qap of Motor R 3Documento7 pagineQap of Motor R 3buntysurat100% (1)

- ITP For Batteries, Chargers and UPSDocumento7 pagineITP For Batteries, Chargers and UPSUtku Can Kılıç100% (1)

- MS - Road and PavingDocumento15 pagineMS - Road and PavingbukhoriNessuna valutazione finora

- QC Inspection CV UpdatedDocumento7 pagineQC Inspection CV UpdatedEr AkhlaqueNessuna valutazione finora

- Ppap Spacer TubeDocumento37 paginePpap Spacer TubeSeenivasagam SeenuNessuna valutazione finora

- GVK Power (Goindwal Sahib) Limited, GVK Power (Goindwal Sahib) Limited Thermal Power PlantDocumento15 pagineGVK Power (Goindwal Sahib) Limited, GVK Power (Goindwal Sahib) Limited Thermal Power PlantRohit100% (1)

- CV (Sr. QA QC Engineer)Documento5 pagineCV (Sr. QA QC Engineer)mansih457100% (1)

- MD 04 MT Rssta CH 501Documento11 pagineMD 04 MT Rssta CH 501Nguyễn Đặng LâmNessuna valutazione finora

- Akhtar Ansari - TPI - FRT PDFDocumento5 pagineAkhtar Ansari - TPI - FRT PDFAkhtar AnsariNessuna valutazione finora

- Tank Nos 16.9.2017Documento9 pagineTank Nos 16.9.2017Anonymous rYZyQQot55Nessuna valutazione finora

- Calibration Service ReportDocumento1 paginaCalibration Service ReportAnonymous rYZyQQot55Nessuna valutazione finora

- Welders Certification Designation Acc. To EN ISO 9606-1Documento1 paginaWelders Certification Designation Acc. To EN ISO 9606-1vonipko100% (9)

- Tank Nos - 315KVADocumento14 pagineTank Nos - 315KVAAnonymous rYZyQQot55Nessuna valutazione finora

- Welders For SS & DuplexDocumento1 paginaWelders For SS & DuplexAnonymous rYZyQQot55Nessuna valutazione finora

- Iso DWG No S/F Joint Size SCH B/FDocumento40 pagineIso DWG No S/F Joint Size SCH B/FAnonymous rYZyQQot55Nessuna valutazione finora

- Welder's Master ListDocumento8 pagineWelder's Master ListAnonymous rYZyQQot55Nessuna valutazione finora

- RT Rejected ReportDocumento1 paginaRT Rejected ReportAnonymous rYZyQQot55Nessuna valutazione finora

- MF-BF-FF-27-0130 - r1 - Fire Fighting Piping Plan For RO Building (1of2)Documento1 paginaMF-BF-FF-27-0130 - r1 - Fire Fighting Piping Plan For RO Building (1of2)Anonymous rYZyQQot55Nessuna valutazione finora

- Geu 001Documento1 paginaGeu 001Anonymous rYZyQQot55Nessuna valutazione finora

- Piping QC Resume-Akhilesh ADocumento3 paginePiping QC Resume-Akhilesh AAnonymous rYZyQQot55Nessuna valutazione finora

- Iso DWG No S/F Joint Size SCH B/FDocumento10 pagineIso DWG No S/F Joint Size SCH B/FAnonymous rYZyQQot55Nessuna valutazione finora

- Egd 001Documento8 pagineEgd 001Anonymous rYZyQQot55Nessuna valutazione finora

- FF Dia Inc ProgressDocumento64 pagineFF Dia Inc ProgressAnonymous rYZyQQot55Nessuna valutazione finora

- Electrode Brand Name and Class MirfaDocumento13 pagineElectrode Brand Name and Class MirfaAnonymous rYZyQQot55Nessuna valutazione finora

- Area Iso DWG No Joint S/F Size SCH Thick Welding Infomation Date W1 W2 W3Documento2 pagineArea Iso DWG No Joint S/F Size SCH Thick Welding Infomation Date W1 W2 W3Anonymous rYZyQQot55Nessuna valutazione finora

- RT History FGDocumento91 pagineRT History FGAnonymous rYZyQQot55Nessuna valutazione finora

- Hydro Vs PneumaticDocumento4 pagineHydro Vs PneumaticAnonymous rYZyQQot55Nessuna valutazione finora

- Welder List For WQTDocumento1 paginaWelder List For WQTAnonymous rYZyQQot55Nessuna valutazione finora

- Pintoosingh Chart BookDocumento8 paginePintoosingh Chart BookAnonymous rYZyQQot55Nessuna valutazione finora

- QC RequirementsDocumento1 paginaQC RequirementsAnonymous rYZyQQot55Nessuna valutazione finora

- MF-BF-FF-27-0130 - r1 - Fire Fighting Piping Plan For RO Building (1of2)Documento1 paginaMF-BF-FF-27-0130 - r1 - Fire Fighting Piping Plan For RO Building (1of2)Anonymous rYZyQQot55Nessuna valutazione finora

- Welder List For WQTDocumento1 paginaWelder List For WQTAnonymous rYZyQQot550% (2)

- Welding Material Requirement Dt. 08.05.2013Documento1 paginaWelding Material Requirement Dt. 08.05.2013Anonymous rYZyQQot55Nessuna valutazione finora

- Welding Record February 2016Documento72 pagineWelding Record February 2016Anonymous rYZyQQot55Nessuna valutazione finora

- Update Welder's List (Material)Documento12 pagineUpdate Welder's List (Material)Anonymous rYZyQQot55Nessuna valutazione finora

- Letter Pad-Mvijay KumarDocumento1 paginaLetter Pad-Mvijay KumarAnonymous rYZyQQot55Nessuna valutazione finora

- Iso DWG No Rev Joint Area W.G B/F SystemDocumento22 pagineIso DWG No Rev Joint Area W.G B/F SystemAnonymous rYZyQQot55Nessuna valutazione finora

- Welder's Mobilisation List: Sr. No. Welder's Name Welding Process Welding Position Welder's I.DDocumento2 pagineWelder's Mobilisation List: Sr. No. Welder's Name Welding Process Welding Position Welder's I.DAnonymous rYZyQQot55Nessuna valutazione finora

- Welding Material Requirement Dt. 08.05.2013Documento1 paginaWelding Material Requirement Dt. 08.05.2013Anonymous rYZyQQot55Nessuna valutazione finora

- Repair of A Hull 15 M Below The WaterlineDocumento8 pagineRepair of A Hull 15 M Below The WaterlineRonny De La CruzNessuna valutazione finora

- Introduction To Casting ProcessesDocumento11 pagineIntroduction To Casting Processesuvsing100% (2)

- Reginald Anesu Tobaiwa: Professional ProfileDocumento2 pagineReginald Anesu Tobaiwa: Professional ProfileARUN VISHWAKARMANessuna valutazione finora

- Layout: Rear View Front ViewDocumento14 pagineLayout: Rear View Front ViewRms AutomotrizNessuna valutazione finora

- Most Common Types of Welding DefectsDocumento23 pagineMost Common Types of Welding DefectsRommel GocotanoNessuna valutazione finora

- BE Specs VG1000 M9000 TableDocumento3 pagineBE Specs VG1000 M9000 TableKumar sssssNessuna valutazione finora

- BHFQ22P1517 ImDocumento14 pagineBHFQ22P1517 ImAlberto Bravo SánchezNessuna valutazione finora

- 4301 L 2 - 2006Documento23 pagine4301 L 2 - 2006Indra H BasriNessuna valutazione finora

- Mercury Verado ManualDocumento186 pagineMercury Verado ManualAnonymous M0OEZEKoGiNessuna valutazione finora

- ME 525 April 17, 2020 Internal Combustion Engine Performance Problems Set 1 InstructionsDocumento2 pagineME 525 April 17, 2020 Internal Combustion Engine Performance Problems Set 1 Instructionssixela arugalNessuna valutazione finora

- Bearing Nomenclature Housing NomenclatureDocumento7 pagineBearing Nomenclature Housing NomenclatureRajmohan KushwahaNessuna valutazione finora

- Delo Protection For Agricultural Equipment: Engine Crankcase Hydraulic SystemDocumento1 paginaDelo Protection For Agricultural Equipment: Engine Crankcase Hydraulic SystemflyinzeskyNessuna valutazione finora

- Power Team Manual Valves - CatalogDocumento1 paginaPower Team Manual Valves - CatalogTitanplyNessuna valutazione finora

- 7 Overhaul Protocol COP 4050 - LR-ForMDocumento2 pagine7 Overhaul Protocol COP 4050 - LR-ForMChachou MohamedNessuna valutazione finora

- Simba E7-SeriesDocumento8 pagineSimba E7-SeriesVictor BalboaNessuna valutazione finora

- SL-SN.0 Drum Brake - 03.09Documento38 pagineSL-SN.0 Drum Brake - 03.09Cem DufourNessuna valutazione finora

- 1221.2 1221.3 en Year 2009Documento295 pagine1221.2 1221.3 en Year 2009crismg1100% (1)

- Homogenizer Commisioning Checklist 2014Documento4 pagineHomogenizer Commisioning Checklist 2014Victor Alberto Ramos BarronNessuna valutazione finora

- FP IgniterDocumento13 pagineFP IgniterDavid AlexanderNessuna valutazione finora

- NOx Reduction MethodsDocumento7 pagineNOx Reduction Methodsmithunsingh90Nessuna valutazione finora

- Relative AccelerationDocumento3 pagineRelative AccelerationJanaka PriyalalNessuna valutazione finora

- K GBDocumento18 pagineK GBLuis Fernando Juchani MoralesNessuna valutazione finora

- Astm A216Documento4 pagineAstm A216salazaralexi100% (1)

- Royal Military College of Science - Cranfield University: ReliabilityDocumento4 pagineRoyal Military College of Science - Cranfield University: ReliabilitySanjay MehrishiNessuna valutazione finora

- Kinesiology MCQ PDFDocumento6 pagineKinesiology MCQ PDFHasan Rahman79% (14)

- Screw Type - Elite Air CompressorDocumento1 paginaScrew Type - Elite Air Compressorimron rosyadiNessuna valutazione finora

- Furmanite Datasheet For FittingDocumento8 pagineFurmanite Datasheet For FittingozcanNessuna valutazione finora

- New Holland E57C Mini Excavator Service Repair ManualDocumento21 pagineNew Holland E57C Mini Excavator Service Repair ManualggjjjjotonesNessuna valutazione finora

- Population Balance Modelling To Describe The Particle Aggregation Process: A ReviewDocumento18 paginePopulation Balance Modelling To Describe The Particle Aggregation Process: A ReviewAlexander FierroNessuna valutazione finora

- Eita Elevators General Function GuideDocumento6 pagineEita Elevators General Function GuideLewKarKeong100% (1)

- The Voice of God: Experience A Life Changing Relationship with the LordDa EverandThe Voice of God: Experience A Life Changing Relationship with the LordNessuna valutazione finora

- Confinement (Book #1 in the Love and Madness series)Da EverandConfinement (Book #1 in the Love and Madness series)Nessuna valutazione finora

- From Raindrops to an Ocean: An Indian-American Oncologist Discovers Faith's Power From A PatientDa EverandFrom Raindrops to an Ocean: An Indian-American Oncologist Discovers Faith's Power From A PatientValutazione: 1 su 5 stelle1/5 (1)

- Locked Away (Book #2 in the Love and Madness series)Da EverandLocked Away (Book #2 in the Love and Madness series)Nessuna valutazione finora

- Cadet Willie McBride - Operation CrocodileDa EverandCadet Willie McBride - Operation CrocodileNessuna valutazione finora