Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

2010-01-04 205417 Bronson

Caricato da

Vladimir StoiljkovićTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

2010-01-04 205417 Bronson

Caricato da

Vladimir StoiljkovićCopyright:

Formati disponibili

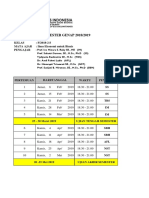

Solutions Guide:

Bronson Company manufactures a variety of ballpoint pens. The company has just

received an offer from an outside supplier to provide the ink cartridge for the companys

Zippo pen line, at a price of $0.48 per dozen cartridges. The company is interested in this

offer, since its own production of cartridges is at capacity. Bronson Company estimates

that if the suppliers offer were accepted, the direct labor and variable manufacturing

overhead costs of the Zippo pen line would be reduced by 10% and the direct materials

cost would be reduced by 20%. Under present operations, Bronson Company

manufactures all of its own pens from start to finish. The Zippo pens are sold through

wholesalers at $4 per box. Each box contains one dozen pens. Fixed manufacturing

overhead costs charged to the Zippo pen line total $50,000 each year. (The same

equipment and facilities are used to produce several pen lines.) The present cost of

producing one dozen Zippo pens (one box) is given below: Direct

materials . . . . . . . . . . . . . . . . . $1.50 Direct labor . . . . . . . . . . . . . . . . . . . . 1.00

Manufacturing overhead . . . . . . . . . . 0.80* Total cost . . . . . . . . . . . . . . . . . . . . . . $3.30

*Includes both variable and fixed manufacturing overhead, based on production of

100,000 boxes of pens each year. Required: 1. Should Bronson Company accept the

outside suppliers offer? Show computations. 2. What is the maximum price that Bronson

Company should be willing to pay the outside supplier per dozen cartridges? Explain. 3.

Due to the bankruptcy of a competitor, Bronson Company expects to sell 150,000 boxes

of Zippo pens next year. As stated above, the company presently has enough capacity to

produce the cartridges for only 100,000 boxes of Zippo pens annually. By incurring

$30,000 in added fixed cost each year, the company could expand its production of

cartridges to satisfy the anticipated demand for Zippo pens. The variable cost per unit to

produce the additional cartridges would be the same as at present. Under these

circumstances, how many boxes of cartridges should be purchased from the outside

supplier and how many should be made by Bronson? Show computations to support your

answer. 4. What qualitative factors should Bronson Company consider in determining

whether it should make or buy the ink cartridges?

1. The fixed overhead costs are common and will remain the same regardless of whether

the cartridges are produced internally or purchased outside. Hence, they are not

relevant. The variable manufacturing overhead cost per box of pens is $0.30, as

shown below:

Total manufacturing overhead cost per box of pens.............................

Less fixed manufacturing overhead ($50,000 100,000 boxes).........

Variable manufacturing overhead cost per box....................................

$0.80

0.50

$0.30

The total variable cost of producing one box of Zippo pens is:

Direct materials....................................................................................

Direct labor...........................................................................................

Variable manufacturing overhead.........................................................

$1.50

1.00

0.30

Total variable cost per box...................................................................

$2.80

If the cartridges for the Zippo pens are purchased from the outside supplier, then the

variable cost per box of Zippo pens would be:

Direct materials ($1.50 80%)............................................................

Direct labor ($1.00 90%)...................................................................

Variable manufacturing overhead ($0.30 90%)................................

Purchase of cartridges..........................................................................

Total variable cost per box...................................................................

$1.20

0.90

0.27

0.48

$2.85

The company should reject the outside suppliers offer. Producing the cartridges

internally costs $0.05 less per box of pens than purchasing them from the supplier.

Another approach to the solution is:

Cost avoided by purchasing the cartridges:

Direct materials ($1.50 20%).........................................................

Direct labor ($1.00 10%)...............................................................

Variable manufacturing overhead ($0.30 10%).............................

Total costs avoided............................................................................

$0.30

0.10

0.03

$0.43

Cost of purchasing the cartridges.........................................................

$0.48

Cost savings per box by making cartridges internally.........................

$0.05

Note that the avoidable cost of $0.43 above represents the cost of making one box of

cartridges internally.

2. The company would not want to pay any more than $0.43 per box, since it can make

the cartridges for this amount internally.

3. The company has three alternatives for obtaining the necessary cartridges. It can:

#1

#2

#3

Produce all cartridges internally.

Purchase all cartridges externally.

Produce the cartridges for 100,000 boxes internally and purchase the cartridges for

50,000 boxes externally.

The costs under the three alternatives are:

Alternative #1Produce all cartridges internally:

Variable costs (150,000 boxes $0.43 per box).....................................

Fixed costs of adding capacity................................................................

Total cost.................................................................................................

Alternative #2Purchase all cartridges externally:

$64,500

30,000

$94,500

Variable costs (150,000 boxes $0.48 per box).......................................

$72,000

Alternative #3Produce 100,000 boxes internally, and purchase 50,000

boxes externally:

Variable costs:

100,000 boxes $0.43 per box........................................................

50,000 boxes $0.48 per box..........................................................

Total cost..............................................................................................

$43,000

24,000

$67,000

Or, in terms of total cost per box of pens, the answer would be:

Alternative #1Produce all cartridges internally:

Variable costs (150,000 boxes $2.80 per box).....................................

Fixed costs of adding capacity................................................................

Total cost.................................................................................................

$420,000

30,000

$450,000

Alternative #2Purchase all cartridges externally:

Variable costs (150,000 boxes $2.85 per box).....................................

$427,500

Alternative #3Produce the cartridges for 100,000 boxes internally, and

purchase the cartridges for 50,000 boxes externally:

Variable costs:

100,000 boxes $2.80 per box.......................................................

50,000 boxes $2.85 per box.........................................................

Total cost..............................................................................................

$280,000

142,500

$422,500

Thus, the company should accept the outside suppliers offer, but only for the

cartridges for 50,000 boxes.

4. In addition to cost considerations, Bronson should take into account the following

factors:

a) The ability of the supplier to meet required delivery schedules.

b) The quality of the cartridges purchased from the supplier.

c) Alternative uses of the capacity that is used to make the cartridges.

d) The ability of the supplier to supply cartridges if volume increases in future years.

e) The problem of alternative sources of supply if the supplier proves undependable.

Potrebbero piacerti anche

- Comprehensive Master Budget Accounting 2302 Professor Norma JacobsDocumento5 pagineComprehensive Master Budget Accounting 2302 Professor Norma JacobsOmar Gibson0% (1)

- 3 Assignment of ACCT-301Documento3 pagine3 Assignment of ACCT-301Tina Bhambbhwani0% (1)

- Tugas Cost AccountingDocumento7 pagineTugas Cost AccountingRudy Setiawan KamadjajaNessuna valutazione finora

- Soal Kuis Asistensi AK1 Setelah UTSDocumento6 pagineSoal Kuis Asistensi AK1 Setelah UTSManggala Patria WicaksonoNessuna valutazione finora

- Problem Set #4Documento2 pagineProblem Set #4Oxky Setiawan WibisonoNessuna valutazione finora

- BMGT 321 Chapter 11 HomeworkDocumento9 pagineBMGT 321 Chapter 11 HomeworkarnitaetsittyNessuna valutazione finora

- Environmental Cost Management: Kelompok 1: Hilmy Fauzan Novia Kumala Sari Try SusantiDocumento34 pagineEnvironmental Cost Management: Kelompok 1: Hilmy Fauzan Novia Kumala Sari Try SusantiSeptian RizkyNessuna valutazione finora

- Profitability of Products and Relative ProfitabilityDocumento5 pagineProfitability of Products and Relative Profitabilityshaun3187Nessuna valutazione finora

- Opdrag: Inhandigingsdatum:: Assignment: Submission DateDocumento5 pagineOpdrag: Inhandigingsdatum:: Assignment: Submission DateVeronica NhlapoNessuna valutazione finora

- 601 13,14 SolutionsDocumento37 pagine601 13,14 SolutionsRudi SyafputraNessuna valutazione finora

- Reigis Steel CompanyDocumento3 pagineReigis Steel CompanyDesy BodooNessuna valutazione finora

- ch-3 To ch-5Documento24 paginech-3 To ch-5Riya DesaiNessuna valutazione finora

- Sixty Employees All Cpas of A Local Public Accounting FirmDocumento1 paginaSixty Employees All Cpas of A Local Public Accounting FirmAmit PandeyNessuna valutazione finora

- HorngrenIMA14eSM ch13Documento73 pagineHorngrenIMA14eSM ch13Piyal Hossain100% (1)

- Tugas Chapter 13Documento6 pagineTugas Chapter 13irga ayudiasNessuna valutazione finora

- Kunci Jawaban Bab 5 Manajemen Biaya CompressDocumento10 pagineKunci Jawaban Bab 5 Manajemen Biaya Compressrilakkuma6Nessuna valutazione finora

- Reichard MaschinenDocumento23 pagineReichard MaschinenAliefiah AZNessuna valutazione finora

- The Cross-Price Elasticity of Demand For The Two Is CalculatedDocumento3 pagineThe Cross-Price Elasticity of Demand For The Two Is CalculatedhaNessuna valutazione finora

- FSDocumento4 pagineFSCiptawan CenNessuna valutazione finora

- Tugas Personal Ke - (1) Minggu 2Documento6 pagineTugas Personal Ke - (1) Minggu 2Olim BariziNessuna valutazione finora

- Olsson Company Uses Special Strapping Equipment in Its PackagingDocumento1 paginaOlsson Company Uses Special Strapping Equipment in Its PackagingM Bilal SaleemNessuna valutazione finora

- Solved Jack S Tracks Sells 24 000 Custom Designed Gokarts Per Year These GokartsDocumento1 paginaSolved Jack S Tracks Sells 24 000 Custom Designed Gokarts Per Year These GokartsAnbu jaromia0% (1)

- Chapter 2 Homework Manufacturing Economics and Computation Exercise With SolutionDocumento9 pagineChapter 2 Homework Manufacturing Economics and Computation Exercise With SolutionPhương NguyễnNessuna valutazione finora

- CH 10 SMDocumento17 pagineCH 10 SMapi-267019092Nessuna valutazione finora

- Kode QDocumento11 pagineKode QatikaNessuna valutazione finora

- Lambeth Custom CabinetsDocumento14 pagineLambeth Custom CabinetsHaider AliNessuna valutazione finora

- Cost Accounting 12-8Documento3 pagineCost Accounting 12-8RichKing100% (1)

- CH 11+16th+globalDocumento37 pagineCH 11+16th+globalAmina SultangaliyevaNessuna valutazione finora

- 150 199 PDFDocumento49 pagine150 199 PDFSamuelNessuna valutazione finora

- CAS 530 SamplingDocumento14 pagineCAS 530 SamplingzelcomeiaukNessuna valutazione finora

- PB8MAT+Relevan Cost - ExerciseDocumento4 paginePB8MAT+Relevan Cost - Exercisemichael winartaNessuna valutazione finora

- Case ReichardDocumento23 pagineCase ReichardDesiSelviaNessuna valutazione finora

- Problem Set #1 Solution: Part 1 (Cost of Capital)Documento4 pagineProblem Set #1 Solution: Part 1 (Cost of Capital)Shirley YeungNessuna valutazione finora

- Presented By: Ubaid Azam Wardag Babar Mustafa Muhammad UsmanDocumento13 paginePresented By: Ubaid Azam Wardag Babar Mustafa Muhammad UsmanShahid AshrafNessuna valutazione finora

- Cash BudgetingDocumento3 pagineCash BudgetingAngel Kitty Labor67% (3)

- 16.1 Chapter 5 Drury SolutionsDocumento14 pagine16.1 Chapter 5 Drury SolutionsNeacail Micallef75% (4)

- Precision Worldwide, Inc.Documento3 paginePrecision Worldwide, Inc.karan_w3Nessuna valutazione finora

- Scott CH 8 TRNSLTDocumento36 pagineScott CH 8 TRNSLTTika Tety PratiwiNessuna valutazione finora

- Problem 1. Classify The Following Costs Incurred by A Step Railing Manufacturing Company As DirectDocumento2 pagineProblem 1. Classify The Following Costs Incurred by A Step Railing Manufacturing Company As DirectRoyyan WicaksonoNessuna valutazione finora

- Chapter 9-45 Excel TemplateDocumento10 pagineChapter 9-45 Excel TemplateAlee Di VaioNessuna valutazione finora

- Chapter 12 SolutionsDocumento29 pagineChapter 12 SolutionsAnik Kumar MallickNessuna valutazione finora

- Chapter 19, Modern Advanced Accounting-Review Q & ExrDocumento17 pagineChapter 19, Modern Advanced Accounting-Review Q & Exrrlg4814100% (2)

- Akuntansi Manajemen Absoprtion CostingDocumento7 pagineAkuntansi Manajemen Absoprtion CostingMuhammad SyahNessuna valutazione finora

- CH 10Documento9 pagineCH 10Saleh RaoufNessuna valutazione finora

- CP - Cma CaseDocumento5 pagineCP - Cma CaseYicong GuNessuna valutazione finora

- FM Aaj KaDocumento15 pagineFM Aaj Kakaranzen50% (2)

- Solution Manual Managerial Accounting Hansen Mowen 8th Editions CH 5Documento1 paginaSolution Manual Managerial Accounting Hansen Mowen 8th Editions CH 5Alvin AdrianNessuna valutazione finora

- Contoh Soal Flexibel Budget PDFDocumento3 pagineContoh Soal Flexibel Budget PDFJaihut NainggolanNessuna valutazione finora

- Akutansi Biaya 3 BaruDocumento3 pagineAkutansi Biaya 3 Baruulfania eka0% (1)

- Chap 014Documento12 pagineChap 014dbjnNessuna valutazione finora

- Kelompok 6 - Tugas Week 13 - Akuntansi Manajemen - LDocumento3 pagineKelompok 6 - Tugas Week 13 - Akuntansi Manajemen - LMuhammad Rizki NoorNessuna valutazione finora

- Earn Hart Corporation Has Outstanding 3 000 000 Shares of Common PDFDocumento1 paginaEarn Hart Corporation Has Outstanding 3 000 000 Shares of Common PDFAnbu jaromiaNessuna valutazione finora

- MA Exam Paper May 2010Documento23 pagineMA Exam Paper May 2010MsKhan0078Nessuna valutazione finora

- Tutorial - Chapter 6 - Monopoly QuestionsDocumento5 pagineTutorial - Chapter 6 - Monopoly QuestionsNandiieNessuna valutazione finora

- ContrsctDocumento23 pagineContrsctMohammed Naeem Mohammed NaeemNessuna valutazione finora

- Chapter 7: Financial Reporting and Changing Prices: International Accounting, 6/eDocumento26 pagineChapter 7: Financial Reporting and Changing Prices: International Accounting, 6/eapi-241660930Nessuna valutazione finora

- 5762 10964 IM FinancialManagementandPolicy12e HorneDhamija 9788131754467Documento152 pagine5762 10964 IM FinancialManagementandPolicy12e HorneDhamija 9788131754467sukriti2812Nessuna valutazione finora

- Blue Book - Set 8-6Documento1 paginaBlue Book - Set 8-6Anna TungNessuna valutazione finora

- Homework Solution - Week 10 - Relevant Costing - GarrisonDocumento6 pagineHomework Solution - Week 10 - Relevant Costing - GarrisonGloria WongNessuna valutazione finora

- Collective Efficiency and Increasing Returns: by Hubert SchmitzDocumento28 pagineCollective Efficiency and Increasing Returns: by Hubert SchmitzFakhrudinNessuna valutazione finora

- A Brief History of Production FunctionsDocumento30 pagineA Brief History of Production Functionssamanfadaie123Nessuna valutazione finora

- Wage Determination Under Free Market ForcesDocumento5 pagineWage Determination Under Free Market ForcesKrishna Das ShresthaNessuna valutazione finora

- Management AccountingDocumento358 pagineManagement AccountingLeojelaineIgcoy100% (1)

- Prof. SARPV Chaturvedi - Business Management ProfileDocumento8 pagineProf. SARPV Chaturvedi - Business Management Profileलक्षमी नृसिहंन् वेन्कटपतिNessuna valutazione finora

- Economies and Diseconomies of ScaleDocumento2 pagineEconomies and Diseconomies of ScalesylveyNessuna valutazione finora

- Free MCX & NCDEX Market Report Via ExpertsDocumento9 pagineFree MCX & NCDEX Market Report Via ExpertsRahul SolankiNessuna valutazione finora

- Assignment # 6Documento9 pagineAssignment # 6Ahtsham Ilyas RajputNessuna valutazione finora

- Ayesha Umar Wahedi - CV 2016Documento4 pagineAyesha Umar Wahedi - CV 2016TanveerNessuna valutazione finora

- Did Quaker Oats Make An Error in Buying Snapple or Did They Manage It BadlyDocumento1 paginaDid Quaker Oats Make An Error in Buying Snapple or Did They Manage It BadlyDeavanjan RanjanNessuna valutazione finora

- Unit 1 MCQDocumento7 pagineUnit 1 MCQHan Nwe OoNessuna valutazione finora

- Econs 101 - Quiz #2 Answer KeyDocumento1 paginaEcons 101 - Quiz #2 Answer KeySano ManjiroNessuna valutazione finora

- Chapter 5 - Foriegn Exchange MarketDocumento67 pagineChapter 5 - Foriegn Exchange MarketHay Jirenyaa100% (1)

- CAPE Economics 2007 U1 P1Documento10 pagineCAPE Economics 2007 U1 P1aliciaNessuna valutazione finora

- Microeconomics An Intuitive Approach With Calculus 1st Edition Nechyba Test BankDocumento35 pagineMicroeconomics An Intuitive Approach With Calculus 1st Edition Nechyba Test Bankanthonytodd5jbw100% (20)

- Chapter 1 LmsDocumento22 pagineChapter 1 LmsSanaky Việt NamNessuna valutazione finora

- Cost, Revenue, and Profit Function Estimates by Kutlu, Liu, and Sickles - Oct-15-2018Documento66 pagineCost, Revenue, and Profit Function Estimates by Kutlu, Liu, and Sickles - Oct-15-2018Faizan MazharNessuna valutazione finora

- Agricultural Production Economics: Chapter 17 Two Inputs and Two OutputsDocumento39 pagineAgricultural Production Economics: Chapter 17 Two Inputs and Two OutputsHusseinNessuna valutazione finora

- Promotion Management: By: Priyanka Dang Subrata Jadon Prashant Gupta Farid Ashraf Anurag PrashantDocumento23 paginePromotion Management: By: Priyanka Dang Subrata Jadon Prashant Gupta Farid Ashraf Anurag PrashantAnurag PrashantNessuna valutazione finora

- Marx Modes of ProductionDocumento10 pagineMarx Modes of Productionnandini negiNessuna valutazione finora

- Accounting (Bcom) : Rotman Commerce Specialist OverviewDocumento4 pagineAccounting (Bcom) : Rotman Commerce Specialist OverviewMichael WangNessuna valutazione finora

- Sarkozy Attacks Focus On Economic GrowthDocumento1 paginaSarkozy Attacks Focus On Economic GrowthCocindau MonicaNessuna valutazione finora

- Summary of IAS 36-Impairment of AssetsDocumento4 pagineSummary of IAS 36-Impairment of AssetsVikash HurrydossNessuna valutazione finora

- Demand, Supply, and Market EquilibriumDocumento18 pagineDemand, Supply, and Market EquilibriumNIKNISHNessuna valutazione finora

- AGK Buddhism EssayDocumento7 pagineAGK Buddhism EssayAaron KingNessuna valutazione finora

- International Business Chapter 10Documento24 pagineInternational Business Chapter 10Rabiatul AndawiyahNessuna valutazione finora

- Presentation - Capital Expenditure and Operating Expenses BudgetsDocumento5 paginePresentation - Capital Expenditure and Operating Expenses BudgetsBVMF_RINessuna valutazione finora

- Operations Management: Customer-Focused PrinciplesDocumento13 pagineOperations Management: Customer-Focused PrinciplesYusranNessuna valutazione finora

- Include Us Out - Economic Development and Social Policy N The Creative IndustriesDocumento20 pagineInclude Us Out - Economic Development and Social Policy N The Creative Industries2lieNessuna valutazione finora

- Multi PageDocumento92 pagineMulti PageturtlebellyNessuna valutazione finora