Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A320 Air

Caricato da

Enrique BarberanTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A320 Air

Caricato da

Enrique BarberanCopyright:

Formati disponibili

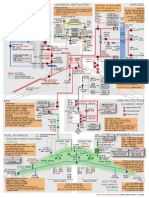

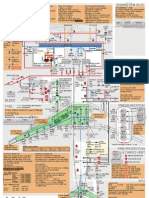

BLEED

AVIONICS VENTILATION

CAUTION, do not use

HP GND air with APU bleed

Regulated pressure 45 +/- 5 psi

Leak detection

- single loop for APU and pylon ducts

- double loop for wing ducts

FANs SPD (-IOM,-JLP-S) SKIN EXCH

HI if T > 40C

OUTLET

LO if T < 35C

BYPASS VLV

ENG A/ICE VALVE

ENG 1 [DC1]

ENG 2 [DC2]

valve opens if unpowered

SKIN HEAT

EXCHANGER

AEVC

[DC1]

[DC ESS

SHED]

FILTER

FAN AIR VALVE

ENG 1 [DC ESS SHED]

ENG 2 [DC2]

regulates BLEED temp at 200C

BLEED MONITORING

COMPUTER

BMC 1 [DC ESS SHED]

BMC 1 [DC2]

AIRCOND

INLET

VALVE

9th

STARTER VLV

*PACK CTL

Prim fail => reg. not optimized

Sec fail => ECAM sgnal lost

Both fail => 5-30C in 6

(IOM, JLP-S)

PACK 1

AIR COND SYS 1 CTL

by a/ice vlv

FLOW

*ZONE CTL

CONTROL *ZONE CTL

Prim

fail

=>

24C

by packs

CABIN

VALVE

Sec fail => no effect

AIR

[DC ESS

*PACK 1 CTL

Both fail => 20C pack 1

SHED]

10C pack 2

FILTER

CAB FAN 1

[AC1]

PACK

COCKPIT

1

HP VLV, maintain 36+/-4 psi

ENG 1 [DC ESS SHED]

ENG 2 [DC2]

HYD

RES

WATER

TANK

EMER

RAM AIR AIRCOND

GND

[DC ESS]

CONNECT

PACK 2

FLOW

CONTROL

VALVE [DC2]

PACK

2

LOOP A

LOOP B

SAFETY

VALVES

HP GND

CONNECT

only SLATS 3,4 & 5

are heated

OUTFLOW

VALVE

APU

ELECTRONIC

APU

LIMITATIONS

CONTROL BOX

BLEED

RPM min 95%, max 107% (auto shut down)

[BAT]

VALVE

running EGT max 682C (5sec) or 700-742

start EGT max 900C > 25'000ft

B

start EGT max 982C < 25'000ft

APU FF

LOW OIL LEVEL => 10 hrs APU ops

start cycles: S 1min S 1min S 60min

APU

Enveloppe:

STARTER

START with AC pwr up to 39'000ft

[BAT]

START with EMER ELEC pwr up to 25'000ft

APU LP VLV

BLEED ON 2packs max 15'000ft, 1 pack max 20'000ft

[DC BAT]

BLEED ON for engine start max 20'000ft

[HOT 1]

BLEED for WING A/ICE not permitted

APU FUEL FLOW ~130 kg/hr

APU PUMP

[DC BAT] P

[AC ESS

SHED]

refueling / defueling lines

feeding lines

FWD

CARGO

COMP

FF

B2

AFT

CARGO

COMP

MAN

MOT

[DC BAT]

MAN V/S

SWITCH

MOT 2

[DC2]

CPC 2

[DC2]

SATCOM

CABIN AIR

(85% recycle air)

IOM, JLP-S

AIR COND SYS CTL

one lane fail => no effect

both lanes fail => PACK lost

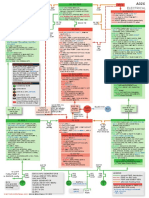

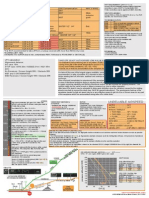

PRESSURIZATION

- CAB PR EXCESS CAB ALT (>9550+/-350ft)

RPCU (IOM, JLP-S)

Depressurizes in case of residual press on GND

FIRE PROTECTION

& CARGO VENT

SMOKE DETECTORS

CIDS (IOM, JLP-S)

CH1 [DC ESS]

CH2 [DC2]

BULK

CABIN AMBIENT AIR

CAB FAN 2

[AC2]

- 2 safety valves (max 8.6psi or -.25psi)

- RAM AIR ON and p<1psi, outfl. vlv 50% opens

SDCU (others)

CH1 [DC ESS SHED]

CH2 [DC2]

A321 only

INLET

ISOL

VALVE

AFT

CABIN

(IOM, JLP-S)

AIR COND SYS 2 CTL

CPC 1

[DC ESS]

SQUIBS

B [DC BAT]

EXTRACT FAN

[AC1]

*ZONE CTL

MOT 1

[DC ESS]

A321 only

OUTLET ISOL

VALVE

*PACK 2 CTL

FWD

CABIN

TRIM

AIR VALVES

FILTER

B1

X-BLEED VLV

AUTOCTL [DC2]

MANCTL [DC ESS SHED]

HOT BLEED

COLD FAN AIR

COLD AIR FROM PACK

MIXED CONDITIONNED AIR

WING ANTI ICE VLV

[AC ESS SHED]

Valve closes if unpowered

FF

FF

temperature

indication

TRIM

AIR VALVES

MIXING

UNIT

(ENG 1 only)

pressure

indication

OVERPRESS

VALVE (85psi)

FLAP

VALVE

HOT AIR

PRESS

REG VLV

SKIN

EXCH

INLET

BYPASS

VLV

cargo

under-floor

5th

BLEED VALVE

ENG 1 [DC ESS SHED]

ENG 2 [DC2]

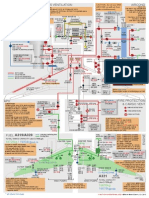

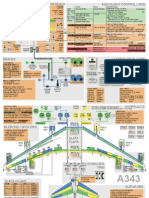

FUEL A319/A320

SKIN

EXCH

ISOL

VLV

BLOWER COCKPIT EXTRACT

PANELS

FAN

FAN SKIN AIR

[AC1]

[AC2] EXTRACT

AVIONICS

VLV

EQPMT

SKIN AIR

INLET VLV

AIRCOND

CAUTION, do not use GND

AIRCOND air with air from

packs simultaneously

CONFIGURATIONS:

CLOSED, on GND (skin<9-12C), in FLT(skin<32-35C)

INTERMEDIATE if (skin>32-35C) then EXTRACT VLV partially opens

OPEN, on GND (skin>9-12C)

SMOKE CONFIG

Air from avionics bay

CARGO

VENTILATION

CONTROL

[DC BAT]

FIRE DETECTORS

FIREX BOTTLES

ELECTRICAL SUPPLY

ENG 1 loop A [DC ESS], loop B [DC2]

ENG 2 loop A [DC2], loop B [DC ESS]

APU loop A & B[DC BAT]

ENG 1&2 BTL 1 squib A [HOT1] squib B [HOT2]

ENG 1&2 BTL 2 squib A [DC2] squib B [DC2]

APU BTL squib A [HOT1] squib B [DC BAT]

APU auto extinguish [DC BAT]

FUEL

EIU

NOZZLES ENG1 [DC BAT]

ENG2 [DC ESS]

18728kg / 19004kg

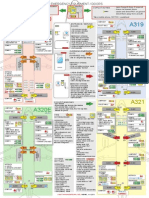

ENGINE

A319: CFM56-5B6/2 23'500lbs

A320: CFM56-5B4/2 27'000lbs

A320E: CFM56-5B4/P 27'000lbs

TOTAL TANKS CAPACITY (den 0.785kg/l)

A321: CFM56-5B1/2 30'000lbs

FF

CENTER TANK

CENTER

TANK

N1 100% = 5000 rpm

(JLP-S)

HP VLV [DC ESS]

N2 100% = 14460 rpm

6437kg

6476kg

OUTER to INNER TRANSFER

FUEL METERING VLV TOGA EGT max 950 (5, 10OEI)

X-FEED

- XFR valves open when INNER have ~750kg

ENG cool-down time 3' (1' for ops)

IDG OIL COOLER

MOT 1 [DC ESS SHED]

LP VALVE

- T/O only with Outer TK full

START cycle 4x(St.2/20) then 15

MOT 2 [DC1]

SERVO FUEL

MOT 1 [DC ESS]

- Automatic XFR after landing

ENG

IGNITION

HEATER

MOT 2 [DC2]

(to avoid, switch REFUEL panel PWR ON!)

FADEC

PMP

FUEL/OIL HEAT ENG1&2 CH A [DC ESS] ENG1&2 A [AC ESS]

jet pump

or transfer via DEFUEL/XFR valve.

or

[AC

STAT INV]

1

ENG1 CHB [DC BAT]

LP VALVE

ENG1 B [AC1]

DEFUEL

ENG2

CHB

[DC2]

MOT 1 [DC ESS]

ENG2 B [AC2]

XFR

FQI

INNER TANKS

1

2

1

2

MOT 2 [DC2]

XFR VALVES

VLV

CH1 [DC ESS SHED]

2

x

5435kg*

1 [DC ESS SHED]

CENTER to WING TRANSFER

CH2 [DC2]

A320

2 [DC2]

2 x 5573kg (JLP-S)

-Valve opens until wing tank is full then wait

A321

A319

until 250kg are used and re-opens

PUMP PUMP

PUMP PUMP

PUMP

- Gravity transfer from CTR TK

RH 1 RH 2

OUTER TANKS

LH 1

LH 2

CTR1

only possible if >2000kg in

CTR

XFR

WING TANKS

[AC1]

[AC2]

[AC1]

[AC2]

REFUEL

VALVE

[AC1]

2 x 691kg

center tank these

VLV

REFUEL

[DC1] [DC2]

2 x 6084kg*

[DC1] [DC2]

[DC2] refueling on

[DC1]

are trapped

L[DC1]

VALVE

[DC ESS]

[DC ESS]

batteries with

2

x

6221kg

(IOM)

R[DC2]

PUMP

[HOT1]

CTR2

REFUEL

REFUEL

[AC2]

COUPLING

COUPLING

VENT TANK

FUEL IMBALANCE A319/A320

[DC2]

~50kg

TOTAL CAPACITY

INNER TK Full, max 1500kg

TANK

PUMPS

WING

PUMPS

INNER TK 4300kg, max 1600kg

(den 0.785kg/l)

A321

FUEL

IMBALANCE

INNER TK 2250kg, max 2250kg

FUEL TEMPERATURE

WING TK Full, max 1350kg

no limitations below 2250kg

JET A1 min -43C max +54C

WING TK 4000kg, max 1500kg

OUTER TK max 530kg, if OUTER+INNER same

JET A min -36C max +54C

WING TK 2350kg, max 2350kg

or INNER of empty OUTER equal or higher (up to 3t) of

(IOM)

no limitations below 2350kg

opposite INNER

A321

18605kg

18879kg

* all others from type

!!! NOT FOR OPERATIONAL USE !!! Pierre-Michel Gasser, 12.1.2013

Potrebbero piacerti anche

- A320 Hyd PDFDocumento1 paginaA320 Hyd PDFStephanie Johnson100% (1)

- A320 Schematics PDFDocumento4 pagineA320 Schematics PDFAlina Costica100% (2)

- A320 EmerDocumento1 paginaA320 EmerEnrique BarberanNessuna valutazione finora

- A320 Quick ReferencesDocumento4 pagineA320 Quick ReferencesRohit Joshi60% (5)

- A320 ElecDocumento1 paginaA320 ElecEnrique Barberan100% (1)

- A320 Class NotesDocumento15 pagineA320 Class NotesRohit Joshi75% (4)

- Abnormal ProceduresDocumento21 pagineAbnormal ProceduresBrenda Bullock100% (1)

- A320 CruiseDocumento1 paginaA320 CruiseZMHQS83% (12)

- A320 Flow PatternDocumento18 pagineA320 Flow PatternAkali Own86% (7)

- A320 Going Around Quick Study GuideDocumento14 pagineA320 Going Around Quick Study GuideLuis100% (3)

- A320 Quiz.v001.130208Documento10 pagineA320 Quiz.v001.130208Tung Do89% (9)

- A320 NotesDocumento112 pagineA320 Notesapi-3753120100% (4)

- A320 SystemsDocumento4 pagineA320 SystemsHarshenDesai100% (8)

- Airbus A320 Performance TestDocumento100 pagineAirbus A320 Performance TestHarjeevChawla87% (15)

- A320 Debrief SchematicsDocumento26 pagineA320 Debrief Schematicsflyjeetu100% (8)

- A320-Engine Start Failure (CFM)Documento5 pagineA320-Engine Start Failure (CFM)Ganesh ChoudharyNessuna valutazione finora

- A320 Automation PDFDocumento1 paginaA320 Automation PDFAlina Costica100% (13)

- Airbus A320 FactsDocumento2 pagineAirbus A320 FactsJoao Melo50% (4)

- A320-Slats or Flaps JammedDocumento19 pagineA320-Slats or Flaps Jammedswathikanagarajan75% (4)

- A320 Exam BDocumento102 pagineA320 Exam Bpatrouilledeafrance100% (2)

- Free A320 Oral Questions 2001Documento20 pagineFree A320 Oral Questions 2001brainstol80% (5)

- A320 Question AnswerDocumento51 pagineA320 Question AnswerJivendra KumarNessuna valutazione finora

- A320 NotesDocumento57 pagineA320 NotesVijay Khot96% (26)

- Airbus A320 Family Non-Normal NotesDocumento106 pagineAirbus A320 Family Non-Normal Notesamuhiddin_2100% (8)

- A 330 FactsDocumento2 pagineA 330 FactsVinay Singh83% (6)

- A320 Memory Items PDFDocumento1 paginaA320 Memory Items PDFPai NangNessuna valutazione finora

- 16 A320 DatasDocumento1 pagina16 A320 DatasVasili Rafaelyan100% (1)

- A320 Normal Procedures ScanflowDocumento31 pagineA320 Normal Procedures Scanflowbojan65100% (6)

- Airbus A320 Technical QuestionsDocumento360 pagineAirbus A320 Technical QuestionsGurpal Singh Chahal91% (43)

- Airbus A320 CalloutsDocumento24 pagineAirbus A320 CalloutsRaúl Martín100% (3)

- Airbus A320 Flight Control LawsDocumento5 pagineAirbus A320 Flight Control LawsKhurram NaseemNessuna valutazione finora

- A320 Question - DefinitionDocumento13 pagineA320 Question - Definitionmorteeza1986100% (1)

- A320 LimitationsDocumento1 paginaA320 Limitationssimcity3000Nessuna valutazione finora

- A320 EmergenciesDocumento26 pagineA320 Emergenciescptpriya100% (10)

- A320 ECAM ManualDocumento11 pagineA320 ECAM Manual104845650% (10)

- Airbus 320 System SummaryDocumento47 pagineAirbus 320 System Summarypontoo100% (4)

- Airbus Flight Control Laws: The Reconfiguration LawsDa EverandAirbus Flight Control Laws: The Reconfiguration LawsValutazione: 4.5 su 5 stelle4.5/5 (16)

- A330 Normal Law: Putting Fly-by-Wire Into PerspectiveDa EverandA330 Normal Law: Putting Fly-by-Wire Into PerspectiveValutazione: 5 su 5 stelle5/5 (2)

- A320 Air PDFDocumento1 paginaA320 Air PDFStephanie Johnson100% (1)

- HP GND Air With APU Bleed: CAUTION, Do Not UseDocumento1 paginaHP GND Air With APU Bleed: CAUTION, Do Not UseElias Iruela100% (1)

- Toyota Mil CodeDocumento3 pagineToyota Mil CodeinayyerNessuna valutazione finora

- A330 HydDocumento1 paginaA330 HydElias Iruela100% (7)

- Checklists Vrs Fa-18e v1.1 Htchd2Documento76 pagineChecklists Vrs Fa-18e v1.1 Htchd2Patrick AdamsNessuna valutazione finora

- Thumb RuleDocumento37 pagineThumb RuleMurugavel VenkatNessuna valutazione finora

- Wet With Sand or Dust: LPC Calculation Take-Off Is Not Authorised (Om A 8.3 8.3.3)Documento7 pagineWet With Sand or Dust: LPC Calculation Take-Off Is Not Authorised (Om A 8.3 8.3.3)solnegro7100% (1)

- A333 Elec PDFDocumento1 paginaA333 Elec PDFStephanie JohnsonNessuna valutazione finora

- About This Document: Fax: 561-658-6489 1422 Goswick Ridge Road Midlothian VA 23114Documento8 pagineAbout This Document: Fax: 561-658-6489 1422 Goswick Ridge Road Midlothian VA 23114Nam Nguyen TrongNessuna valutazione finora

- Power Plant EmergencyDocumento22 paginePower Plant Emergencysekhar_ntpc75% (4)

- A320 EACM Message RESET CB PDFDocumento44 pagineA320 EACM Message RESET CB PDFbluesky_1976100% (5)

- Landing Gear / Nws Brakes: X F/CTL Altn Law (Prot Lost)Documento1 paginaLanding Gear / Nws Brakes: X F/CTL Altn Law (Prot Lost)Elias IruelaNessuna valutazione finora

- Basis of Engine ControlDocumento10 pagineBasis of Engine ControlmihajlovichenkelNessuna valutazione finora

- Immediate Actions: MO MODocumento2 pagineImmediate Actions: MO MOsebless3775Nessuna valutazione finora

- Airbus A320 Family CB List and ResetsDocumento30 pagineAirbus A320 Family CB List and ResetsZbor ZborNessuna valutazione finora

- Date: 04/10/2007: Area - TG UNIT - 3/4/5/6Documento3 pagineDate: 04/10/2007: Area - TG UNIT - 3/4/5/6netygen1Nessuna valutazione finora

- Pin No. Acronym Description Voltage-KOEO: Use Tachometer With Buffer (t2100DU) - Reads Approx 2500-3000 RPMDocumento6 paginePin No. Acronym Description Voltage-KOEO: Use Tachometer With Buffer (t2100DU) - Reads Approx 2500-3000 RPMAnonymous 10cG5eRp8Nessuna valutazione finora

- E5801 1 01 05 - Oil Air Coolers El Neu PDFDocumento11 pagineE5801 1 01 05 - Oil Air Coolers El Neu PDFFolpoNessuna valutazione finora

- Chapter 29 Embraer DescriptionDocumento3 pagineChapter 29 Embraer Descriptionaerologik_347746151Nessuna valutazione finora

- Reset TipsDocumento66 pagineReset TipsJoe Ho100% (3)

- Cooler DetailsDocumento11 pagineCooler DetailsLoganathan ThulasiNessuna valutazione finora

- Hydac SCADocumento6 pagineHydac SCADenis JimenezNessuna valutazione finora

- 7754 Vol1Documento244 pagine7754 Vol1Enrique Barberan100% (1)

- Airbus A320 EosidDocumento52 pagineAirbus A320 EosidJoao Melo67% (3)

- A320 Hyd PDFDocumento1 paginaA320 Hyd PDFkpil100% (1)

- Airbus A320 EosidDocumento52 pagineAirbus A320 EosidJoao Melo67% (3)

- A320 TakeOffDocumento1 paginaA320 TakeOffEnrique Barberan100% (4)

- HydraulicDocumento44 pagineHydraulicEnrique Barberan67% (3)

- Getting To Grips With Performance Monitoring PDFDocumento241 pagineGetting To Grips With Performance Monitoring PDFVictor Borioli Yancovitz100% (1)

- Airbus Abbreviations DictionaryDocumento74 pagineAirbus Abbreviations DictionaryEnrique Barberan100% (1)