Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

THK Design Calculation

Caricato da

alexnomitaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

THK Design Calculation

Caricato da

alexnomitaCopyright:

Formati disponibili

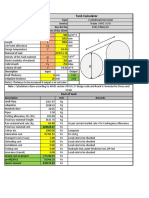

CALCULATION FOR SA 516 GR.

70

Design Calculation as per ASME SEC. VIII DIV-1 ADDITION 2001

Material Data:-

Design Data :

Design Pressure Kg/cm2 g

Operating Pressure Kg/cm2

Design Temp.

10.5

8

65

Deg C.

Allowable stress in Kg/CM^2 at -- Room temp.=

at --Design temp.=

Material:-

3

--Shell =SA 516 GR. 70

Radiography ( for Shell, 10% s 10% --Dish = SA 516 GR. 70

Radiography ( for Dish)

100%

Corrosion Allowance, mm C

Joint Efficiency ( Shell) , E

0.85

Joint Efficiency ( Dish) , E

Calculation for Shell thickness:Shell inside Dia, mm

Di

1800

Allowable stress, Kg/cm S

1406

Joint efficiency,

0.85

Corrosion allowance, mm C

Tc =

P * Di/2

S*E- 0.6*P

Required minimum thickness

=

Provided nom.thickness

mm

Calculation for Dish Thickness:

Dish I/D ,

mm

I/S Crown radius,

mm

DI

1800

Li

1620

I/S Knuckle Radius, mm

ri

180

Allowable stress ,Kg/cm

1406

Joint efficiency,

Corr.Allowance,

Factor

mm

mm

Thinning Allowance mm

Calculated min. thickness(in mm) :-

1.50

Th

Required min.thickness

Provided nom.thickness

mm

--Design temp.=

Di/2

1406

1406

7.95

=Tc+C

10.95

12

1.50

9.08

=Tc+C+ Th

mm

13.08

14

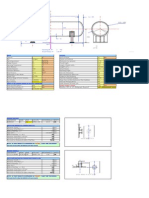

THICKNESS CALCULATION FOR AIR RECEIVER (10KL)

Design Calculation as per ASME SEC. VIII DIV-1 ADDITION 2001

Design Data :

Material Data:-

11

Operating Pressure Kg/cm2

10

Design Temp. Deg C.

65

Corrosion Allowance, mm C

3

Radiography ( for Shell, 10% s 10%

Radiography ( for Dish)

100%

Allowable stress in Kg/CM^2 at -- Room temp.=

at --Design temp.=

Material:--Shell =IS 2062

--Dish = IS 2062

Design Pressure Kg/cm2 g

Joint Efficiency ( Shell) , E

0.85

Joint Efficiency ( Dish) , E

1167.1

1167.1

Calculation for Shell thickness:Shell inside Dia, mm

Di

1500

Allowable stress, Kg/cm2 S

1167.1

Joint efficiency,

E

Corrosion allowance, mm C

1

3

Tc =

P * Di/2

7.11

S*E- 0.6*P

Required minimum thickness

=

Provided nom.thickness

mm

=Tc+C

10.11

12

Calculation for Dish Thickness:

Dish I/D ,

mm

DI

1500

I/S Crown radius,

mm

Li

1350

I/S Knuckle Radius, mm

ri

255

Allowable stress ,Kg/cm2

1167.1

Joint efficiency,

Corr.Allowance,

Factor

mm

mm

Thinning Allowance mm

Factor M = 1/4 ( ( L / r)^0.5 +3 )

1.33

Calculated min. thickness(in mm) :Tc = P * Li * M

8.44

2SE - 0.2P

1.33

Th

Required min.thickness

=Tc+C+ Th

mm

Provided nom.thickness

mm

12.44

14

Potrebbero piacerti anche

- Design Calculations of Storage Tank: According To API 650 Code, 11 EditionDocumento3 pagineDesign Calculations of Storage Tank: According To API 650 Code, 11 EditionAkash Kazama100% (1)

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocumento32 pagineStorage Tank Design Calculation - Api 650: Close Floating RoofhgagNessuna valutazione finora

- Storage Tank Design Calculation - Api 650Documento21 pagineStorage Tank Design Calculation - Api 650miteshpatel191100% (3)

- Shell Thickness Calculation ..: MAWP Design PressureDocumento6 pagineShell Thickness Calculation ..: MAWP Design PressureSatish ShindeNessuna valutazione finora

- 50KL Tank - API CalcDocumento1 pagina50KL Tank - API CalcRathika100% (1)

- Sagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LDocumento7 pagineSagging of The Pipe (F) Between 2 Pipe Clamps (1/"?") X LEdwardhutaurukNessuna valutazione finora

- Vdocuments - MX Rectangular Tank CalculationDocumento34 pagineVdocuments - MX Rectangular Tank CalculationAtilla TekinNessuna valutazione finora

- PV Elite ResultDocumento239 paginePV Elite ResultChaitanya Sai TNessuna valutazione finora

- Skirt Design - For Small VesselsDocumento7 pagineSkirt Design - For Small VesselsSakthi VelNessuna valutazione finora

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDocumento1 paginaRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutNessuna valutazione finora

- API-650 Water Storage Tank TK-2Documento27 pagineAPI-650 Water Storage Tank TK-2Athira ZahraNessuna valutazione finora

- API 650 Tank Nozzle Stand OutDocumento5 pagineAPI 650 Tank Nozzle Stand Outtry&try100% (1)

- Vessel Weight CalculationDocumento5 pagineVessel Weight CalculationAniket royNessuna valutazione finora

- API Standard Storage Tank Data Sheet Rev 0Documento3 pagineAPI Standard Storage Tank Data Sheet Rev 0vijay10484Nessuna valutazione finora

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareDocumento127 paginePC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresNessuna valutazione finora

- Beam Spreadsheet: Ignore Lateral Torsional BucklingDocumento5 pagineBeam Spreadsheet: Ignore Lateral Torsional BucklingPurnima ArkalgudNessuna valutazione finora

- Spreaer Beam&Lifting Line Beam p3Documento2 pagineSpreaer Beam&Lifting Line Beam p3Sabrang LorNessuna valutazione finora

- 3191-CS-01 Rev A-009-011Documento3 pagine3191-CS-01 Rev A-009-011Syed Zain AliNessuna valutazione finora

- Thickness Calculation of Pressure Vessel ShellDocumento16 pagineThickness Calculation of Pressure Vessel ShellClaudia BonocoreNessuna valutazione finora

- Etank Full ReportDocumento108 pagineEtank Full ReportFaizal Sattu100% (1)

- PVElite RefDocumento6 paginePVElite RefakhilNessuna valutazione finora

- What Is An ASME Appendix 2 Flange Design PDFDocumento1 paginaWhat Is An ASME Appendix 2 Flange Design PDFMangesh BanaleNessuna valutazione finora

- API 650 Water Storage TankDocumento6 pagineAPI 650 Water Storage TankJoeNessuna valutazione finora

- Ligament Efficiency and Thickness of The Support PlateDocumento10 pagineLigament Efficiency and Thickness of The Support PlatePankajDhobleNessuna valutazione finora

- Sample Vessel Design (Sec - VIII Div.1)Documento34 pagineSample Vessel Design (Sec - VIII Div.1)Chano Hanok100% (1)

- Pipe&Shell Design Tool 600KLDocumento1 paginaPipe&Shell Design Tool 600KLJoshua Rivera100% (1)

- Toriconical Head Ver 1.1Documento4 pagineToriconical Head Ver 1.1Iqbal AhmadsNessuna valutazione finora

- Coupling UW16.2 KL Ver 1.1Documento4 pagineCoupling UW16.2 KL Ver 1.1gopaltryNessuna valutazione finora

- Coupling Calculations and Ug-32 Unstayed Head CalculationsDocumento9 pagineCoupling Calculations and Ug-32 Unstayed Head CalculationsLcm TnlNessuna valutazione finora

- Design of Partition PlateDocumento5 pagineDesign of Partition Platepippo2378793Nessuna valutazione finora

- WRC Check List CriteriaDocumento1 paginaWRC Check List CriteriaAlvin Smith100% (1)

- External Pressure Calculation ResultsDocumento8 pagineExternal Pressure Calculation ResultsAndika DearsonNessuna valutazione finora

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDocumento4 pagineUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNessuna valutazione finora

- Technical Evaluation HAM BAKERDocumento1 paginaTechnical Evaluation HAM BAKEReko123Nessuna valutazione finora

- Pressure Vessel Design Old (Eugyene F Megysey)Documento31 paginePressure Vessel Design Old (Eugyene F Megysey)David FonsecaNessuna valutazione finora

- PVV Cal Sheet LabixDocumento45 paginePVV Cal Sheet LabixPranpath Narupantawart50% (2)

- IS.5216 1982part2Documento27 pagineIS.5216 1982part2Mahendra SuryavanshiNessuna valutazione finora

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocumento49 pagineDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Nessuna valutazione finora

- Horizontal Cylindrical Tank Volume and Level CalculatorDocumento5 pagineHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraNessuna valutazione finora

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocumento1 paginaK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjNessuna valutazione finora

- Bulk Air Eliminator R1Documento1 paginaBulk Air Eliminator R1hydrothermsNessuna valutazione finora

- Skirt Support TrialDocumento11 pagineSkirt Support TrialAbhishek Nag50% (2)

- WI06-0260 Calculations For Obround Nozzle ConnectionsDocumento4 pagineWI06-0260 Calculations For Obround Nozzle ConnectionskumarNessuna valutazione finora

- PV Elite Vessel Analysis Program HorizontalDocumento55 paginePV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriNessuna valutazione finora

- Storage Volume of TanksDocumento90 pagineStorage Volume of TanksRamachandran VenkateshNessuna valutazione finora

- Skirt Support Analysis Per en 13445Documento13 pagineSkirt Support Analysis Per en 13445karthik1amar100% (1)

- Doshi Ion Exchange & Chemical Ind. LTD.: Material DataDocumento7 pagineDoshi Ion Exchange & Chemical Ind. LTD.: Material DataMakrand Sakpal100% (5)

- 31barg CalculationDocumento10 pagine31barg Calculationshani5573Nessuna valutazione finora

- ASME Air Tank DesignDocumento2 pagineASME Air Tank Designchethan100% (1)

- AD2000 (31barg) CalculationDocumento10 pagineAD2000 (31barg) CalculationMagdaline Matabang100% (1)

- Design Calculations For V2703 Rev 0Documento9 pagineDesign Calculations For V2703 Rev 0Dilip KatekarNessuna valutazione finora

- Ibr CalculationsDocumento9 pagineIbr Calculationsaroonchelikani67% (3)

- Vessel THKDocumento8 pagineVessel THKdigm25Nessuna valutazione finora

- Design Calculation For Dirty Brackish Water Tank (129-0T2540)Documento9 pagineDesign Calculation For Dirty Brackish Water Tank (129-0T2540)Dhakshina KNessuna valutazione finora

- Api - 650 2008Documento27 pagineApi - 650 2008WinsonLimHuiWahNessuna valutazione finora

- Tank Calc - Api650Documento90 pagineTank Calc - Api650kamleshyadavmoney100% (4)

- Weight Estimation of Vessels AppsDocumento39 pagineWeight Estimation of Vessels Appsmacwan23Nessuna valutazione finora

- Tank Calculation PDFDocumento3 pagineTank Calculation PDFAlvin SmithNessuna valutazione finora

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocumento31 pagineStorage Tank Design Calculation - Api 650: Close Floating RoofNguyễn Duy HưngNessuna valutazione finora

- Design of Concentrated Sulfuric Acid TankDocumento12 pagineDesign of Concentrated Sulfuric Acid TankAbdelrhman Uossef100% (1)

- 3.068 Hugh Brian: Author: Download FromDocumento10 pagine3.068 Hugh Brian: Author: Download FromalexnomitaNessuna valutazione finora

- Dish EndDocumento5 pagineDish EndalexnomitaNessuna valutazione finora

- 26 Pressure Vessel.Documento21 pagine26 Pressure Vessel.mishtinil93% (14)

- Tank VolumeDocumento5 pagineTank VolumealexnomitaNessuna valutazione finora

- THK Design CalculationDocumento3 pagineTHK Design CalculationalexnomitaNessuna valutazione finora

- CONE DEVELOPMENT Concentric: PetalsDocumento13 pagineCONE DEVELOPMENT Concentric: PetalsalexnomitaNessuna valutazione finora

- Round To SQDocumento2 pagineRound To SQalexnomitaNessuna valutazione finora

- Tank Calculator: Cylindrical Tank With Domed RoofDocumento22 pagineTank Calculator: Cylindrical Tank With Domed RoofalexnomitaNessuna valutazione finora

- Type ONLY in The Green Cells Below: Square Tank Inches Square Tank FeetDocumento1 paginaType ONLY in The Green Cells Below: Square Tank Inches Square Tank FeetalexnomitaNessuna valutazione finora

- GEMI Equations ToolDocumento12 pagineGEMI Equations ToolalexnomitaNessuna valutazione finora

- Tank VolumeDocumento5 pagineTank VolumealexnomitaNessuna valutazione finora

- Retention TimeDocumento10 pagineRetention TimealexnomitaNessuna valutazione finora

- Cone BottomDocumento1 paginaCone BottomalexnomitaNessuna valutazione finora