Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CMP (Phase) Murano

Caricato da

Guillermo Rojas0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

298 visualizzazioni8 pagineThis document provides information about diagnosing DTC codes P0340 and P0345 related to the camshaft position sensor (PHASE) on a 2004 Nissan Murano.

The camshaft position sensor senses the position of the intake camshaft and sends signals to identify each cylinder. When the crankshaft position sensor fails, the camshaft sensor provides engine timing control instead.

The diagnostic procedure involves checking the starting system, sensor power and ground circuits, input signal circuit, and inspecting the sensor, camshaft, and investigating intermittent issues. Component inspection of the sensor checks for damage and proper resistance values.

Descrizione originale:

nissan

Titolo originale

Cmp(Phase)Murano

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document provides information about diagnosing DTC codes P0340 and P0345 related to the camshaft position sensor (PHASE) on a 2004 Nissan Murano.

The camshaft position sensor senses the position of the intake camshaft and sends signals to identify each cylinder. When the crankshaft position sensor fails, the camshaft sensor provides engine timing control instead.

The diagnostic procedure involves checking the starting system, sensor power and ground circuits, input signal circuit, and inspecting the sensor, camshaft, and investigating intermittent issues. Component inspection of the sensor checks for damage and proper resistance values.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

298 visualizzazioni8 pagineCMP (Phase) Murano

Caricato da

Guillermo RojasThis document provides information about diagnosing DTC codes P0340 and P0345 related to the camshaft position sensor (PHASE) on a 2004 Nissan Murano.

The camshaft position sensor senses the position of the intake camshaft and sends signals to identify each cylinder. When the crankshaft position sensor fails, the camshaft sensor provides engine timing control instead.

The diagnostic procedure involves checking the starting system, sensor power and ground circuits, input signal circuit, and inspecting the sensor, camshaft, and investigating intermittent issues. Component inspection of the sensor checks for damage and proper resistance values.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 8

DTC P0340, P0345 CMP SENSOR (PHASE)

DTC P0340, P0345 CMP SENSOR (PHASE) Perzaran

Component Description ese

The camshaft position sensor (PHASE) senses the retraction of

intake valve camshaft to identify a particular cylinder. The camshaft

position sensor (PHASE) senses the piston position.

When the crankshaft position sensor (POS) system becomes inoper-

ative, the camshaft position sensor (PHASE) provides various con-

trols of engine parts instead, utilizing timing of cylinder identification

signals,

The sensor consists of a permanent magnet and Hall IC.

When engine is running, the high and low parts of the teeth cause

the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change

Due to the changing magnetic field, the voltage from the sensor changes.

On Board Diagnosis Logic ses?

DTC No] Trouble dagnosi namo DTC datecing conion Possible cause

Po880 = Hamess or conneciors

«The onder No, signa is not sent to ECM

cane Te cinder No, Salis ot sentio ECM» rego acl open or shored)

40 ir Jureg engi

Q ‘cranking. ‘¢ Camshaft position sensor (PHASE)

Camshaft poston sen- S Comshat entae

poses | SareunsSicur™ | # Tim iintarNo snl netsonti Eom « Cana (nto)

Pose 8 engine running «Str motor (Reer io SC-9 )

(eanx2) The cylinder No. signals notin the normal | « staring system cult (Refer o SC-9 »)

palto during engine running 5 eas weak watery

DTC Confirmation Procedure vase

NOTE:

if DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5V with igni-

tion switch ON.

WITH CONSULT-

41. Turn ignition switch ON.

2. Select “DATA MONITOR’ mode with CONSULT-I

3. Crank engine for at least 2 seconds and run it for at least 5 sec-

onds at idle speed.

4. If st trip DTC is detected, go to EC-272, "Diagnostic Procedure"

if 1st trip DTC is not detected, go to next step.

5. Maintaining engine speed at more than 800 rpm for at least 5

seconds,

6. If strip DTCis detected, go to EC-272, "Diagnostic Procedure"

WITH GST

Follow the procedure ‘WITH CONSULT-II" above.

Revision: 2004 November EC-268 2004 Murano

DTC P0340, P0345 CMP SENSOR (PHASE)

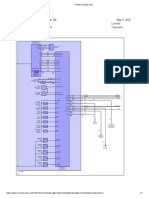

Wiring Diagram ‘asses

BANK

BATTERY EC-PHSB1-01

x

mmm: DETECTABLE LINE FOR OTC

:Non-DeTECTABLE LINE FOR OTC

TELLIGENT

MODULE ENGINE REFER TO PG-POWER,

ooM

ot

ecw

RELAY

+o

Eih00

fe

2,

lcausuary

onion SENSOR

PRASE) TeANK

GD

E}-—

88

—

88

z,

al

2 ea TOES MAN

Saahe

68

A

ii—

nie

Revision: 2004 November EC-269 2004 Murano

DTC P0340, P0345 CMP SENSOR (PHASE)

‘Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-IL

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

vine | SIRE

MINAL Tem CONDITION DATA (DC Vottage)

Me | cour

1.0-4.0ve

[Engine is running}

‘© Warm-up condition

« Idle speed

Note:

The pulse cycle changes depending on rpm at

idle Biba ae

aw» ly Camshaft position sensor se

(PHASE) (bank 1)

[Engine is running}

1 Engine speed is 2,000 rpm.

10-4.0ve

‘Average voltage for pulse signal (Actual pulse signal can be confirmed by osciloscope.)

Revision: 2004 November

EC-270

2004 Murano

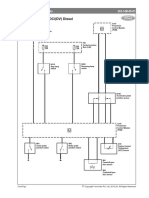

DTC P0340, P0345 CMP SENSOR (PHASE)

BANK 2

BATTERY EC-PHSB2-01

mms: DETECTABLE LINE FOR OTC

pom er Non-DeTECTABLE LINE FOR DTC ci

FoweRostagsmion | neren TO Pe-POMER

ROOM)

ecw

RELAY

@ Periion Sensor

PaASE) weaned)

@D

al

=e

oat

>

De

——

[

Ee

i]

g

a z igs ==a0on

fed D> Ebert]

atskah ee Telshene[elipie|

Revision: 2004 November EC-271 2004 Murano

DTC P0340, P0345 CMP SENSOR (PHASE)

‘Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-IL

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

vine | SIRE

MINAL Tem CONDITION DATA (OC Voltage)

coLor

No.

1.0-4.0ve

[Engine is running}

‘© Warm-up condition

« ldo speed

Note:

The pulse cycle changes depending on rpm at

idle Biba ae

Camshatt postion sensor ene

14 fw

(PHASE) (bank 2) 1.0-4.0ve

[Engine is running}

‘© Engine speed is 2,000 rpm.

‘Average voltage for pulse signal (Actual pulse signal can be confirmed by osciloscope.)

Diagnostic Procedure sos

1. CHECK STARTING SYSTEM

Tum ignition switch to START position,

Does the engine turn over?

Does the starter motor operate?

Yes or No

Yes >>GOTO2

No >> Check starting system. (Refer to SC-9, "STARTING SYSTEM" .)

2. CHECK GROUND CONNECTIONS

1. Tum ignition switch OFF.

2. Loosen and retighten two ground screws on the body.

Refer to EC-139, "Ground Inspection"

OK orNG

OK >>GOTO3.

NG >> Repair or replace ground connections.

Revision: 2004 November EC-272 2004 Murano

DTC P0340, P0345 CMP SENSOR (PHASE)

3. CHECK CAMSHAFT POSITION (CMP) SENSOR (PHASE) POWER SUPPLY CIRCUIT

4. Disconnect camshaft position (CMP) sensor (PHASE) harness connector.

Camshaft pstton Sensor

(PHASE) Gank 2) ~

3. Check voltage between CMP sensor (PHASE) terminal 3 and

ground with CONSULT-Il or tester.

Voltage: Baty voltage Sac

4. Also check hamess for short to ground and short to power. fa

OK or NG t

OK >> GOTOS.

NG >>GOTO4.

4. DETECT MALFUNCTIONING PART

Check the following

‘© Hamess connectors E110, M7

‘© Hamess connectors M82, F102

‘Hames for open or short between camshaft position sensor (PHASE) and ECM

‘Hames for open or short between camshaft position sensor (PHASE) and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

5. CHECK CMP SENSOR (PHASE) GROUND CIRCUIT FOR OPEN AND SHORT

4. Tumignition switch OFF.

2. Check harness continuity between CMP sensor (PHASE) terminal 1 and ground.

Continuity should exist.

3. Also check hamess for short to power.

OK or NG

OK >>GOTO7,

NG >>GOTO6.

6. DETECT MALFUNCTIONING PART

Check the following

‘© Hamess connectors F102, M82

‘Hames for open or short between CMP sensor (PHASE) and ground

>> Repair open circuit or short to power in hamess or connectors.

Revision: 2004 November EC-273 2004 Murano

DTC P0340, P0345 CMP SENSOR (PHASE)

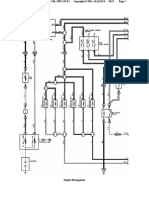

‘7. CHECK CMP SENSOR (PHASE) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM hamess connector.

2. Check harness continuity between ECM terminal 33 or 14 and CMP sensor (PHASE) terminal 2.

Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground or short to power.

OK or NG

OK >>GOTO8.

NG >> Repair open circuit or short to ground or short to power in hamess or connectors.

8. CHECK CAMSHAFT POSITION SENSOR (PHASE)

Refer to EC-275, "Component Inspection”

OK or NG

OK >>GOTOS.

NG >> Replace camshaft position sensor (PHASE),

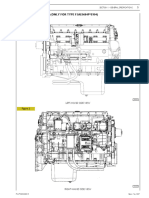

Q. CHECK CAMSHAFT (INTAKE)

Check the following,

¢ Accumulation of debris to the signal plate of camshaft rear end -

‘¢ Chipping signal plate of camshaft rear end

OK of NG

OK or NG o Camshatt

OK >> GOTO 10. (intake)

NG >> Remove debris and clean the signal plate of camshaft

rear end or replace camshaft.

eS}

Oa.

10. CHECK INTERMITTENT INCIDENT

Refer to EC-130, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT"

>> INSPECTION END

Revision: 2004 November EC-274 2004 Murano

DTC P0340, P0345 CMP SENSOR (PHASE)

Component Inspection

CAMSHAFT POSITION SENSOR (PHASE)

4. Loosen the fixing bolt of the sensor.

2. Disconnect camshaft position sensor (PHASE) hamess connector.

3. Remove the sensor.

4. Visually check the sensor for chipping

5. Check resistance as shown in the figure.

TerminalNo.(Polariy) | ‘Resistance lal2e-C(7F]

Tey?

1-30 Excopt 0 oF =

2-3

Removal and Installation

CAMSHAFT POSITION SENSOR (PHASE)

Refer to EM-77, "CAMSHAFT"

Revision: 2004 November EC-275

2004 Murano

Potrebbero piacerti anche

- Montana, Silhouette & Venture: 1999 Chevrolet Venture LT 1999 Chevrolet Venture LTDocumento9 pagineMontana, Silhouette & Venture: 1999 Chevrolet Venture LT 1999 Chevrolet Venture LTcarlosmhNessuna valutazione finora

- Hydrocarbon Crack SystemDocumento2 pagineHydrocarbon Crack SystemLucian Si Silvia PoneaNessuna valutazione finora

- DTC P1120/19 Accel. Position Sensor Circuit (Open/Short)Documento7 pagineDTC P1120/19 Accel. Position Sensor Circuit (Open/Short)Jehuty88Nessuna valutazione finora

- 2006fileaveo MTDocumento63 pagine2006fileaveo MTeurospeed2100% (1)

- Mapa o Diagrama Electrico de BMW 525i 1991Documento2 pagineMapa o Diagrama Electrico de BMW 525i 1991wernnickNessuna valutazione finora

- cx-9 Ecu DiagramDocumento24 paginecx-9 Ecu Diagramblueyo100% (9)

- DTC P055B-P055D: Applies ToDocumento5 pagineDTC P055B-P055D: Applies ToWillie AustineNessuna valutazione finora

- U1146-Lost Communication With External Memory: Theory of OperationDocumento7 pagineU1146-Lost Communication With External Memory: Theory of Operationkikin strong100% (1)

- Code P1693Documento21 pagineCode P1693احمدميدوNessuna valutazione finora

- Atos Fuel SDocumento133 pagineAtos Fuel Singenieriaelectronic100% (1)

- (HYUNDAI) Manual de Taller Hyundai Accent 1995 2010 PDFDocumento15 pagine(HYUNDAI) Manual de Taller Hyundai Accent 1995 2010 PDFFabián Castro CamposNessuna valutazione finora

- Transmissions - A - T Circuit (Transmission and Drivetrain) - ALLDATA RepairDocumento2 pagineTransmissions - A - T Circuit (Transmission and Drivetrain) - ALLDATA RepairManuel AyalaNessuna valutazione finora

- Cableado Tierra Electrica y Circuitos Nissan VersaDocumento78 pagineCableado Tierra Electrica y Circuitos Nissan VersaHumberto Vega Sanchez100% (1)

- Transmision Diagrama Electrico PathfinderDocumento1 paginaTransmision Diagrama Electrico PathfinderJORGE RUZ100% (1)

- 89 ZF 1 4hp22-24Documento10 pagine89 ZF 1 4hp22-24Aussi SidNessuna valutazione finora

- Camshaft Sensor 2.4 MitsubishiDocumento14 pagineCamshaft Sensor 2.4 MitsubishiJoselorenzo Torres ANessuna valutazione finora

- P0405-96 P0406-96 Taken From 2KD Manual - To Be CheckedDocumento4 pagineP0405-96 P0406-96 Taken From 2KD Manual - To Be CheckedBiniyam BekeleNessuna valutazione finora

- ECM PINOUT Chevrolet Sail PDFDocumento2 pagineECM PINOUT Chevrolet Sail PDFoswill bravo100% (1)

- Air Conditioning: Ymms: Jun 21, 2021 Engine: 1.8L Eng License: Vin: Odometer: 2014 Nissan Sentra SLDocumento5 pagineAir Conditioning: Ymms: Jun 21, 2021 Engine: 1.8L Eng License: Vin: Odometer: 2014 Nissan Sentra SLAndre VP100% (1)

- Diagnostic Trouble Code Chart: Sae ControlledDocumento4 pagineDiagnostic Trouble Code Chart: Sae ControlledShameer KhanNessuna valutazione finora

- Engine Temperature Control Actuator - N493-, CHECKING: General DescriptionDocumento3 pagineEngine Temperature Control Actuator - N493-, CHECKING: General Descriptionbyungchul kimNessuna valutazione finora

- AEM Undocumented Settings v1Documento13 pagineAEM Undocumented Settings v1Franklyn RamirezNessuna valutazione finora

- #1-Sist. de Dirección Electrónica Kia Rio 1.4Documento3 pagine#1-Sist. de Dirección Electrónica Kia Rio 1.4Daniel rodriguez alayoNessuna valutazione finora

- Tracción ControlDocumento212 pagineTracción Controltallermae100% (1)

- 2002 Expedition C174 PCM PinoutsDocumento3 pagine2002 Expedition C174 PCM Pinoutskamaleon dorado0% (1)

- Module Name Acronym SCP Address Can AddressDocumento2 pagineModule Name Acronym SCP Address Can AddressMarius Neagoe0% (2)

- Relevador Throttle NissanDocumento1 paginaRelevador Throttle Nissanatkins6vera6loiNessuna valutazione finora

- Sistema de Lubricación VW Passat 1.8LDocumento6 pagineSistema de Lubricación VW Passat 1.8LOsvaldoMarianoNessuna valutazione finora

- Chevrole Cruser Pi Out X2ecotechDocumento3 pagineChevrole Cruser Pi Out X2ecotechManuel SuarezNessuna valutazione finora

- PDF Bosch Motronic Me75 18t Aum Pinout DDDocumento7 paginePDF Bosch Motronic Me75 18t Aum Pinout DDDanny OchoaNessuna valutazione finora

- BMW Mini Cooper 2002 ABS Codes ABS3Documento2 pagineBMW Mini Cooper 2002 ABS Codes ABS3daz7691Nessuna valutazione finora

- P1449 Fallos de La Batería Del Civic Híbrido.Documento4 pagineP1449 Fallos de La Batería Del Civic Híbrido.Norman Valle SáenzNessuna valutazione finora

- 1997 Nissan Altima ECU: Pin Color Name Symbol Description SignalDocumento8 pagine1997 Nissan Altima ECU: Pin Color Name Symbol Description SignalEscobar Medellin Juan Pablo0% (1)

- DTC C1554/23 Power Supply Relay Failure DTC C1555/25 Motor Relay Welding FailureDocumento3 pagineDTC C1554/23 Power Supply Relay Failure DTC C1555/25 Motor Relay Welding FailureOswaldo Sierra100% (1)

- 2006 Volkswagen Bora: System Wiring Diagrams System Wiring DiagramsDocumento1 pagina2006 Volkswagen Bora: System Wiring Diagrams System Wiring DiagramsYoNessuna valutazione finora

- 1.4L Ford FigoDocumento21 pagine1.4L Ford FigoAmit Garg100% (1)

- C100 Service Training Manual: Engine Mechanical (2.4L DOHC) : Participant's HandoutDocumento32 pagineC100 Service Training Manual: Engine Mechanical (2.4L DOHC) : Participant's Handoutsertex_joNessuna valutazione finora

- Nissan 300ZX 90 95 Maxima VE30DE 92 94Documento2 pagineNissan 300ZX 90 95 Maxima VE30DE 92 94Superlano JoséNessuna valutazione finora

- Actyon A0 A06005Documento10 pagineActyon A0 A06005Arimbi GembiekNessuna valutazione finora

- DTC P2714 Pressure Control Solenoid "D" Performance (Shift Solenoid Valve SLT)Documento7 pagineDTC P2714 Pressure Control Solenoid "D" Performance (Shift Solenoid Valve SLT)Igor MarkovicNessuna valutazione finora

- 2007 Dodge Caliber ManualDocumento360 pagine2007 Dodge Caliber ManualJinyuan FangNessuna valutazione finora

- ECM PINOUT Chevrolet-Sail PDFDocumento2 pagineECM PINOUT Chevrolet-Sail PDFJhonatan Jibaja RamírezNessuna valutazione finora

- Esquema Volvo s40Documento5 pagineEsquema Volvo s40enoqueNessuna valutazione finora

- Siemens MS43 PinoutDocumento5 pagineSiemens MS43 Pinoutzozo0424Nessuna valutazione finora

- Ecu HW - Nissan ECU REDocumento15 pagineEcu HW - Nissan ECU RESameh ElmahdyNessuna valutazione finora

- DTC Fallas Caja Automatica OptraDocumento64 pagineDTC Fallas Caja Automatica OptraFernando Jordan BarretoNessuna valutazione finora

- Motronic M5.9.2 Component DifferencesDocumento8 pagineMotronic M5.9.2 Component DifferencesIonel AlexandruNessuna valutazione finora

- Apredizaje Aceleración Nissan X-TrailDocumento5 pagineApredizaje Aceleración Nissan X-TrailHERNAN DARIO ZAPATA BUSTAMANTENessuna valutazione finora

- Instructivo para Programar Inmovilizador BenniDocumento4 pagineInstructivo para Programar Inmovilizador BenniElectronica Ave FenixNessuna valutazione finora

- Toyota 3f PDFDocumento5 pagineToyota 3f PDFJOSE,ENessuna valutazione finora

- Obd 2 CodesDocumento29 pagineObd 2 CodescalvinyewNessuna valutazione finora

- LACETTI Engine (71-100) - 1.8DDocumento30 pagineLACETTI Engine (71-100) - 1.8DDangLuyenNessuna valutazione finora

- Tomihawk Tools CatalogueDocumento60 pagineTomihawk Tools CatalogueRosília DomingosNessuna valutazione finora

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualDa EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNessuna valutazione finora

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualDa EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualValutazione: 2.5 su 5 stelle2.5/5 (2)

- P 0340Documento3 pagineP 0340Carlos Medina CastilloNessuna valutazione finora

- Throttle Position Sensor Circuit TestDocumento8 pagineThrottle Position Sensor Circuit TestDaniel AmanorNessuna valutazione finora

- Diagnostic Trouble CodesDocumento6 pagineDiagnostic Trouble CodesTaras KNessuna valutazione finora

- Receptor Satélite Fortecstar Lifetime UltraDocumento28 pagineReceptor Satélite Fortecstar Lifetime UltraHugo Roberto RibeiroNessuna valutazione finora

- Iphone 6S Plus Schematic - Vietmobile - VNDocumento62 pagineIphone 6S Plus Schematic - Vietmobile - VNMiguel Angel Aguilar Moreira75% (4)

- Water Pom CivicDocumento1 paginaWater Pom CivicGuillermo RojasNessuna valutazione finora

- Mitsubishi 4b12 Service Manual EngineDocumento90 pagineMitsubishi 4b12 Service Manual EnginePatricio OlivaresNessuna valutazione finora

- Mitsubishi 4 B 12Documento20 pagineMitsubishi 4 B 12Guillermo Rojas100% (1)

- Outboard Motor: Parts CatalogueDocumento245 pagineOutboard Motor: Parts Catalogueernesto tejedaNessuna valutazione finora

- Hydraulic Cylinder Unit (Sep 2015) PDFDocumento31 pagineHydraulic Cylinder Unit (Sep 2015) PDFValeriy DomashenkoNessuna valutazione finora

- Isuzu Rodeo X22SE PDFDocumento576 pagineIsuzu Rodeo X22SE PDFOrlando ZaldivarNessuna valutazione finora

- Service Manual Iveco Cursor DemoDocumento15 pagineService Manual Iveco Cursor Democharbah2007Nessuna valutazione finora

- ProEFI Pro128 BMW E46 M3 Pinout SheetDocumento2 pagineProEFI Pro128 BMW E46 M3 Pinout SheetHugoCar77100% (1)

- CARB Daewoo-Tico-Incomplete Dismantling - TranslatedDocumento5 pagineCARB Daewoo-Tico-Incomplete Dismantling - TranslatedAble TonNessuna valutazione finora

- C90 E90 300 350 Engine LimitsDocumento3 pagineC90 E90 300 350 Engine Limitskingair555Nessuna valutazione finora

- Reading Guía Engine PartsDocumento7 pagineReading Guía Engine PartsPuro Rock DiiegoNessuna valutazione finora

- 3 Axis Modern TrailerDocumento24 pagine3 Axis Modern TrailerRATHANNessuna valutazione finora

- 8t2700 Blowby AirDocumento16 pagine8t2700 Blowby AirRichard Henry Sanchez Calderon100% (1)

- Motronic Control Unit, Fuel Pump Relay, Air Mass Meter, InjectorsDocumento7 pagineMotronic Control Unit, Fuel Pump Relay, Air Mass Meter, InjectorsDan AvNessuna valutazione finora

- Fuel System C27Documento7 pagineFuel System C27insano008Nessuna valutazione finora

- Cat Engine History From Inception With Emmission ManagementDocumento6 pagineCat Engine History From Inception With Emmission Managementtenderncare100% (1)

- Army PartsDocumento155 pagineArmy Partsejen_gl100% (1)

- 2az-Fe Diagnostic Trouble Code ChartDocumento6 pagine2az-Fe Diagnostic Trouble Code ChartEdi Farnando100% (3)

- DFMA ProjectDocumento7 pagineDFMA ProjectHirmanto Suib0% (1)

- Compresor Aire RespirableDocumento32 pagineCompresor Aire RespirableJorge Cruz PoolNessuna valutazione finora

- 6284 5 00 PDFDocumento9 pagine6284 5 00 PDFnpsNessuna valutazione finora

- Cyl Heads Suggested Pilots - Inserts ProfilesDocumento10 pagineCyl Heads Suggested Pilots - Inserts ProfilesRyo ChannelNessuna valutazione finora

- Crankshaft AssemblyDocumento51 pagineCrankshaft AssemblySlobodanNessuna valutazione finora

- AMW - Exhaust ManifoldDocumento2 pagineAMW - Exhaust ManifoldAaryan RNNessuna valutazione finora

- Ign ElectDocumento39 pagineIgn ElectNoel Ramirez AngolaNessuna valutazione finora

- Yamaha Beartracker 03Documento398 pagineYamaha Beartracker 03tidozx6100% (1)

- Dpico: Inj. Pump Calibration DataDocumento2 pagineDpico: Inj. Pump Calibration DataRene VCNessuna valutazione finora

- Workshop Manual: 3LD 450 3LD 510 3LD 450/S 3LD 510/S 4LD 640 4LD 705 4LD 820Documento33 pagineWorkshop Manual: 3LD 450 3LD 510 3LD 450/S 3LD 510/S 4LD 640 4LD 705 4LD 820Ilie Viorel75% (4)

- Motor Diesel GDF 8320zcd-8Documento204 pagineMotor Diesel GDF 8320zcd-8Sebitas Briceño CambaNessuna valutazione finora

- Shakurbasti Diesel Shed Report NewDocumento25 pagineShakurbasti Diesel Shed Report NewDeepak Chandhok100% (1)

- 1.L425-1-2017 S6SDocumento132 pagine1.L425-1-2017 S6SJOAO BIANCHININessuna valutazione finora

- Marine Gas Turbine: Comparing The Design of The LM2500+G4 To The LM2500+Documento2 pagineMarine Gas Turbine: Comparing The Design of The LM2500+G4 To The LM2500+vogid38712Nessuna valutazione finora

- Mack MP8 Cabeza de Cilindros CambioDocumento15 pagineMack MP8 Cabeza de Cilindros Cambiohamilton mirandaNessuna valutazione finora