Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Met Reg 01-01 Registro de Especificacion Procedimiento de Soldadura d1.1

Caricato da

vizcensoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Met Reg 01-01 Registro de Especificacion Procedimiento de Soldadura d1.1

Caricato da

vizcensoCopyright:

Formati disponibili

REGISTRO

REG.

MET/REG-01-01

PLAN DE CALIDAD

HOJA:

1 de 1

WELDING PROCEDURE SPECIFICATION (WPS)

(De acuerdo a AWS D1.1-2010)

ELABOR:

JSCH

REVISO:

Company Name: LTA INGENIEROS S.A.C

Welding Process (es)

SMAW

Supporting PQR N. (s) 001

BASE METALS

Material Spec.

ASTMA A36-A500

Type or Grade. Acero al Carbono

Thickness:

Groove

60

Fillet

Diameter (Pipe)

--De canal 9.5 mm. 3.0 mm a 19 mm.

PREHEAT

Preheat Temp., Min

Interpass Temp., Min

-----

---

Max

REVISION:

APROBO:

JTC

Type

Manual

Machine

Semi-Automatic

Automatic

POSITION

Position of Groove:

4G

Fillet:

V

Vertical Progression: Up

Down

SOBRECABEZA

Supporting position:

ELECTRICAL CHARACTERISTICS

Transfer Mode (GMAW)

Short-Circuiting

Globular

Spray

Current:

AC

DCEP

CCEP

Pulsed

Other

Tungsten Electrode (GTAW)

Size: --Type: --TECHNIQUE

Stringer or Weave Bead:

Multi-pass or Single Pass (per side)

Number of Electrodes

Electrode Spacing

Longitudinal

Lateral

Angle

Contac tube to Work Distance

Peening

Interpass Cleaning

AWS A5.1

E-6011/ E-7018

1/8 3/16

SHIELDING

Flux

--Gas --Composition

--Electrode-Flux (Class) --Flow Rate

--Gas Cup Size

14-04-2014

Identification

19-WPS-PC-4G

Revision

1

Date

by

Authorized by MCC -JTC

Date 16-04-14

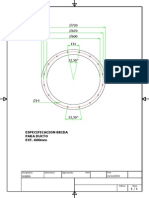

JOINT DESIGN USED

Type: A TOPE V

Single:

SI

Double Weld

Backing: Yes --- No

Back weld: Yes

No --Backing / Back weld Material: SI

Root Opening

Root Face Dimension

Groove Angle: 60

Radius (J-U) --Back Gouging: Yes

No

Method

--ESMERILADO

FILLER METALS

AWS Specification

AWS Classification

Trade name

MCC

EMISION:

-----------

POSTWELD HEAT TREATMENT

Temp. N.A.

Time N.A.

---

WELDING PROCEDURE

Pass

or

Weld

Layers

(S)

Process

1

2

SMAW

SMAW

Filler Metals

Class

Current

Diam.

Type

&Polarity

Amps or

Wire Feed

Speed

3/32

1/8

DCEP

DCEP

<100

<120

Elaborated by:

Name:

Signature:

Volts

Travel

Speed

(cm/min)

18

20

8cm/min

10cm/mi

Joint Details

Approved by:

D

M

A

Name:

Signature:

Quality control:

D

M

A

Name:

Signature:

D

M

A

Potrebbero piacerti anche

- C-Band PLL 3000: Innovative Communication SolutionsDocumento1 paginaC-Band PLL 3000: Innovative Communication SolutionsSam RichNessuna valutazione finora

- Plano Piñon v3 FinalDocumento1 paginaPlano Piñon v3 FinalvizcensoNessuna valutazione finora

- Serial AIDA64Documento1 paginaSerial AIDA64vizcensoNessuna valutazione finora

- Plano General 02Documento1 paginaPlano General 02vizcensoNessuna valutazione finora

- Cad de Nave Piura Layout1Documento1 paginaCad de Nave Piura Layout1vizcensoNessuna valutazione finora

- Plano Polin Conductor AnguloDocumento1 paginaPlano Polin Conductor AngulovizcensoNessuna valutazione finora

- Fabricar: 1 Colector: Designed by Checked by Approved by Date Date Proyecto: Planta de Cal-PachachacaDocumento1 paginaFabricar: 1 Colector: Designed by Checked by Approved by Date Date Proyecto: Planta de Cal-PachachacavizcensoNessuna valutazione finora

- Versa-Grip Dual Function Drum HandlerDocumento1 paginaVersa-Grip Dual Function Drum HandlervizcensoNessuna valutazione finora

- ReadmeDocumento1 paginaReadmeEmilio CBNessuna valutazione finora

- BridaDocumento1 paginaBridavizcensoNessuna valutazione finora

- Generated Using A Trial Version of Simlab PDF Exporter For Inventor Generated Using A Trial Version of Simlab PDF Exporter For InventorDocumento1 paginaGenerated Using A Trial Version of Simlab PDF Exporter For Inventor Generated Using A Trial Version of Simlab PDF Exporter For InventorvizcensoNessuna valutazione finora

- Ertalyte TXDataDocumento5 pagineErtalyte TXDatavizcensoNessuna valutazione finora

- Ertalyte TXDataDocumento5 pagineErtalyte TXDatavizcensoNessuna valutazione finora

- Sweet Child oDocumento1 paginaSweet Child ovizcensoNessuna valutazione finora

- CANT: 02 CANT: 01 CANT: 01 CANT: 02: Proyecto: Constructora-Cheves SacDocumento1 paginaCANT: 02 CANT: 01 CANT: 01 CANT: 02: Proyecto: Constructora-Cheves SacvizcensoNessuna valutazione finora

- Clase 20-03-2014Documento12 pagineClase 20-03-2014vizcensoNessuna valutazione finora

- Actives CanDocumento3 pagineActives CanvizcensoNessuna valutazione finora

- Clase 20-03-2014Documento12 pagineClase 20-03-2014vizcensoNessuna valutazione finora

- EIA - Marcona Wind ProjectDocumento1 paginaEIA - Marcona Wind ProjectvizcensoNessuna valutazione finora

- A ExandalDocumento13 pagineA ExandalvizcensoNessuna valutazione finora

- Horas MakylDocumento1 paginaHoras MakylvizcensoNessuna valutazione finora

- Toto Lyrics: "St. George and The Dragon"Documento8 pagineToto Lyrics: "St. George and The Dragon"vizcensoNessuna valutazione finora

- Expander Material: P22, NON-IBR Expander Size: 200 NB X 400 NB Expander Schedule: SCH 80Documento1 paginaExpander Material: P22, NON-IBR Expander Size: 200 NB X 400 NB Expander Schedule: SCH 80vizcensoNessuna valutazione finora

- Fatigue ANSYSDocumento22 pagineFatigue ANSYSHooman GhasemiNessuna valutazione finora

- (Guitar Tab) Andy Timmons - Electric GypsyDocumento14 pagine(Guitar Tab) Andy Timmons - Electric GypsyJohn LealNessuna valutazione finora

- Expander Material: P22, NON-IBR Expander Size: 200 NB X 400 NB Expander Schedule: SCH 80Documento1 paginaExpander Material: P22, NON-IBR Expander Size: 200 NB X 400 NB Expander Schedule: SCH 80vizcensoNessuna valutazione finora

- ClearanceDocumento29 pagineClearanceIvelin ValchevNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Aluminium FabricationDocumento21 pagineAluminium Fabricationjohn doe100% (1)

- Classification of SteelsDocumento29 pagineClassification of SteelsjanakNessuna valutazione finora

- MCQs Chapter Test 9Documento4 pagineMCQs Chapter Test 9wjeelani100% (1)

- Sheet Metal Gauge Size ChartDocumento2 pagineSheet Metal Gauge Size ChartaselabollegalaNessuna valutazione finora

- QTI Leaflet - 2018-LRDocumento4 pagineQTI Leaflet - 2018-LRTaherNessuna valutazione finora

- 5 Types of Heat Treating and Their Purpose in Precision MachiningDocumento5 pagine5 Types of Heat Treating and Their Purpose in Precision MachiningAnanduNessuna valutazione finora

- General Discussion of Lanthenides and ActinidesDocumento53 pagineGeneral Discussion of Lanthenides and ActinidesFaraz SiddiquiNessuna valutazione finora

- ME - 32021 Chapter (10) Economics of Machining ProcessesDocumento18 pagineME - 32021 Chapter (10) Economics of Machining ProcessesWILY100% (1)

- Bill of MaterialsDocumento4 pagineBill of MaterialsMark Gerald Prades RegalaNessuna valutazione finora

- 1278 - Continuous Sheet Casting - ELDocumento2 pagine1278 - Continuous Sheet Casting - ELYaman AkcanNessuna valutazione finora

- Folder Grobblech Heads Cones 1608Documento28 pagineFolder Grobblech Heads Cones 1608Filip StojkovskiNessuna valutazione finora

- Ms Pipe: Mighty and StrongDocumento16 pagineMs Pipe: Mighty and StrongVISHNU GAIDHANINessuna valutazione finora

- CSIR Chemical Science December 2014Documento41 pagineCSIR Chemical Science December 2014sampreetiNessuna valutazione finora

- OK Tigrod 13.32Documento1 paginaOK Tigrod 13.32Paulo CorreiaNessuna valutazione finora

- Vimp Theory of Metal Cutting 2Documento100 pagineVimp Theory of Metal Cutting 2Harsh PawarNessuna valutazione finora

- Heat Treatment by Quenching - DiagramsDocumento20 pagineHeat Treatment by Quenching - Diagramssunilmathew4477Nessuna valutazione finora

- Test Certificate: Suryakoti CastDocumento2 pagineTest Certificate: Suryakoti CastshitijkumarNessuna valutazione finora

- Tool and Die Making Troubleshooter PDFDocumento281 pagineTool and Die Making Troubleshooter PDFMalasiqui Central School INessuna valutazione finora

- Catalog Profile StandardDocumento16 pagineCatalog Profile StandardBogdan AndreiNessuna valutazione finora

- P Number, F Number and A Number in Welding (ASME Section IX) - Welding and NDTDocumento3 pagineP Number, F Number and A Number in Welding (ASME Section IX) - Welding and NDTAshish Ghadiya100% (1)

- Inserto Cuadrado SEET12T3Documento2 pagineInserto Cuadrado SEET12T3WILMER LLMUTASIGNessuna valutazione finora

- Astm F 436 - 11Documento6 pagineAstm F 436 - 11Marcos Verissimo Juca de PaulaNessuna valutazione finora

- Repair GI CoatingDocumento2 pagineRepair GI CoatingcashloverNessuna valutazione finora

- Hydrogen Transportation PipelinesDocumento83 pagineHydrogen Transportation PipelinesWolf1604100% (5)

- Ferric Chloride ParametersDocumento7 pagineFerric Chloride ParametersAnonymous 20VAruNessuna valutazione finora

- Iso 17655 2003Documento9 pagineIso 17655 2003azzaz abdelatifNessuna valutazione finora

- MaterialsDocumento3 pagineMaterialsRevanNessuna valutazione finora

- B.A. Washers - BA Washers - : Specification For Specification ForDocumento8 pagineB.A. Washers - BA Washers - : Specification For Specification ForcoolkaisyNessuna valutazione finora

- Analisis Kandungan Logam Berat Kromium (CR) Pada Air, Sedimen Dan Kerang Hijau (Perna Viridis) Di Perairan Trimulyo SemarangDocumento10 pagineAnalisis Kandungan Logam Berat Kromium (CR) Pada Air, Sedimen Dan Kerang Hijau (Perna Viridis) Di Perairan Trimulyo SemarangFera YuniarNessuna valutazione finora

- SAE J404 2000 Chemical Compositions of SAE Alloy Steels PDFDocumento5 pagineSAE J404 2000 Chemical Compositions of SAE Alloy Steels PDFMadirley PimentaNessuna valutazione finora