Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Unit - I: Electron Beam Welding

Caricato da

api-2713546820 valutazioniIl 0% ha trovato utile questo documento (0 voti)

249 visualizzazioni15 pagineTitolo originale

ebw

Copyright

© © All Rights Reserved

Formati disponibili

PPT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

249 visualizzazioni15 pagineUnit - I: Electron Beam Welding

Caricato da

api-271354682Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 15

MANUFACTURING TECHNOLOGY

UNIT I

ELECTRON BEAM WELDING

ELECTRON BEAM WELDING

Introduction

Electron beam machining (EBW) is a fusion welding

process that uses high velocity stream of electrons

focused on work piece surface to weld material by

melting and vaporization

In

electron-beam

welding

(EBW),

electrons

are

accelerated to a velocity nearly three-fourths that of light

(~200,000 km/sec).

ELECTRON BEAM WELDING

How it Works

An electron beam machine works in much the same way

as a cathode ray tube in a television.

A cathode section generates an electron beam.

An anode section accelerates the beam.

The lens system converges and deflects the electron

beam to the desired position.

ELECTRON BEAM WELDING

Operating principle

A high velocity stream of electrons is directed against a

precisely limited area of the work piece; on impact, the

kinetic energy of the electrons is converted into thermal

energy that melts and joins the materials to be weld.

The process is performed in a vacuum chamber to reduce

the scattering of electrons by gas molecules in the

atmosphere.

ELECTRON BEAM WELDING

Equipment

Schematic illustration of the Electron Beam Welding Process

ELECTRON BEAM WELDING

Equipment

Schematic illustration of the Electron Beam Welding Process

ELECTRON BEAM WELDING

Overall setup

ELECTRON BEAM WELDING

Sub systems of the Equipment

Electron Gun

The electron beam is formed inside of an electron gun,

which has

Cathode Hot tungsten filament emitting electrons

Grid Cup Element which is negatively biased with

respect to the filament

Anode a neutral element through which the

accelerated electron pass

ELECTRON BEAM WELDING

Sub systems of the Equipment

Magnetic Lens

Used to focus the electron beam to any desired diameter to

less than 0.00254 cm at a precise location on the work piece

Vacuum Chamber

It prevents collision of electrons with gas molecules which

would scatter or diffuse the electron beam

It prevents the possibility of an arc discharge between the

electrons

ELECTRON BEAM WELDING

Process Parameters

Processing material

Power supply

Beam current (A)

pulse duration (s)

Lens Current

Focusing length

Beam Deflection

Safety characteristics

ELECTRON BEAM WELDING

Process capabilities

A range of materials such as stainless steel, nickel and

cobalt alloys, copper, aluminium, titanium, ceramic,

leather and plastics can be processed by this method

This is mainly used to weld metals about 0.1 to 1.4 mm

in thicknesses up to 10 mm can be made

Aspect ratios as large as 15:1(Depth:width) can be

achieved in most materials

ELECTRON BEAM WELDING

Applications

The metals about 0.5 to 1.5mm thick can be welded

It is used to weld non-metallic materials and alloys.

It is used to weld dissimilar metals

Electron beam machining is being used extensively in

the electronic. aerospace and automotive industries.

Welding of cams

Suitable for large scale production

ELECTRON BEAM WELDING

Advantages

Single pass welding of thick joints

Hermetic seals of components retaining a vacuum

Low distortion

Low contamination in vacuum

Weld zone is narrow

Heat affected zone is narrow

Dissimilar metal welds of some metals

Uses no filler metal

ELECTRON BEAM WELDING

Limitations

High equipment cost

Work chamber size constraints

Time delay when welding in vacuum

High weld preparation costs

X-rays produced during welding

Rapid solidification rates can cause cracking in some

materials

END

Potrebbero piacerti anche

- Electron Beam Machining: D.Palani Kumar, Assistant Prof. / Mech. Engg., Kamaraj College of Engg. & Tech. VirudhunagarDocumento26 pagineElectron Beam Machining: D.Palani Kumar, Assistant Prof. / Mech. Engg., Kamaraj College of Engg. & Tech. VirudhunagarvaniNessuna valutazione finora

- Elctron Beam MachiningDocumento3 pagineElctron Beam MachiningTanu RdNessuna valutazione finora

- 13 Electron Beam WeldingDocumento11 pagine13 Electron Beam WeldingVarun KajaNessuna valutazione finora

- Indian Institute of Technology RoorkeeDocumento14 pagineIndian Institute of Technology Roorkeenikhilgyl93Nessuna valutazione finora

- Tungsten Filament Which Is Heated, Freeing Electrons.: - The Electron Beam Gun Has ADocumento13 pagineTungsten Filament Which Is Heated, Freeing Electrons.: - The Electron Beam Gun Has APrashant PuriNessuna valutazione finora

- Electron Beam Machining:: Principle of EBMDocumento5 pagineElectron Beam Machining:: Principle of EBMZaky MuzaffarNessuna valutazione finora

- Electron Beam Machining EBMDocumento8 pagineElectron Beam Machining EBMSuzzana DequetteNessuna valutazione finora

- Electron Beam Machining (EBM)Documento8 pagineElectron Beam Machining (EBM)RakeshSaini100% (3)

- Electron Beam MachineDocumento23 pagineElectron Beam MachineMQ ZerooNessuna valutazione finora

- Working Principle: Laser Beam WeldingDocumento14 pagineWorking Principle: Laser Beam WeldingAkash KumarNessuna valutazione finora

- 05 (Ebm Pam)Documento26 pagine05 (Ebm Pam)ssNessuna valutazione finora

- 13 Electron Beam WeldingDocumento13 pagine13 Electron Beam WeldingparidhiNessuna valutazione finora

- EBM - (Electron Beam Machining)Documento11 pagineEBM - (Electron Beam Machining)prankur giriNessuna valutazione finora

- NTMP - EbmDocumento20 pagineNTMP - EbmShuvroneil Sinha RoyNessuna valutazione finora

- 4A. Electron Beam Machining (EBM)Documento3 pagine4A. Electron Beam Machining (EBM)Tanu RdNessuna valutazione finora

- Document 1Documento8 pagineDocument 1sadiqali4244Nessuna valutazione finora

- Elecron Beam MachiningDocumento9 pagineElecron Beam Machiningpatel ketanNessuna valutazione finora

- User Guide To Machinery - EdmDocumento36 pagineUser Guide To Machinery - Edmggi internationalNessuna valutazione finora

- Electron Beam: MachiningDocumento37 pagineElectron Beam: MachiningraghurockramNessuna valutazione finora

- Electron Beam MachiningDocumento19 pagineElectron Beam MachiningHarshal NilNessuna valutazione finora

- Ebw LBW 28 May 09Documento13 pagineEbw LBW 28 May 09naveenaNessuna valutazione finora

- Electron Beam MachiningDocumento33 pagineElectron Beam MachiningMr PotatoNessuna valutazione finora

- EdmDocumento31 pagineEdmSuvin PsNessuna valutazione finora

- Electron Beam WeldingDocumento19 pagineElectron Beam WeldingRajan BhadoriyaNessuna valutazione finora

- Ucmp Unit-5Documento77 pagineUcmp Unit-5Rashida BegumNessuna valutazione finora

- Electron Beam WeldingDocumento25 pagineElectron Beam Weldingகார்த்திகேயன் ராஜன்Nessuna valutazione finora

- Admp 6th SemDocumento262 pagineAdmp 6th SemmishtisonuNessuna valutazione finora

- Advance ProductionDocumento5 pagineAdvance ProductiontamertunaliNessuna valutazione finora

- Electron Beam Machining: Principle of EBMDocumento4 pagineElectron Beam Machining: Principle of EBMPragyan Kumar PradhanNessuna valutazione finora

- Ele Ctric Dis Cha Rge Ma ChiningDocumento48 pagineEle Ctric Dis Cha Rge Ma ChiningfarizanNessuna valutazione finora

- Digital Assigment-2: Name - Mukund Misra REG NO.-17BEM0134Documento7 pagineDigital Assigment-2: Name - Mukund Misra REG NO.-17BEM0134mukund misNessuna valutazione finora

- Ebm and LBMDocumento20 pagineEbm and LBMVaibhav KakkarNessuna valutazione finora

- Electron Beam Welding: Author's: A. Leonard Pawan, A. Antony Ajay, K. Manjunath, S .Yuvaraj PandiDocumento11 pagineElectron Beam Welding: Author's: A. Leonard Pawan, A. Antony Ajay, K. Manjunath, S .Yuvaraj PandiLeonard PawanNessuna valutazione finora

- Lect 32Documento25 pagineLect 32shashankmay18Nessuna valutazione finora

- Electron Beam MachiningDocumento14 pagineElectron Beam MachiningDoopukuntla SmithaNessuna valutazione finora

- ELECTRON BEAM MACHINING PrashanthDocumento20 pagineELECTRON BEAM MACHINING PrashanthSurender NarmetaNessuna valutazione finora

- Ebm PPT Vga 2022-23-28-32Documento5 pagineEbm PPT Vga 2022-23-28-32Sherazi AshrafiNessuna valutazione finora

- Electron Beam MachiningDocumento7 pagineElectron Beam MachiningDiaz LaksmanaNessuna valutazione finora

- Production Technology: Electron Beam MachiningDocumento14 pagineProduction Technology: Electron Beam MachiningFuxNessuna valutazione finora

- EDM, LBM and ECMDocumento30 pagineEDM, LBM and ECMSparsh KatiyarNessuna valutazione finora

- Pallavi DubeyDocumento17 paginePallavi DubeyPallavi DwivediNessuna valutazione finora

- Electron Beam MachiningDocumento7 pagineElectron Beam MachiningsatyanitwNessuna valutazione finora

- Electrobeam MachiningDocumento8 pagineElectrobeam Machiningpatel ketan67% (3)

- Advanced Machining Processes - Module 3 Part 1Documento33 pagineAdvanced Machining Processes - Module 3 Part 1Kenneth C.LinojNessuna valutazione finora

- Advanced Manufacturing Choices: MAE 165-265 Spring 2012, Class 5Documento46 pagineAdvanced Manufacturing Choices: MAE 165-265 Spring 2012, Class 5snvijayanNessuna valutazione finora

- Bimetallic Welding, Ecm and EdmDocumento6 pagineBimetallic Welding, Ecm and EdmShivan NaikNessuna valutazione finora

- Recent Trends in Non-Traditional Machining Processes: Unit - 5Documento12 pagineRecent Trends in Non-Traditional Machining Processes: Unit - 5DISHA VNessuna valutazione finora

- Unit Iii NotesDocumento29 pagineUnit Iii NotesSadhasivam CNessuna valutazione finora

- Electric Discharge Machining (Edm) BY: Dr. Manas Das Assistant ProfessorDocumento40 pagineElectric Discharge Machining (Edm) BY: Dr. Manas Das Assistant ProfessorSrinivasanNessuna valutazione finora

- NTM Assigment Topic: Electron Beam Machining: Name: Venu Kabra USN: 1RV07ME115 Branch: Mecanical Sem: 7 "C"Documento19 pagineNTM Assigment Topic: Electron Beam Machining: Name: Venu Kabra USN: 1RV07ME115 Branch: Mecanical Sem: 7 "C"Venu KabraNessuna valutazione finora

- Edm NotesDocumento98 pagineEdm NotesDeepankumar AthiyannanNessuna valutazione finora

- Electro Chemical MachiningDocumento40 pagineElectro Chemical Machiningnashk18Nessuna valutazione finora

- Welcome To The Presentation On Other Welding Processes: Presented by Tanay Roy Roll No: 1805024Documento47 pagineWelcome To The Presentation On Other Welding Processes: Presented by Tanay Roy Roll No: 1805024Tanay RoyNessuna valutazione finora

- Module-1: Electric Welding byDocumento17 pagineModule-1: Electric Welding byveena bhatNessuna valutazione finora

- Machining Process 2: Electron Beam Machining (EBM)Documento5 pagineMachining Process 2: Electron Beam Machining (EBM)hmoa2050Nessuna valutazione finora

- Edm PDFDocumento32 pagineEdm PDFPrashantJangidNessuna valutazione finora

- Electron Beam Machining 1Documento9 pagineElectron Beam Machining 1Anonymous NUIEgENessuna valutazione finora

- Basics in WeldingDocumento63 pagineBasics in WeldingK JeevanNessuna valutazione finora

- Air Breathing Propulsion Unit-1Documento37 pagineAir Breathing Propulsion Unit-1api-271354682Nessuna valutazione finora

- As1018 6 Sem 7Documento2 pagineAs1018 6 Sem 7api-271354682Nessuna valutazione finora

- As1018 6 Sem 4Documento5 pagineAs1018 6 Sem 4api-271354682Nessuna valutazione finora

- As1018 6 Sem 6Documento2 pagineAs1018 6 Sem 6api-271354682Nessuna valutazione finora

- As1018 6 Sem 5Documento2 pagineAs1018 6 Sem 5api-271354682Nessuna valutazione finora

- 15as304 Air Breathing Propulsion SyllabusDocumento2 pagine15as304 Air Breathing Propulsion Syllabusapi-271354682Nessuna valutazione finora

- Cycle Test 2 Rocket PropulsionDocumento3 pagineCycle Test 2 Rocket Propulsionapi-271354682Nessuna valutazione finora

- Rocket Propulsion ct-1 2017 QPDocumento5 pagineRocket Propulsion ct-1 2017 QPapi-271354682100% (1)

- Gate Question and Answer For Aerospace by Vinothkumar AnnamalaiDocumento138 pagineGate Question and Answer For Aerospace by Vinothkumar Annamalaiapi-271354682Nessuna valutazione finora

- Propulsion2 QPDocumento12 paginePropulsion2 QPapi-271354682100% (1)

- List of Rockets AssignmentDocumento4 pagineList of Rockets Assignmentapi-271354682Nessuna valutazione finora

- Assignment 3Documento3 pagineAssignment 3api-271354682Nessuna valutazione finora

- Intake and Nozzle Problems NumericalDocumento7 pagineIntake and Nozzle Problems Numericalapi-271354682100% (1)

- As0306 Propulsion IIDocumento3 pagineAs0306 Propulsion IIapi-271354682Nessuna valutazione finora

- Air Breathing Propulsion Unit-3Documento22 pagineAir Breathing Propulsion Unit-3api-271354682Nessuna valutazione finora

- Lab Manual Stud CP II To Be Used With The Right One 1Documento21 pagineLab Manual Stud CP II To Be Used With The Right One 1api-271354682Nessuna valutazione finora

- Program 1Documento35 pagineProgram 1api-271354682Nessuna valutazione finora

- Rocket Propulsion Unit-3Documento53 pagineRocket Propulsion Unit-3api-271354682100% (4)

- Air Breathing Propulsion Unit-2Documento54 pagineAir Breathing Propulsion Unit-2api-271354682Nessuna valutazione finora

- Rocket Propulsion-2 ct-1 QP Key-2016Documento3 pagineRocket Propulsion-2 ct-1 QP Key-2016api-271354682Nessuna valutazione finora

- Rocket Propulsion Unit-4Documento21 pagineRocket Propulsion Unit-4api-271354682100% (1)

- Rocket Propulsion-2 ct-2 qp-2016Documento5 pagineRocket Propulsion-2 ct-2 qp-2016api-271354682Nessuna valutazione finora

- Rocket Propulsion Unit-5Documento44 pagineRocket Propulsion Unit-5api-271354682Nessuna valutazione finora

- Rockets History and EvolutionDocumento11 pagineRockets History and Evolutionapi-271354682Nessuna valutazione finora

- Matching of Turbine and CompressorDocumento2 pagineMatching of Turbine and Compressorapi-271354682100% (5)

- Rocket Propulsion Unit-1Documento47 pagineRocket Propulsion Unit-1api-271354682100% (4)

- Rocket Propulsion Unit-2Documento8 pagineRocket Propulsion Unit-2api-271354682Nessuna valutazione finora

- Numerical ProblemsDocumento12 pagineNumerical Problemsapi-271354682Nessuna valutazione finora

- Choice of Blade Profile, Pitch and ChordDocumento6 pagineChoice of Blade Profile, Pitch and Chordapi-27135468260% (5)

- TYPES 2N1671, 2N1671A, 2N1671B, 2N2160 P-N Grown Silicon Unijunction TransistorDocumento1 paginaTYPES 2N1671, 2N1671A, 2N1671B, 2N2160 P-N Grown Silicon Unijunction Transistorluis.sinatoNessuna valutazione finora

- Stefan Mayer Instruments: Triaxial Fluxgate Sensor With High Sensitivity Measurement Range Up To ±200 Μt, Dc To 1 KhzDocumento2 pagineStefan Mayer Instruments: Triaxial Fluxgate Sensor With High Sensitivity Measurement Range Up To ±200 Μt, Dc To 1 KhzAbd'Errahmen MharbiNessuna valutazione finora

- C 4 OkkDocumento15 pagineC 4 OkkTeguh WiyonoNessuna valutazione finora

- 6F2T0177 r2.1 GRE140 Manual PDFDocumento395 pagine6F2T0177 r2.1 GRE140 Manual PDFNazi Sweet0% (1)

- Ee8703 Renewable Energy Systems L T P CDocumento3 pagineEe8703 Renewable Energy Systems L T P CPadukolai KarupaiahNessuna valutazione finora

- CBIP Substation Manual 2006 PDFDocumento122 pagineCBIP Substation Manual 2006 PDFPravin Narkhede83% (18)

- Evaluasi Keandalan PLTA Bakaru: Akbar Tanjung, Arman Jaya, Suryanto, ApolloDocumento8 pagineEvaluasi Keandalan PLTA Bakaru: Akbar Tanjung, Arman Jaya, Suryanto, Apollohilda tangkeNessuna valutazione finora

- Physics Investigatory Project On Kirchhoffs Current LawDocumento4 paginePhysics Investigatory Project On Kirchhoffs Current LawAakash PandeyNessuna valutazione finora

- Chapter 6 Logic FamiliesDocumento49 pagineChapter 6 Logic FamiliesRajan PaulNessuna valutazione finora

- 2-Lecture 02 Electrical Networks Transfer FunctionDocumento18 pagine2-Lecture 02 Electrical Networks Transfer FunctionHamza KhanNessuna valutazione finora

- 405 ZXM7-SHLD108 182 - 1728×1134 (30×28) - 395-415W - 350mm - 20210714 - EDocumento2 pagine405 ZXM7-SHLD108 182 - 1728×1134 (30×28) - 395-415W - 350mm - 20210714 - Esteven6diaz-2Nessuna valutazione finora

- Test 1 Skee1013 20172018 - 1Documento5 pagineTest 1 Skee1013 20172018 - 1Andy QklNessuna valutazione finora

- Water Pump and Water Filter Using Solar-Hybrid Energy With Mobile VehicleDocumento4 pagineWater Pump and Water Filter Using Solar-Hybrid Energy With Mobile VehicleFengXuan YangNessuna valutazione finora

- Customer TCM-4028-001 TCU-2800 Universal Harness With OptionDocumento2 pagineCustomer TCM-4028-001 TCU-2800 Universal Harness With OptionDavid FuentesNessuna valutazione finora

- NFS-DHA-E-TC-05 - Testing of Earthing and LPSDocumento25 pagineNFS-DHA-E-TC-05 - Testing of Earthing and LPSirshadNessuna valutazione finora

- Cable Systems - ETAPDocumento10 pagineCable Systems - ETAPJoeDabidNessuna valutazione finora

- Sentron Harmonic Mitigating Transformers (HM1 & HM2)Documento2 pagineSentron Harmonic Mitigating Transformers (HM1 & HM2)Alfredorodriguez GutierrezNessuna valutazione finora

- Cn-201 Ab Diagrama DaewooDocumento74 pagineCn-201 Ab Diagrama DaewooJairo PadronNessuna valutazione finora

- Standards of Professional Practice For Electrical Engineers and ElectriciansDocumento15 pagineStandards of Professional Practice For Electrical Engineers and ElectriciansKevin Cabante73% (11)

- Catalogue - 40.5kV T Type OVCB PDFDocumento20 pagineCatalogue - 40.5kV T Type OVCB PDFGanesh Duraisamy0% (1)

- 4.1 EHW24 Rules&RegulationsDocumento58 pagine4.1 EHW24 Rules&Regulationsmm22b002Nessuna valutazione finora

- Metal Detector: Submitted by Guided BYDocumento21 pagineMetal Detector: Submitted by Guided BYGaurav Sharma100% (1)

- UWB Time Domain AntennaDocumento3 pagineUWB Time Domain AntennaSrikanth SrinadhuniNessuna valutazione finora

- pm402 NardaDocumento4 paginepm402 NardaflegiasNessuna valutazione finora

- Surge Protec IIDocumento14 pagineSurge Protec IIRaj ChavanNessuna valutazione finora

- TA8246AHQ: Dual Audio Power Amplifier 6 W × 2 CHDocumento11 pagineTA8246AHQ: Dual Audio Power Amplifier 6 W × 2 CHinggreg1Nessuna valutazione finora

- Medium Frequency Coreless Induction Furnaces MFTDocumento16 pagineMedium Frequency Coreless Induction Furnaces MFTCem AlpaslanNessuna valutazione finora

- Answer KeyDocumento2 pagineAnswer KeyJeremy PanerioNessuna valutazione finora

- Ae SMM6 60 - 275 300W - enDocumento2 pagineAe SMM6 60 - 275 300W - enyorastaNessuna valutazione finora

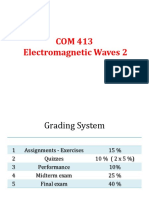

- Lecture - 0 - Course DescriptionDocumento5 pagineLecture - 0 - Course DescriptionNour YehiaNessuna valutazione finora