Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lampiran Adul Banggggeeeeeeeet

Caricato da

Wyda Novayanti SaragiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lampiran Adul Banggggeeeeeeeet

Caricato da

Wyda Novayanti SaragiCopyright:

Formati disponibili

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S.

Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

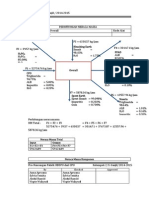

2.2. Neraca Massa pada masing-masing alat

2.2.1. Degumming Tank(T-103)

Berfungsiuntukmengikat gum dan CPO

Degumming Tank

F2 = 57550,64457 kg/ jam

Trigliserida 96,33%

FFA 3,5%

H2O 0,02%

I mpuritis 0,02 %

F3

H3PO4 85%

Kadar Air 15%

F4 = ?

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

Gum = ?

Neraca Massa Total :

F2+ F3 = F4

F4 = 57.608,195 kg/jam

Neraca Massa Komponen :

No

Komponen

Input (Kg/jam) Output (Kg/jam)

F2 F3 F4

1 Trigliserida 55.438,5359 - 55.438,53591

2 FFA 2.014,27256 - 2.014,27256

3 H2O 86,32596685 8,632596685 94,95856354

4 Impuritis 11,5101289 - 7,021178637

5 H3PO4 - 48,91804788 -

6 Gum - - 53,40699816

Total

57.550,64457 57,55064457

57.608,19521 57.608,19521

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

2.2.2. Bleacher Tank(T-105)

Berfungsi untuk menghilangkanzatwarna yang

tidakdiinginkandenganmenggunakanKaolin.

Bleacher Tank

F4

Trigliserida

FFA

H2O

I mpuritis

Gum

F6 = ?

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

Gum = ?

Spent Kaolin = ?

Kaolin 98,15%

Air 1,85%

F5

Neraca Massa Total :

F6 = F4 + F5

F6 = 57608,1952 Kg/jam + 1151,0129 Kg/jam

F6 = 58759,2081 Kg/jam

Neraca Massa Komponen :

NO Komponen Input (Kg/jam) Output (Kg/jam)

F4 F5 F6

1 Trigliserida 55.438,5359 - 55.438,5359

2 FFA 2.014,27356 - 2.014,27356

3 H2O 94,958856 21,2937385 116,252302

4 Impuritis 11,510129 - 11,510129

5 Gum 53,4069982 - 53,4069982

6 Kaolin - 1.129,71915 -

7 Spent Kaolin - - 1.130,68877

Total

57.608,1952 1.151,01289 58.759,2081

58.759,2081 58.759,2081

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

2.2.3. Niagar Filter(F-101)

Berfungsiuntukmenyaringgumdanspent kaolin.

Niagara Filter

F6

Trigliserida

FFA

H2O

I mpuritis

Gum

Spent Kaolin

F8

Gum

Spent Kaolin

F7 = ?

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

Gum = ?

Spent Kaolin = ?

Neraca Massa Total :

F7=888,0718 Kg/jam

F8= 57752,7267Kg/jam

F6 = F7 + F8

F7 + F8 = 58759,2181 Kg/jam

Neraca Massa Komponen :

No Komponen Input (kg/jam) Output (kg/jam)

F6 F8 F7

1 Trigliserida 55.438,5359 - 55.438,54

2 FFA 2014,27256 - 2.014,273

3 H2O 116,252302 - 116,2523

4 Impuritis 6,05156538 - 6,051565

5 Spent earth 1.130,68877 961,085451 169,6033

6 Gum 53,4069932 45,3959484 8,01105

Total

58.759,2081 1006,4814 57.752,73

58.759,2081 58.759,2081

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

2.2.4. Polishing Filter I(F-102)

Berfungsiuntukmemurnikan RBDPO.

Polishing Filter

F7

Trigliserida

FFA

H2O

I mpuritis

Gum

Spent Kaolin

F10 = ?

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

F9

Gum

Spent Kaolin

Neraca Massa Total :

F10 = 57601,7545 Kg/jam

F9 = 150,9722 Kg/jam

F7= F10 + F9

F10 + F9 = 57752,7267 Kg/jam

Neraca Massa Komponen :

No Komponen Input (kg/jam) Output (kg/jam)

F7 F9 F10

1 Trigliserida 55.438,54 - 55.438,5359

2 FFA 2.014,273 - 2.014,273

3 H2O 116,252302 - 116,2523

4 Impuritis 6,051565 - 32,6937201

5 Spent earth 169,603315 144,162 -

6 Gum 8,01104972 6,809392 -

Total

57.752,7267 150,9722 57.601,7545

57.752,7267 57.752,7267

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

2.2.5. Deodorizer Tank(T-106)

Berfungsiuntukmemisahkan Asam Lemak Bebas menjadi Palm Fatty Acid

Neraca Massa Total :

F12=1622,4139 Kg/jam

F14= 55979,3406 Kg/jam

F10 = F12 + F14

F12+ F14 = 57601,7545 Kg/jam

Neraca Massa Komponen :

No Komponen Input (kg/jam) Output (kg/jam)

F10 F12 F14

1 Trigliserida 55.438,53591 - 55.438,536

2 FFA 2.014,27256 - 503,56814

3 PFAD - 1.510,70442 -

4 H2O 116,252302 87,18922652 29,063076

5 Impuritis 32.69372007 24,52029006 8,17343

Total

57.601,75449 1.622,413936 55.979,341

57.601,75449 57.601,75449

Deodorizer Tank

F10

Trigliserida

FFA

H2O

I mpuritis

F14 = ?

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

F12

PFAD

I mpuritis

H2O

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

2.2.6. Polishing FilterII(F-103)

Berfungsiuntuk memurnikan RBDPO

Polishing Filter

F14

Trigliserida

FFA

H2O

I mpuritis

F18 = ?

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

F17

I mpuritis

Neraca Massa Total :

F17= waste = impuritis yang masih terikut akan dibuang dalam aliran ini

F17= 55973,2105 Kg/jam

F14 = F17 + F18

F17 + F18= 55979,3406 Kg/jam

Neraca Massa Kompenen :

No Komponen Input (kg/jam) Output (kg/jam)

F14 F17 F18

1 Trigliserida 55438.5359 - 55438.53591

2 FFA 503.56814 - 503.56814

3 H2O 29.0630755 - 29.06307551

4 Impuritis 8.17343002 6.130073 2.043357505

Total

55979.3406 6.130073 55973.21048

55979.3406 55979.3406

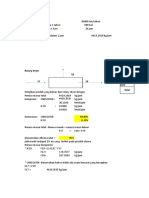

2.2.7. Crystalizer Tank(T-107)

Berfungsi untuk mendinginkan campuran olein dan stearin agar terbentukslurry

Crystalizer

F18

Trigliserida

FFA

H2O

I mpuritis

F21

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

Neraca Massa Total :

F18 = F21

F21 = 55973,2105 Kg/jam

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Neraca Massa Komponen :

No

Komponen

Input (kg/jam) Output (kg/jam)

F18 F21

1 Trigliserida 55.438,53591 55.438,53591

2

FFA 503,56814 503,56814

3

Impuritis 29,06307551 29,06307551

4

H2O 2,043357505 2,043357505

Total

55.973,21048 55.973,21048

2.2.8. Membran Filter(F-104)

Berfungsi untuk memisahkan fraksi padat (stearin) dengan fraksi cair (olein).

Asumsi konversi olein 75% dari umpan crystalizer (Yusoff, 2000)

Asumsi Kadar FFAdan H2O 0,1 % yang disesuaikan dengans pesifikasi produk

(BSN, 2006)

Membran Filter

F21

Trigliserida

FFA

H2O

I mpuritis

F22

Olein = ?

FFA = ?

H2O = ?

F23

Stearin = ?

FFA = ?

H2O = ?

I mpuritis = ?

Neraca Massa Total :

F23 = 14477,0669 Kg/jam

F22 = 419791436 Kg/jam

F21 = F23 + F22

F22 + F23 = 55973,2105 Kg/jam

Neraca Massa Komponen :

No

Komponen

Masuk (kg/jam) Keluar (kg/jam)

F21 F22 F23

1 Trigliserida 55438.53591 - -

2

FFA

503.56814 0.377676105 503.1904639

3

Impuritis

2.043357505

-

2.043357505

4

H2O

29.06307551 0.021797307 29.0412782

5

Olein -

41495.74413

-

6

Stearin - -

13942.79178

Total

55973.21048 41496.1436 14477.06688

55973.21048 55973.21048

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

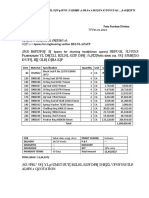

2.3. Neraca Massa pada Overall

Process

F4 = 57550,64 Kg/ jam

Trigliserida = 55438,54 Kg/ jam

FFA = 2014,273 Kg/ jam

H2O = 86,32597 Kg/ jam

I mpurities = 11,51013 Kg/ jam

F3 = 57,5506 Kg/jam

H3PO4 = 48,9181 Kg/jam

H2O = 8,63260 Kg/jam

F6 = 1151,0129 Kg/ jam

Kaolin = 1129,7192 Kg/ jam

H2O = 21,293738 Kg/ jam

F9a = 1006,4814 Kg/ jam

Gum = 45,395948 Kg/ jam

spent kaolin = 961,08545 Kg/ jam

F9b = 150,9722 Kg/ jam

Gum = 6,809392 Kg/ jam

spent kaolin = 144,1628 Kg/ jam

F11a = 1622,4139 Kg/ jam

FFAD = 1510,70442 Kg/ jam

I mpuritis = 24,5202901 Kg/ jam

H2O = 87,1892265 Kg/ jam

F17 = 14477,067 Kg/ jam

Stearin = 13942,792 Kg/ jam

FFA = 503,19046 Kg/ jam

H2O = 29,041278 Kg/ jam

I mpuritis = 2,0433575 Kg/ jam

F14a = 6,130073 Kg/ jam

I mpuritis = 6,130073 Kg/ jam

F18 = 41496,1436 Kg/ jam

Olein = 41495,7441 Kg/ jam

FFA = 0,37767611 Kg/ jam

H2O = 0,02179731 Kg/ jam

Neraca Massa Total

MASUK KELUAR

58759,2081 Kg/ jam 58759,2081 Kg/ jam

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

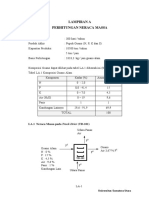

LAMPIRAN A.1

Dasar Perancangan Pabrik :

Kapasitas pabrik = 300.000 ton/tahun = 300.000.000 kg/tahun

Operasi pabrik = 300 hari

Kapasitas per hari = 300.000.000 kg/tahun : 300 hari = 1.000.000 kg/hari

Kapasitas per jam = 1.000.000 kg/hari : 24 jam = 41.666,66667 kg/jam

Laju Alir F2 = 57.550,64457 kg/jam

Asumsi :

Jumlah H3PO4 yang digunakanadalah 0,1% dari CPO yang masuk

H3PO4 yang dibutuhkan = 0,1% x 57.550,64457kg/jam ( Sumarna, 2007)

Fospatida yang menjadi gum = 62,26% (Sumarna, 2007)

Fospatida yang tertinggal = 37,74% (Sumarna, 2007)

Laju alir F3 = 57,550645 kg/jam

Degumming Tank

F2 = 57550,64457 kg/ jam

Trigliserida 96,33%

FFA 3,5%

H2O 0,02%

I mpuritis 0,02 %

F3

H3PO4 85%

Kadar Air 15%

F4 = ?

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

Gum = ?

Neraca Massa Total :

F2+ F3= F4

F4 = 57.608,195 kg/jam

Neraca Massa Komponen :

Trigliserida : F4X4Trigliserida = F2X2Trigliserida

F4X4Trigliserida= 55.438,5391 kg/jam

FFA : F4X4FFA = F2X2FFA

F4X4FFA = 2.014,27256 kg/jam

H2O : F4X4H2O = F2X2H2O

F4X4H2O= 94,95856354 kg/jam

Perhitungan Neraca Massa

Alat Degumming Tank Kode

Fungsi Mengikat gum dan CPO T-103

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Fospatida :F4 X4 Fospatida= 37,74% F2X2 Fospatida

F4 X4 Fospatida= 37,74% (0,0078% x 57.550,645 kg/jam

F4X4 Fospatida= 1,694129 kg/jam

Aldehid :F4 X4 Aldehid = F2X2 Aldehid

F4 X4 Aldehid = (0,0083% x 57.550,645 kg/jam

F4X4 Aldehid = 4,776703 kg/jam

Karoten :F4 X4 Karoten = F2X2 Karoten

F4 X4 Karoten = (0,0039% x 57.550,645 kg/jam

F4X4 Karoten = 2,244475 kg/jam

H3PO4 : F4X4 H3PO4 = F3X3 H3PO4

F4X4 H3PO4 = 85% x 57,550645

F4X4 H3PO4 = 48,91804788 kg/jam

Gum :F4X4Gum = (00897665) F4X4Gum

F4X4Gum = 00897665x 57.608,195

F4X4Gum = 51,71286 kg/jam

Komposisi Aliran F4 :

F4X4Trigliserida= 55.438,536 kg/jam

X4 Trigliserida =

= 0,962338

F4X4FFA = 2.014,2726 kg/jam

X4FFA =

= 0,034965

F4X4 H2O = 94,958564 kg/jam

X4H2O =

= 0,001648

F4X4 Aldehid = 4,7767035 kg/jam

X4 Aldehid =

= 8,291 x 10

-5

F4X4 Karoten = 2,2444751 kg/jam

X

4

Karoten =

= 3,8961 x 10

-5

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

F4X4 Fospatida = 1,6941298 kg/jam

X4 Fospatida =

= 2,940 x 10

-5

F4X4Gum = 51,712868 kg/jam

X4Gum =

= 0,00089767

Tabel 1. Neraca massa pada degumming tank

No

Komponen

Input (Kg/jam) Output (Kg/jam)

F2 F3 F4

1 Trigliserida 55.438,5359 - 55.438,53591

2 FFA 2.014,27256 - 2.014,27256

3 H2O 86,32596685 8,632596685 94,95856354

4 Impuritis 11,5101289 - 7,021178637

5 H3PO4 - 48,91804788 -

6 Gum - - 53,40699816

Total

57.550,64457 57,55064457

57.608,19521 57.608,19521

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Perhitungan Neraca Massa

Alat Bleacher Kode

Fungsi Menghilangkan zat warna yang tidak

diinginkan

T-105

Asumsi :

Bleaching earth yang digunakan yaitu jenisSimnit (Kaolin), maka Kaolin yang

dibutuhkan : 2,00 % x kg/jam = 1.151,01289 kg/jam

Laju 5Alir F5 : 1.151,01289 kg/jam

Efisiensi dayaserap kaolin sebesar 43,2 % mengikatkaroten (Nasution, 2003)

Konsentrasi Kaolin 98,15% sehingga : 98,15% x 1.151,01289 = 1.129,71915 kg/jam

Kadar Air (H2O) 1,85% sehingga : 1,85 % x 1.151,01289 = 21,2937385 kg/jam

Kandungan Karoten yang terkandung dalam impurities sebesar 19.5 % sedangkan

kandungan aldehid 41,5%

maka: 19,5% x 11,510129 = 2,244475 kg/jam

maka :41,5% x 11,510129= 4,776703 kg/jam (Gunstone, 1987).

Bleacher Tank

F4

Trigliserida

FFA

H2O

I mpuritis

Gum

F6 = ?

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

Gum = ?

Spent Kaolin = ?

Kaolin 98,15%

Air 1,85%

F5

Neraca Massa Total :

F6 = F4 + F5

F6 = 57.608,1952 Kg/jam + 1151,0129 Kg/jam

F6 = 58.759,2081 Kg/jam

Neraca Massa Komponen :

Trigliserida : F4X4Trigliserida = F6X6Trigliserida

55.438,536 kg/jam = F6X6Trigliserida

FFA : F4X4 FFA = F6X6 FFA

2.014,27256 kg/jam = F6X6FFA

H2O : F4X4H2O + F5X5H2O= F6X6H2O

(94,9585635 + 21,2937385 kg/jam) = F6X6H2O

116,252302 kg/jam = F6X6H2O

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Fospatida : F4X4 Fospatida = F6X6 Fospatida

(0,002940% x 57.608,19521) = F6X6 Fospatida

1,694129834 kg/jam = F6X6 Fospatida

Karoten : F4X4 Karoten = F6X6 Karoten

(0,003896104% x 57.608,19521) = F6X6 Karoten

1,79558011 kg/jam = F6X6 Karoten

Aldehid : F4X4 Aldehid = F6X6 Aldehid

(0,008291708% x 57.608,19521) = F6X6 Aldehid

4,776703499 kg/jam = F6X6 Aldehid

Gum : (0,089766513%) F4X4Gum = F6X6Gum

51,71286832 kg/jam = F6X6Gum

Kaolin : F5X5kaolin= F6X6kaolin

(0,01923389 x 58.759,2081) =F6X6 kaolin

1.130,168048 kg/jam = F6X6 kaolin

Mencari F5 dan F6

F5 = F5H2O + F5 kaolin

= 21,2937385 + 1.129,71915

= 1.151,012889kg/jam

F6 = F4 +F5

= (57.608,195 + 1.151,012889)kg/jam

= 58.759,2081 kg/jam

Komposisi Aliran F6 :

F6X6Trigliserida= 55.438,5359 kg/jam

X6 Trigliserida =

= 0,943486778

F6X6FFA = 2.014,27256 kg/jam

X6FFA =

= 0,034280118

F6X6H2O = 116,252302 kg/jam

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

X6H2O =

=0,001978452

F4X4 Aldehid = 4,7767035 kg/jam

X4 Aldehid =

= 8,1293 x 10

-5

F4X4 Karoten = 1,79558011 kg/jam

X4 Karoten =

= 3,0558 x 10

-5

F4X4 Fospatida = 1,6941298 kg/jam

X4 Fospatida =

= 2,8832 x 10

-5

F6X6Gum = kg/jam

X6 Gum =

= 0,00088008

F6X6Spent kaolin = 1.130,168048 kg/jam

X6Spent kaolin =

=0,01923389

Tabel 2. Neraca massa pada bleacher tank

NO Komponen Input (Kg/jam) Output (Kg/jam)

F4 F5 F6

1 Trigliserida 55.438,5359 - 55.438,5359

2 FFA 2.014,27356 - 2.014,27356

3 H2O 94,958856 21,2937385 116,252302

4 Impuritis 11,510129 - 11,510129

5 Gum 53,4069982 - 53,4069982

6 Kaolin - 1.129,71915 -

7 Spent Kaolin - - 1.130,68877

Total

57.608,1952 1.151,01289 58.759,2081

58.759,2081 58.759,2081

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Perhitungan Neraca Massa

Alat Niagara Filter Kode

Fungsi Menyaringgumdanspent earth F-101

Asumsi : niagara filter memisahkan gum and spent kaolin 85% (Pieter, 1993)

Niagara Filter

F6

Trigliserida

FFA

H2O

I mpuritis

Gum

Spent Kaolin

F8

Gum

Spent Kaolin

F7 = ?

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

Gum = ?

Spent Kaolin = ?

Neraca Massa Total :

F6 = F7 + F8

F7 + F8 = 58.759,2081 Kg/jam

Neraca Massa Komponen :

Trigliserida : F6X6Trigliserida = F7X7Trigliserida

55.438,5359 kg/jam = F7X7 Trigliserida

FFA : F6X6 FFA = F7X7 FFA

2.014,27256 kg/jam = F7X7FFA

H2O : F6X6 H2O = F7X7H2O

116,252302 kg/jam = F7X7H2O

Fospatida : F6X4 Fospatida = F7X7 Fospatida

(0,002940% x 57.608,19521) = F7X7 Fospatida

1,694129834 kg/jam = F7X7 Fospatida

Karoten : F6X6 Karoten = F7X7 Karoten

(0,003896104% x 57.608,19521) = F7X7 Karoten

1,79558011 kg/jam = F7X7 Karoten

Aldehid : F6X6 Aldehid = F7X7 Aldehid

(0,008291708% x 57.608,19521) = F7X7 Aldehid

4,776703499 kg/jam = F7X7 Aldehid

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Gum : 85% F6X6Gum = F8X8Gum

51,7128683 kg/jam = F8X8Gum

: 85% F6X6Gum = F7X7Gum

43,95594kg/jam = F7X7Gum

:( F6X6Gum )- F7X7Gum = F8X8Gum

: 7,75693 kg/jam = = F8X8Gum

Spent Kaolin : F6X6kaolin= (85% x F6 Spent kaolin + F7X7kaolin)

1.130,68877kg/jam =960,542841 kg/jam + F7X7kaolin

F7X7kaolin = 1.130,68877 961,085451 kg/jam

F7X7 kaolin =169,5252 kg/jam

Mencari F7 dan F8

F7 = F7Gum + F7 spent kaolin

= (43,95594 + 960,6428) kg/jam

= 1004,599 kg/jam

F8 = F6 - F7

= (58.759,2081 1004,599)kg/jam

= 57754,60932kg/jam

Komposisi Aliran F7:

F8X8Gum = 43,95594 kg/jam

X8Gum =

= 0,04375472

F8X8Spent kaolin = 960,6428 kg/jam

X8Spent kaolin =

= 0.95624528

Komposisi Aliran F8:

F6X6Trigliserida= 55.438,53591 kg/jam

X6 Trigliserida =

= 0,959898033

F6X6FFA = 2.014,27256 kg/jam

X6FFA =

= 0,034876395

F6X6H2O = 116,252302 kg/jam

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

X6H2O =

=0,002012866

F4X4 Aldehid = 4,7767035 kg/jam

X4 Aldehid =

= 8,27069 x 10

-5

F4X4 Karoten = 1,79558011 kg/jam

X4 Karoten =

= 3,10898 x 10

-5

F4X4 Fospatida = 1,6941298 kg/jam

X4 Fospatida =

= 2,93332 x 10

-5

F6X6Gum = kg/jam

X6 Gum =

= 0,000134398

F6X6Spent kaolin = 169,5252072kg/jam

X6Spent kaolin =

=0,002935267

Tabel 3. Neraca massa pada Niagara filter

No Komponen Input (kg/jam) Output (kg/jam)

F6 F8 F7

1 Trigliserida 55.438,5359 - 55.438,54

2 FFA 2014,27256 - 2.014,273

3 H2O 116,252302 - 116,2523

4 Impuritis 6,05156538 - 6,051565

5 Spent earth 1.130,68877 961,085451 169,6033

6 Gum 53,4069932 45,3959484 8,01105

Total

58.759,2081 1006,4814 57.752,73

58.759,2081 58.759,2081

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Perhitungan Neraca Massa

Nama Alat Polishing Filter Kode

Fungsi Memurnikan RBDPO F-102

Asumsi efisiensi 100% memisahkan Gum dan BE

Polishing Filter

F7

Trigliserida

FFA

H2O

I mpuritis

Gum

Spent Kaolin

F10 = ?

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

F9

Gum

Spent Kaolin

Neraca Massa Total :

F7 = F9 + F10

57754.60932 kg/jam = F9 + F10

Neraca Massa Komponen :

Trigliserida : F7X7 Trigliserida = F10X10Trigliserida

55.438,53591 kg/jam = F10X10Trigliserida

FFA : F7X7FFA = F10X10FFA

2.014,2725 kg/jam = F10X10FFA

H2O : F7X7H2O= F10X10H2O

116,2523 kg/jam = F10X10 H2O

Fospatida : F7X7 Fospatida = F10X10 Fospatida

(0,002940% x 57.608,19521) = F10X10 Fospatida

1,694129834 kg/jam = F10X10 Fospatida

Karoten : F6X6 Karoten = F7X7 Karoten

(0,003896104% x 57.608,19521) = F7X7 Karoten

1,79558011 kg/jam = F7X7 Karoten

Aldehid : F6X6 Aldehid = F7X7 Aldehid

(0,008291708% x 57.608,19521) = F7X7 Aldehid

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

4,776703499 kg/jam = F7X7 Aldehid

Gum : F7X7Gum = F9X9Gum

7,756930249 kg/jam = F8X8Gum

Spent Kaolin : F7X7Spent Kaolin= F9X9Spent kaolin

169,5252072 kg/jam = F9X9Spent kaolin

Mencari F9 dan F10

F9 = F9X9Gum + F9X9 Spent kaolin

= 7,756930249 kg/jam + 169,5252072 kg/jam

= 177,2821 kg/jam

F10 = F8 F9

= 57754,60932kg/jam 177,2821 kg/jam

= 57577,32719kg/jam

Komposisi Aliran F9 :

F9X9Gum = 7,756930249 kg/jam

X9Gum =

= 0,043755

F9X9 Spent kaolin = 169,5252072kg/jam

X9 Spent kaolin =

= 0,956245

Komposisi Aliran F10 :

F10X10 Trigliserida = 55.438,5359 kg/jam

X10 Trigliserida =

= 0,96244527

F10X10FFA = 2.014,27256 kg/jam

X10FFA =

= 0,0349838

F10X10H2O = 116,252302 kg/jam

X10H2O =

= 0,0020191

F4X4 Aldehid = 4,7767035 kg/jam

X4 Aldehid =

= 8,296 x 10

-5

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

F4X4 Karoten = 1,79558011 kg/jam

X4 Karoten =

= 3,119 x 10

-5

F4X4 Fospatida = 1,6941298 kg/jam

X4 Fospatida =

= 2,942 x 10

-5

Tabel 4. Neraca Massa pada polishing filter

No Komponen Input (kg/jam) Output (kg/jam)

F7 F9 F10

1 Trigliserida 55.438,54 - 55.438,5359

2 FFA 2.014,273 - 2.014,273

3 H2O 116,252302 - 116,2523

4 Impuritis 6,051565 - 32,6937201

5 Spent earth 169,603315 144,162 -

6 Gum 8,01104972 6,809392 -

Total

57.752,7267 150,9722 57.601,7545

57.752,7267 57.752,7267

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Perhitungan Neraca Massa

Nama Alat Deodorizer Kode

Fungsi

Memisahkan Asam Lemak Bebas menjadi

Palm Fatty Acid

T-106

Asumsi : 100% Aldehid + Psopatida Teruapkan

100% Air tersisihkan

75% ALB

Deodorizer Tank

F10

Trigliserida

FFA

H2O

I mpuritis

F14 = ?

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

F12

PFAD

I mpuritis

H2O

Neraca Massa Total :

F10 = F12 + F11

57577,32719 kg/jam = F12 + F11

Neraca Massa Komponen :

Trigliserida : F10X10 Trigliserida = F11X111 Trigliserida

55.438,53591 kg/jam = F11X141Trigliserida

FFA : F10X10FFA = F12X12FFA + 75% F11X11FFA

2.014,27256 kg/jam =F12X12 FFA + (75% x 2.014,27256)

2.014,27256 kg/jam 1510,70442 kg/jam = F12X12FFA

503,56814kg/jam = F12X12FFA

H2O : F10X10H2O= F12X12H2O + 100% F11X11H2O

116,252302 kg/jam = F12X12H2O + (100% x 116,252302)

116,252302 kg/jam 116,252302 /jam = F12X12H2O

0 kg/jam = F12X12H2O

Fospatida : F10X10 Fospatida = F12X12 Fospatida + 100%F11X11 Fospatida

(0,002940% x 57.608,19521) = F12X12 Fospatida + (100% x 1,694129834)

0 kg/jam = F12X12 Fospatida

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Karoten : F10X10 Karoten = F12X12Karoten

(0,003896104% x 57.608,19521) = F12X12 Karoten

1,79528925 kg/jam = F7X7 Karoten

Aldehid : F10X10 Aldehid = F12X12 Aldehid + 100 % F11X11 Aldehid

(0,008291708% x 57.608,19521) = F12X12 Aldehid + (100% x 4,776703499) F7X7

0 kg/jam = F12X12Aldehid

Mencari F11 dan F12

F11 = F11X11FFA + F11X11H2O + F11`X11 Posfatida+ F11`X11 Aldehid

= 1510.70442 kg/jam + 116,252302+1,694129834 +4,775703499

= 1633,427555 kg/jam

F12 = F10 F11

= 57577,32719 kg/jam - 1633,427555 kg/jam

= 55943,8996 kg/jam

Komposisi Aliran F11 :

F11X11PFAD = 1510.70442 kg/jam

X11PFAD =

= 0,924867721

F11X11H2O = 116,252302 kg/jam

X11H2O =

= 0,071170773

F11X11 Posfatida = 1,694129834 kg/jam

X11 Posfatida =

= 0,001037163

F11X11 Aldehid = 4,776703499 kg/jam

X11 Aldehid =

= 0,002924344

Komposisi Aliran F12 :

F12X12Trigliserida =55438.5359 kg/jam

X14 Trigliserida =

= 0,990966

F12X12FFA = 503.56814 kg/jam

X12FFA =

= 0,00900131

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

F12X12 Aldehid = 1,79554892 kg/jam

X12 Aldehid =

= 3,2096 x 10

-5

Tabel 5. Neraca massa pada deodorizer tank

No Komponen Input (kg/jam) Output (kg/jam)

F10 F12 F14

1 Trigliserida 55.438,53591 - 55.438,536

2 FFA 2.014,27256 - 503,56814

3 PFAD - 1.510,70442 -

4 H2O 116,252302 87,18922652 29,063076

5 Impuritis 32.69372007 24,52029006 8,17343

Total

57.601,75449 1.622,413936 55.979,341

57.601,75449 57.601,75449

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Perhitungan Neraca Massa

Nama Alat Polishing Filter Kode

Fungsi Memurnikan RBDPO F-103

Asumsi efisiensi alat 75%

Polishing Filter

F14

Trigliserida

FFA

H2O

I mpuritis

F18 = ?

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

F17

I mpuritis

Neraca Massa Total :

F16 = F17 + F18

55.943,8996 kg/jam = F17 + F18

Neraca Massa Komponen :

Trigliserida : F16X16 Trigliserida = F18X18 Trigliserida

55.438,53591kg/jam = F18X18 Trigliserida

FFA : F14X14FFA = F18X18FFA

503,56814 kg/jam = F18X18FFA

Karoten : F16X16 Karoten = F17X17 Karoten

1,795548925kg /jam = 100% F17X17impuritis + F18X18impuritis

1,795548925 kg/jam - 1,795548925 kg/jam = F18X18 impuritis

0 kg/jam = F18X18impuritis

Mencari F17 dan F18

F17 = F17X17 Karoten

= 1,795548925 kg/jam

F18 = F16 F17

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

= 55.943,8996 kg/jam 1,795548925 kg/jam

= 55.943,8996 kg/jam

Komposisi Aliran F17 :

F17X17 Karoten = 1,795548925 kg/jam

X17impuritis =

= 1,000

Komposisi Aliran F18 :

F18X18Trigliserida =55.438.5359 kg/jam

X18 Trigliserida =

= 0,9909984

F18X18FFA = 503.56814 kg/jam

X18FFA =

= 0,0090016

Tabel 6. Neraca masaa pada polishing filter

No Komponen Input (kg/jam) Output (kg/jam)

F14 F17 F18

1 Trigliserida 55438.5359 - 55438.53591

2 FFA 503.56814 - 503.56814

3 H2O 29.0630755 - 29.06307551

4 Impuritis 8.17343002 6.130073 2.043357505

Total

55979.3406 6.130073 55973.21048

55979.3406 55979.3406

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Crystalizer

F18

Trigliserida

FFA

H2O

I mpuritis

F21

Trigliserida = ?

FFA = ?

H2O = ?

I mpuritis = ?

Asumsi : Trigliserida terpisah menjadi fase olein dan stearin

Olein : 75,81%

Stearim : 24,19% (BPS, 2004)

Neraca Massa Total :

F18= F21

55.942,10402 kg/jam = F21

Neraca Massa Komponen :

Trigliserida : F18X18Trigliserida = F21X21 Trigliserida

55.438.53591 kg/jam = F21X21 Trigliserida

FFA : F8X18FFA = F21X21FFA

503.56814 kg/jam = F21X21FFA

Olein : 75,81% F18X18 Olein = F21X21Olein

42.028,7958 = F21X21Olein

Stearin : 24,19% F18X18 F18X18 Olein = F21X21Olein

1.3409,7401 F18X18 Olein = F21X21Olein

PerhitunganNeraca Massa

Nama Alat Crystalizer Kode

Fungsi

Mendinginkancampuranoleindan stearin agar

terbentukslurry

T-107

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Tabel 7. Neraca masa Crystalizer

No

Komponen

Input (kg/jam) Output (kg/jam)

F18 F21

1 Trigliserida 55.438,53591 55.438,53591

2

FFA 503,56814 503,56814

3

Impuritis 29,06307551 29,06307551

4

H2O 2,043357505 2,043357505

Total

55.973,21048 55.973,21048

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Perhitungan Neraca Massa

Nama Alat Membran Filter Kode

Fungsi

Memisahkan fraksi padat (stearin) dengan

fraksi cair (olein)

F-104

Asumsi : Konversi olein 75% dariumpancrystalizer (Yusoff, 2000)

Asumsi Kadar FFAdan H2O 0,1 % yang disesuaikandenganspesifikasiproduk (BSN,

2006)

Membran Filter

F21

Trigliserida

FFA

H2O

I mpuritis

F22

Olein = ?

FFA = ?

H2O = ?

F23

Stearin = ?

FFA = ?

H2O = ?

I mpuritis = ?

Neraca Massa Total :

F21 = F22+F23

55.942,10405 kg/jam = F22 +F23

Neraca Massa Komponen :

FFA : F21X21 FFA = 503,56814 kg/jam

Olein : 75,81% F21X21 Olein = F22X22Olein

42.028,7958 = F21X21Olein

Stearin : 24,19% F21X21Stearin = F23X23Olein

1.3409,7401 F21X21 Olein = F23X23Olein

Mencari F22 dan F23

F22 = F22X22Olein

= 42.028,7958 kg/jam

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

F23 = F21 F22

= 55.942,10405 42.028,7958 kg/jam

= 13.913,30824 kg/jam

Komposisi Aliran F22 :

F22X22Olein = 42.028,7958 kg/jam

X22Olein =

= 1,000

Komposisi Aliran F23 :

F23X23 Stearin = 13.409,7401 kg/jam

X23 Stearin =

= 0,963807

F23X23 FFA = 503,1904639 kg/jam

X23FFA

= 0,03619

Tabel 8. Neraca massa pada membrane filter

No

Komponen

Masuk (kg/jam) Keluar (kg/jam)

F21 F22 F23

1 Trigliserida 55438.53591 - -

2

FFA

503.56814 0.377676105 503.1904639

3

Impuritis

2.043357505

-

2.043357505

4

H2O

29.06307551 0.021797307 29.0412782

5

Olein -

41495.74413

-

6

Stearin - -

13942.79178

Total

55973.21048 41496.1436 14477.06688

55973.21048 55973.21048

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Neraca Massa Overall

overall

F2

F3

F6

F8

F10

F13

F15

F21

F22

CPO

Trigliserida 94%

FFA 5%

H

2

O 0.5%

I mpuritis 0.5%

H3PO4

H

3

PO

4

85%

H

2

O 15%

Bleaching Earth

Simnit 98.15%

H

2

O 1.85%

Niagara Waste

Gum 15.6%

Simnit 84.4%

Polishing 1 waste

Gum 15.6%

Simnit 84.4%

PFAD

FFA 85.53%

H

2

O 9.28%

I mpuritis 5.19%

Polishing 2 waste

I mpuritis 100%

Palm Stearin

Stearin 94.71%

FFA 4.94%

H

2

O 0.27%

I mpuritis 0.08%

Palm Olein

Olein 99.8%

FFA 0.1%

H

2

O 0.1%

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

Komponen

Masuk Keluar

F2 F3 F6 F8 F10 F13 F15 F21 F22

kg/jam kg/jam kg/jam kg/jam kg/jam kg/jam kg/jam kg/jam kg/jam

Trigliserida 54737.6122 - - - - - - - -

FFA 2911.5751 - - - - 2183.6813 - 686.2271 41.6667

Impuritis 291.1575 - - - - 132.4417 33.1104 11.0368 -

H2O 291.1575 8.7347 16.1592 - - 237.0386 - 37.3462 41.6667

H3PO4 - 49.4968 - - - - - - -

Olein - - - - - - - - 41583.33338

Stearin - - - - - - - 13154.2788 -

Gum - - - 138.5910 20.7886 - - - -

Simnit - - 857.3133 749.5643 112.4347 - - - -

Jumlah 58231.5023 58.2315 873.4725 888.1553 133.2233 2553.1617 33.1104 13888.8889 41666.6667

Total 59163.2063 59163.2063

Pra-Rancangan Pabrik RBD Palm Olein Kelompok 7/S. Ganjil/2014-2015

By Checked Approved

Adi Maulana Putra

Jatikta Yuni Harti

Wyda N Saragi

Muhammad Rahman

DAFTAR PUSTAKA

Badan Standarisasi Nasional (BSN), 2006, Standar Mutu Minyak Kelapa Sawit

Mentah, BSN, Jakarta

Badan Standarisasi Nasional (BSN), 2006, Standar Mutu Minyak Goreng, BSN,

Jakarta

Gunstone, F.D.,1987, Palm Oil, John Wiley and Sons, Inc, New York.

NasutionEZ Manfaat Beberapa Bleaching Earth Terhadap Warna CPO

Jurnal Sains Kimia, Vol.7, No.2, 2003: 31-35.

Yusoff, M. S. A., 2000. Refining and Modification of Palm and Palm Kernel Oil,

didalam : Basiron, Yusof., B. S, Jailani., K. W, Chan, Advances in Oil Palm

Research Vol II, Malaysian Palm Oil Board Ministry of Primary Industries,

Malaysia

Potrebbero piacerti anche

- Lampiran OverallDocumento2 pagineLampiran OverallAbdul RasyidNessuna valutazione finora

- Crusher: Lembar Perhitungan Neraca Massa Dan Neraca Energi Nama Alat Kode Alat FungsiDocumento20 pagineCrusher: Lembar Perhitungan Neraca Massa Dan Neraca Energi Nama Alat Kode Alat FungsiFernando SihotangNessuna valutazione finora

- Ak Uuuuuu Uuuuuuu UuuuuuuDocumento17 pagineAk Uuuuuu Uuuuuuu UuuuuuuNila Sari SiregarNessuna valutazione finora

- Material BalanceDocumento47 pagineMaterial BalancewaqaskhanNessuna valutazione finora

- Appendix Static Mixer PDFDocumento165 pagineAppendix Static Mixer PDFNaldi SinagaNessuna valutazione finora

- Appendix A Perhitungan Neraca MassaDocumento27 pagineAppendix A Perhitungan Neraca MassariyantimalinaNessuna valutazione finora

- Article Febri Yuliani Et Al Published 2018Documento133 pagineArticle Febri Yuliani Et Al Published 2018Mardhyana AlbanjariNessuna valutazione finora

- Data Perhitungan RevisiDocumento2 pagineData Perhitungan RevisiKelvin WijayaNessuna valutazione finora

- Desain RatbDocumento211 pagineDesain RatbAzzis Dwi HertantoNessuna valutazione finora

- 123b.pharmacy Project SD of Glimepiride 121212Documento19 pagine123b.pharmacy Project SD of Glimepiride 121212manvitha varmaNessuna valutazione finora

- Bab Iv Hasil Dan Pembasahan: Cynodon DactyllonDocumento1 paginaBab Iv Hasil Dan Pembasahan: Cynodon DactyllonDeni DarmawanNessuna valutazione finora

- Purchase NoteDocumento7 paginePurchase Notesabar purNessuna valutazione finora

- Tabla 1Documento723 pagineTabla 1Jose Rivera RamirezNessuna valutazione finora

- Experiment 3 Determination of Fatty Acid Using Gas Chromatography (GC)Documento7 pagineExperiment 3 Determination of Fatty Acid Using Gas Chromatography (GC)NUR IZZATI OTHMAN BASRI100% (1)

- Stream Report Mini DPDocumento8 pagineStream Report Mini DPfaraaaalyaNessuna valutazione finora

- Maintenance Chart and PriceDocumento21 pagineMaintenance Chart and PriceDibas BaniyaNessuna valutazione finora

- Fluonptfe EngDocumento6 pagineFluonptfe Eng2742481Nessuna valutazione finora

- Batch Card Mar-12Documento1.323 pagineBatch Card Mar-12AjitKumarJhaNessuna valutazione finora

- Bab Iii Neraca Massa: CrusherDocumento5 pagineBab Iii Neraca Massa: Crushermaya srNessuna valutazione finora

- AIGA 029 - 10 CP Nitrogen Trifluoride - Reformated Jan 12Documento29 pagineAIGA 029 - 10 CP Nitrogen Trifluoride - Reformated Jan 12Ivonn OchoaNessuna valutazione finora

- (Done) Appendix A Neraca MassaDocumento21 pagine(Done) Appendix A Neraca MassaJefry NovenantoNessuna valutazione finora

- NM CobaDocumento10 pagineNM CobaLuthfi Ma'arifNessuna valutazione finora

- NM CobaDocumento25 pagineNM CobaLuthfi Ma'arifNessuna valutazione finora

- Crude Assay AnalysisDocumento34 pagineCrude Assay Analysismeenaneer007100% (3)

- Thai Guava Thai Guava: ZL CZL Cml8"S (RZ G "ZLDocumento12 pagineThai Guava Thai Guava: ZL CZL Cml8"S (RZ G "ZLAbhu VasaniNessuna valutazione finora

- CHEMFISH Fluorinated CompoundsDocumento11 pagineCHEMFISH Fluorinated Compoundssunny StevenNessuna valutazione finora

- Lampiran 3 GPMDocumento6 pagineLampiran 3 GPMEka trisnawatiNessuna valutazione finora

- P5370JL - FASTlab FLT Cassettes (5 Pack)Documento2 pagineP5370JL - FASTlab FLT Cassettes (5 Pack)nadirerutNessuna valutazione finora

- Date of Production: 18.06.2013: If Out Put Comes More Than Standard We Are Considering The Performance As 100%Documento6 pagineDate of Production: 18.06.2013: If Out Put Comes More Than Standard We Are Considering The Performance As 100%Prasanna GopalrathinamNessuna valutazione finora

- PFD UP VI BalonganDocumento70 paginePFD UP VI BalonganNadia Shofiana100% (1)

- XHUN Deom 7Documento22 pagineXHUN Deom 7FagioloNessuna valutazione finora

- Ejlt 201300502 PDFDocumento10 pagineEjlt 201300502 PDFSrđan TufegdžićNessuna valutazione finora

- Resultados Gladidadores Off Road - Tercera Valida 2021 - GirardotDocumento33 pagineResultados Gladidadores Off Road - Tercera Valida 2021 - GirardotLorena Mora AriasNessuna valutazione finora

- Bomba de EngranagesDocumento0 pagineBomba de EngranagesPablo OrtegaNessuna valutazione finora

- Unit 042 CCR Presentation Very GoodDocumento29 pagineUnit 042 CCR Presentation Very GoodNguyễn Ngọc Tưởng100% (1)

- Salinan Salinan MasterDocumento45 pagineSalinan Salinan MasterHafidz ChannelNessuna valutazione finora

- FFB Crop ForecastDocumento6 pagineFFB Crop ForecastAmeen ZennNessuna valutazione finora

- Voltage Drop of Lighting System-Futaba VN Phase-3 ProjectDocumento2 pagineVoltage Drop of Lighting System-Futaba VN Phase-3 ProjectThai VoNessuna valutazione finora

- Formulation and Evaluation of Sustained Release Metoprolol Succinate Tablet Using Hydrophilic Gums As Release ModifiersDocumento5 pagineFormulation and Evaluation of Sustained Release Metoprolol Succinate Tablet Using Hydrophilic Gums As Release ModifiersAryanto DedyNessuna valutazione finora

- Proton Saga Service GuideDocumento8 pagineProton Saga Service GuideErin Lam100% (1)

- 3 - Shortenings - Science and TechnologyDocumento41 pagine3 - Shortenings - Science and TechnologyJulesNessuna valutazione finora

- Group Prject: Teknik Produksi Ii STT Migas Balikpapan 2014Documento15 pagineGroup Prject: Teknik Produksi Ii STT Migas Balikpapan 2014Rasya RefanNessuna valutazione finora

- Group Prject: Teknik Produksi Ii STT Migas Balikpapan 2014Documento15 pagineGroup Prject: Teknik Produksi Ii STT Migas Balikpapan 2014Rasya RefanNessuna valutazione finora

- Chapter 4 - OutlineDocumento10 pagineChapter 4 - OutlineJoshua Emmanuel PagulongNessuna valutazione finora

- Format Import Nilai Keterampilan Kelas Kelas 7.1Documento5 pagineFormat Import Nilai Keterampilan Kelas Kelas 7.1Ari RahmadNessuna valutazione finora

- Vogele Supper 1800-2Documento2 pagineVogele Supper 1800-2Gayashan Kulathunga100% (3)

- Al Shaheen AssayDocumento23 pagineAl Shaheen Assaydassi99Nessuna valutazione finora

- IFFCO Kalol Internship ReportDocumento67 pagineIFFCO Kalol Internship ReportSiddhant Dhiman50% (2)

- Hqfa 513 K 2 Lo 70709560 ECPPTDocumento119 pagineHqfa 513 K 2 Lo 70709560 ECPPTHenna KadyanNessuna valutazione finora

- MAxiFors Hydraulic - KitsDocumento13 pagineMAxiFors Hydraulic - KitsokovalskiNessuna valutazione finora

- Lampiran A Asam TerepthalatDocumento32 pagineLampiran A Asam TerepthalatAbay Hanzo KunNessuna valutazione finora

- Tashtego SolutionDocumento8 pagineTashtego Solutionsathyanl90Nessuna valutazione finora

- Jadual Waktu Jan 2021Documento2 pagineJadual Waktu Jan 2021Asyraf FikriNessuna valutazione finora

- QPA - LTSA BOG Compressors-Budgetary Proposal To PertaminaDocumento8 pagineQPA - LTSA BOG Compressors-Budgetary Proposal To PertaminadikaNessuna valutazione finora

- Cumene To PhenolDocumento73 pagineCumene To Phenolvpsrpuch67% (3)

- Iv. Neraca Massa Dan Neraca Energi: Neraca Massa 1. Neraca Massa Komponen Tiap Alat 1. Digester 201 A/E (D-201 A/E)Documento8 pagineIv. Neraca Massa Dan Neraca Energi: Neraca Massa 1. Neraca Massa Komponen Tiap Alat 1. Digester 201 A/E (D-201 A/E)Asuna ToukaNessuna valutazione finora

- Olympian Generator Set Engine FiltersDocumento6 pagineOlympian Generator Set Engine FiltersJavier Méndez100% (1)

- Fine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlDa EverandFine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlNessuna valutazione finora

- Lawsuit!: Reducing the Risk of Product Liability for ManufacturersDa EverandLawsuit!: Reducing the Risk of Product Liability for ManufacturersNessuna valutazione finora

- Hydrogen and Syngas Production and Purification TechnologiesDa EverandHydrogen and Syngas Production and Purification TechnologiesNessuna valutazione finora

- Alkali Actived Fly Ash Based Geopolimer Concrete Ammar MotorlawaDocumento8 pagineAlkali Actived Fly Ash Based Geopolimer Concrete Ammar MotorlawaWyda Novayanti SaragiNessuna valutazione finora

- Niagara Filter BaruDocumento4 pagineNiagara Filter BaruWyda Novayanti Saragi100% (1)

- Lampiran BDocumento11 pagineLampiran BWyda Novayanti SaragiNessuna valutazione finora

- 3 VIVIDocumento4 pagine3 VIVIWyda Novayanti SaragiNessuna valutazione finora

- Kaver Rita BBBBDocumento3 pagineKaver Rita BBBBWyda Novayanti SaragiNessuna valutazione finora

- Neraca Energy Niii FixDocumento35 pagineNeraca Energy Niii FixWyda Novayanti SaragiNessuna valutazione finora

- Lampiran B HT ExcelDocumento15 pagineLampiran B HT ExcelWyda Novayanti SaragiNessuna valutazione finora