Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Guide For ORB PDF

Caricato da

Udana Hettiarachchi100%(4)Il 100% ha trovato utile questo documento (4 voti)

595 visualizzazioni29 pagineTank cleaning operations are now only done occasionally prior drydock or for voyage repairs. This has caused some errors to be made with respect to the code used for various operations or for missing out entry for some operations. This guide would assist in making Correct Entries in the ORB for CARGO AND BALLAST OPERATIONS in tankers.

Descrizione originale:

Titolo originale

Guide for ORB.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoTank cleaning operations are now only done occasionally prior drydock or for voyage repairs. This has caused some errors to be made with respect to the code used for various operations or for missing out entry for some operations. This guide would assist in making Correct Entries in the ORB for CARGO AND BALLAST OPERATIONS in tankers.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(4)Il 100% ha trovato utile questo documento (4 voti)

595 visualizzazioni29 pagineGuide For ORB PDF

Caricato da

Udana HettiarachchiTank cleaning operations are now only done occasionally prior drydock or for voyage repairs. This has caused some errors to be made with respect to the code used for various operations or for missing out entry for some operations. This guide would assist in making Correct Entries in the ORB for CARGO AND BALLAST OPERATIONS in tankers.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 29

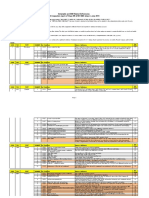

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 1 of 29

GUIDE FOR CORRECT ENTRIES IN

THE ORB PART II CARGO AND

BALLAST OPERATIONS

(FOR TANKERS)

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 2 of 29

FOREWARD

With the advent of Double Hull and SBT tankers, tank cleaning operations are now only

done occasionally prior drydock or for voyage repairs.

This has now resulted in vessels making entries for these operations occasionally. It

has also caused some errors to be made with respect to the code used for various

operations or for missing out entry for some operations which are later pointed out by

Vetting / PSC Inspectors during their Inspection of the Oil Record Book.

The guide to entries for machinery operations is covered in Intertanko Publication

Guide for correct entries in the ORB (part I machinery operations) and this guide

serves a similar purpose for cargo & ballast operations in tankers.

Following are some of the errors which have been pointed out by vetting Inspectors:

1) Vessel carried out washing of cargo tanks for voyage repairs. However, the

filling of ballast in Slop tanks was not entered under E i.e. ballasting of cargo

tank. There were no records in the ORB for filling of water in slop tanks.

2) Vessel reached repairs berth with slops. There was only one entry for

discharge of slop quantity under J Disposal of oil mixture not otherwise dealt

with. The washing of Slop tank was not shown under G and the entire quantity

of wash water and the original slop quantity were shown under J.

3) The transfer of slop from one slop to another was shown under O , additional

remarks while the correct entries would be under J

4) The transfer of Oily water from engine room recorded under J while the

correct entries would be under O.

This guide would assist in making correct entries. The guide is based on operation of a

convention tanker. Tankers with submersible pumps and a separate tank cleaning pump

to adjust their entries for this change. The flow of operations would remain the same

with only differences in the entries.

Responsible officer refers to Chief Officer who makes the entries in the ORB for

Ballast and Cargo Operations.

IMPORTANT NOTES

NOTE: ALL CARGO TANKS IN WHICH BALLAST WATER IS TO BE TAKEN

MUST BE CRUDE OIL WASHED AS PER MARPOL.

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 3 of 29

DIRTY

BALLAST

BALLAST TAKEN IN CARGO TANKS THAT HAVE NOT BEEN

WATER WASHED. (Eg: Heavy Wx Ballast or Ballast taken in

discharge port for Air draft Clearance).

CLEAN

BALLAST

BALLAST TAKEN IN CARGO TANKS THAT HAVE BEEN

WATER WASHED AND INSPECTED / CLEANED(if required).

(Eg: For Cargo tank Inspection by Rafting).

Tank Cleaning :

Tanks can be cleaned by machine washing, hand washing or chemical washing. The

method used must be stated under G 30. (Method of cleaning) in ORB. If chemicals are

used, the chemical used and amount should also be stated. Normally, machine washing is

carried out by vessels. Machines can be either Portable or Fixed washing machines.

Normally fixed washing machines would be used with tanks in inerted condition.

Portable Washing Machines

Normally, these are non programmable machines which are used for local cleaning of

the shadow sector of fixed washing machines.

Fixed Washing Machines

There are two types of Machines. Machines that can be programmed and wash cycles

would be as per the program set. The Non Programmable machines carry out all round

washing and cannot be set to wash a particular arc or angle.

With programmable machines, Multi stage washing can be done i.e. top wash and then

bottom wash separately or only bottom wash.

When washing with Programmable washing machine and carrying out multi stage or

bottom wash, the code in D13 (washing pattern) should state the arc that is covered

and the number of times that the arc is covered. Example: 120-0-40-0-40.

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 4 of 29

INDEX

Section 1 ORB entries for regular Operations

Section 2 ORB entries for Drydock

Section 3 ORB Entries for Dirty ballast

Section 4 ORB entries for ODMCE

Section 5 ORB entries for Transfer from Engine room

Section 6 Appendix

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 5 of 29

S

S

E

E

C

C

T

T

I

I

O

O

N

N

1

1

O

O

R

R

B

B

E

E

n

n

t

t

r

r

i

i

e

e

s

s

f

f

o

o

r

r

R

R

e

e

g

g

u

u

l

l

a

a

r

r

O

O

p

p

e

e

r

r

a

a

t

t

i

i

o

o

n

n

s

s

Loading, Cargo transfer during Loading, Cargo transfer during

voyage, COW , Discharging voyage, COW , Discharging

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 6 of 29

1.1 Loading Cargo

Date

Code

(letter)

Item

(number)

Record of operations/ signature of officer in

charge

11.11.07 A 1 Kharg Island

2 Iranian Light, 1C,2C,3C,4C,5C, 6C & Slop P

3 161,300 M3

Signature of Officer

A 1 Kharg Island

2 Iranian Heavy, 1C,3W,5W & Slop S

3 160,600 M3

Signature of Officer

1.2 Internal Transfer of Cargo

Date

Code

(letter)

Item

(number)

Record of operations/ signature of officer in

charge

15.11.07 B 4.1 From 1C

4.2 To 6C ( Transferred 160 M3).

Final quantities :

6C 15855 M3

5 NO, 1C not emptied. 1 C 12200 M3

Signature of Officer

Note : Enter Grades separately

Note : Please check with commercial operators prior transfer

and obtain approval from Owners / Commercial operators

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 7 of 29

1.2.2 Internal Transfer of Cargo / Alternate

(Used by VLCC in time interval between

lightering)

Date

Code

(letter)

Item

(number)

Record of operations/ signature of officer in

charge

15.11.07 B 4.1 From 3C

4.2 To 6C ( Transferred 161 M3).

Final quantities :

6C 5200 M3

5 NO, 1C not emptied, 1 C 5 M3

Signature of Officer

15.11.07 B 4.1 From 3C

4.2 To Slop S ( Transferred 5 M3).

Final quantities : Slop S 2955 M3

5 Yes, 3C Nil.

Signature of Officer

Note : Please check with commercial operators prior transfer

and obtain approval from Owners / Commercial operators

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 8 of 29

1.3 Crude Oil Washing at Discharge Port

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

16.11.07 D 9 Sriracha

10 1C 6C 3C

11 3 4 4

12 0105 LT 0145 LT 0300 LT

13 40-0-40 40-0-40 40-0-40

14 10 Kg/cm2 10 Kg/cm2 10 Kg/cm2

15 0140 LT 0215 LT 0335 LT

16 MANUAL DIP OR MANUAL SOUNDING

17 NIL

Signature of Officer

2.1 Ballasting of Cargo Tanks

Additional Notes: Vertical arc to be mentioned only for Multi stage

washing. For Non programmable machines, enter Single stage(non

programmable) at D13.

Note : 1. To be completed for each tank, code for each tank mentioned

seperately or in tabulated coloumns for set of tanks as above

2. Ships position to be entered for D 9 if COW being done between

discharge ports

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 9 of 29

1.4 Unloading Oil cargo : One Port Discharge

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

16.11.06 C 6 Meizhou, China

7 1C,2C,3C,4C,5C,6C,1W,3W,5W,7W,

Slop (P) & Slop (S)

8 Yes. ROB : 6 M3

Signature of Officer

1.5 Unloading Oil cargo : Two Port Discharge of one

Grade with Part discharge at 1

st

Port

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

16.11.06 C 6 Rotterdam

7 1C,2C,3C,4C,5C,6C

8 No, Quantity retained are

1C 5200 M3, 2C 5930 M3,

3C 5558 M3, 4C 4282 M3

5C 6611 M3, 6C 4998 M3

Signature of Officer

Note : 1. Mentioning of ROB is not required, only recommended.

Note : If two port discharge of different grade, enter as previous for

each port and show relevant tank empty for each port.(Assuming full

discharge of each grade at the each port for the 2 grades).

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 10 of 29

S

S

e

e

c

c

t

t

i

i

o

o

n

n

2

2

O

O

R

R

B

B

E

E

n

n

t

t

r

r

i

i

e

e

s

s

f

f

o

o

r

r

D

D

r

r

y

y

d

d

o

o

c

c

k

k

B

B

a

a

l

l

l

l

a

a

s

s

t

t

i

i

n

n

g

g

s

s

l

l

o

o

p

p

s

s

,

,

W

W

a

a

t

t

e

e

r

r

w

w

a

a

s

s

h

h

i

i

n

n

g

g

,

,

C

C

l

l

e

e

a

a

n

n

b

b

a

a

l

l

l

l

a

a

s

s

t

t

,

,

D

D

i

i

s

s

p

p

o

o

s

s

a

a

l

l

o

o

f

f

r

r

e

e

s

s

i

i

d

d

u

u

e

e

,

,

All tanks to be Crude Oil

Washed at last discharge port

Prior proceeding for

Drydock

Ensure all fixed tank washing machines and wash water heater

(where filled) are is good operational condition

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 11 of 29

IMPROTANT NOTES

Operation Type 1 :

Vessels proceeding for dry-dock or lay up repairs with CAP / CAS

surveys would normally have to take clean ballast for inspection of

cargo tanks by rafting and all entries in section 2 would be

applicable.

Operation Type 2 :

Vessels proceeding for dry-dock or lay up repairs without CAP / CAS

surveys would normally not have to take clean ballast. In this case,

Section 2.3 -2.5 would not be applicable (taking clean ballast,

transfer and discharge of clean ballast.)

Operation Type 3 :

Vessels carrying out voyage repairs would not require sec 2.3 -2.5

and entry in 2.9 would be restricted to J. There would be no entry

under G as slop tanks would not be washed. Section 2.10 would also

not be applicable.

For any other operations not covered by above, please use as

applicable.

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 12 of 29

2.1 Ballasting of Cargo Tanks

DATE CODE

(LETTER)

ITEM

(NUMBER)

RECORD OF OPERATIONS/ SIGNATURE OF

OFFICER IN CHARGE

16.11.06 E 18 Start : 04 31 N 104 15 E; Stop : 23 27 N 118

21 E

19.1 Slop P & Slop S

19.2 Start : 0330 LT, Stop : 0700 LT

19.3 Slop (P) : 852 M3 ;

19.3 Slop (S) : 748 M3

Signature of Officer

Note : Example above is ballasting of slop tank for wash water for

carrying out water washing. Indicate total Quantity of ballast for

each tank involved in the operation.

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 13 of 29

2.2 Water washing of Cargo Tanks

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

16.11.06 G 27 1C, 1P, 1S,2C

To 28 At sea, Start 10 21 N 081 45 E

17.11.06 28 Stop 10 11 N 081 37 E

29 1C 06 H 10 M, 1P 05 H 32 M

29 1S 05 H 42 M , 2C 06H 12 M

30 Tank washing machine

31.2 Slop P & Slop S, Transferred to slop (P) -

31.2 217 M3, Transferred to slop (S) 200 M3

31.2 Total Qty Slop(P): 1217 M3, Slop(S): 1276 M3

Signature of Officer

Note :There is no requirement to show individual tank start and stop time in ORB

However, correct records to be maintained in cargo log

For 31.2, enter total qty transferred to slops and also show total qty.

For this, ullage and interface to be checked prior and after washing.

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 14 of 29

2.3 Ballasting of Cargo Tanks (for Rafting or any other

purpose i.e. clean ballast)

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

18.11.06 E 18 Start : 04 31 N 104 15 E; Stop : 23 27 N 118

21 E

19.1 1P,1S,1C & 2C

19.2 Start : 0700 LT, Stop : 1800 LT

19.3 1C 5153 M3, 2C : 5153 M3,

1P 3291 M3, 1S : 3190 M3

Signature of Officer

2.4 Transfer of clean ballast in Cargo Tank

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

19.11.06 O Transferred 3291 M3 from 1P and 3190 M3

from 1S

1 P & 1S to 1C and 2C for rafting.

Final qty of ballast in 1C 8444 M3 &

2C 8343 M3

Signature of Officer

2.5 Discharge of clean ballast in Cargo Tank

Note : Ballasting of cargo tanks should be shown as for ballasting of slop tanks.

This is clean ballast as tanks have been water washed prior filling

ballast in the cargo tank.

Note : Transfer of clean ballast not to be entred in B which is only for oil cargo

Write the quanitity of ballast water transferred from each tank

and the final quanitity remaining in each tank from which transfer

carried out and the tank to which ballast has been transferred.

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 15 of 29

2.5 Discharge of clean Ballast with final quantity to

Slop from cargo tank

2.5.1 Discharge of clean Ballast with final quantity to Slop from cargo tank.

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

21.11.06 K 58 Start : 11 26.1 N 070 19.0 E

59 1C & 2C

60 No. remaining in 1C 150 M3, 2C 188 M3

61 Stop : 11 54.2 n 070 18.5 E

62 Yes

Signature of Officer

O - Transferred 150 M3 from 1C and 188 M3

From 2C to Slop (P) and Slop (S).

1C and 2C empty. Quantity in slop (P) : 1377 M3

And slop (S) : 1454 M3

Signature of Officer

2.5.2 Discharge of all Clean ballast to sea.

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

21.11.06 K 58 Fujairah

59 1C & 2C

60 Yes

62 Yes

Signature of Officer

Note: Check the surface of ballast (similar to segregated ballast) prior pumping

out. No sheen or oil should be visible on the surface.

Note : MARPOL allows complete discharge of clean ballast to sea.

However, vessel may strip final quantity in Clean ballast tanks

to slop tank and not overborad if vessel still has slop.

If clean ballast in tank after docking with no slop on board,

clean ballast can be pumped completly overboard and O not required

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 16 of 29

2.6 Decanting of Slop Tanks (First Decant)

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

21.11.06 I 41 Slop (P) & Slop (S)

42 36 Hrs 25 Minutes

44 Start 1045 LT, 17 Deg 10.0 N 117 Deg 30.8 E

45 Slop(P) 9.30 M, Slop (S) 9.41 M

46 Slop(P) 9.40 M, Slop(S) 9.85 M

47 1030 M3, Rate : 200 M3

48 1154 M3, Rate : 80 M3

49 Stop 1740 LT, 18 Deg 44.0 N 116 Deg 27.4 E

50 Yes

51 Slop (P) 12.74 M3, Slop(S) 18.60 M3

52 12.5 Kts

53 Yes

54 Yes

Signature of Officer

NOTE: HEATING OF SLOP TANK CONTENTS ENHANCES OIL - WATER SEPARATION.

Note : Any failure of the Oil Discharging monitoring and control system shall stop the

discharge. In the event of failure of the Oil discharging and control system, a

manually operated alternative method may be used, but the defective unit shall be

made operable as soon as possible.

Subject to allowance by the Port State authority, a tanker with defective ODMCE

may undertake one ballast voyage prior proceeding to a repair port

Note :

Slops to be decanted only during daytime ( Wallem Requirement)

Slops to be decanted only with stripping pump(Wallem Requirement)

Note : Enter either 42 (time since last entry of residue) or 43 (time since

last discharge) as applicable.

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 17 of 29

2.7 Decanting of slops Transfer from One slop to

another and consolidate in one slop tank

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

21.11.06 J 55 Slop (S)

56 350 M3, retained Nil

57.3 Transferred to slop (P)

Transferred 350 M3,

Total qty in slop (P) : 1438 M3.

Signature of Officer

Note : Quantity transferred from one slop to another

to be entered under J.

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 18 of 29

2.8 Decanting of Slop Tanks (Final Decant)

Important : All Notes mentioned in 2.6 would also apply for final decant.

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

21.11.06 I 41 Slop (P)

42 24 Hrs 30 Minutes

44 Start 1045 LT, 17 Deg 10.0 N 117 Deg 30.8 E

45 3.74 M

46 4.55 M

47 1030 M3, Rate : 200 M3

48 1154 M3, Rate : 120 M3

49 Stop 1715 LT, 18 Deg 44.0 N 116 Deg 27.4 E

50 Yes

51 17.17 - Interface

52 12.5 Kts

53 Yes

54 Yes

Signature of Officer

Note : If vessel has insufficient time to carry out first decant, then

transfer from one slop to another and then final decant, vessel can decant

from both slops. Oily mixture can then be discharged from both slops at

repair berth and then the Slops washed.

In this case, 2.7 & 2.8 would not be applicable. Entires would be for two

tanks and not for one tank but only would only be as shown in 2.6.

Note: Slops to be decanted only during daytime (Wallem Requirement)

Slops to be decanted only with stripping pump (Wallem requirement)

Decanting only done under direct supervision by chief officer

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 19 of 29

2.9 Discharging and washing of slops

Discharging to Barge / shore reception of Oily mixture in slops shown

under J. Subsequently, if the tank is washed, the washing is to be shown under

G as below.

If vessel has finished voyage repairs in a few other tanks and only needs

to discharge slops to shore reception/ slop barge, then only entry under J would

be required.

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

21.11.06 J 55 Slop (P)

56 Discharged 376 M3, Retained Nil

57.1 Slop Barge Affinity @Singapore

Certificate attached for 376 M3

Signature of Officer

G 27 Slop (P)

28 Singapore Anchorage

29 2Hrs 10 Minutes

30 Machine Washing

31.1 Slop Barge affinity @ Singapore

31.1 Transferred 174 M3 of wash water.

Signature of Officer

Note: Transfer of remains in slop (P) and then washing to be shown separately as

above.

Total Quantity is to be equivalent to Quantity in slop certificate. In case

when the barge/shore quantity is different, the slop certificate is to be

endorsed with the ships quantity (small difference that may arise due to

nature of measurement.

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 20 of 29

2.10 Discharge of Sludge to Shore Reception / Sludge

Barge

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

21.11.06 J 55 1C,2C,3C,4C,5C, Slop (P) & Slop(S)

56 Total amount 240 MT sludge landed

56 1C 30 M3, 2C 32 M3, 3C 55 M3

4C- 62 M3, 5C 31 M3, Slop (P) 22 M3

Slop (S) 18 M3

57.1 Keppel shipyard, Singapore

Signature of Officer

Note : Sludge qty to be shown for individual tanks as well as total quantity

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 21 of 29

SECTION 3

ORB Entries : Ballasting

and discharge of dirty

ballast

SECTION 3

SECTION 3

ORB Entries : Ballasting

ORB Entries : Ballasting

and discharge of dirty

and discharge of dirty

ballast

ballast

Tanks not required to be water washed for taking heavy Tanks not required to be water washed for taking heavy Wx Wx

ballast or water for air draft restrictions in discharge port. ballast or water for air draft restrictions in discharge port.

However, tank should have been crude oil washed However, tank should have been crude oil washed

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 22 of 29

3.1 Ballasting of cargo tanks for taking Dirty Ballast

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

16.11.06 E 18 Start : 04 31 N 104 15 E; Stop : 23 27 N 118

21 E

19.1 4C

19.2 Start : 0330 LT, Stop : 1500 LT

19.3 4C : 14520 M3

Signature of Officer

Note : The Code for taking dirty ballast or clean ballast is the same.

However, discharge ballast to be discharged under code H while

discharge of Clean ballast contained in cargo tank to be entered

under Code K

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 23 of 29

3.2 Discharge of Dirty Ballast

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

16.11.06 H 32 4C

33 Start : 26 Deg 22.0 N, 121 Deg 30.5E

34 Stop : 27 Deg 25.4 N, 122 Deg 33.8E

35 14020 M3

36 12.5 Kts

37 Yes

38 Yes

39 470 M3, slop (S), Total Slop(S) : 470 M3

40 N/A

Signature of Officer

Note : H35 refers to quantity that has been pumped to sea.

The final content to be transferred to slop and entered under 39 or

disposed to shore reception under code 40(identify port & quantity)

Note : Any failure of the Oil Discharging monitoring and control system shall stop the

discharge. In the event of failure of the Oil discharging and control system, a

manually operated alternative method may be used, but the defective unit shall be

made operable as soon as possible. Subject to allowance by the Port State authority,

a tanker with defective ODMCE may undertake one ballast voyage prior proceeding to

a repair port

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 24 of 29

S

S

E

E

C

C

T

T

I

I

O

O

N

N

4

4

O

O

R

R

B

B

E

E

n

n

t

t

r

r

i

i

e

e

s

s

:

:

O

O

D

D

M

M

C

C

E

E

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 25 of 29

4.1 Entries for ODMCE Failure

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

16.11.06 M 70 1000 LT

72 Low Flow alarm and failure of sampling

Signature of Officer

4.2 Entry when ODMCE Operational after Failure

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

17.11.06 M 71 1000 LT

Signature of Officer

Note : If vessel has failure of ODMCE prior or during Decant of slop or discharge of

Dirty Ballast, the entry under 4.1 to be made prior entry on decanting of slop or

discharge of dirty ballast.

Note : The repair report on ODMCE by shore service technician to be clipped to the page

where entry as per 4.2.

This is especially important when the ODMCE has failed prior or during decant so

s to show PSC/ vetting inspectors that Unit is fully operational again

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 26 of 29

S

S

E

E

C

C

T

T

I

I

O

O

N

N

5

5

O

O

R

R

B

B

E

E

n

n

t

t

r

r

i

i

e

e

s

s

:

:

T

T

r

r

a

a

n

n

s

s

f

f

e

e

r

r

o

o

f

f

O

O

i

i

l

l

y

y

W

W

a

a

t

t

e

e

r

r

f

f

r

r

o

o

m

m

E

E

n

n

g

g

i

i

n

n

e

e

R

R

o

o

o

o

m

m

T

T

r

r

a

a

n

n

s

s

f

f

e

e

r

r

c

c

a

a

n

n

o

o

n

n

l

l

y

y

d

d

o

o

n

n

e

e

i

i

f

f

t

t

h

h

i

i

s

s

m

m

e

e

t

t

h

h

o

o

d

d

o

o

f

f

d

d

i

i

s

s

p

p

o

o

s

s

a

a

l

l

i

i

s

s

a

a

l

l

l

l

o

o

w

w

e

e

d

d

i

i

n

n

F

F

o

o

r

r

m

m

B

B

o

o

f

f

t

t

h

h

e

e

I

I

O

O

P

P

P

P

C

C

e

e

r

r

t

t

i

i

f

f

i

i

c

c

a

a

t

t

e

e

.

.

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 27 of 29

5.1 Entry for transfer of Oily water from engine

room

Date

Code

(letter)

Item

(number)

Record of Operations/ Signature of officer in

charge

16.11.06 O Transferred 5 M3 of Oily water

from engine room to slop Tank (P).

Signature of Officer

Note : Oily water can only be transferred if the transfer piping is

approved by Class and is included in Form B of the IOPP

Certificate.

Individual Owners may have a requirement that vessel to obtain

prior approval form Commercial operators/Owners prior transfer

and this is to be complied with.

Transfer not to be done during loaded passage to avoid possible

contamination claims for the cargo on board.

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 28 of 29

S

S

E

E

C

C

T

T

I

I

O

O

N

N

6

6

A

A

p

p

p

p

e

e

n

n

d

d

i

i

x

x

WALLEM A Guide for Correct Entries in the ORB (Part II

Cargo & Ballast Operation(Tankers))

WSM SMS CD PUBLICATION 1 20

th

May 2008

Page 29 of 29

6.1 Dirty and Clean Ballast : Differences

Dirty Ballast Clean Ballast

Cargo tanks needs to be only Crude

oil washed

Crude oil washing and Water washing to

be done prior taking clean ballast. Local

cleaning may also be required to ensure

water is clean and can be pumped out even

in Port or for personnel to carry out tank

structure inspection by rafting.

Cargo Lines and Pumps need not be

flushed for taking dirty ballast in

cargo tank

Applicable cargo Pumps and lines to be

thoroughly flushed prior taking clean

ballast in cargo tanks

Dirty Ballast discharge to be done

only through ODMCE and with

regular check on effluent

Clean ballast discharge does not require

ODMCE to be running. However, it is

highly recommended that the ODMCE is

running while discharging clean ballast. In

any case, regular check to be kept on the

effluent and the surface of water in the

locality of the discharge

The final oily water mixture should

be transferred to slops or

discharged to shore reception

facility

Entire quantity can be discharged to sea.

However, it is recommended that final

quantity be transferred to slops

6.2 Author

AUTHOR Capt.S.Rajagopal

Marine Superintendent

Safety and Insurance Department

Wallem Ship Management, Hong Kong.

CHECKED & Director,

APPROVED Safety & Insurance Department.

Potrebbero piacerti anche

- 2-OrB-I Guidelines Rev 8Documento21 pagine2-OrB-I Guidelines Rev 8Analyn O. Aurel100% (2)

- Detainable and ISM Related Deficiencies PSC Inspection Report of Class NK & NK-SMC Ships in June 2015Documento9 pagineDetainable and ISM Related Deficiencies PSC Inspection Report of Class NK & NK-SMC Ships in June 2015Btwins123100% (1)

- Training Material 126 Company Guidance For Recording Operations in The Oil Record Book PDFDocumento37 pagineTraining Material 126 Company Guidance For Recording Operations in The Oil Record Book PDFkurupath100% (1)

- Oil Record Book Guidelines (Rev.00)Documento9 pagineOil Record Book Guidelines (Rev.00)Harun KınalıNessuna valutazione finora

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7Da EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7Nessuna valutazione finora

- Code of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)Da EverandCode of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)Nessuna valutazione finora

- Commercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysDa EverandCommercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysValutazione: 4.5 su 5 stelle4.5/5 (6)

- C.E On Preventing PollutionDocumento3 pagineC.E On Preventing Pollutionwinhlaingoo100% (1)

- Errors in Oil Record Book Part I EntriesDocumento3 pagineErrors in Oil Record Book Part I EntriesAbdul Anis100% (1)

- Marpol Annex II GuideDocumento46 pagineMarpol Annex II GuidelgtpwsNessuna valutazione finora

- Bunkers Quality and Quantity ClaimsDocumento36 pagineBunkers Quality and Quantity ClaimsParthiban NagarajanNessuna valutazione finora

- SAF-25 Checklist For PSC Pre-Inspection - EnG (REV-03)Documento40 pagineSAF-25 Checklist For PSC Pre-Inspection - EnG (REV-03)RiskyMaulana100% (1)

- Every Day Checks in Engine Room Rounds From Funnel To Tunnel On ShipDocumento5 pagineEvery Day Checks in Engine Room Rounds From Funnel To Tunnel On ShipjoyceNessuna valutazione finora

- 5 ORB Entries Training 2017Documento45 pagine5 ORB Entries Training 2017Nirjhar Ganguly75% (4)

- Vetting Introduction For SuprintendentsDocumento17 pagineVetting Introduction For SuprintendentsknellerNessuna valutazione finora

- Oil Record Book Guidelines PDFDocumento4 pagineOil Record Book Guidelines PDFBaderN100% (3)

- Crude Oil Washing Check List: Before C.O.WDocumento2 pagineCrude Oil Washing Check List: Before C.O.Wopytnymoryak100% (1)

- Partnership Towards A Safe and Better Marine Future: MISC Maritime Services (MMS) Shipowner and Charterer ForumDocumento22 paginePartnership Towards A Safe and Better Marine Future: MISC Maritime Services (MMS) Shipowner and Charterer Forumclaudio santellanesNessuna valutazione finora

- Oil Record Book: Code GuideDocumento23 pagineOil Record Book: Code GuideCosmin Moroldi67% (3)

- Oil Record BookDocumento1 paginaOil Record BookAbdallah MansourNessuna valutazione finora

- Port State ControlDocumento14 paginePort State ControlPeter100% (2)

- IO Cadet Survey and Best Practice Guide 2014Documento42 pagineIO Cadet Survey and Best Practice Guide 2014alkazum100% (2)

- Disposal For Spilled Oil and Prevention For Secondary DisasterDocumento4 pagineDisposal For Spilled Oil and Prevention For Secondary DisasterIonescu EdaNessuna valutazione finora

- Oral-Preparation-Guide (Rifat Azad-Bma 49) PDFDocumento105 pagineOral-Preparation-Guide (Rifat Azad-Bma 49) PDFTarek Aziz100% (2)

- SIRE Inspection Preparation Document BLANKDocumento5 pagineSIRE Inspection Preparation Document BLANKhmmbacon100% (1)

- Detainable Deficiency by PSCDocumento23 pagineDetainable Deficiency by PSCSardar Sirajul Islam100% (3)

- Panamax Cargo Hold Cleaning Manual Rev01Documento22 paginePanamax Cargo Hold Cleaning Manual Rev01livslx100% (2)

- PSC Pocket Checklist PDFDocumento16 paginePSC Pocket Checklist PDFRalf Tholen100% (1)

- Life Boat and Life Raft Required - EquipmentDocumento3 pagineLife Boat and Life Raft Required - EquipmentdkpushpdkNessuna valutazione finora

- Vetting PreparationsDocumento10 pagineVetting PreparationsSardar Sirajul Islam100% (1)

- Vetting CDI ObservationsDocumento42 pagineVetting CDI Observationsstopless_dalian685100% (5)

- Orb Criminal Cases PDFDocumento27 pagineOrb Criminal Cases PDFvivek100% (1)

- Avoiding Cargo Claims - HTMLDocumento5 pagineAvoiding Cargo Claims - HTMLstamatisNessuna valutazione finora

- NEW Oil Record Book CodesDocumento5 pagineNEW Oil Record Book Codesswapneel_kulkarniNessuna valutazione finora

- 1 Oil Record BookDocumento24 pagine1 Oil Record Bookcarmelo panebianco100% (1)

- Vetting ObservationsDocumento11 pagineVetting ObservationsChandergupt Mehta100% (1)

- Lloyds Marine Pollution Checklist (R2)Documento0 pagineLloyds Marine Pollution Checklist (R2)Dimitris PaliktoglouNessuna valutazione finora

- Battery Room Ventilationa and Proper UpkeepingDocumento2 pagineBattery Room Ventilationa and Proper Upkeepingdassi99Nessuna valutazione finora

- VGP Logbook - Sample EntriesDocumento13 pagineVGP Logbook - Sample EntriesRiaz AhmedNessuna valutazione finora

- Asm Orals Jan 2014Documento10 pagineAsm Orals Jan 2014Mayank SethNessuna valutazione finora

- Inerting Oil TankersDocumento22 pagineInerting Oil TankersDebashish Priyanka Sinha100% (1)

- Marpol SummaryDocumento5 pagineMarpol SummaryrigelNessuna valutazione finora

- Huong Dan Ghi So Nhat Ky Dau Part IIIDocumento5 pagineHuong Dan Ghi So Nhat Ky Dau Part IIIRavindra100% (1)

- Lloyds FOBAS Guidance On CominglingDocumento11 pagineLloyds FOBAS Guidance On CominglingBruno KosNessuna valutazione finora

- Module 008 MARPOLDocumento135 pagineModule 008 MARPOLallan kasem alcazaren100% (2)

- MARPOL Online Training 05.04.2020 PDFDocumento11 pagineMARPOL Online Training 05.04.2020 PDFRen Mark ZuniegaNessuna valutazione finora

- MEO Class I OralsDocumento2 pagineMEO Class I OralsGurvindarNessuna valutazione finora

- Commentary On Entries in The Ballast Water Record Book (BWRB)Documento17 pagineCommentary On Entries in The Ballast Water Record Book (BWRB)Reda HmrNessuna valutazione finora

- SEQ Survey Checks PDFDocumento23 pagineSEQ Survey Checks PDFAnonymous XtvvG80zu100% (3)

- Cargo Line Clearance Safe Procedure For Chemical TankersDocumento8 pagineCargo Line Clearance Safe Procedure For Chemical TankersJeet SinghNessuna valutazione finora

- SIRE 2.0 - Strategic Goal & Objectives: Tentative RoadmapDocumento14 pagineSIRE 2.0 - Strategic Goal & Objectives: Tentative Roadmapugur100% (5)

- SIRE Inspection Deficiencies RepliesDocumento57 pagineSIRE Inspection Deficiencies Repliesmanojvarrier100% (2)

- Chemical Tanker OperationsDocumento12 pagineChemical Tanker OperationsJeet Singh75% (4)

- Checklist For The Renewal Survey of Iopp Certificate PDFDocumento8 pagineChecklist For The Renewal Survey of Iopp Certificate PDFAnita GangzNessuna valutazione finora

- USCG Inspection Self ChercklistDocumento5 pagineUSCG Inspection Self ChercklistVipin JainNessuna valutazione finora

- Crude Oil Washing and Heating PolicyDocumento6 pagineCrude Oil Washing and Heating PolicyGuss Kontarakis100% (1)

- INTERTANKO Vetting Committee 26.05.2022Documento29 pagineINTERTANKO Vetting Committee 26.05.2022soner100% (1)

- Falchem Spec SUPER SOLDocumento2 pagineFalchem Spec SUPER SOLUdana HettiarachchiNessuna valutazione finora

- Air EjectorsDocumento2 pagineAir EjectorsAnkit DedhiyaNessuna valutazione finora

- Hydraulic Governors: Graph of % Speed Against Engine LoadDocumento4 pagineHydraulic Governors: Graph of % Speed Against Engine LoadRoddy UlieNessuna valutazione finora

- 11 - Reversing of Two Stroke EngineDocumento13 pagine11 - Reversing of Two Stroke EngineAisha Zaheer90% (29)

- All About Marine Enginnering OralsDocumento76 pagineAll About Marine Enginnering OralsUdana Hettiarachchi100% (3)

- Guide For ORB PDFDocumento29 pagineGuide For ORB PDFUdana Hettiarachchi100% (4)

- Marine Oral QuestionsDocumento23 pagineMarine Oral QuestionsUdana HettiarachchiNessuna valutazione finora

- Hydraulic Governors: Graph of % Speed Against Engine LoadDocumento4 pagineHydraulic Governors: Graph of % Speed Against Engine LoadRoddy UlieNessuna valutazione finora

- Main Engine Shutdowns Marine Two Stroke EnginesDocumento12 pagineMain Engine Shutdowns Marine Two Stroke EnginesUdana Hettiarachchi67% (3)

- Bitumen Brochure WebDocumento12 pagineBitumen Brochure Webanjali narula100% (1)

- Man B&W 6s60mc-c Tanker ManualDocumento281 pagineMan B&W 6s60mc-c Tanker Manualgurcanoglu67% (3)

- Bunker Lines TestingDocumento2 pagineBunker Lines Testinghackey720Nessuna valutazione finora

- Calculation of Thermal Stresses For A 7000 DWT Oil Tanker: TEAM 2008, Oct. 6-9, 2008, Istanbul, TurkeyDocumento7 pagineCalculation of Thermal Stresses For A 7000 DWT Oil Tanker: TEAM 2008, Oct. 6-9, 2008, Istanbul, TurkeySamet OzcelikNessuna valutazione finora

- Merchant Ship ConstructionDocumento143 pagineMerchant Ship Constructionharjono100% (1)

- Jabatan Laut Semenanjung Malaysia Notice To MarinersDocumento3 pagineJabatan Laut Semenanjung Malaysia Notice To MarinerstaufikNessuna valutazione finora

- Significant Ships 1995Documento104 pagineSignificant Ships 1995Marcel Schmal100% (1)

- TankerDocumento60 pagineTankerlopezdestructionNessuna valutazione finora

- Guidelines For Implementation of The Requirements For Construction and Equipment of Tankers of Oil Industry Organizations, 2010 PDFDocumento158 pagineGuidelines For Implementation of The Requirements For Construction and Equipment of Tankers of Oil Industry Organizations, 2010 PDFlanNessuna valutazione finora

- Quality Safety PDFDocumento9 pagineQuality Safety PDFRizaldie Zambra Jr.Nessuna valutazione finora

- Here Is What You Need To Know About Enhanced Survey ProgrammeDocumento30 pagineHere Is What You Need To Know About Enhanced Survey ProgrammeJeet Singh100% (1)

- Sailing DirectionsDocumento340 pagineSailing DirectionsŞcî Andrei100% (1)

- Self Checklist For Company Safety Management SystemDocumento10 pagineSelf Checklist For Company Safety Management SystemErgul Neroglu100% (1)

- Marine Oil Spill TezDocumento53 pagineMarine Oil Spill Tezhalit canNessuna valutazione finora

- CHAPTER V - Midstream Oil and Gas SectorDocumento9 pagineCHAPTER V - Midstream Oil and Gas SectorRUFFALYN FINCALERONessuna valutazione finora

- Project Standards and Specifications Loading Road Tankers Rev01Documento12 pagineProject Standards and Specifications Loading Road Tankers Rev01Henrique Becker100% (1)

- Parametric Design 1Documento48 pagineParametric Design 1Jorge HL100% (1)

- Ghana - FSPODocumento37 pagineGhana - FSPOLegend AnbuNessuna valutazione finora

- Marflex Brochure Deepwell Pumps - lr2013Documento12 pagineMarflex Brochure Deepwell Pumps - lr2013Subramoniam Marine100% (1)

- Project Overview: Marine Terminal - Fuel Receiving Facility - PipelineDocumento11 pagineProject Overview: Marine Terminal - Fuel Receiving Facility - PipelineYagmur SimsekNessuna valutazione finora

- Assessment of Ballast Water Management PlansDocumento12 pagineAssessment of Ballast Water Management PlansmariodalNessuna valutazione finora

- Eagle Brasilia Crude Oil TankerDocumento2 pagineEagle Brasilia Crude Oil TankerbpidkhhNessuna valutazione finora

- Doc. No. 3 - TCDocumento12 pagineDoc. No. 3 - TCDanutirta ChrisraftianoNalaraka'19Nessuna valutazione finora

- QA Monthly Report 2022-12 DecemberDocumento37 pagineQA Monthly Report 2022-12 DecemberMark Mirosevic-SorgoNessuna valutazione finora

- CatalogDocumento12 pagineCatalogDv Maria PradhikaNessuna valutazione finora

- Tandem Loading Guidelines v1 21Documento129 pagineTandem Loading Guidelines v1 21Cindy100% (1)

- Intertanko Tanker Chartering Questionnaire 88 1. Vessel DescriptionDocumento8 pagineIntertanko Tanker Chartering Questionnaire 88 1. Vessel DescriptionHtunlynn HtunNessuna valutazione finora

- Catalist-Listed ES Group Announces Revised Chartering Agreement and New Vessel Sale To Sea Hub Tankers For S$29.4 MillionDocumento3 pagineCatalist-Listed ES Group Announces Revised Chartering Agreement and New Vessel Sale To Sea Hub Tankers For S$29.4 MillionWeR1 Consultants Pte LtdNessuna valutazione finora

- 038 Oil Tanker Training System, AdvancedDocumento3 pagine038 Oil Tanker Training System, AdvancedKhasy Jeans P. Tampos100% (1)

- Typical AMSA Oral QuestionsDocumento37 pagineTypical AMSA Oral Questionsrigel93% (15)