Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Base Plate Design Is 800-2007

Caricato da

Suneesh P91%(11)Il 91% ha trovato utile questo documento (11 voti)

17K visualizzazioni6 paginebase plate design

Titolo originale

Base Plate Design is 800-2007

Copyright

© © All Rights Reserved

Formati disponibili

XLS, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentobase plate design

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

91%(11)Il 91% ha trovato utile questo documento (11 voti)

17K visualizzazioni6 pagineBase Plate Design Is 800-2007

Caricato da

Suneesh Pbase plate design

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 6

DESIGNED CHECKED SHEET

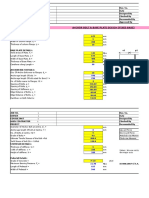

Size of the column HD 500 X 492 92.5 b (1mm strip)

Factored loads: x y

Max. compression 3980 KN Node: 8 465 650

Max. tension 1350 KN Node: 13 a (1mm strip)

Max. shear 534 KN Node: 13 C/C = 450

For Compression

Assume the base plate size as 550 x 650 mm

2

Concrete Grade, fck = 30 N/mm

2

Max. compression 3980 KN

Hence base pressure -(w) 11.13 N/mm

2

< than 0.45times the strength of bedding material

From Mukhanov's chart, Edge condition - Plate supported on three sides.

a1 = 275 mm Checking whether panel acting as cantilever

d1 = 232.5 mm (Length of free edge) a1/d1 > 0.5

Hence a1/d1 = 1.18 Cantilever moment M

d =

NOT APPLICABLE

Hence coefficient = 0.1184

Hence moment on the base plate M

d

= 0.1184*11.13*232.5^2= 71234.8938 N-mm g

mo

= 1.1

Edge cantilever moment M

d

= 11.13X92.5X92.5 / 2= 47615.5313 N-mm f

y

= 250 N/mm2

Thickness of plate required = (5 M

d

g

mo

/ b

fy) As per IS 800- 2007,Clause 8.2.1.2 f

u

= 410 N/mm2

Assuming width of the plate b = 1 mm

t

reqd

= 39.59 mm (From Compression only)

Minimum thickness check as per cl. 7.4.3

t

s

= > t

f

t

f

= 72 mm

= 14 mm a = 64.5 mm

72 mm b = 92.5 mm

Check for weld size connecting base plate to Column t

w

= 45 mm

Total length availble for welding along the periphery of column A = 75490 mm2

2x(421-72+465)-45 = 1583 mm

Deducting length 10% for end return = 1424.7 mm

Capcacity of 30 mm weld = 4.017 KN / mm g

mw

= 1.25

f

wn

= f

u

/ 3 = 236.71 f

wd

= f

wn

/ g

mw

= 189.37

Design force for weld = 5147 KN

Required length of weld = 1281 mm < 1424.7 mm HENCE SAFE

For Tension

Support reaction = 1350 KN (Max Tension)

Assume 8 Nos 56 dia H.D bolts Grade 4.6 (Bearing type bolt)

Tension capacity of bolt T

db

= T

nb

/ g

mb

(As per Cl. 10.3.5) g

mb

= 1.25

T

nb

= 0.9 f

ub

A

n

< f

yb

A

sb

(g

mb

/ g

m0

) f

yb

= 240 N/mm

2

f

ub

= 400 N/mm

2

0.9 f

ub

A

n

= 709.35 KN Shank area of the bolt(A

sb

)= 2463.01 mm

2

(2.5 w (a

2

- 0.3 b

2

)g

mo

/ f

y

Hence, ts =

As per IS 800- 2007,Table 5

550

421

Hence O.K

PROJECT

DOCUMENT NO DATE

TITLE

DESIGNED CHECKED SHEET

PROJECT

DOCUMENT NO DATE

TITLE

f

yb

A

sb

(g

mb

/g

m0

)= 671.73 KN Net tensile area at the bottom of threads (A

n

)= 1970.408 mm^2

T

nb

= 671.73 KN ( Approx. 80 % of A

sb

)

Tension capacity of single bolt T

db

= 537.38 KN

Tension capacity of single bolt as per RIL standards = 608 KN

DESIGNED CHECKED SHEET

PROJECT

DOCUMENT NO DATE

TITLE

Hence tension capacity of single bolt = 537.38 KN

Tension/bolt (T

b

) = 1350/8= 168.8 KN Hence O.K

Diagonal distance from bolt centre to web = 263.69 mm

Moment in the plate due to bolt tension= 168.75 x 1000 x 263.69 = 44497688 N-mm

Assuming width of the plate= 232.5 mm

Thickness of plate required = (5 M

d

g

mo

/ b

fy) As per IS 800- 2007,Clause 8.2.1.2

t

reqd

= 64.89 mm (From tension only)

Hence provide thickness of base plate= 72 mm Round to 12 mm

Shear capacity of bolt:

V

nsb

= f

u

A

n

/ 3 = 455046.2 N V

dsb

= 364.04 KN

Bearing capacity of the bolt:

V

npb

= 2.5 k

b

d t f

u

K

b

= Min (e / 3d

o

, p/ 3 d

o

- 0.25, f

ub

/f

u

, 1) e = 95.2

= 371952 N = 0.54 f

u

= 410

V

dpb

= 297.56 KN d

o

= 59 mm

Shear capacity of single bolt as per RIL standards = 253 KN

Therefore Shear capacity of single Bolt= 253 KN Hence O.K

Check for combined shear and Tension:

(Vsb / Vdb)^2 + (Tb / Tdb)^2 = 0.17 Vsb = 66.75 KN

<1 Hence O.K Tb = 168.75 KN

Design of stiffner plate x -

Moment at the face of the column web -(for compression in the coulmn)

11.13*465/2*(550/2)^2/2= 97848351.56 N-mm

Moment at face of stiffener (due to bolt tension) -

168750*450/2= 37968750 N-mm

Assume plate thickness - 16 mm

Height of plate required = (5 M

d

g

mo

/ b

fy) As per IS 800- 2007,Clause 8.2.1.2

= 366.8 mm Hence, Provide stiffner plate height as 100 mm

Design of stiffner plate y -

Moment at the face of the column flange - (for compression on column)

11.13*(465/4+92.5)*((550^2)/2= 351412359.4 N-mm

Moment at face of stiffener (due to bolt tension) -

168750*(465-450)/2= C/C = 1265625 N-mm

Height of plate required = (5 M

d

g

mo

/ b

fy) As per IS 800- 2007,Clause 8.2.1.2

= 695.12 mm Hence, Provide stiffner plate height as 100 mm

Design for shear key - H (max) = 801 KN (1.2xShear capacity of the member, (AvXfy/(3X

m0

)X1.2))

Shear key size 250 x 30 thk. cross

Provide 250 mm deep shear key

Z

e

of the section = 317000

mm

3

Z

p

of the section = 525000

mm

3

Z

e

/Z

p

= 0.6

udl on the shear key = 801000/250= 3204 N/mm

Hence cantilever moment on the shear key (M)= 3204*250^2/2 = 100125000 N-mm = 100.13 KN-m

Section classification as per Table- 2 of IS 800: 2007:

d/t = 8.33 e = 1.86339 Plastic

DESIGNED CHECKED SHEET

PROJECT

DOCUMENT NO DATE

TITLE

Design bending strength M

d

= b

b

Z

p

f

y

/g

mo

For a Plastic section,

b

= 1

M

d

= 119.32 KN- m

M < Md, Hence O.K Hence provide shear key size as 250x250x30

DESIGNED CHECKED SHEET

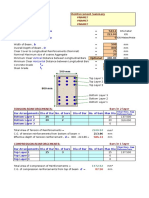

Size of the column HE 400 84 b (1mm strip)

Factored loads: x y

Max. compression 1781 KN Node: 7 432 600

Max. tension 1020 KN Node: 11 a (1mm strip)

Max. shear 430 KN Node: 11 C/C = 390

For Compression

Assume the base plate size as 450 x 600 mm

2

Concrete Grade, fck = 30 N/mm

2

Max. compression 1781 KN

Hence base pressure -(w) 6.60 N/mm

2

< than 0.45times the strength of bedding material

From Mukhanov's chart, Edge condition - Plate supported on three sides.

a1 = 225 mm Checking whether panel acting as cantilever

d1 = 216 mm (Length of free edge) a1/d1 > 0.5

Hence a1/d1 = 1.04 Cantilever moment M

d =

NOT APPLICABLE

Hence coefficient = 0.112

Hence moment on the base plate M

d

= 0.112*6.6*216^2= 34488.1152 N-mm g

mo

= 1.1

Edge cantilever moment M

d

= 6.6X84X84 / 2= 23284.8 N-mm f

y

= 250 N/mm2

Thickness of plate required = (5 M

d

g

mo

/ b

fy) As per IS 800- 2007,Clause 8.2.1.2 f

u

= 410 N/mm2

Assuming width of the plate b = 1 mm

t

reqd

= 27.55 mm (From Compression only)

Minimum thickness check as per cl. 7.4.3

t

s

= > t

f

t

f

= 40 mm

= 15 mm a = 71.5 mm

40 mm b = 84 mm

Check for weld size connecting base plate to Column t

w

= 21 mm

Total length availble for welding along the periphery of column A = 32600 mm2

2x(307-40+432)-21 = 1377 mm

Deducting length 10% for end return = 1239.3 mm

Capcacity of 30 mm weld = 4.017 KN / mm g

mw

= 1.25

f

wn

= f

u

/ 3 = 236.71 f

wd

= f

wn

/ g

mw

= 189.37

Design force for weld = 2223 KN

Required length of weld = 553.4 mm < 1239.3 mm HENCE SAFE

For Tension

Support reaction = 1020 KN (Max Tension)

Assume 4 Nos 48 dia H.D bolts Grade 4.6 (Bearing type bolt)

Tension capacity of bolt T

db

= T

nb

/ g

mb

(As per Cl. 10.3.5) g

mb

= 1.25

T

nb

= 0.9 f

ub

A

n

< f

yb

A

sb

(g

mb

/ g

m0

) f

yb

= 240 N/mm

2

f

ub

= 400 N/mm

2

0.9 f

ub

A

n

= 521.15 KN Shank area of the bolt(A

sb

)= 1809.56 mm

2

Hence O.K

PROJECT

DOCUMENT NO DATE

TITLE

(2.5 w (a

2

- 0.3 b

2

)g

mo

/ f

y

Hence, ts =

As per IS 800- 2007,Table 5

450

307

DESIGNED CHECKED SHEET

PROJECT

DOCUMENT NO DATE

TITLE

f

yb

A

sb

(g

mb

/g

m0

)= 493.52 KN Net tensile area at the bottom of threads (A

n

)= 1447.648 mm^2

T

nb

= 493.52 KN ( Approx. 80 % of A

sb

)

Tension capacity of single bolt T

db

= 394.82 KN

Tension capacity of single bolt as per RIL standards = 441 KN

Potrebbero piacerti anche

- Base Plate Design for Column SupportDocumento180 pagineBase Plate Design for Column Supportbuildcon62% (13)

- Fixed Base Anchor Bolt DesignDocumento3 pagineFixed Base Anchor Bolt Designkhan84mind50% (2)

- Base Plate DesignDocumento32 pagineBase Plate DesignGautam Sharma50% (2)

- Moment Connection - Flush End Plate-19.01.06Documento48 pagineMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- Anchor Bolt Design IS Code LSDDocumento33 pagineAnchor Bolt Design IS Code LSDdebjyoti_das_663% (8)

- Moment Connection Beam Column IS & BS SECTION FOR IS800Documento29 pagineMoment Connection Beam Column IS & BS SECTION FOR IS800pjuvvadi86% (7)

- Design of Base Plate & Anchor BoltDocumento2 pagineDesign of Base Plate & Anchor Boltrameshdorage12100% (8)

- Design of Purlins per IS800 and SP38Documento2 pagineDesign of Purlins per IS800 and SP38MM93% (29)

- Insert Plate Design LugsDocumento8 pagineInsert Plate Design Lugsvrajan1988Nessuna valutazione finora

- Design of Embeded Plate (INDIAN STANDARD)Documento3 pagineDesign of Embeded Plate (INDIAN STANDARD)Shubham Verma100% (2)

- Insert Plate DesignDocumento8 pagineInsert Plate Designvrajan1988Nessuna valutazione finora

- Insert Plate DesignDocumento1 paginaInsert Plate DesignDivya MohanNessuna valutazione finora

- Design of I-Shape Column Base PlateDocumento6 pagineDesign of I-Shape Column Base PlatebuildconNessuna valutazione finora

- Base PlateDocumento48 pagineBase PlatePrantik Adhar Samanta0% (1)

- Base Plate DesignDocumento3 pagineBase Plate DesignrajarshiboseNessuna valutazione finora

- Design of Shear KeyDocumento13 pagineDesign of Shear Keynhulugalla100% (1)

- Base Plate and Anchor Bolt DesignDocumento9 pagineBase Plate and Anchor Bolt DesignShaikh Muhammad Ateeq100% (2)

- Is800 2007Documento8 pagineIs800 2007Abhijit Hazarika25% (4)

- BASE PLATE DESIGN OPTIMIZATIONDocumento45 pagineBASE PLATE DESIGN OPTIMIZATIONMuhammed Ali60% (5)

- Design of Moment and Shear Connections (boltedDocumento4 pagineDesign of Moment and Shear Connections (boltedAmit Ghosh67% (3)

- Combined Gusset Plate DesignDocumento3 pagineCombined Gusset Plate Designkalpanaadhi100% (3)

- Base Plate Andf Anchor Bolt Design For Minor Axis MomentDocumento2 pagineBase Plate Andf Anchor Bolt Design For Minor Axis MomentSunil Pulikkal100% (1)

- End Plate DesignDocumento4 pagineEnd Plate DesignAgnon Fung100% (4)

- RCC Corbel AS PER IS 456Documento1 paginaRCC Corbel AS PER IS 456PAWAN100% (1)

- Anchor Bolt and Base Plate Design CheckDocumento48 pagineAnchor Bolt and Base Plate Design CheckmaheshbandhamNessuna valutazione finora

- Eccentric FootingDocumento8 pagineEccentric Footinghemantkle2uNessuna valutazione finora

- Design of Steel Beam to Column Bolted ConnectionDocumento3 pagineDesign of Steel Beam to Column Bolted ConnectionibrahimNessuna valutazione finora

- Bolted Moment ConnectionDocumento3 pagineBolted Moment Connectionprabhu81100% (3)

- Design of Pedestal ReinforcementDocumento2 pagineDesign of Pedestal Reinforcementsaravanan4286Nessuna valutazione finora

- Weld ConnectionDocumento70 pagineWeld ConnectionSudhakar KrishnamurthyNessuna valutazione finora

- Connection Design SheetDocumento47 pagineConnection Design SheetStephen James100% (1)

- Horizontal Bracing Connection Bolted Type - IS800-2007Documento55 pagineHorizontal Bracing Connection Bolted Type - IS800-2007Nitesh SinghNessuna valutazione finora

- Shear Connection - Is 800-ModifiedDocumento159 pagineShear Connection - Is 800-ModifiedDarshan Panchal100% (1)

- Design of Tube Purlin Standalone StaircaseDocumento16 pagineDesign of Tube Purlin Standalone Staircasevrajan1988Nessuna valutazione finora

- Pinned and fixed base plate design calculations for I-section and tube columnsDocumento7 paginePinned and fixed base plate design calculations for I-section and tube columnsabdul karee100% (6)

- RD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryDocumento25 pagineRD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryHanuman Sharma83% (6)

- 2 0 Insert Plate Calculations Type 14 PDF PDF FreeDocumento4 pagine2 0 Insert Plate Calculations Type 14 PDF PDF Freearchetype design100% (1)

- Base Plate Design Is 800 2007Documento147 pagineBase Plate Design Is 800 2007pandian100% (1)

- Design of Steel Plate - R0 - 20.04.21Documento1 paginaDesign of Steel Plate - R0 - 20.04.21Srishti Project ConsultantsNessuna valutazione finora

- Beam-Column Moment ConnectionDocumento10 pagineBeam-Column Moment Connectionrammohan100% (3)

- Calculation of base plate size for concrete gradeDocumento22 pagineCalculation of base plate size for concrete gradeArmaan Gupta100% (2)

- PURLIN - DESIGN - AS - PER - IS - CODE LatestDocumento22 paginePURLIN - DESIGN - AS - PER - IS - CODE Latestnitin chaudharyNessuna valutazione finora

- Crack Width Calculation Is 456Documento2 pagineCrack Width Calculation Is 456sansarep100% (5)

- End Plate-Splice ConnectionDocumento76 pagineEnd Plate-Splice ConnectionHemant Ramesh Narkar100% (6)

- Chequered PlateDocumento3 pagineChequered Platerammohan100% (4)

- 2 0 Insert Plate Calculations Type 14 PDFDocumento4 pagine2 0 Insert Plate Calculations Type 14 PDFKho C AhlNessuna valutazione finora

- Shear Connection - Beam - Steel Column - Fin PlateDocumento30 pagineShear Connection - Beam - Steel Column - Fin Platekalpanaadhi100% (3)

- Design of Composite Steel Girder BridgeDocumento10 pagineDesign of Composite Steel Girder BridgesorowareNessuna valutazione finora

- Base PlateDocumento32 pagineBase PlateSunil SinghNessuna valutazione finora

- Design of combined footing and strap beamDocumento4 pagineDesign of combined footing and strap beamSakar ShresthaNessuna valutazione finora

- Design of base plates for steel structureDocumento43 pagineDesign of base plates for steel structureGautam SharmaNessuna valutazione finora

- Aci BeamDocumento6 pagineAci BeamkumsbamaNessuna valutazione finora

- Design of Beam Ledge Reinforcement as per ACI 318M95Documento2 pagineDesign of Beam Ledge Reinforcement as per ACI 318M95auatipu100% (1)

- Input Data: Subject: Base Plate ConnectionDocumento5 pagineInput Data: Subject: Base Plate ConnectionSambhav PoddarNessuna valutazione finora

- Section Size: W200X36: Refer Appendix D For Support ReactionsDocumento10 pagineSection Size: W200X36: Refer Appendix D For Support Reactionsramuce04Nessuna valutazione finora

- Pad Footing DesignDocumento15 paginePad Footing DesignMalayan TigerNessuna valutazione finora

- 30m 24sq.m SQ 100kpaDocumento20 pagine30m 24sq.m SQ 100kpamanohargudNessuna valutazione finora

- T Beam Roof SlabDocumento22 pagineT Beam Roof SlabRohit Khandelwal100% (1)

- TB1Documento7 pagineTB1Feliciano Esteban DominguezNessuna valutazione finora

- SteelDocumento9 pagineSteelMohammedAlasaadNessuna valutazione finora

- Civil & Architectural Engineering Department: June 23, 2016Documento71 pagineCivil & Architectural Engineering Department: June 23, 2016Suneesh PNessuna valutazione finora

- April 2014: Kumar Neeraj JhaDocumento35 pagineApril 2014: Kumar Neeraj JhaNavarang R KobbeNessuna valutazione finora

- Slab Formwork DesignDocumento7 pagineSlab Formwork DesignRaja SundarapandianNessuna valutazione finora

- STAAD Rayleigh Frequency PDFDocumento3 pagineSTAAD Rayleigh Frequency PDFSuneesh PNessuna valutazione finora

- Is - 14687-1999 Falsework For Concrete StructuresDocumento27 pagineIs - 14687-1999 Falsework For Concrete StructuresJarrod HarrellNessuna valutazione finora

- MSB Part 9 ConnectionsDocumento2 pagineMSB Part 9 ConnectionsSana UllahNessuna valutazione finora

- Is - 14687-1999 Falsework For Concrete StructuresDocumento27 pagineIs - 14687-1999 Falsework For Concrete StructuresJarrod HarrellNessuna valutazione finora

- Hilti Profis Anchor calculation for concrete anchorsDocumento5 pagineHilti Profis Anchor calculation for concrete anchorsSuneesh PNessuna valutazione finora

- E2 Dae-Sang KimDocumento11 pagineE2 Dae-Sang KimconcretetechgroupNessuna valutazione finora

- Is - 14687-1999 Falsework For Concrete StructuresDocumento27 pagineIs - 14687-1999 Falsework For Concrete StructuresJarrod HarrellNessuna valutazione finora

- CIVL 392 - Chapter 6 - FormworkDocumento69 pagineCIVL 392 - Chapter 6 - FormworkGerold MolinaNessuna valutazione finora

- Wind Analysis On ChimneysDocumento4 pagineWind Analysis On ChimneysanilpradeepNessuna valutazione finora

- 1 Introduction To EC3 Handout PDFDocumento2 pagine1 Introduction To EC3 Handout PDFAmila KulasooriyaNessuna valutazione finora

- Design Rules For Fillet Welds in Eurocode 3 and Aisc: EUROSTEEL 2014, September 10-12, 2014, Naples, ItalyDocumento8 pagineDesign Rules For Fillet Welds in Eurocode 3 and Aisc: EUROSTEEL 2014, September 10-12, 2014, Naples, ItalyDele TedNessuna valutazione finora

- Tension Members HandoutDocumento2 pagineTension Members HandoutNur IzzaidahNessuna valutazione finora

- 2006 Beam Column Joint ICJDocumento9 pagine2006 Beam Column Joint ICJBrian LamNessuna valutazione finora

- Lighting Project Calculator SummaryDocumento323 pagineLighting Project Calculator SummarySuneesh PNessuna valutazione finora

- Load Capacity vs Crack LengthDocumento26 pagineLoad Capacity vs Crack LengthSuneesh PNessuna valutazione finora

- 17502-Drawing Template PDFDocumento6 pagine17502-Drawing Template PDFveerash100Nessuna valutazione finora

- 17502-Drawing Template PDFDocumento6 pagine17502-Drawing Template PDFveerash100Nessuna valutazione finora

- 04 ChapterDocumento52 pagine04 ChapterYirga BezabehNessuna valutazione finora

- FLRPLATEDocumento3 pagineFLRPLATEcravikumar1971Nessuna valutazione finora

- State-Of-practice of Seismic Design and Construction in IndonesiaDocumento18 pagineState-Of-practice of Seismic Design and Construction in IndonesiaSuneesh PNessuna valutazione finora

- Seismic Design of Industrial PlantsDocumento14 pagineSeismic Design of Industrial PlantsSuneesh PNessuna valutazione finora

- Diff BWT Is 800 101Documento96 pagineDiff BWT Is 800 101tops123Nessuna valutazione finora

- Aisc 34Documento3 pagineAisc 34Suneesh PNessuna valutazione finora

- Grade SlabDocumento16 pagineGrade SlabSuneesh PNessuna valutazione finora

- V44i01p42 PDFDocumento3 pagineV44i01p42 PDFSuneesh PNessuna valutazione finora

- V44i01p42 PDFDocumento3 pagineV44i01p42 PDFSuneesh PNessuna valutazione finora

- State-Of-practice of Seismic Design and Construction in IndonesiaDocumento18 pagineState-Of-practice of Seismic Design and Construction in IndonesiaSuneesh PNessuna valutazione finora

- The Business Model Canva EnglishDocumento45 pagineThe Business Model Canva EnglishFerrara Biagi HinojosaNessuna valutazione finora

- Asu Map Tempe 2011 ParkingDocumento1 paginaAsu Map Tempe 2011 ParkingJacob LauxmanNessuna valutazione finora

- "Super Blues" Scales For Leveling-Up Your Jazz Blues ImprovDocumento5 pagine"Super Blues" Scales For Leveling-Up Your Jazz Blues ImprovShreyans Jain100% (4)

- PC power supply voltages in the form of DC currentDocumento8 paginePC power supply voltages in the form of DC currentsoegyNessuna valutazione finora

- The Forrester Wave™ Collaborative Work Management Tools, Q4 2020Documento15 pagineThe Forrester Wave™ Collaborative Work Management Tools, Q4 2020AbdelfattahHabibNessuna valutazione finora

- x5 CatalogueDocumento18 paginex5 CatalogueKmt_AeNessuna valutazione finora

- Forecasted Sales From LeadsDocumento3 pagineForecasted Sales From LeadsRoselyn LustreNessuna valutazione finora

- Adobe Acrobat XI Pro 10116 Multilingual Crack Serial Key PDFDocumento4 pagineAdobe Acrobat XI Pro 10116 Multilingual Crack Serial Key PDFNicoleNessuna valutazione finora

- DocumentDocumento5 pagineDocumentKaran KirubajkNessuna valutazione finora

- (Post Malone) Feeling WhitneyDocumento2 pagine(Post Malone) Feeling WhitneySaul GuerraNessuna valutazione finora

- Beverages Guide: Alcoholic & Non-AlcoholicDocumento28 pagineBeverages Guide: Alcoholic & Non-Alcoholicprince KumarNessuna valutazione finora

- AdditionDocumento26 pagineAdditionilu593Nessuna valutazione finora

- Dynamics projectile motion problemsDocumento2 pagineDynamics projectile motion problemsVon A. Damirez0% (1)

- Platform Guide 3600Documento58 paginePlatform Guide 3600momoNessuna valutazione finora

- Simpleterms BTP PricingModel PDFDocumento34 pagineSimpleterms BTP PricingModel PDFpreetigopalNessuna valutazione finora

- CWS 315 2I en StudentManual 1 3 Days v03Documento455 pagineCWS 315 2I en StudentManual 1 3 Days v03Onurcan YahyaoğluNessuna valutazione finora

- BEAM200Documento2 pagineBEAM200ArunkumarNessuna valutazione finora

- TriaxDocumento7 pagineTriaxvijay dharmavaramNessuna valutazione finora

- Fma 2014 2015Documento118 pagineFma 2014 2015AlexsanderMNessuna valutazione finora

- Bonfire BlanketDocumento4 pagineBonfire BlanketRoganNessuna valutazione finora

- Myths About ConstellationsDocumento14 pagineMyths About ConstellationssnezanaNessuna valutazione finora

- Tugas 2 Present Perfect Vs Simple Past PDFDocumento2 pagineTugas 2 Present Perfect Vs Simple Past PDFSovania NiaNessuna valutazione finora

- ENGLISH Quarter 2 Week 3 Day 2 Literary Devices and Techniques To Craft Short Prose FormDocumento2 pagineENGLISH Quarter 2 Week 3 Day 2 Literary Devices and Techniques To Craft Short Prose FormZoakWoodNessuna valutazione finora

- EW0921150ENN enDocumento307 pagineEW0921150ENN envishNessuna valutazione finora

- Breakfast-Pack:: RM 5/per PaxDocumento2 pagineBreakfast-Pack:: RM 5/per PaxbailiniNessuna valutazione finora

- Group2 Rationale TitlesDocumento3 pagineGroup2 Rationale TitlesMacky VillarinoNessuna valutazione finora

- Key Word Transformation - TaskDocumento2 pagineKey Word Transformation - TaskracoNessuna valutazione finora

- LASER 400: Assembly InstructionsDocumento8 pagineLASER 400: Assembly InstructionsbellscbNessuna valutazione finora

- Gnomes EncyclopediaDocumento15 pagineGnomes EncyclopediaGeorge YountsNessuna valutazione finora