Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sigma Marine Coatings

Caricato da

Ahmed SaadCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sigma Marine Coatings

Caricato da

Ahmed SaadCopyright:

Formati disponibili

Amsterdamseweg 14

1422 AD Uithoorn

Telefoon 0297-541911

Telefax 0297-566331

P.O. Box 42

1420 AA Uithoorn

The Netherlands

e-mail siguitmarine@

sigmacoatings.com

A member of the SigmaKalon

Group of Companies

2000 February 2000

SI GM A COATI NGS

MA R I NE

M ARI N E COATI N GS

M AN UAL

M

A

R

I

N

E

C

O

A

T

I

N

G

S

M

A

N

U

A

L

Prot ect ing t he Fut ure

page 1/5

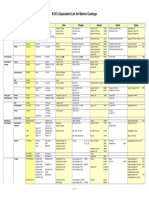

3003 SHIPS SHEET INDEX

a five page issue March 2000

revision of 5-1997

Sheet nrs. INFORMATION SHEETS

1410 Conversion tables

1411 Explanation to product data sheets

1412 Nomograph conversion from English units to metric units

1413 S.I. Units

1430 Safety indications

1431 Safety in confined spaces and health safety explosion hazard - toxic hazard

1432 Safety colours identification colours pipes

1433 Safe working in confined spaces

1434 Directives for ventilation practice

1490 Cleaning of steel and removal of rust

1491 Specification for mineral abrasives

1498 Hydrojetting

1650 Relative Humidity - substrate temperature - air temperature

1880 Welding certificates for prefabrication primers

1881 Health certificates for prefabrication primers

1882 Certificates for drinking water

1883 Certificates for low-flame spread

1883A Certificates for low-flame spread (Schwerentflambarkeit) (S.B.G.)

1884 Food certificates

1886 Recognized corrosion control coating (Lloyds register)

1891 Type approvals

Sheet nrs. SYSTEM SHEETS

3003 Ships sheet index

3006 Paint system guide

3015 Prefabrication primers

3100 General aspects anticorrosive paints

3101 Anticorrosive systems for underwater and boottop to be overcoated

with antifoulings

3102 Systems for boottop and topside

3103 Systems for decks

3104 Systems for superstructure and deckfittings

3105 Systems for interior(s)

3106 Systems for ballast-, freshwater and polluted water tanks

3107 Systems for cargo holds

3108 Miscellaneous systems

3110 General aspects - antifoulings

3111 Sigmaplane HB antifouling systems

3113 Sigma Pilot Ecol antifouling systems

3114 Sigmaplane TA antifouling systems

3117 Sigmaplane HC antifouling system

COATINGS

back to previous view

page 2/5

3003 SHIPS SHEET INDEX

March 2000

Sheet nrs. SYSTEM SHEETS

3118 Sigmaplane TC antifouling system

3120 Sigmaplane Ecol antifouling systems

3121 Sigmaplane NC antifouling system

3122 Sigmaplane HA antifouling systems

3125 Sigma Alphagen 50 antifouling systems

3126 Sigma Alphagen 20 antifouling systems

3140 Heat resistant systems

3141 Hot water resistant systems

3310 Tankcoating selection table

3320 Sigmaguard EHB tankcoating system

3322 Sigma Phenguard tankcoating system

3323 Sigma Silguard MC tankcoating system

3325 Systems for drinking water tanks (+ cleaning procedure)

3328 Sigmaguard CSF 7462 tankcoating system

Sheet nrs. PRODUCT DATA SHEETS

7102 Sigma Emaline 3000

7104 Sigma Balamastic

7110 Sigmarine Multiprimer

7111 Sigmarine Alu primer

7113 Sigmarine primer RL

7131 Sigmaferro primer ZP

7135 Sigmarine primer ZP

7150 Sigmacrylic primer

7171 Sigma Proferral MC

7177 Sigmaweld MC

7190 Sigmarine Holdbrite

7213 Sigmarine undercoat

7238 Sigmarine BTD

7240 Sigmarine Enamel

7250 Sigmacrylic finish

7260 Sigmarine Aluminium HR

7261 Sigmarine Aluminium HR 500

7263 Sigmarine Hold paint alu

7282 Sigmaplane TA antifouling

7284 Sigmaplane HB antifouling

7285 Sigma Pilot Ecol antifouling

7287 Sigmaplane HA antifouling

7288 Sigmaplane TC antifouling

7290 Sigmaplane NC antifouling

7292 Sigmaplane HC antifouling

7297 Sigmaplane Ecol antifouling

COATINGS

back to previous view

page 3/5

3003 SHIPS SHEET INDEX

March 2000

Sheet nrs. PRODUCT DATA SHEETS

7318 Sigmachlor primer

7343 Sigmavinyl primer

7346 Sigma Biguard primer

7347 Sigma Biguard coating

7350 Sigma Topacryl coating

7355 Sigma Topacryl finish

7371 Sigma Alphagen 10 antifouling

7372 Sigma Alphagen 20 antifouling

7375 Sigma Alphagen 50 antifouling

7400 Sigmaguard Tankshield primer

7409 Sigma Phenguard primer

7417 Sigma Universal primer

7424 Sigma Universal primer LT

7430 Sigma Multimastic

7433 Sigmaguard EHB

7435 Sigma Phenguard coating

7436 Sigma Phenguard finish

7443 Sigmaguard CSF

7448 Sigmaguard HS

7455 Sigmaguard Maintenance

7462 Sigmaguard CSF 7462

7465 Sigma CM miocoat

7466 Sigma CM coating

7467 Sigma Hullrite

7472 Sigma TCN 300

7473 Sigmaguard Tankshield coating

7479 Sigma TCN tiecoat

7483 Sigma TCN-LT 300

7524 Sigmadur HB finish

7528 Sigmadur gloss

7551 Sigma Silguard MC

7568 Sigma Silicate MC

7785 Sigmaguard CSF 85 (+ cleaning procedure)

7921 Sigmaguard BT primer PR 0616

7922 Sigma Multiguard primer

7925 Sigmaguard Tankshield LT-V primer

7951 Sigma Multiguard

7952 Sigma Glassflake

7953 Sigmaguard BT TP 1095

7954 Sigmaguard CSF Glassflake

7958 Sigmaguard Tankshield LT-V coating

8103 Sigmavar gloss

8215 Sigmatex

COATINGS

back to previous view

page 4/5

3003 SHIPS SHEET INDEX

March 2000

Sheet nrs. PRODUCT DATA SHEETS

ALPHABETICAL

7371 Sigma Alphagen 10 antifouling

7372 Sigma Alphagen 20 antifouling

7375 Sigma Alphagen 50 antifouling

7104 Sigma Balamastic

7347 Sigma Biguard coating

7346 Sigma Biguard primer

7466 Sigma CM coating

7465 Sigma CM miocoat

7102 Sigma Emaline 3000

7952 Sigma Glassflake

7467 Sigma Hullrite

7951 Sigma Multiguard

7922 Sigma Multiguard primer

7430 Sigma Multimastic

7435 Sigma Phenguard coating

7436 Sigma Phenguard finish

7409 Sigma Phenguard primer

7285 Sigma Pilot Ecol antifouling

7171 Sigma Proferral MC

7551 Sigma Silguard MC

7568 Sigma Silicate MC

7479 Sigma TCN tiecoat

7472 Sigma TCN 300

7483 Sigma TCN-LT 300

7350 Sigma Topacryl coating

7355 Sigma Topacryl finish

7417 Sigma Universal primer

7424 Sigma Universal primer LT

7318 Sigmachlor primer

7150 Sigmacrylic primer

7250 Sigmacrylic finish

7524 Sigmadur HB finish

7528 Sigmadur gloss

7131 Sigmaferro primer ZP

7953 Sigmaguard BT TP 1095

7921 Sigmaguard BT primer PR 0616

7443 Sigmaguard CSF

7954 Sigmaguard CSF Glassflake

7462 Sigmaguard CSF 7462

7785 Sigmaguard CSF 85

7433 Sigmaguard EHB

7448 Sigmaguard HS

COATINGS

back to previous view

page 5/5

3003 SHIPS SHEET INDEX

March 2000

Sheet nrs. PRODUCT DATA SHEETS

ALPHABETICAL

7455 Sigmaguard Maintenance

7958 Sigmaguard Tankshield LT-V coating

7925 Sigmaguard Tankshield LT-V primer

7473 Sigmaguard Tankshield coating

7400 Sigmaguard Tankshield primer

7297 Sigmaplane Ecol antifouling

7287 Sigmaplane HA antifouling

7284 Sigmaplane HB antifouling

7292 Sigmaplane HC antifouling

7290 Sigmaplane NC antifouling

7282 Sigmaplane TA antifouling

7288 Sigmaplane TC antifouling

7111 Sigmarine Alu primer

7260 Sigmarine Aluminium HR

7261 Sigmarine Aluminium HR 500

7238 Sigmarine BTD

7240 Sigmarine Enamel

7263 Sigmarine Hold paint alu

7190 Sigmarine Holdbrite

7110 Sigmarine Multiprimer

7113 Sigmarine primer RL

7135 Sigmarine primer ZP

7213 Sigmarine undercoat

8215 Sigmatex

8103 Sigmavar gloss

7343 Sigmavinyl primer

7177 Sigmaweld MC

Limitation of Liability - Ihe information in this data sheet is based upon laboratory tests we believe to

be accurate and is intended for guidance only. All recommendations or suggestions relating to the use of the

products made by Sigma Coatings, whether in technical documentation, or in response to a specific enquiry,

or otherwise, are based on data which to the best of our knowledge are reliable. Ihe products and

information are designed for users having the requisite knowledge and industrial skills and it is the end-

user's responsibility to determine the suitability of the product for its intended use.

Sigma Coatings has no control over either the quality or condition of the substrate, or the many factors

affecting the use and application of the product. Sigma Coatings does therefore not accept any liability

arising from loss, injury or damage resulting from such use or the contents of this data sheet (unless there

are written agreements stating otherwise).

Ihe data contained herein are liable to modification as a result of practical experience and continuous

product development.

Ihis data sheet replaces and annuls all previous issues and it is therefore the user's responsibility to ensure

that this sheet is current prior to using the product.

COATINGS

back to previous view

page 1/6

3006 PAINT SYSTEM GUIDE

a six page issue December 1999

revision of 5-1997

This guide indicates which Sigma systems may be used for the protection of the various parts of a vessel.

Sheet numbers in the 3000 range refer to the system data sheets which are found in the green coloured

section of the Sigma Marine Manual.

The various paint specifications as mentioned on a system data sheet are indicated by the figures 1 up to 8.

These specification numbers refer to paint systems that can be used for those parts of a vessel being

mentioned in this guide.

SPECIFICATION NUMBERS FOR:

TYPE OF SYSTEM conven- chlori- vinyl tar epoxy poly- chlori- sili-

COATING SHEET tional nated tar epoxy ure- nated cates

FOR NUMBER rubber thane rubber/

modif.

acrylic

SPEC. SPEC. SPEC. SPEC. SPEC. SPEC. SPEC. SPEC.

BOTTOM AND BOOTTOP

anticorrosive system 3101 8 7 6 1 2,3,4,5

from keel to d.l.l.,

rudder and sea inlet

boxes

antifouling system 3111 1,2 1,2 1,2 1,2

3113 1,2 1,2 1,2 1,2 1,2

3114 1,2,3 1,2,3 1,2 1,2

3117 1,2 1,2 1,2 1,2

3118 1,2,3 1,2,3 1,2 1,2

3120 1,2,3 1,2,3 1,2,3 1,2,3

3121 1 1 1 1

3122 1,2 1,2 1,2 1,2

3125 1,2 1,2 1,2 1,2

3126 1,2 1,2 1,2 1,2

TOPSIDE AND BOOTTOP

from l.l.l. to top of 3102 6 1,2,3,4 1,2,3 5

bulkwarks, forecastle

and poop sides

including hawsepipes

COATINGS

back to previous view

page 2/6

3006 PAINT SYSTEM GUIDE

December 1999

SPECIFICATION NUMBERS FOR:

TYPE OF SYSTEM conven- chlori- vinyl tar epoxy poly- chlori- sili-

COATING SHEET tional nated tar epoxy ure- nated cates

FOR NUMBER rubber thane rubber/

modif.

acrylic

SPEC. SPEC. SPEC. SPEC. SPEC. SPEC. SPEC. SPEC.

WEATHER DECKS

exposed steel decks 3103 4 2,3 2,3 5 1

and house tops

under deck planking 3108 1

SUPERSTRUCTURE

EXTERIORS

exposed accommo- 3104 2 1 1 3,4

dation, deck and

mast houses,

forecastle and poop

bulkheads, hatch

covers and coamings,

bulwarks (inside),

masts, derrick posts

and derricks (outside),

funnel (outside)

DECK FITTINGS

windlass and 3104 2 1 1 3,4

winches, bollards

and fairleads,

ladders and catwalk,

davits, piping,

ventilators, engine

room skylight etc.,

inside masts and

derrick posts,

seatings and

trunking

COATINGS

back to previous view

page 3/6

3006 PAINT SYSTEM GUIDE

December 1999

SPECIFICATION NUMBERS FOR:

TYPE OF SYSTEM conven- chlori- vinyl tar epoxy poly- chlori- sili-

COATING SHEET tional nated tar epoxy ure- nated cates

FOR NUMBER rubber thane rubber/

modif.

acrylic

SPEC. SPEC. SPEC. SPEC. SPEC. SPEC. SPEC. SPEC.

LIFE BOATS

aluminium parts 3108 4 4

steel parts 3103 4 2,3 2,3 5

wooden parts 3103 4

3108 3

ANCHORS, CHAINS, 3108 1

CHAINLOCKERS

MACHINERY SPACES

AND PUMP ROOMS

exposed steel in dry 3105 1 1

and wet spaces

above floor level

steel behind linings 3108 1 2

and insulation

asbestos insulation 3105 4

ACCOMMODATION

AND STORES

exposed steel in

dry spaces 3105 2 1 1 3

wet spaces 3105 1 1 3

steel behind linings 3108 1 2

and insulation

battery locker 3104 3

woodwork 3105 2 1 1

3108 3

COATINGS

back to previous view

page 4/6

3006 PAINT SYSTEM GUIDE

December 1999

SPECIFICATION NUMBERS FOR:

TYPE OF SYSTEM conven- chlori- vinyl tar epoxy poly- chlori- sili-

COATING SHEET tional nated tar epoxy ure- nated cates

FOR NUMBER rubber thane rubber/

modif.

acrylic

SPEC. SPEC. SPEC. SPEC. SPEC. SPEC. SPEC. SPEC.

CARGO HOLDS AND

VOID SPACES

dry cargo hold and 3107 5 1,2,3,4

access trunks

abrasive bulk cargo 3107 1,2

(coal, ore, scrap etc.)

bulk foodstuffs 3107 1,2,3,4

(grain, dry foods,

sugar etc.)

chemical bulk cargo 3107 1,2

(cement, fertilizer,

sulphur etc.)

void spaces, 3108 1 2

cofferdams,

duct keel

refrig. holds,

steel 3108 4 4

wood 3105 2 1 1

floodable hold 3106 4

3107 1,2,3,4

DOUBLE BOTTOM 3106 4 1,2,3

TANKS

ballast water and 3106 4 1,2,3

fresh water

polluted water 3106 6,7

hot water 3141 1

COATINGS

back to previous view

page 5/6

3006 PAINT SYSTEM GUIDE

December 1999

SPECIFICATION NUMBERS FOR:

TYPE OF SYSTEM conven- chlori- vinyl tar epoxy poly- chlori- sili-

COATING SHEET tional nated tar epoxy ure- nated cates

FOR NUMBER rubber thane rubber/

modif.

acrylic

SPEC. SPEC. SPEC. SPEC. SPEC. SPEC. SPEC. SPEC.

drinking water 3325 1

animal-, fish-, and 3320 1

vegetable oils 3322 1

3323 1

3328 1

chemicals 3320 1

3322 1

3328 1

extended white 3320 1

products 3323 1

3328 1

white aliphatic 3320 1

products 3323 1

3328 1

solvents 3322 1

3323 1

wine 3322 1

bilges, drain wells 3106 4 1,2,3

GALVANIZED STEEL

AND NON FERROUS

METALS

superstructure, 3108 4 4

mast, hand rail,

ladder, stanchion,

etc.

COATINGS

back to previous view

page 6/6

3006 PAINT SYSTEM GUIDE

December 1999

SPECIFICATION NUMBERS FOR:

TYPE OF SYSTEM conven- chlori- vinyl tar epoxy poly- chlori- sili-

COATING SHEET tional nated tar epoxy ure- nated cates

FOR NUMBER rubber thane rubber/

modif.

acrylic

SPEC. SPEC. SPEC. SPEC. SPEC. SPEC. SPEC. SPEC.

WOODWORK

furniture, door, 3103 4

hand rail and 3108 3

wooden deck, etc.

HEAT RESISTANT 3140 1,3 2

SYSTEMS

Limitation of Liability - Ihe information in this data sheet is based upon laboratory tests we believe to

be accurate and is intended for guidance only. All recommendations or suggestions relating to the use of the

products made by Sigma Coatings, whether in technical documentation, or in response to a specific enquiry,

or otherwise, are based on data which to the best of our knowledge are reliable. Ihe products and

information are designed for users having the requisite knowledge and industrial skills and it is the end-

user's responsibility to determine the suitability of the product for its intended use.

Sigma Coatings has no control over either the quality or condition of the substrate, or the many factors

affecting the use and application of the product. Sigma Coatings does therefore not accept any liability

arising from loss, injury or damage resulting from such use or the contents of this data sheet (unless there

are written agreements stating otherwise).

Ihe data contained herein are liable to modification as a result of practical experience and continuous

product development.

Ihis data sheet replaces and annuls all previous issues and it is therefore the user's responsibility to ensure

that this sheet is current prior to using the product.

COATINGS

back to previous view

* The chromium content of these primers may be detrimental to the health of operatives

and Sigma Coatings has therefore discontinued the use of these products.

page 1/4

3015 PREFABRICATION PRIMERS

a four page issue November 1999

revision of 5-1997

GENERIC TYPES

The most commonly encountered prefabrication primers are:

Reinforced polyvinyl butyral (PVB) prefabrication primers.*

These have satisfactory application, welding and handling properties, but have a lower anticorrosive

performance, especially as part of a system for immersed areas in conjunction with cathodic protection.

Zinc epoxy prefabrication primers.

These have good anticorrosive properties and acceptable cutting and welding properties.

Red oxide epoxy prefabrication primers.

These have good weatherability, reasonable cutting and welding properties, but show a moderate thermal

stability and poor resistance to seawater exposure with cathodic protection.

Zinc silicate prefabrication primers. (Sigma Proferral MC)

These have excellent heat resistance and weatherability and acceptable cutting and welding properties.

Reduced zinc silicate prefabrication primers. (Sigmaweld MC)

These have excellent cutting and welding properties, especially in MIG/MAG welding techniques, excellent

heat resistance and good weatherability.

WELDING

The welding techniques generally used, are:

Manual Metal Arc welding (MMA)

Gravity welding

Submerged Arc welding (SAW)

Metal Inert Gas / Metal Active Gas welding (MIG/MAG)

It is known that automatic welding confers considerable economic advantages to construction yards and the

MIG/MAG technique in particular has become economically attractive because it can also be used on thin

plate without too much distortion.

These welding techniques are characterized by the following properties.

MMA Gravity Welding SAW MIG/MAG

Welding position all horizontal horizontal all

Automatisation minor yes common yes

Deposition rate low high high medium

Heat distortion medium high high low

Cost indication high medium low medium

COATINGS

back to previous view

page 2/4

3015 PREFABRICATION PRIMERS

November 1999

The weldability of a prefabrication primer is generally described by the tendency of the primer to produce

little or no porosity in a weld.

During welding, the type of primer will influence spatter formation, especially in case of MIG/MAG welding.

Generic type MMA/gravity

Prefabrication primer all positions

MIG/MAG SAW

1G 2F 3F 1G 2F

Red oxide epoxy +

(P) P P (P) P

Epoxy-zinc + +

(P) P P P

Zinc silicate + + +

Sigma Proferral MC (S, P) S, P (P)

reduced zinc silicate + + + + + +

Sigmaweld MC

1G = Butt welding

2F = Horizontal (automatic) welding of T-joint

3F = Vertical downward welding of T-joints

P = Porosity

S = Spatter

+ = Excellent

= Possible defects, between brackets the type of defect

= Defects

THERMAL STABILITY

The thermal stability of a prefabrication primer depends on its composition.

Because of its inorganic nature, the behaviour of silicate primers is, in this respect, excellent.

During cutting and welding, silicate primers, like Sigmaweld MC and Sigma Proferral MC,

can withstand temperatures up to 1000C for short periods.

This high level of thermal stability has several practical advantages

cutting and welding damage is minimised

fumes created by hot work procedures will be reduced

the amount of weld spatter will be reduced

weld spatter will not adhere to the primed steel

By comparison organic prefabrication primers can only resist temperatures up to 500C for short periods.

COATINGS

back to previous view

page 3/4

3015 PREFABRICATION PRIMERS

November 1999

HEALTH AND SAFETY

Fumes are inevitably generated during welding and cutting due to combustion of primer material.

The amount and composition of such fumes depends on the raw materials from which the prefabrication

primer has been made.

Fume extracting equipment should be used in case primed steel has to be welded or cut in confined spaces.

All Sigma Coatings prefabrication primers are checked by the North of England Industrial Health Service and

fulfil Occupational Exposure Limits requirements (see information sheet Health certificates for prefabrication

primers 1881).

WEATHERABILITY

The weatherability of a primer is a function of the quality of surface preparation, film thickness applied, type

of environment to which the plates and/or sections are stored and degree of damage to which they are

subjected during this period.

In general zinc dust primers will perform better during atmospheric exposure than primers formulated with a

minimum amount of zinc or containing no zinc at all.

Primers with a high zinc content can therefore be applied at lower dry film thicknesses.

General indication of weathering properties of Sigma Coatings prefabrication primers:

dft average weathering period

Sigmaweld MC 22 m 6 months

Sigma Proferral MC 15 m 9 months

SECONDARY SURFACE PREPARATION

In order to ensure satisfactory adhesion of the subsequently applied system, prefabrication primed sections

have to undergo some degree of secondary surface preparation prior to system application.

The degree and type of secondary surface preparation required before application of the full coating system

depends on:

the resistance to exterior exposure of the prefabrication primer

the service conditions of the subsequently applied system

the prevailing shop regulations

At the very least, this involves removal of dirt, dust and debris; but other problems will be associated with

handling damage, weldseams, burn damage or excessively weathered plate.

Generally, weldseam areas and corroded or burned areas will require thorough blast cleaning or mechanical

cleaning. Zinc salts should be removed by sweepblasting or by abrading mechanically using silicon carbide

impregnated abrasive pads (SCAP).

COATINGS

back to previous view

page 4/4

3015 PREFABRICATION PRIMERS

November 1999

A total lack of surface preparation, an insufficient degree thereof or an inappropriate service situation can all

lead to rather serious consequences for the coating system on heat affected zones, weldseam areas and

contaminated, corroded or damaged areas.

RECOATABILITY

Beside the function to protect shot blast cleaned steel during storage and construction, a prefabrication

primer is often also the first coat of anticorrosive paint systems. Proper organisation of all shop activities,

taking into consideration all specific properties of the prefabrication primer involved, will lead to the

avoidance of extensive surface preparation before overcoating.

Epoxy prefabrication primers in sound condition may be used in coating systems which are resistant to

seawater exposure without cathodic protection.

In practice, however, these kinds of prefabrication primers are often heavily damaged by heat or

mechanical influences. This means that extra attention should be paid to the pretreatment of these

damaged areas when the steel structure has to be exposed to immersion in (sea) water. Experience

shows that blast cleaning to ISO-Sa2 is the most effective pretreatment method for these areas and

exposure conditions.

Zinc containing prefabrication primers may show the formation of zinc salts during weathering, depending

on exposure conditions and time. The formation of zinc salts can be avoided by overcoating the

prefabrication primer before the structure leaves the shop. If this is not possible, a second surface

preparation should take place especially after long weathering periods.

The presence of a prefabrication primer in tankcoating systems is generally not accepted because the

chemical resistance of the tankcoating system will be diminished.

REFERENCES

Sigma Proferral MC see product data sheet 7171

Sigmaweld MC see product data sheet 7177

Quality control for prefabrication primer application see information sheet 1701

Limitation of Liability - Ihe information in this data sheet is based upon laboratory tests we believe to

be accurate and is intended for guidance only. All recommendations or suggestions relating to the use of the

products made by Sigma Coatings, whether in technical documentation, or in response to a specific enquiry,

or otherwise, are based on data which to the best of our knowledge are reliable. Ihe products and

information are designed for users having the requisite knowledge and industrial skills and it is the end-

user's responsibility to determine the suitability of the product for its intended use.

Sigma Coatings has no control over either the quality or condition of the substrate, or the many factors

affecting the use and application of the product. Sigma Coatings does therefore not accept any liability

arising from loss, injury or damage resulting from such use or the contents of this data sheet (unless there

are written agreements stating otherwise).

Ihe data contained herein are liable to modification as a result of practical experience and continuous

product development.

Ihis data sheet replaces and annuls all previous issues and it is therefore the user's responsibility to ensure

that this sheet is current prior to using the product.

COATINGS

back to previous view

page 1/3

SHIPS

3100 GENERAL ASPECTS ANTICORROSIVE PAINTS

a three page issue December 1999

revision of 5-1997

INTRODUCTION

The importance of anticorrosive underwater hull coatings systems is not restricted to the avoidance of steel

loss only. The coating system is also responsible for smooth hulls by preventing the development of

roughness due to corrosion and/or fouling. Smooth hulls have a direct bearing on fuel consumption and other

economic factors in the operation of a vessel.

Antifouling performance and service time is highly dependent upon the performance of the anticorrosive

system. Bare steel exposed by broken blisters and/or flaking will foul while the presence of these defects

will obviously increase surface roughness. Therefore, it is true to say THE ANTIFOULING IS ONLY AS GOOD

AS THE ANTICORROSIVE UNDERNEATH.

SURFACE PRETREATMENT

Correct steel preparation is of the utmost importance to the performance and service lifetime of an

anticorrosive hull system. Presence of rust will always cause defects of the coating system when immersed

in water.

The shop primer type and condition of the shop primed steel, particularly the degree of corrosion and the

breakdown of the shop primer, will determine the performance of the system. An approved shop primer (zinc

silicate) is the best and here good performance will be obtained by the appropriate/described cleaning

methodes. The presence of shop primer other than a zinc silicate may require complete removal by abrasive

blasting in order to ensure good performance.

PAINT SELECTION

Most bottom systems used are of the bituminous, chlorinated rubber, vinyl or epoxy type. In the light of

modern advanced coating technology the bituminous paints have become less important. Their performance

and recoatability with new classes of antifoulings is no longer up to the standard acceptable in the present

day.

Bituminous, chlorinated rubber, and vinyltar coatings are physically drying types and for proper drying,

reasonable temperatures as well as ventilation and air movement are necessary. Although temperatures as

low as -10C are possible, at excessively low temperatures combined with short drying times and/or high

dfts these coatings tend to retain solvents which can result in blistering and early breakdown of the coating

system.

While the introduction of tar in epoxy coatings gives a cost saving, this is not the most important feature

since the tar, as an essential part of the binder improves the water resistance. It's good wetting properties

not only provide good adhesion but also increase the tolerance to marginal surface pretreatment.

However, there is now a trend away from the use of tar and tar containing products as tar is fast becoming

environmentally unacceptable with straight epoxies and modified epoxies are increasingly being used.

Without tar it is possible to increase specific properties of straight and modified epoxies such as abrasion

and impact resistance thus significantly improving performance, particularly in specialist areas.

COATINGS

back to previous view

page 2/3

SHIPS

3100 GENERAL ASPECTS ANTICORROSIVE PAINTS

December 1999

Epoxies are chemically reacting coatings, they need polyamide or polyamine hardeners to effect cure. To

obtain the properties as indicated by the paint manufacturer, epoxy coatings require a certain temperature to

cure.

Highly advanced epoxies need temperatures around 5C to obtain adequate curing rate and to reach final

cure, although application can be carried out down to 5C. To overcome the difficulties of application and

curing at low temperatures special low temperature versions of various epoxy products are available.

The straight and modified epoxies are usually of the high solid type and contain less solvents and will meet

the latest regulations regarding volatile organic compounds (voc). The advantage of high solid coatings is

expressed by their comparatively lower price per square metre compared to low solid materials when

applied at the same dry film thickness.

PERFORMANCE

The performance as well as the practical service of any anticorrosive system is directly related to the dry film

thickness applied. It is therefore not economical, to choose critical low dry film thicknesses, since costs of

application constitute a substantial part of the total investment in the coating operation. However application

of excessively high film thicknesses of solvent containing paints, particularly in single coat application is also

not advisable as it can lead to solvent retention and subsequent coating failure and should therefore also be

avoided. The generic type of coating binder will also influence the actual service lifetime of the underwater

hull systems. This refers to principal properties such as degree of (sea)water absorption and to the

resistance to the cathodic protection system. When in these respects the various coatings are evaluated,

epoxies give the best results followed by vinyl tar and chlorinated rubber coatings.

The term service lifetime of coating systems requires some clarification: service lifetime has been defined

as period of time until first maintenance painting is necessary. This is indicated by the condition of the

coating system before reaching rust grade or blistering grade representing approximately 3% breakdown of

the coating film.

CATHODIC PROTECTION

With normal and correctly controlled cathodic protection, all coating types will perform well but with

overprotection differences will be evident and early breakdown of the coating system especially at low film

thickness areas can occur.

It is for this reason that it is recommended to apply protective shields around the anodes of impressed

current systems.

Sacrificial zinc anodes produce potential differences related to the Ag/AgCl electrode of approx. minus 1050

mV. As the resistance of bituminous aluminium coating and chlorinated rubber coating lie in the region of

this figure it is therefore recommended to apply a protective shield around the anodes when a vessel with

these coating systems is fitted with zinc anodes. For this purpose a heavy coat of coaltar epoxy coating at

approx 300-400 microns dft can be used as a protective shield.

COATINGS

back to previous view

page 3/3

SHIPS

3100 GENERAL ASPECTS ANTICORROSIVE PAINTS

December 1999

PRINCIPAL AREAS OF PROTECTION

From this introduction and the general aspects of protection of ships it becomes clear that a number of areas

can be distinguished with various degrees of corrosion severity. The most important areas are:

Underwater and boottop

Boottop and topside

Decks

Superstructure and deckfittings

Interior

Ballast and freshwater tanks

Cargoholds

REFERENCES

Anticorrosive systems for underwater and boottop

to be finished with antifoulings see system sheet 3101

Systems for boottop and topside see system sheet 3102

Systems for decks see system sheet 3103

Systems for superstructure and deckfittings see system sheet 3104

Systems for interior(s) see system sheet 3105

Systems for ballast and freshwater tanks see system sheet 3106

Systems for cargoholds see system sheet 3107

Miscellaneous systems see system sheet 3108

Limitation of Liability - Ihe information in this data sheet is based upon laboratory tests we believe to

be accurate and is intended for guidance only. All recommendations or suggestions relating to the use of the

products made by Sigma Coatings, whether in technical documentation, or in response to a specific enquiry,

or otherwise, are based on data which to the best of our knowledge are reliable. Ihe products and

information are designed for users having the requisite knowledge and industrial skills and it is the end-

user's responsibility to determine the suitability of the product for its intended use.

Sigma Coatings has no control over either the quality or condition of the substrate, or the many factors

affecting the use and application of the product. Sigma Coatings does therefore not accept any liability

arising from loss, injury or damage resulting from such use or the contents of this data sheet (unless there

are written agreements stating otherwise).

Ihe data contained herein are liable to modification as a result of practical experience and continuous

product development.

Ihis data sheet replaces and annuls all previous issues and it is therefore the user's responsibility to ensure

that this sheet is current prior to using the product.

COATINGS

back to previous view

page 1/6

3101

ANTICORROSIVE SYSTEMS FOR UNDERWATER AND BOOTTOP -

TO BE OVERCOATED WITH ANTIFOULINGS

a six page issue

revision of 5-1997

Contains following specifications:

Specification 1: coaltar epoxy coating system

Specification 2: high solid tar free epoxy coating system

Specification 3: high solid tar free epoxy coating system

Specification 4: high solid epoxy mastic coating system

Specification 5: high solid glassflake reinforced epoxy coating system

Specification 6: vinyl tar coating system

Specification 7: chlorinated rubber coating system

Specification 8: bituminous aluminium coating system

SURFACE PRETREATMENT

The quality of the surface pretreatment affects the performance of underwater and boottop systems,

particularly when cathodic protection is applied. Best results will only be obtained on substrates blast

cleaned to ISO-Sa2 which means that the shop primer should be removed. This is particularly important

when (underfilm) corrosion has already started. Also the right blasting profile will be obtained.

ACCEPTANCE OF SHOP PRIMER

The quality and generic type of shop primer, will determine the performance of the coating system.

The types of shop primer acceptable, are those which are approved by Sigma Coatings and equivalent to the

following products:

Sigma Proferral MC and Sigmaweld MC - zinc silicate.

In addition, any degradation or underfilm corrosion of the shop primer will limit the performance of the total

system, unless correctly treated.

These remarks are of particular importance when cathodic protection is installed.

The general condition of the weathered shop primer may vary widely throughout the structure and in many

instances it is difficult to assess the severity of breakdown.

Experience shows that in practice reblasting of corroded shop primed steel to ISO-Sa2 is the most

satisfactory method of correcting corrosion defects and eliminating the detrimental effect of surface

contamination.

Approved shop primers in good condition should be cleaned to remove contamination and/or zinc salts.

If necessary sweep blasting according to SPSS/Ss or mechanical cleaning according to SPSS-Pt3 should be

carried out.

Special attention should be paid to heat damaged areas, including areas alongside weldseams and

backburns.

SHIPS

COATINGS

back to previous view

page 2/6

SHIPS

3101

ANTICORROSIVE SYSTEMS FOR UNDERWATER AND BOOTTOP -

TO BE OVERCOATED WITH ANTIFOULINGS

November 1999

SPECIFICATION 1 coaltar epoxy system for UNDERWATER and BOOTTOP with good

resistance to mechanical impact, abrasion and well designed cathodic

protection

pretreatment steel; blast cleaned to ISO-Sa2

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss,

weld seams, burned and rusty areas blast cleaned to ISO-Sa2 or

powertool cleaned to SPSS-Pt3

|f a holding primer is required Sigma Universal primer can be used

(dft of 50 m)

steel; hydrojetted to VIS WJ2 L (for more info see sheet 1498)

paint system Sigma TCN 300 brown 125 m

Sigma TCN tiecoat 125 m

antifouling as specified

maintenance should preferably be carried out to this specification

SPECIFICATION 2 high solid tar free epoxy system for UNDERWATER and BOOTTOP with

good resistance to mechanical impact, abrasion and well designed

cathodic protection

pretreatment steel; blast cleaned to ISO-Sa2

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss,

weld seams, burned and rusty areas blast cleaned to ISO-Sa2 or

powertool cleaned to SPSS-Pt3

steel; hydrojetted to VIS WJ2 L (for more info see sheet 1498)

paint system Sigma Multiguard primer 125 m

Sigma Hullrite 125 m

maintenance should preferably be carried out to this specification

SHIPS

COATINGS

back to previous view

page 3/6

SHIPS

3101

ANTICORROSIVE SYSTEMS FOR UNDERWATER AND BOOTTOP -

TO BE OVERCOATED WITH ANTIFOULINGS

November 1999

SPECIFICATION 3 high solid tar free epoxy system for UNDERWATER and BOOTTOP with

excellent resistance to mechanical impact, abrasion and well designed

cathodic protection

pretreatment steel; blast cleaned to ISO-Sa2

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss,

weld seams, burned and rusty areas blast cleaned to ISO-Sa2 or

powertool cleaned to SPSS-Pt3

steel; hydrojetted to VIS WJ2 L (for more info see sheet 1498)

paint system Sigma Multiguard primer 100 m

Sigma Multiguard 150 m

Sigma Hullrite 75 m

antifouling as specified

maintenance should preferably be carried out to this specification

note If a holding primer is required, Sigma Multiguard primer can be replaced

by Sigma Universal primer at 50 m, followed by Sigma Multiguard in a dft

of 200 m

SPECIFICATION 4 high solid, epoxy mastic coating system for maintenance of

UNDERWATER and BOOTTOP with good resistance to mechanical

impact and well designed cathodic protection

pretreatment steel; blast cleaned to ISO-Sa2, blasting profile (R

z

) 40-70 m

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss,

or powertool cleaned to SPSS-Pt3

for maintenance abrasive blasting to ISO-Sa2 or hydrojetted to VIS WJ2 L

(for more info see sheet 1498)

paint system Sigma Multimastic aluminium 125 m

Sigma Hullrite 125 m

maintenance should preferably be carried according to this specification

SHIPS

COATINGS

back to previous view

page 4/6

SHIPS

3101

ANTICORROSIVE SYSTEMS FOR UNDERWATER AND BOOTTOP -

TO BE OVERCOATED WITH ANTIFOULINGS

November 1999

SPECIFICATION 5 high solid, glassflake reinforced epoxy system on top of in situ applied

epoxy primer for UNDERWATER and BOOTTOP with good resistance to

heavy impact (fender areas - ice going vessels) and well designed

cathodic protection

pretreatment steel; blast cleaned to ISO-Sa2, blasting profile (R

z

) 50-100 m

paint system Sigma Multiguard primer 100 m

Sigma Glassflake 400 m

Sigma Hullrite 75 m

antifouling as specified

maintenance should preferably be carried out to the original specification

note if a holding primer is required, Sigma Multiguard primer can be replaced

by Sigma Universal primer in a dft of 50 m

SPECIFICATION 6 vinyl tar system for UNDERWATER and BOOTTOP with good resistance to

well designed cathodic protection

pretreatment steel; blast cleaned to ISO-Sa2

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss,

weld seams, burned and rusty areas blast cleaned to ISO-Sa2 or

powertool cleaned to SPSS-Pt3

paint system Sigmavinyl primer light 75 m

Sigmavinyl primer dark 75 m

Sigmavinyl primer light 75 m

antifouling as specified

maintenance should be carried out with Sigmavinyl primer

SPECIFICATION 7 chlorinated rubber system on top of an in situ applied epoxy primer for

UNDERWATER and BOOTTOP with good resistance to well designed

cathodic protection

pretreatment steel; blast cleaned to ISO-Sa2

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss,

weld seams, burned and rusty areas blast cleaned to ISO-Sa2 or

powertool cleaned to SPSS-Pt3

paint system Sigmachlor primer light 75 m

Sigmachlor primer dark 75 m

Sigmachlor primer light 75 m

antifouling as specified

maintenance should be carried out with Sigmachlor primer

SHIPS

COATINGS

back to previous view

page 5/6

SHIPS

3101

ANTICORROSIVE SYSTEMS FOR UNDERWATER AND BOOTTOP -

TO BE OVERCOATED WITH ANTIFOULINGS

November 1999

SPECIFICATION 8 bituminous aluminium system suitable for UNDERWATER and BOOTTOP

with fair resistance to well designed cathodic protection

pretreatment steel; blast cleaned to ISO-Sa2

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss,

weld seams, burned and rusty areas blast cleaned to ISO-Sa2 or

powertool cleaned to SPSS-Pt3

paint system Sigmarine alu primer light 75 m

Sigmarine alu primer dark 75 m

antifouling as specified

maintenance should be carried out with Sigmarine alu primer

MAINTENANCE

As in normal docking practice, fouling, loose paint and other contaminants should be removed by high

pressure water cleaning (HPWC). Any fouling and/or loose paint remaining after HPWC must be removed by

scraping or sweep blasting. The removal of an oil or grease belt can be achieved by scraping heavy deposits

from the surface followed by HPWC in combination with the use of suitable detergents. This should be

followed by a thorough fresh water wash and drying prior to blasting and/or repainting. It might, however, be

necessary to blast clean such areas after this operation when oil has penetrated the underlying paint

systems. Rusty spots should be pretreated by blast cleaning and touched up with the original anticorrosive

system within the requirements given in the relevant specifications.

CATHODIC PROTECTION

Sacrificial zinc anodes produce potential differences related to the Ag/AgCl electrode of approx.

minus 1050 mV. As the resistance of bituminous aluminium coating and chlorinated rubber coating lie in the

region of this figure it is therefore recommended to apply a protective shield around the anodes when a

vessel with a these coating systems is fitted with zinc anodes. For this purpose a heavy coat of coaltar epoxy

coating at approx. 300-400 microns dft can be used as a protective shield.

SHIPS

COATINGS

back to previous view

page 6/6

SHIPS

3101

ANTICORROSIVE SYSTEMS FOR UNDERWATER AND BOOTTOP -

TO BE OVERCOATED WITH ANTIFOULINGS

November 1999

REFERENCES

Sigma Glassflake see product data sheet 7952

Sigma Hullrite see product data sheet 7467

Sigma Multiguard see product data sheet 7951

Sigma Multiguard primer see product data sheet 7922

Sigma Multimastic see product data sheet 7430

Sigma Proferral MC see product data sheet 7171

Sigma TCN tiecoat see product data sheet 7479

Sigma TCN 300 see product data sheet 7472

Sigma Universal primer see product data sheet 7417

Sigmachlor primer see product data sheet 7318

Sigmarine alu primer see product data sheet 7111

Sigmavinyl primer see product data sheet 7343

Sigmaweld MC see product data sheet 7177

Cleaning of steel and removal of rust see information sheet 1490

Hydrojetting see information sheet 1498

Prefabrication primers see system sheet 3015

Limitation of Liability - Ihe information in this data sheet is based upon laboratory tests we believe to

be accurate and is intended for guidance only. All recommendations or suggestions relating to the use of the

products made by Sigma Coatings, whether in technical documentation, or in response to a specific enquiry,

or otherwise, are based on data which to the best of our knowledge are reliable. Ihe products and

information are designed for users having the requisite knowledge and industrial skills and it is the end-

user's responsibility to determine the suitability of the product for its intended use.

Sigma Coatings has no control over either the quality or condition of the substrate, or the many factors

affecting the use and application of the product. Sigma Coatings does therefore not accept any liability

arising from loss, injury or damage resulting from such use or the contents of this data sheet (unless there

are written agreements stating otherwise).

Ihe data contained herein are liable to modification as a result of practical experience and continuous

product development.

Ihis data sheet replaces and annuls all previous issues and it is therefore the user's responsibility to ensure

that this sheet is current prior to using the product.

SHIPS

COATINGS

back to previous view

page 1/5

SHIPS

3102 SYSTEMS FOR BOOTTOP AND TOPSIDE

a five page issue December 1999

revision of 5-1997

Contains following specifications:

Specification 1: high solid epoxy coating linked with 3101-spec. 1, 2 or 3

Specification 2: recoatable epoxy coating system linked with 3101-spec. 1, 2 or 3

Specification 3: high solid epoxy mastic coating system linked with 3101-spec. 1, 2, 3 or 4

Specification 4: glassflake epoxy coating system linked with 3101-spec. 1, 2, 3 or 5

Specification 5: chlorinated rubber/modified acrylic coating system linked with 3101-spec. 6 or 7

Specification 6: bituminous aluminium/alkyd coating system linked with 3101-spec. 8

SURFACE PRETREATMENT

The quality of the surface pretreatment affects the performance of boottop and topside systems, particularly

when for the boottop area cathodic protection is applied. Best results are only obtained on substrates blast

cleaned to ISO-Sa2, which means that up to the deep loadline the shop primer should be removed. This is

particularly important when (underfilm) corrosion has already started. Also the right blasting profile will be

obtained.

ACCEPTANCE OF SHOP PRIMER

The quality and generic type of shop primer, will determine the performance of the coating system. The

types of shop primer acceptable, are those which are equivalent to the Sigma qualities:

Sigma Proferral MC and Sigmaweld MC - zinc silicate.

In addition, the condition of the shop primer with regard to degradation and underfilm corrosion will

determine the performance of the total system.

These remarks are of particular importance when cathodic protection is installed.

The general condition of the weathered shop primer may vary widely throughout the structure and in many

instances it is difficult to assess the severity of breakdown.

Experience shows that reblasting of corroded shop primed steel to ISO-Sa2 is the most satisfactory

method of correcting corrosion defects and eliminating the detrimental effect of surface contamination.

Approved shop primers in good condition should be cleaned to remove contamination and/or zinc salts. If

necessary sweep blasting according to SPSS-Ss or mechanical cleaning according to SPSS-Pt3 should be

carried out.

Special attention should be taken for heat damaged areas, including areas alongside weldseams and

backburns.

SHIPS

COATINGS

back to previous view

page 2/5

SHIPS

3102 SYSTEMS FOR BOOTTOP AND TOPSIDE

December 1999

SPECIFICATION 1 high solid epoxy system for BOOTTOP and TOPSIDE with excellent

resistance to mechanical impact, and abrasion

system linked with 3101-spec. 1, 2 or 3

pretreatment steel; blast cleaned to ISO-Sa2

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss,

or power tool cleaned to SPSS-Pt3

steel; hydrojetted to VIS WJ2/3 L (for more info see sheet 1498)

paint system Sigma Multiguard primer 100 m

Sigma Multiguard 150 m

Sigma CM coating 75 m

notes if gloss is required, an extra coat of Sigmadur gloss (dft of 50 m)

should be applied

if a holding primer is required, Sigma Multiguard primer can be

replaced by Sigma Universal primer in a dft of 50 m followed

by Sigma Multiguard in a dft of 200 m

maintenance should preferably be carried out to this specification

SPECIFICATION 2 recoatable epoxy system for BOOTTOP and TOPSIDE with good resistance

to mechanical impact and abrasion

system linked with 3101-spec. 1, 2 or 3

pretreatment steel; blast cleaned to ISO-Sa2

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss

or powertool cleaned to SPSS-Pt3

steel; hydrojetted to VIS WJ2/3 L (for more info see sheet 1498)

paint system Sigma Universal primer 50 m

Sigma CM miocoat 100 m

Sigma CM coating 100 m

note if gloss is required, an extra coat of Sigmadur gloss (dft of 50 m) should

be applied

maintenance should preferably be carried out to this specification both Sigma CM

miocoat and Sigma CM coating have good overcoating and good curing

characteristics also below 0C, which simplifies maintenance

SHIPS

COATINGS

back to previous view

page 3/5

SHIPS

3102 SYSTEMS FOR BOOTTOP AND TOPSIDE

December 1999

SPECIFICATION 3 high solid, epoxy mastic coating system for maintenance of BOOTTOP

and TOPSIDE with good resistance to mechanical impact

pretreatment steel; blast cleaned to ISO-Sa2, blasting profile (R

z

) 40-70 m

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss,

or powertool cleaned to SPSS-Pt3

for maintenance abrasive blasting to ISO-Sa2 or hydrojetted to VIS WJ2 L

(for more info see sheet 1498)

paint system Sigma Multimastic aluminium 125 m

Sigma Multimastic 125 m

note if gloss is required, an extra coat of Sigmadur gloss (dft of 50 m) should

be applied

maintenance should preferably be carried according to this specification

SPECIFICATION 4 high solid, glassflake reinforced epoxy system on top of in situ applied

epoxy primer for BOOTTOP (and topside), with good resistance to heavy

impact (fender areas - ice going vessels)

can be finished with a recoatable epoxy coating

system linked with 3101-spec. 1, 2, 3 or 4

pretreatment steel; blast cleaned to ISO-Sa2,

blasting profile (R

z

) 50-100 m

paint system Sigma Multiguard primer 100 m

Sigma Glassflake 400 m

notes if a recoatable epoxy coating is required as top coat, Sigma CM coating

in a dft of 75 m can be applied on top of Sigma Glassflake

if a holding primer is required, Sigma Multiguard primer can be

replaced by Sigma Universal primer in a dft of 50 m

maintenance should be carried out to this specification

SHIPS

COATINGS

back to previous view

page 4/5

SHIPS

3102 SYSTEMS FOR BOOTTOP AND TOPSIDE

December 1999

SPECIFICATION 5 chlorinated rubber/modified acrylic system for BOOTTOP and TOPSIDE

system linked with 3101-spec. 5 or 6

pretreatment steel; blast cleaned to ISO-Sa2

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss

or power tool cleaned to SPSS-Pt3

paint system Sigmachlor primer 75 m

Sigma Topacryl coating 100 m

Sigma Topacryl finish 35 m

maintenance should preferably be carried out to this specification.

the Topacryl range have good overcoating and good drying characteristics

also below 0C, which simplifies maintenance

SPECIFICATION 6 bituminous aluminium/alkyd system for BOOTTOP (and topside), colours

black, redbrown or green (4199)

system linked with 3101-spec. 7

pretreatment steel; blast cleaned to ISO-Sa2

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss

or power tool cleaned to SPSS-Pt3

paint system Sigmarine alu primer light 75 m

Sigmarine alu primer dark 75 m

Sigmarine BTD 35 m

Sigmarine BTD 35 m

maintenance should be carried out to this specification

MAINTENANCE

As in normal docking practice, fouling, flaking paint and salt deposits must be removed by high pressure

water cleaning. The removal of an oil or grease belt can be achieved by scraping heavy deposits from the

surface followed by high pressure water cleaning in combination with the use of suitable detergents.

This should be followed by a thorough fresh water wash and drying prior to blasting and/or repainting.

It might, however, be necessary to blast clean such areas after this operation when oil has penetrated the

underlying paint systems. Rusty spots should be pretreated by blast cleaning and touched up with the

original system, or with Sigma Universal primer, followed by build and topcoat within the requirements given

in the relevant specifications.

SHIPS

COATINGS

back to previous view

page 5/5

SHIPS

3102 SYSTEMS FOR BOOTTOP AND TOPSIDE

December 1999

REFERENCES

Sigma CM coating see product data sheet 7466

Sigma CM miocoat see product data sheet 7465

Sigma Glassflake see product data sheet 7952

Sigma Multiguard see product data sheet 7951

Sigma Multiguard primer see product data sheet 7922

Sigma Multimastic see product data sheet 7430

Sigma Proferral MC see product data sheet 7171

Sigma Topacryl coating see product data sheet 7350

Sigma Topacryl finish see product data sheet 7355

Sigma Universal primer see product data sheet 7417

Sigmachlor primer see product data sheet 7318

Sigmadur gloss see product data sheet 7528

Sigmarine alu primer see product data sheet 7111

Sigmarine BTD see product data sheet 7238

Sigmaweld MC see product data sheet 7177

Cleaning of steel and removal of rust see information sheet 1490

Hydrojetting see information sheet 1498

Prefabrication primers see system sheet 3015

Limitation of Liability - Ihe information in this data sheet is based upon laboratory tests we believe to

be accurate and is intended for guidance only. All recommendations or suggestions relating to the use of the

products made by Sigma Coatings, whether in technical documentation, or in response to a specific enquiry,

or otherwise, are based on data which to the best of our knowledge are reliable. Ihe products and

information are designed for users having the requisite knowledge and industrial skills and it is the end-

user's responsibility to determine the suitability of the product for its intended use.

Sigma Coatings has no control over either the quality or condition of the substrate, or the many factors

affecting the use and application of the product. Sigma Coatings does therefore not accept any liability

arising from loss, injury or damage resulting from such use or the contents of this data sheet (unless there

are written agreements stating otherwise).

Ihe data contained herein are liable to modification as a result of practical experience and continuous

product development.

Ihis data sheet replaces and annuls all previous issues and it is therefore the user's responsibility to ensure

that this sheet is current prior to using the product.

SHIPS

COATINGS

back to previous view

page 1/5

SHIPS

3103 SYSTEMS FOR DECKS

a five page issue December 1999

revision of 5-1997

Application areas: all decks on ships, interior and exterior.

Contains following specifications:

Specification 1: zinc silicate coating system

Specification 2: high build epoxy coating system

Specification 3: epoxy coating system

Specification 4: alkyd coating system

Specification 5: chlorinated rubber/modified acrylic coating system

GENERAL ASPECTS

Decks on ships are constantly exposed to the environment (UV in sunlight, rain, wind) and periodically awash

with seawater. They are subject to occasionally heavy foot and mechanical traffic and sometimes chemical

spillage. Their aesthetic properties are always important, but they also have a strong protective element

(both anticorrosive and safety).

The main requirements for such coating systems are:

good anticorrosive properties

excellent adhesion

flexibility

good impact resistance

resistance against spillage of hydrocarbons, aromatics, chemicals and detergents

easy to maintain

non slippery

Non-skid properties can be obtained by adding 10% by weight of a special silica (such as Minigrain No. IV),

or fine coconut shells to the last coat of a paint system. In case of contamination with oil or lubricants a very

coarse material like Minigrain No. 1 can be used to further enhance non-skid properties. In this case an extra

coat is necessary to ensure adhesion of the embedded anti-skid material and the dft of the total system

should be increased in order to give the correct anticorrosive protection.

SURFACE PRETREATMENT

Best results are obtained on ISO-Sa2 blast cleaned steel. If the surface has been treated with a suitable

shop primer, sweep blasting is required to a minimum of SPSS-Ss or powertool cleaning to SPSS-Pt3.

Rusty areas should be blast cleaned to ISO-Sa2. Also possible is cleaning by hydrojetting.

SHIPS

COATINGS

back to previous view

page 2/5

SHIPS

3103 SYSTEMS FOR DECKS

December 1999

SPECIFICATION 1 in situ applied zinc silicate system, excellent resistant to corrosion,

abrasion and mechanical impact

pretreatment steel; blast cleaned to ISO-Sa2

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss

paint system Sigma silicate MC 75 m

maintenance small areas should be spot blasted to ISO-Sa2 or power tool cleaned to

SPSS-Pt3

major repairs must be carried out to this specification

SPECIFICATION 2 high build epoxy coating with excellent abrasion resistance

pretreatment steel; blast cleaned to ISO-Sa2

steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss,

or power tool cleaned to SPSS-Pt3

steel; hydrojetted to VIS WJ2/3 L (for more info see sheet 1498)

paint system Sigma Multiguard primer 100 m

Sigma Multiguard 150 m

Sigma CM coating 75 m

notes if gloss is required, an extra coat of Sigmadur gloss (dft of 50 m)

should be applied

if a holding primer is required, Sigma Multiguard primer can be

replaced by Sigma Universal primer in a dft of 50 m

maintenance should preferably be carried out to this specification

SHIPS

COATINGS

back to previous view

page 3/5

SHIPS

3103 SYSTEMS FOR DECKS

December 1999

SPECIFICATION 3 epoxy system in situ applied. Good resistance to abrasion, spillage of oils

and mild chemicals

pretreatment steel; blast cleaned to ISO-Sa2

shop primed steel; sweep blasted to SPSS-Ss or power tool cleaned to

SPSS-Pt3

steel; hydrojetted to VIS WJ2/3 L (for more info see sheet 1498)

paint system Sigma Multimastic aluminium 125 m

Sigma Multimastic 125 m

notes if gloss is required, an extra coat of Sigmadur gloss (dft of 50 m)

should be applied

if a holding primer is required, Sigma Multiguard primer can be

replaced by Sigma Universal primer in a dft of 50 m followed

by Sigma Multiguard in a dft of 200 m

if a recoatable epoxy system is required, Sigma CM coating should be

specified as topcoat

maintenance should preferably be carried out to this specification

SPECIFICATION 4 alkyd based system on top of a zinc phosphate rust inhibiting primer

moderate abrasion resistance

pretreatment steel; blast cleaned to ISO-Sa2 or power tool cleaned to ISO-St3

steel with approved shop primer; power tool cleaned to SPSS-Pt3

paint system Sigmarine primer ZP 35 m

Sigmarine primer ZP 35 m

Sigmarine BTD 35 m

Sigmarine BTD 35 m

note Sigmarine primer ZP is free from lead and chrome containing pigments

if required, Sigmarine primer RL is available

maintenance should preferably be carried out to this specification or with Sigmarine

Multiprimer as first coat (dft of 75 m)

SHIPS

COATINGS

back to previous view

page 4/5

SHIPS

3103 SYSTEMS FOR DECKS

December 1999

SPECIFICATION 5 chlorinated rubber/modified acrylic system applied in situ

not suitable for decks where spillage of oils and/or solvents can be

expected

pretreatment steel; blast cleaned to ISO-Sa2 or power tool cleaned to ISO-St3

steel with shop primer; sweepblasted to SPSS-Ss or power tool cleaned to

SPSS-Pt3

paint system Sigmachlor primer 75 m

Sigma Topacryl coating 75 m

maintenance should preferably be carried out to this specification or with Sigmarine

Multiprimer as first coat (dft of 75 m)

the Topacryl range has good overcoating and good drying characteristics

(to below 0C) which simplifies maintenance

MAINTENANCE

The system to be used for maintenance will depend on the size of repair, possibilities of surface preparation

and the weather conditions.

The removal of oil, grease and contamination can be achieved by high pressure water cleaning in

combination with the use of suitable detergents. This should be followed by a thorough fresh water wash

and drying before blast cleaning and/or repainting.

For major areas of breakdown maintenance is normally carried out by a fresh water wash and reblasting to

ISO-Sa2 and recoating with the original system. Minor areas can be power tool cleaned to SPSS-Pt3.

When blast cleaning (dry or wet) is impossible or not tolerated the surface should be derusted by means of

power tool cleaning to a minimum of SPSS-Pt2 and primed with Sigma Multimastic (dft of 60 m) followed

by the build coat and top coat as described in the specification.

SHIPS

COATINGS

back to previous view

page 5/5

SHIPS

3103 SYSTEMS FOR DECKS

December 1999

REFERENCES

Sigma CM coating see product data sheet 7466

Sigma Multiguard see product data sheet 7951

Sigma Multiguard primer see product data sheet 7922

Sigma Multimastic see product data sheet 7430

Sigma silicate MC see product data sheet 7568

Sigma Topacryl coating see product data sheet 7350

Sigma Universal primer see product data sheet 7417

Sigmachlor primer see product data sheet 7318

Sigmadur gloss see product data sheet 7528

Sigmarine BTD see product data sheet 7238

Sigmarine Multimastic see product data sheet 7430

Sigmarine Multiprimer see product data sheet 7110

Sigmarine primer RL see product data sheet 7113

Sigmarine primer ZP see product data sheet 7135

Cleaning of steel and removal of rust see information sheet 1490

Hydrojetting see information sheet 1498

Limitation of Liability - Ihe information in this data sheet is based upon laboratory tests we believe to

be accurate and is intended for guidance only. All recommendations or suggestions relating to the use of the

products made by Sigma Coatings, whether in technical documentation, or in response to a specific enquiry,

or otherwise, are based on data which to the best of our knowledge are reliable. Ihe products and

information are designed for users having the requisite knowledge and industrial skills and it is the end-

user's responsibility to determine the suitability of the product for its intended use.

Sigma Coatings has no control over either the quality or condition of the substrate, or the many factors

affecting the use and application of the product. Sigma Coatings does therefore not accept any liability

arising from loss, injury or damage resulting from such use or the contents of this data sheet (unless there

are written agreements stating otherwise).

Ihe data contained herein are liable to modification as a result of practical experience and continuous

product development.

Ihis data sheet replaces and annuls all previous issues and it is therefore the user's responsibility to ensure

that this sheet is current prior to using the product.

SHIPS

COATINGS

back to previous view

page 1/4

SHIPS

3104 SYSTEMS FOR SUPERSTRUCTURE AND DECK FITTINGS

a four page issue October 1999

revision of 9-1998

Application areas: all ferrous and non ferrous metal surfaces of superstructure and deck fittings.

Contains following specifications:

Specification 1: polyurethane/epoxy coating system

Specification 2: alkyd coating system

Specification 3: chlorinated rubber/modified acrylic coating system

Specification 4: water borne acrylic coating system

GENERAL ASPECTS

With superstructures on vessels, aesthetic considerations are very much to the fore. Well maintained

superstructures are a reflection of the care and attention enjoyed by the vessel.

Superstructure systems should have:

good adhesion and anticorrosive properties

resistance to wind, rain, seawater

non-yellowing properties

good gloss retention

easy to maintain

SURFACE PRETREATMENT

Steel: the quality of the secondary surface pretreatment affects the performance of the recommended paint

systems.

It is not common practice to reblast a superstructure and deck fittings despite the fact that this pretreatment

results in the best performance.

In general most types of shop primers are accepted provided that the surface is cleaned of all kind of

contamination and rust.

Sigmarine primer ZP, Sigmarine Multiprimer and Sigma Universal primer in particular have a good tolerance

for substrates which are pretreated by means of mechanical cleaning.

Galvanized steel and aluminium; degreasing and removal of salts by means of mechanical cleaning and

rinsing e.g. by brushing with nylon brushes and use of abundant clean freshwater. Surface must be allowed

to dry completely.

SHIPS

COATINGS

back to previous view

page 2/4

SHIPS

3104 SYSTEMS FOR SUPERSTRUCTURE AND DECK FITTINGS

October 1999

SPECIFICATION 1 recoatable polyurethane/epoxy system for SUPERSTRUCTURE with

excellent durability and gloss retention

pretreatment steel; blast cleaned to ISO-Sa2 or power tool cleaned to ISO-St3

steel with approved shop primer; sweep blasted to SPSS-Ss or power

tool cleaned to SPSS-Pt3 or SPSS-Pt2

galvanized steel and aluminium; degreasing and removal of salts by

means of mechanical cleaning and rinsing e.g. by brushing with nylon

brushes and use of abundant clean freshwater

surface must be allowed to dry completely

steel; hydrojetted to VIS WJ2/3 L (for more info see sheet 1498)

paint system Sigma Universal primer 50 m

Sigma CM coating 75 m

Sigmadur gloss 50 m

maintenance should preferably be carried out to this specification

both Sigma CM coating and Sigmadur gloss have good overcoating and

good curing characteristics also below 0C, which simplifies maintenance

SPECIFICATION 2 alkyd system for SUPERSTRUCTURE and DECK FITTINGS

pretreatment steel; blast cleaned to ISO-Sa2 or power tool cleaned to ISO-St3

steel with approved shop primer; sweep blasted to SPSS-Ss or power

tool cleaned to SPSS-Pt3 or SPSS-Pt2

galvanized steel and aluminium; degreasing and removal of salts by

means of mechanical cleaning and rinsing e.g. by brushing with nylon

brushes and use of abundant clean freshwater

surface must be allowed to dry completely

paint system Sigmarine primer ZP 35 m

Sigmarine primer ZP 35 m

Sigmarine undercoat 35 m

Sigmarine Enamel white 35 m

note 1 for galvanized steel and aluminium substrates, Sigmarine primer ZP

should be replaced by Sigma Universal primer (dft of 50 m)

note 2 Sigmarine primer ZP is free from lead and chrome containing pigments

if required Sigmarine primer RL is available

note 3 if faster drying is required two coats of Sigmarine primer ZP can be

replaced by one coat of Sigmarine Multiprimer (dft of 75 m)

maintenance should preferably be carried out to this specification or with Sigmarine

Multiprimer as first coat (dft of 75 m)

SHIPS

COATINGS

back to previous view

page 3/4

SHIPS

3104 SYSTEMS FOR SUPERSTRUCTURE AND DECK FITTINGS

October 1999

SPECIFICATION 3 chlorinated rubber/modified acrylic system for SUPERSTRUCTURE and

DECK FITTINGS

pretreatment steel; blast cleaned to ISO-Sa2 or power tool cleaned to ISO-Pt3

steel with approved shop primer; sweepblasted to SPSS-Ss or power

tool cleaned to SPSS-Pt3

paint system Sigmachlor primer 75 m

Sigma Topacryl coating 75 m

Sigma Topacryl finish 35 m

note for galvanized steel and aluminium substrates Sigmachlor primer

must be replaced by Sigma Universal primer (dft of 50 m)

maintenance should preferably be carried out with Sigmarine Multiprimer as first

coat (dft of 75 m) or to this specification

the Topacryl range has good overcoating and good drying characteristics

also below 0C, which simplifies maintenance

SPECIFICATION 4 waterborne acrylic coating system for SUPERSTRUCTURE and DECK

FITTINGS

pretreatment steel without mill scale; blastcleaned to ISO-Sa2 or power tool

cleaned to ISO-St3

steel with approved shop primer; sweepblasted to SPSS-Ss or power

tool cleaned to SPSS-Pt2

paint system Sigmacrylic primer 50 m

Sigmacrylic primer 50 m

Sigmacrylic finish 50 m

maintenance should preferably be carried out to this specification

SHIPS

COATINGS

back to previous view

page 4/4

SHIPS

3104 SYSTEMS FOR SUPERSTRUCTURE AND DECK FITTINGS

October 1999

MAINTENANCE

The system to be used for maintenance will depend on the size of repair, possibilities of surface preparation

and the weather conditions.

The removal of oil, grease and contamination can be achieved by high pressure water cleaning in

combination with the use of suitable detergents. This should be followed by a thorough freshwater wash and

drying before blast cleaning and/or repainting.

For major areas of breakdown maintenance is normally carried out by a freshwater wash and reblasting to

ISO-Sa2 and recoating with the original system. Minor areas can be power tool cleaned to SPSS-Pt3.

When blast cleaning (dry or wet) is impossible or not tolerated the surface should be derusted by means of

power tool cleaning to a minimum of SPSS-Pt2 and primed with Sigma Multimastic (dft of 60 m) followed

by the build coat and top coat as described in the specification.

REFERENCES

Sigma CM coating see product data sheet 7466

Sigma Multimastic see product data sheet 7430

Sigma Topacryl coating see product data sheet 7350

Sigma Topacryl finish see product data sheet 7355

Sigma Universal primer see product data sheet 7417

Sigmachlor primer see product data sheet 7318

Sigmacrylic primer see product data sheet 7150

Sigmacrylic finish see product data sheet 7250

Sigmadur gloss see product data sheet 7528

Sigmarine BTD see product data sheet 7238

Sigmarine Enamel see product data sheet 7240

Sigmarine Multiprimer see product data sheet 7110

Sigmarine primer RL see product data sheet 7113

Sigmarine primer ZP see product data sheet 7135

Sigmarine undercoat see product data sheet 7213

Cleaning of steel and removal of rust see information sheet 1490

Hydrojetting see information sheet 1498

Limitation of Liability - Ihe information in this data sheet is based upon laboratory tests we believe to

be accurate and is intended for guidance only. All recommendations or suggestions relating to the use of the

products made by Sigma Coatings, whether in technical documentation, or in response to a specific enquiry,

or otherwise, are based on data which to the best of our knowledge are reliable. Ihe products and

information are designed for users having the requisite knowledge and industrial skills and it is the end-

user's responsibility to determine the suitability of the product for its intended use.

Sigma Coatings has no control over either the quality or condition of the substrate, or the many factors

affecting the use and application of the product. Sigma Coatings does therefore not accept any liability

arising from loss, injury or damage resulting from such use or the contents of this data sheet (unless there

are written agreements stating otherwise).

Ihe data contained herein are liable to modification as a result of practical experience and continuous

product development.

Ihis data sheet replaces and annuls all previous issues and it is therefore the user's responsibility to ensure

that this sheet is current prior to using the product.

SHIPS

COATINGS

back to previous view

page 1/3

SHIPS

3105 SYSTEMS FOR INTERIOR(S)

a three page issue February 2000

revision of 5-1997

Application areas: wet and dry accommodation spaces, service spaces.

Contains following specifications:

Specification 1: recoatable polyurethane/epoxy system

Specification 2: alkyd system

Specification 3: waterborne acrylic coating system

Specification 4: emulsion paint system

GENERAL ASPECTS

Paint systems for wet accommodation spaces, such as bath rooms, showers, galleys and toilets must be

corrosion inhibiting, water, soap and scratch-resistant, easy to clean and non yellowing. For reasons of

hygiene they should be light coloured.