Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Belt Drive Lab Report

Caricato da

nachu_crazyTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Belt Drive Lab Report

Caricato da

nachu_crazyCopyright:

Formati disponibili

1

Belt drive

Elankumaran Nagarajan

22

nd

February 2012

2

Summary

Belt drives are transmission devices that are used for transmitting power from

one machine to another. The goal of this experiment was to measure the tensions

on the both sides of a flat belt wrapped around a revolving pulley and then

compare it to the theoretical formulae raised by Grosjean and Fawcett and

Burdess. The results from the experiment supported the theoretical formulae,

although there were slight differences in the experimental and theoretical

values. These differences were due to belt slip and the uncertainties in the

calculation of the coefficient of the friction between the belt and the pulley. It

was also discovered that the efficiency of the electric motor varies with the

torque.

3

Index

Page no

Introduction 4

Theory 4

Experimental procedure 6

Results 6

Discussion 10

Conclusion 12

References 12

4

Introduction

Belt dives are used in wide range of machines such as CD player, cars, washing

machine, etc. They are economical in terms of cost of production and

maintenance but still effective. They are used for the transmission of power from

one machine to another. Earlier flat belts, made of leather were used. Now a days

vee belts made of synthetic rubber and composite steel are used, as they are

more efficient than the flat belts. The vee belts has an advantage over the gear

based transmissions that it can work on pulley of variable diameter thus

providing a relatively inexpensive form of continuously variable transmission.

The main disadvantage associated with the belt drives is that they tend to slip

between the belt and the pulley, which affects the efficiency of the machine. The

amount of the slip will depend upon the coefficient of friction between the pulley

and belt, the belt profile and the torque transmitted.

The ultimate aim of this experiment is to investigate the relationship between

the tensions in a slipping pulley and compare that with the results predicted by

the theory.

Theory

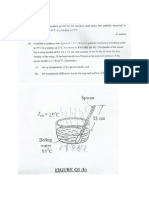

The relationship between tensions in a slipping pulley was examined in detail by

Grosjean and Fawcett and Burdess. They showed that for a stationary belt as

shown in fig 1, the ratio of the tensions is related to the coefficient of friction and

the angle of contact between the belt and pulley as shown in equation (1).

.. (1)

5

for a flat belt the angle is 90.

The motor torque transmitted by the belt is given by

Torque = (T - T ) R (2)

Where R is the radius of the pulley.

The power transmitted by the belt drive is given by the following equation

Power = torque ..(3)

Where is the rotational speed.

Fig 1. Belt drive apparatus

6

Experimental procedure

The experimental rig comprised of fixed radius pulley (50mm) driven by a DC

electric motor at a constant voltage of 10v. Three other pulley were present at

different places around the centre pulley so that the angle of contact between the

belt and pulley could be set at different angles (90, 180, 270, 360) as shown

in fig 1.

A flat belt, wrapped around the pulley was supported by a series of weights

ranging from 100 grams to 800 grams at one end and a load cell at the other end.

The centre pulley was directly connected the electric motor, which rotate against

the motion of the weights.

The angle of contact between the belt and pulley was set to 90 and the tension T

on the load cell is noted by varying the weights (T ) at the other end of the belt

from 100 grams to 800 grams. This procedure was repeated for three different

angle of contact between the belt and pulley (i.e. 180, 270 and 360)

Finally for one set of reading (in this experiment for the set of results at 360)

the current supplied and the rotational speed of the electric motor was

calculated. The motor current was measured by a digital meter and the pulley

rotational speed was measured with a hand held optical tachometer.

Results

The tensions T and T at four different angles of contact are shown are shown in

table 1. The graph form of table 1 is shown in fig 2. A graph of ln (T / T ) against

the belt contact angle is shown in fig 3.

From the graph in fig 3, the coefficient of friction between the belt and pulley is

calculated to be 0.23.

7

T

(N)

T

at 90

(N)

T

at 180

(N)

T

at 270

(N)

T

at 360

(N)

0.98 0.60 0.45 0.20 0.15

1.96 1.25 0.90 0.50 0.40

2.94 2.00 1.30 0.80 0.60

3.92 2.65 1.85 1.10 0.85

4.90 3.40 2.20 1.50 1.15

5.88 3.95 2.80 1.75 1.40

6.86 4.70 3.20 2.15 1.70

7.84 5.30 3.65 2.35 2.00

Table 1. Experimental data of T and T for different belt contact angle

Fig 2. T against T

0

1

2

3

4

5

6

0 2 4 6 8 10

T (90 )

T (180 )

T (270 )

T (360 )

8

Fig 3. ln (T /T ) against belt contact angle

Belt contact angle

(rads)

Experimental belt

tension ratio

Theoretical belt

tension ratio

1.57 1.4 1.43

3.14 2.3 2.05

4.71 3.12 2.95

6.28 3.69 4.22

Table 2. Experimental and theoretical belt tension ratio for different belt contact

angle

A graph form of table 2 is shown in fig 4.

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

0 2 4 6 8

ln (T /T )

9

Fig 4. Experimental and theoretical belt tension ratio against the belt contact

angle

T

Current

(A)

Rotational

speed

(rads/s)

Input

power

(watts)

Output

power

(watts)

Torque

(Nm)

Efficiency

(%)

0.15 1.3 147.55 13.26 5.90 0.04 44.50

0.40 2.1 141.58 21.42 11.33 0.08 52.90

0.60 2.9 135.51 29.58 16.26 0.12 54.97

0.85 3.3 129.33 33.66 19.40 0.15 57.64

1.15 3.9 124.09 39.78 23.58 0.19 59.27

1.40 4.2 118.23 42.84 26.01 0.22 60.71

1.70 5.1 112.78 52.02 29.32 0.26 56.36

2.00 5.8 106.71 59.16 30.95 0.29 52.32

Table 3. Motor input and out power, motor torque and its efficiency at 360 belt

contact angle.

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

0 2 4 6 8

theoretical belt tension

ratio (T /T )

experimental belt

tension ratio (T /T )

10

The motor input power, motor output power, motor torque and its efficiency for

360 belt contact angle are presented in table 3. A graph of motor efficiency

against motor torque for 360 belt contact angle is shown in fig 5.

Fig 5. Motor efficiency against motor torque at 360 belt contact angle

Discussion

It is evident from the above results that the experimental results demonstrate

the validity of the formula, although there were differences between the

theoretical and experimental values of the belt tension ratio.

The graph in fig 2 and table 2 shows that as the angle of contact increases the

belt tension ratio also increases as predicted by the theory. Fig 3 also shows that

the theoretical and experimental belt tension ratio were very much similar. This

again proves that the experimental values support the predicted theory. But still

the experimental and theoretical values were not the same. This is due to the belt

slip and the uncertainties associated with the calculation of coefficient of friction

between the pulley and belt.

0

10

20

30

40

50

60

70

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35

11

These differences were due to the lack of constant friction between the belt and

pulley. During the experiment there were some visible slips between the belt and

pulley. There could have been many such slips happened without being noticed,

which certainly would have affected the readings in the load cell.

The other reason why the experimental and theoretical belt tension ratio were

not identical is that if the coefficient of friction between the belt and pulley had

varied. The coefficient of friction was calculated to be 0.23 from fig 3. Any

uncertainties associated with this calculation will be very small and hence can be

neglected. But considering the exponential term in the formulae in equation (1),

even that small change can affect the theoretical belt tension ratio to certain

effect.

From the above discussions it is evident that even though the experimental and

theoretical results were not the same, it still demonstrates that the derived

formulae in equation (1) is valid. By preventing the belt slip and uncertainties

with the calculation of coefficient of friction, the experimental results will agree

with the theoretical values.

The efficiency of the motor was calculated (see table 3) from the output and

input motor power. Fig 5 clearly shows that the efficiency of the electric motor

varies with its torque. Fig 5 also shows that the maximum efficiency is around

61% and that occurs when the motor torque is around 0.22 Nm. From the graph

in fig 5 it can be learnt that the efficiency increases with torque, reaches a

maximum value and then it starts to decrease with the motor torque still

increasing.

From this one can understand that the motor is at its peak efficiency with a

torque of 0.22 Nm (approximately). Increasing or decreasing this torque will

lower the efficiency of the motor.

12

Conclusion

The analysis of the results show that the experimental and theoretical values of

the belt tension ratio were not identical, but the results were almost similar. The

differences were due to the constant slipping between the pulley and belt and

the uncertainties associated with the calculation of the coefficient of friction.

These errors justify the differences in the results. Hence the theory was

experimentally proved.

The efficiency of the electric motor was found to vary with the motor torque. The

maximum efficiency of the electric motor 60.71% is achieved at a torque of 0.22

Nm

References

Grosjean,j., principles of dynamics, Stanley Throne (publishers) ltd,

ISBN0 85950 2953, 1986.

Fawcett, J.N. and Burdess, j.s, basics mechanics with engineering

applications, Edward Arnold, ISBN 07131 3620 0, 1988.

Wikipedia (online). Available from :

http://en.wikipedia.org/wiki/Belt_%28mechanical%29 (accessed 21

February 2012).

Potrebbero piacerti anche

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsDa EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNessuna valutazione finora

- Flow Through A Nozzle: Themodynamics Lab (0904345) Short Lab ReportDocumento8 pagineFlow Through A Nozzle: Themodynamics Lab (0904345) Short Lab ReportSameeh KaddouraNessuna valutazione finora

- Epicyclical Gear Train System Lab ReportDocumento15 pagineEpicyclical Gear Train System Lab ReportIbrahim Hussain50% (2)

- Vibrations Lab ReportDocumento16 pagineVibrations Lab ReportJawad Hussain100% (1)

- Acceleration of Gears (Exp)Documento10 pagineAcceleration of Gears (Exp)zeeshan arifNessuna valutazione finora

- Lab10b - SERVO TRAINER 2 Response Calculating and MeasurementsDocumento8 pagineLab10b - SERVO TRAINER 2 Response Calculating and MeasurementssairafiNessuna valutazione finora

- Wheel N AxleDocumento11 pagineWheel N AxleCarey FernandesNessuna valutazione finora

- Design of Machine Elements: (Project Based Lab) Design Project:1 Belt DrivesDocumento25 pagineDesign of Machine Elements: (Project Based Lab) Design Project:1 Belt DrivesSurajNessuna valutazione finora

- Trifilar Suspension 1Documento4 pagineTrifilar Suspension 1Ninad BhanuNessuna valutazione finora

- Cam Follower Lab ReportDocumento16 pagineCam Follower Lab ReportAustin Williams80% (5)

- Belt Experiment Analyzes Power TransmissionDocumento9 pagineBelt Experiment Analyzes Power TransmissionFajar Rumanto100% (1)

- Vibration Lab 2 Belt Friction Lab ReportDocumento15 pagineVibration Lab 2 Belt Friction Lab ReportYann YeuNessuna valutazione finora

- Slotted Link Mechanism SHM ExperimentDocumento6 pagineSlotted Link Mechanism SHM ExperimentShawn Waltz50% (2)

- Presented By-Raghav Maheshwari Roll No.-124086Documento20 paginePresented By-Raghav Maheshwari Roll No.-124086RaghavMaheshwari100% (1)

- Faculty of Engineering & Built Environment Subject: Ege 3411 Laboratory Investigations 2 Experiment 1: Gear TrainDocumento7 pagineFaculty of Engineering & Built Environment Subject: Ege 3411 Laboratory Investigations 2 Experiment 1: Gear TrainJameel MalikNessuna valutazione finora

- ExperimentsDocumento4 pagineExperimentsRohitGuptaNessuna valutazione finora

- Hooke's ExperimentDocumento9 pagineHooke's ExperimentUmange Ranasinghe67% (3)

- Cam and FollowerDocumento12 pagineCam and Followerkulkajinkya100% (2)

- Epicyclic Gear Train ApparatusDocumento8 pagineEpicyclic Gear Train ApparatusGurmeet Mehma83% (6)

- Mechanics of Machinery 2 - Balancing of Rotating MassesDocumento11 pagineMechanics of Machinery 2 - Balancing of Rotating MassesAhmed Zawad ShovonNessuna valutazione finora

- Belt Drives: Power Transmission DevicesDocumento16 pagineBelt Drives: Power Transmission Devicesniaz kilamNessuna valutazione finora

- KDM 6Documento54 pagineKDM 6KarthikeyanRamanujamNessuna valutazione finora

- 3 Phase Lab ReportDocumento2 pagine3 Phase Lab ReportSheikh BajunaidNessuna valutazione finora

- Module 4Documento27 pagineModule 4Sweshkannan Sk0% (1)

- Moment of Inertia of FlywheelDocumento18 pagineMoment of Inertia of Flywheelgaurav singhNessuna valutazione finora

- Torsional Vibration HandoutsDocumento3 pagineTorsional Vibration HandoutsjaycobsmillanNessuna valutazione finora

- Porter Governor Speed vs Load DisplacementDocumento16 paginePorter Governor Speed vs Load DisplacementShahir Afif Islam50% (2)

- Lab11a - SERVO TRAINER 3 Proportional Control of Servo Trainer SpeedDocumento9 pagineLab11a - SERVO TRAINER 3 Proportional Control of Servo Trainer SpeedsairafiNessuna valutazione finora

- Equation of Motion ExperimentDocumento7 pagineEquation of Motion ExperimentfazeenNessuna valutazione finora

- MECHANICAL ENGINEERING DEPARTMENT DATE: 15/7/2013 COURSE CODE: MBB 42223Documento11 pagineMECHANICAL ENGINEERING DEPARTMENT DATE: 15/7/2013 COURSE CODE: MBB 42223Muhammad Khuzairi33% (3)

- Design of Machinery: Chapter 7 - Acceleration AnalysisDocumento44 pagineDesign of Machinery: Chapter 7 - Acceleration AnalysisKen Vu100% (1)

- Electric Vehicle Motor TypesDocumento20 pagineElectric Vehicle Motor TypesRahulNessuna valutazione finora

- Whirling of ShaftDocumento0 pagineWhirling of ShaftGinu ThomasNessuna valutazione finora

- Applications of Belt Drive and Selection MethodDocumento10 pagineApplications of Belt Drive and Selection MethodRushikesh KhadilkarNessuna valutazione finora

- Experiment No. 10 Moment of Inertia of FlywheelDocumento9 pagineExperiment No. 10 Moment of Inertia of FlywheelSarthak VishnuNessuna valutazione finora

- Lab 2 Experiment Polygon of ForcesDocumento18 pagineLab 2 Experiment Polygon of ForcesalexNessuna valutazione finora

- Lecture in Machine ElementsDocumento30 pagineLecture in Machine ElementsMark Angelo PagadorNessuna valutazione finora

- Gear Train ExperimentDocumento8 pagineGear Train ExperimentRaza MutahirNessuna valutazione finora

- Experiment No: 1 Date: Whirling of Shaft ApparatusDocumento3 pagineExperiment No: 1 Date: Whirling of Shaft ApparatustiyifaxaNessuna valutazione finora

- Belt Friction Full ReportDocumento8 pagineBelt Friction Full ReportPristine Fx100% (2)

- G6 - Bending Stress in A BeamDocumento4 pagineG6 - Bending Stress in A BeamBilal ÇayaNessuna valutazione finora

- Angular velocity and forces in reciprocating enginesDocumento39 pagineAngular velocity and forces in reciprocating enginesrajashekar reddy nallalaNessuna valutazione finora

- Tutorial Chapter 3-1Documento2 pagineTutorial Chapter 3-1imranNessuna valutazione finora

- Course No: - ME 3256: "Heaven's Light Is Our Guide"Documento8 pagineCourse No: - ME 3256: "Heaven's Light Is Our Guide"Dibya joy100% (1)

- Cam Analysis Apparatus ExperimentDocumento2 pagineCam Analysis Apparatus ExperimentGaurav KumarNessuna valutazione finora

- ME2113-2 Torsion of Circular Shafts Lab ReportDocumento6 pagineME2113-2 Torsion of Circular Shafts Lab ReportStuart TangNessuna valutazione finora

- CAM ExperimentDocumento8 pagineCAM Experimenthiltoneng100% (2)

- 6.acceleration of Gear SystemDocumento9 pagine6.acceleration of Gear SystemMuhammed Shameem N Edavannappara50% (2)

- 3.whirling of ShaftDocumento3 pagine3.whirling of ShaftRishi ShuklaNessuna valutazione finora

- Mom Lab ManualDocumento77 pagineMom Lab ManualHammad SubhaniNessuna valutazione finora

- Moment of Inertia of a FlywheelDocumento5 pagineMoment of Inertia of a FlywheelRajaswi BeleNessuna valutazione finora

- Lab Report Experiment 1Documento12 pagineLab Report Experiment 1Mohd Sayfull33% (3)

- JJ309 Fluid Mechanics Unit 5Documento21 pagineJJ309 Fluid Mechanics Unit 5Adib AzharNessuna valutazione finora

- Belt Friction ExperimentDocumento4 pagineBelt Friction Experimentsajanasubhasinghe75% (8)

- Experiment 6 Motorized Gyroscope: AIM: To Study The Gyroscopic Principle and Verify The Relation Between The AppliedDocumento3 pagineExperiment 6 Motorized Gyroscope: AIM: To Study The Gyroscopic Principle and Verify The Relation Between The AppliedDr Praveen Kumar100% (1)

- Shear Force Bending Moment Test ReportDocumento5 pagineShear Force Bending Moment Test ReportZahed AbdAzizNessuna valutazione finora

- Belt Drive: Mustapha BelloDocumento9 pagineBelt Drive: Mustapha BelloMustapha BelloNessuna valutazione finora

- BeltfrictionlabreportfullDocumento12 pagineBeltfrictionlabreportfullShasmita LakshmiNessuna valutazione finora

- PulleyDocumento14 paginePulleySantoso WibowoNessuna valutazione finora

- Summarization Heat TransferDocumento26 pagineSummarization Heat TransferNadia BalqisNessuna valutazione finora

- Minute MeetingDocumento4 pagineMinute MeetingNadia BalqisNessuna valutazione finora

- BDA30603 Tutorial 4Documento7 pagineBDA30603 Tutorial 4Firdaus JannahNessuna valutazione finora

- CH 3.1 (Uniform)Documento29 pagineCH 3.1 (Uniform)Nadia BalqisNessuna valutazione finora

- Bda 40303 Finite Element Method Task Report 1Documento4 pagineBda 40303 Finite Element Method Task Report 1Nadia BalqisNessuna valutazione finora

- Test 1 FEM Sem 1 20102011 FinalDocumento7 pagineTest 1 FEM Sem 1 20102011 FinalNadia BalqisNessuna valutazione finora

- Task Report ExampleDocumento3 pagineTask Report ExamplewanpudinNessuna valutazione finora

- BDA 40303 Finite Element Method TasksDocumento6 pagineBDA 40303 Finite Element Method TasksNadia BalqisNessuna valutazione finora

- 40603Documento10 pagine40603Nadia BalqisNessuna valutazione finora

- Task 3Documento8 pagineTask 3Nadia BalqisNessuna valutazione finora

- Measuring Pressure & Flow at Water Treatment PlantDocumento3 pagineMeasuring Pressure & Flow at Water Treatment PlantNadia BalqisNessuna valutazione finora

- Binding Report FormatDocumento7 pagineBinding Report FormatNadia BalqisNessuna valutazione finora

- Heat Exchanger IDocumento21 pagineHeat Exchanger INadia BalqisNessuna valutazione finora

- Rotors Frequency and Time Response of Torsional Vibration Using Hybrid ModelingDocumento8 pagineRotors Frequency and Time Response of Torsional Vibration Using Hybrid ModelingNadia BalqisNessuna valutazione finora

- ConclusionDocumento1 paginaConclusionNadia Balqis50% (2)

- Assignment 2 Mekanik Mesin S1 - 20132014Documento2 pagineAssignment 2 Mekanik Mesin S1 - 20132014Nadia BalqisNessuna valutazione finora

- ObservationDocumento1 paginaObservationNadia BalqisNessuna valutazione finora

- Final Examination: FormulaeDocumento4 pagineFinal Examination: FormulaeNadia BalqisNessuna valutazione finora

- Axial beam analysisDocumento4 pagineAxial beam analysisNadia BalqisNessuna valutazione finora

- Tutorium Compressor SolutionDocumento12 pagineTutorium Compressor SolutionNadia Balqis0% (1)