Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pelton Turbine Lab

Caricato da

lufiman0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

824 visualizzazioni12 paginePelton Turbine Lab

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoPelton Turbine Lab

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

824 visualizzazioni12 paginePelton Turbine Lab

Caricato da

lufimanPelton Turbine Lab

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 12

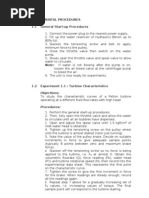

PELTON WHEEL TURBINE LAB

PURPOSE: The main purpose of this lab is to measure

the power output of a Pelton Wheel turbine and to

compare this to the theoretical power output. Another

purpose of the lab is to check turbine scaling laws.

PROCEDURE: Set the driving pressure at a low level.

Measure the flow rate through the turbine. Set the

brake at some level and measure the brake load using

the load cell and the rotor speed using a tachometer.

Repeat for various brake settings. Set the driving

pressure at a high level and repeat the experiment.

REPORT: Using the measured data, calculate the brake

torque and the bucket speed: then calculate the brake

power output of the turbine. Plot Power P versus RPM

for each driving pressure. Plot Power Coefficient C

P

versus Speed Coefficient C

S

. Compare Actual Power with

Theoretical Power. Comment on the results.

MEASUREMENTS

The brake power output of the turbine is:

P = T

where T is the torque on the rotor and is the

rotational speed of the rotor. The torque is:

T = L d

where L is load measured by the brake load cell and d

is the moment arm of the cell from the rotor axis. The

rotor speed is measured using a tachometer.

The theoretical power is a function of the bucket

speed V

B

and the jet speed V

J

. The bucket speed is:

V

B

= R

where R is the distance out to the bucket from the

rotor axis. The jet speed is approximately:

V

J

= k [2P/]

where k is a nozzle loss factor, is the density of

water and P is the jet driving pressure: this is

measured using a pressure gage. For the lab turbine, k

is 0.97, d is 15cm and R is 5cm.

PELTON WHEEL TURBINE THEORY

The power output of the turbine is:

P = T

where T is the torque on the rotor and is the

rotational speed of the rotor. The torque is:

T = (Q V

T

R)

where Q is the volumetric flow rate through the

turbine and V

T

is the tangential flow velocity. The

tangential flow velocities at inlet and outlet are:

V

IN

= V

J

V

OUT

= (V

J

- V

B

) K Cos + V

B

where, relative to the tangential direction, is the

angle of the relative velocity vector and K is a loss

factor. So power becomes:

P = Q (V

J

- V

B

) (1 K Cos) V

B

For the lab turbine, is 168

o

and K is 0.8. In the

lab, the flow rate Q is measured using a V Notch Weir.

SCALING LAWS FOR TURBINES

For turbines, we are interested mainly in the power of

the device as a function of its rotational speed. The

simplest way to develop a nondimensional power is to

divide power P by something which has the units of

power. The power in a flow is equal to its dynamic

pressure P times its volumetric flow rate Q:

P Q

So, we can define a power coefficient C

P

:

C

P

= P / [P Q]

For a Pelton Wheel turbine, the dynamic pressure P is

approximately equal to the driving pressure.

To develop a nondimensional version of the rotational

speed of the turbine, we can divide the tip speed of

the blades R by the flow speed U. For a Pelton Wheel

turbine, the flow speed U is equal to the jet speed V

J

.

So, we can define a speed coefficient C

S

:

C

S

= R / V

J

DATA SHEET FOR PELTOM WHEEL TURBINE

JET PRESSURE =

FLOW RATE =

RUN

BRAKE LOAD

ROTOR RPM

DATA SHEET FOR PELTOM WHEEL TURBINE

JET PRESSURE =

FLOW RATE =

RUN

BRAKE LOAD

ROTOR RPM

Potrebbero piacerti anche

- Lab7-Phelton Turbine Experiment-UpdatedDocumento7 pagineLab7-Phelton Turbine Experiment-Updatedtomtoms92Nessuna valutazione finora

- Orifice and Free Jet Flow Experiment: Updated 8/9/06Documento3 pagineOrifice and Free Jet Flow Experiment: Updated 8/9/06shaneshaneshaneshaneNessuna valutazione finora

- Pelton Wheel TurbineDocumento8 paginePelton Wheel TurbineSiew LynNessuna valutazione finora

- Flow in Open ChannelDocumento24 pagineFlow in Open ChannelSue IlaNessuna valutazione finora

- Hydraulic Laboratory Civil Engineering Department Sultan Azlan Shah Polytechnic Experiment: 2 Title: Impact of Jet TestDocumento8 pagineHydraulic Laboratory Civil Engineering Department Sultan Azlan Shah Polytechnic Experiment: 2 Title: Impact of Jet TestAzrol Azmir Long100% (3)

- Impact of A Water JetDocumento5 pagineImpact of A Water JetAnirban SardarNessuna valutazione finora

- Venturi MeterDocumento15 pagineVenturi MeterFatimah BadruddinNessuna valutazione finora

- 5 Calibration of Triangular NotchDocumento8 pagine5 Calibration of Triangular Notchkanavan monNessuna valutazione finora

- StabilityDocumento5 pagineStabilityJenelia Jojo50% (2)

- LAB SHEET For Pelton Wheel 21 Sept 2011Documento3 pagineLAB SHEET For Pelton Wheel 21 Sept 2011Mohd FazliNessuna valutazione finora

- Theory VenturiDocumento7 pagineTheory VenturiMahendranath RamakrishnanNessuna valutazione finora

- Lab Soil-Hydrometer TestDocumento6 pagineLab Soil-Hydrometer TestSyed Zulfaizzuan AljufriNessuna valutazione finora

- BFC 32002Documento8 pagineBFC 32002syah123Nessuna valutazione finora

- Venturi Meter Experiment ProceduresDocumento2 pagineVenturi Meter Experiment ProceduresAnonymous mRBbdopMKf100% (1)

- EXP 6 Study of Impact of Free Water JetDocumento11 pagineEXP 6 Study of Impact of Free Water Jetsiva ramNessuna valutazione finora

- Experiment 3 Hydraulics LabDocumento12 pagineExperiment 3 Hydraulics LabMatt NashrudinNessuna valutazione finora

- Specific Energy Hydraulic Jumps WeirsDocumento23 pagineSpecific Energy Hydraulic Jumps WeirsHaris jugnooNessuna valutazione finora

- Introduction Impact JetDocumento4 pagineIntroduction Impact JetIniaan SaminathanNessuna valutazione finora

- Bernoulli's TheoremDocumento5 pagineBernoulli's TheoremVrushiket PatilNessuna valutazione finora

- Impact of JetDocumento7 pagineImpact of JetHeng Xiu KohNessuna valutazione finora

- Swinburne University of Technology: School of Engineering (Sarawak Campus)Documento19 pagineSwinburne University of Technology: School of Engineering (Sarawak Campus)Mahfuzah MustaphaNessuna valutazione finora

- Centre of Pressure Level 1Documento12 pagineCentre of Pressure Level 1Mohd Azeem RizalNessuna valutazione finora

- Mka-03 Pelton and Francis TurbinesDocumento11 pagineMka-03 Pelton and Francis TurbineshasshosNessuna valutazione finora

- Venturimeter ExperimentDocumento9 pagineVenturimeter ExperimentcoutohahaNessuna valutazione finora

- Lab Impact of Jet RevisedDocumento4 pagineLab Impact of Jet RevisedMunzirKhanNessuna valutazione finora

- Adiabatic Gas Law Apparatus Model TD1000 PDFDocumento10 pagineAdiabatic Gas Law Apparatus Model TD1000 PDFSyifauliyah AzmiNessuna valutazione finora

- H.W#01 and 02 PDFDocumento33 pagineH.W#01 and 02 PDFVikaas SagerNessuna valutazione finora

- Material LaboratoryDocumento14 pagineMaterial LaboratoryAnonymous tLXKwTNessuna valutazione finora

- Bernoulli's ExperimentDocumento29 pagineBernoulli's ExperimentAnonymous NyvKBWNessuna valutazione finora

- List of Experiments of Fluid LabDocumento24 pagineList of Experiments of Fluid LabGhufran Ahmed0% (1)

- Report 3a Pelton Turbine - HydraulicDocumento13 pagineReport 3a Pelton Turbine - HydraulicAin SherinNessuna valutazione finora

- Experiment 1: Flow Over A NotchDocumento15 pagineExperiment 1: Flow Over A NotchLai YenNessuna valutazione finora

- EXP 5 - Study of Hydraulic Jump in A Rectangular ChannelDocumento9 pagineEXP 5 - Study of Hydraulic Jump in A Rectangular Channelsiva ramNessuna valutazione finora

- Report Buckling of StructsDocumento7 pagineReport Buckling of StructsAnonymous 59kjvq4OLBNessuna valutazione finora

- Revised LabDocumento18 pagineRevised LabAbu AyemanNessuna valutazione finora

- Fluid Mechanics Lab Experiment 2Documento8 pagineFluid Mechanics Lab Experiment 2SSShakeelNessuna valutazione finora

- Coventry UniversityDocumento20 pagineCoventry UniversityDuncoh DunNessuna valutazione finora

- V Notch PracticalDocumento13 pagineV Notch PracticalAnushaBheenuck0% (2)

- Lab 2.1 Impact of A Jet 1Documento8 pagineLab 2.1 Impact of A Jet 1Shehan FernandoNessuna valutazione finora

- Open Channel LabDocumento27 pagineOpen Channel Labஅருண்ராஜ் கிருஷ்ணன்சாமிNessuna valutazione finora

- Centre of Hidrostatic PressureDocumento16 pagineCentre of Hidrostatic PressureVanithaa Ponnaiah0% (1)

- Impact of JetDocumento12 pagineImpact of JetShafizNessuna valutazione finora

- Pelton Turbine TestDocumento10 paginePelton Turbine TestViknesh MjNessuna valutazione finora

- Experiment 2, Flow Over A Broad Crested WeirDocumento4 pagineExperiment 2, Flow Over A Broad Crested WeirRayanNessuna valutazione finora

- Free VortexDocumento3 pagineFree VortexVrushiket Patil67% (3)

- Pelton Turbine Experiment ResultDocumento2 paginePelton Turbine Experiment ResultShea Cheng KuangNessuna valutazione finora

- Stability of A Floating BodyDocumento11 pagineStability of A Floating BodyDember Paul100% (1)

- Impact of JetDocumento5 pagineImpact of Jetميسرة33% (3)

- Mechanics of Fluids Lab Impact of A JetDocumento10 pagineMechanics of Fluids Lab Impact of A JetpatrickNX942088% (17)

- Pipe FrictionDocumento4 paginePipe FrictionShubham ChauhanNessuna valutazione finora

- Pelton TurbineDocumento4 paginePelton TurbineHenDricky Magosi100% (1)

- Pelton Turbine Lab ReportDocumento8 paginePelton Turbine Lab ReportPink FloydaNessuna valutazione finora

- My ProjectDocumento6 pagineMy ProjectNiall McInerneyNessuna valutazione finora

- Performance Characteristics of Pelton Wheel Purpose: To Investigate The Performance Characteristics of An Impulse Turbine (Pelton Wheel)Documento2 paginePerformance Characteristics of Pelton Wheel Purpose: To Investigate The Performance Characteristics of An Impulse Turbine (Pelton Wheel)Douglas FabrisNessuna valutazione finora

- TP Turbomachine1 Pelton Wheel Lab SheetDocumento7 pagineTP Turbomachine1 Pelton Wheel Lab SheetAbdelwahab.gfNessuna valutazione finora

- Pelton TurbineDocumento6 paginePelton Turbineendoparasite50% (2)

- Automation PracticalDocumento15 pagineAutomation PracticalSABAREESH ENessuna valutazione finora

- MCE 4423 Experiment 4 - Efficiency and Performance of A Pelton TurbineDocumento7 pagineMCE 4423 Experiment 4 - Efficiency and Performance of A Pelton TurbineMan AlbNessuna valutazione finora

- Pelton Wheel Experiment: Fig-1 Fig-2Documento5 paginePelton Wheel Experiment: Fig-1 Fig-2Caleb KreegerNessuna valutazione finora

- Hydraulic Machines Lab ManualDocumento8 pagineHydraulic Machines Lab ManualMuneeb MalikNessuna valutazione finora

- 01TC1703 Training - NeptunDocumento12 pagine01TC1703 Training - NeptunlufimanNessuna valutazione finora

- 06 TC1703 Training - ToolboxDocumento16 pagine06 TC1703 Training - ToolboxlufimanNessuna valutazione finora

- 06 TC1703 Training - ToolboxDocumento16 pagine06 TC1703 Training - ToolboxlufimanNessuna valutazione finora

- 2016 03 18 Training - Digital GovernorDocumento28 pagine2016 03 18 Training - Digital GovernorlufimanNessuna valutazione finora

- Wampu HPP Installation For The EMDocumento71 pagineWampu HPP Installation For The EMlufiman100% (1)

- Hydro NewsDocumento36 pagineHydro NewslufimanNessuna valutazione finora

- Hy Andritz Hydro enDocumento20 pagineHy Andritz Hydro enlufimanNessuna valutazione finora

- v16.00 Release NotesDocumento41 paginev16.00 Release NotesArjan BrabanderNessuna valutazione finora

- Hydro NewsDocumento32 pagineHydro NewslufimanNessuna valutazione finora

- 03 ModularizationDocumento5 pagine03 ModularizationsumnatarajNessuna valutazione finora

- IS4242 W3 Regression AnalysesDocumento67 pagineIS4242 W3 Regression Analyseswongdeshun4Nessuna valutazione finora

- Cable Size Calculations SpreadsheetDocumento4 pagineCable Size Calculations Spreadsheetbhavin24uNessuna valutazione finora

- C V RamanDocumento8 pagineC V RamanJayesh KomalwarNessuna valutazione finora

- Customer DemandDocumento42 pagineCustomer Demandtulika_ajwaniNessuna valutazione finora

- Programming For Problem SolvingDocumento5 pagineProgramming For Problem SolvingAPOLLO Sem 4 I.T.Nessuna valutazione finora

- ElectrolysisDocumento3 pagineElectrolysisRaymond ChanNessuna valutazione finora

- Computer Dictionary PDFDocumento95 pagineComputer Dictionary PDFMarjenneilNessuna valutazione finora

- Leading The Industry In: Solar Microinverter TechnologyDocumento2 pagineLeading The Industry In: Solar Microinverter TechnologydukegaloNessuna valutazione finora

- Real Time Operating SystemsDocumento15 pagineReal Time Operating SystemsSaro VrsNessuna valutazione finora

- Psychometric Development and Validation of GaslightingDocumento15 paginePsychometric Development and Validation of GaslightingYang ZhangNessuna valutazione finora

- ASCE 7 ASD Basic Load CombosDocumento1 paginaASCE 7 ASD Basic Load CombosAamirShabbirNessuna valutazione finora

- Configuration A: Unloaded BJT Transistor AmplifiersDocumento3 pagineConfiguration A: Unloaded BJT Transistor AmplifiersdasdNessuna valutazione finora

- 5-Canal Irrigation SystemDocumento23 pagine5-Canal Irrigation Systemwajid malikNessuna valutazione finora

- 1 s2.0 0304386X9190055Q MainDocumento32 pagine1 s2.0 0304386X9190055Q MainJordan Ulloa Bello100% (1)

- Put Call ParityDocumento37 paginePut Call ParityVaidyanathan Ravichandran100% (1)

- 3 Perform Industry CalculationsDocumento90 pagine3 Perform Industry CalculationsRobinson ConcordiaNessuna valutazione finora

- Fundamentals of Physics Sixth Edition: Halliday Resnick WalkerDocumento4 pagineFundamentals of Physics Sixth Edition: Halliday Resnick WalkerAhmar KhanNessuna valutazione finora

- Yang Learning Face Age CVPR 2018 PaperDocumento9 pagineYang Learning Face Age CVPR 2018 Paperandr234ibateraNessuna valutazione finora

- Oracle Goldengate: Oracle Installation and Setup Guide 11 Release 2 (11.2.1.0.0)Documento188 pagineOracle Goldengate: Oracle Installation and Setup Guide 11 Release 2 (11.2.1.0.0)kashifmeoNessuna valutazione finora

- OcrDocumento16 pagineOcrBeena JaiswalNessuna valutazione finora

- Gas Turbine Compressor WashingDocumento8 pagineGas Turbine Compressor Washingwolf_ns100% (1)

- RCC-DI-AC PipeDocumento10 pagineRCC-DI-AC PipeNaveen NagisettiNessuna valutazione finora

- 06 DoniaDocumento12 pagine06 DoniaOmar ZazaNessuna valutazione finora

- Tlsiw - Class X - Project Details - 2023-24Documento2 pagineTlsiw - Class X - Project Details - 2023-24how toNessuna valutazione finora

- Failure Mode and Effects Analysis of A Process of Reflow Lead-Free SolderingDocumento5 pagineFailure Mode and Effects Analysis of A Process of Reflow Lead-Free SolderingSRIDHAREEE61Nessuna valutazione finora

- Tecumseh Parts List OHV 135Documento5 pagineTecumseh Parts List OHV 135M MNessuna valutazione finora

- BS en 00405-2001 + A1-2009 PDFDocumento48 pagineBS en 00405-2001 + A1-2009 PDFShan Sandaruwan AbeywardeneNessuna valutazione finora

- A Report On Traffic Volume StudyDocumento33 pagineA Report On Traffic Volume StudyManoj Durairaj100% (1)

- Processing of Synthetic Aperture Radar Images - H. Maitre (Wiley, 2008) WWDocumento411 pagineProcessing of Synthetic Aperture Radar Images - H. Maitre (Wiley, 2008) WWbehzad100% (4)