Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

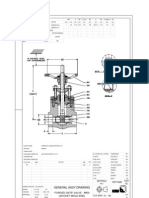

Piston check drawing

Caricato da

gigiphiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Piston check drawing

Caricato da

gigiphiCopyright:

Formati disponibili

DESCRIPTION

DRAWING

Piston check - 800 - Red B. - Bolted - SW

RP 4 5 2 - 6 / SW

Std. pressure test (PSIG) : SHELL 2975, SEAT 2175

Ref

10

11

13

14

22

24

28

50

Qty Description

1

1

1

1

1

4

1

1

Material

Body

Cover

Piston

Seat ( Renewable ) c

Spiral wound gasket

Body screw

Return spring

Identification Plate

ASTM A105N

ASTM A105N

AISI 410

AISI 410 stellited

AISI 316L + GRAPHITE

ASTM A193 / B7M HDG ( ASTM A153 )

INCONEL X750

STAINLESS STEEL 316 c

Client

: OIL & NATURAL GAS CORPORATION LTD. (ONGC)

Project

: HRD PROCESS PLATFORM PROJECT

c

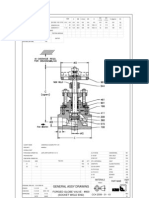

Dim.

DRAWING

Design construction

BS EN ISO 15761

Socket weld Ends

API 602

Rating to

Marking

ASME B16.34

MSS SP-25

Testing according

ASME B16.11 - SW (#9000)

BS EN 12266-1

API 598

NOTES

1 PIPING SPEC.: A1N / B1N / D1N c

2 NACE MR0175/ISO 15156 - 1/2/3 - ACC. TO CLAUSE 5.2 OF ONGC SPEC 2004A R.7 c

3 CORROSION ALLOWANCE: 6,0 mm

4 THIS DRAWING SHALL BE READ IN CONJUNCTION WITH APPROVED

DATA SHEET VC-45 (DOC. NO. 00812-200-JSD-1300-0002-114) c

5 PAINTING ACC. TO ONGC SPEC 2005 REV.4 - CLAUSE NO. 13.2.2 c

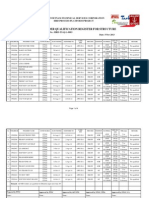

RP452 / SW

1/2"

RP453 / SW

3/4"

RP454 / SW

1"

RP455 / SW

1.1/4"

RP456 / SW

1.1/2"

RP457 / SW

2"

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

Sw

Pt

Im

Pf

Ht

Ff

21,7

0,85

27,1

1,07

33,8

1,33

42,6

1,68

48,6

1,91

61,1

2,41

9,5

0,37

12,5

0,49

12,5

0,49

14,0

0,55

12,5

0,49

16,0

0,63

39,0

1,54

49,0

1,93

64,0

2,52

64,0

2,52

78,0

3,07

80,0

3,15

10,0

0,39

13,5

0,53

19,0

0,75

27,0

1,06

32,0

1,26

35,0

1,38

56,0

2,20

74,0

2,91

79,0

3,11

100,0

3,94

109,0

4,29

135,0

5,31

90,0

3,54

110,0

4,33

127,0

5,00

145,0

5,71

170,0

6,69

210,0

8,27

Wt

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

2,2

4,85

3,0

6,61

4,1

9,04

6,2

13,67

9,4

20,72

13,3

29,32

PREPARED BY

APPROVED BY

DATE

REV.

M.Marazzi

G. Menni

03/02/14

Item

14 - 16

3-5

CUSTOMER CODE N

VC-45

FILE

VC-45.xls

Potrebbero piacerti anche

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Piping Classes PDFDocumento429 paginePiping Classes PDFMichael Jordan100% (4)

- AWS D1.i/Di.iM:2010 Clause 6 inspection criteriaDocumento1 paginaAWS D1.i/Di.iM:2010 Clause 6 inspection criteriagigiphi75% (8)

- Data Sheet Ball ValveDocumento1 paginaData Sheet Ball ValveIkhsan Hj SiratNessuna valutazione finora

- Pressure Safety Valve DatasheetDocumento1 paginaPressure Safety Valve DatasheetAlvin Smith100% (5)

- VGL 65Documento1 paginaVGL 65gigiphiNessuna valutazione finora

- Valve SheetDocumento23 pagineValve SheetAris KancilNessuna valutazione finora

- Catalog Valve KSBDocumento58 pagineCatalog Valve KSByoboo100% (1)

- #800 Gate SWDocumento1 pagina#800 Gate SWAmit Kumar SharmaNessuna valutazione finora

- Valve Data Sheet DetailsDocumento1 paginaValve Data Sheet DetailsMargaret DaughertyNessuna valutazione finora

- API 594 Dual PLT CheckDocumento18 pagineAPI 594 Dual PLT Checkandy131078Nessuna valutazione finora

- Ansi - 2012 - Ball ValveDocumento12 pagineAnsi - 2012 - Ball ValveFAR_A_DAYNessuna valutazione finora

- Control Valve Data Sheet for Gate Valves up to 8 InchesDocumento1 paginaControl Valve Data Sheet for Gate Valves up to 8 InchesMohamed gaballa SaidNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- Data sheets and GA drawings of valvesDocumento12 pagineData sheets and GA drawings of valvesvenka07Nessuna valutazione finora

- Piping Material Classes: NotesDocumento16 paginePiping Material Classes: NotesVedran KosanovicNessuna valutazione finora

- Data Sheet: (Approved by ClientDocumento3 pagineData Sheet: (Approved by ClientTanmoy DuttaNessuna valutazione finora

- Check Valves With Tilting DiscDocumento2 pagineCheck Valves With Tilting DiscSamir RawalNessuna valutazione finora

- Flow Tek C4700 Series Cryo Ball ValveDocumento8 pagineFlow Tek C4700 Series Cryo Ball ValveDanielle JohnsonNessuna valutazione finora

- Bill of Material: Amco Industrial ValvesDocumento1 paginaBill of Material: Amco Industrial ValvesFrancis NelsonNessuna valutazione finora

- Ball Valve Datasheet for 6”-12” Flanged ValvesDocumento1 paginaBall Valve Datasheet for 6”-12” Flanged ValvesJohnNessuna valutazione finora

- DSFSDFDVDFDocumento33 pagineDSFSDFDVDFfahmi azisNessuna valutazione finora

- VAAS C47 Series Cryo Ball Valve CatalogueDocumento8 pagineVAAS C47 Series Cryo Ball Valve CatalogueDanielle JohnsonNessuna valutazione finora

- Datasheet CHK VLV (14in #150)Documento1 paginaDatasheet CHK VLV (14in #150)chintanNessuna valutazione finora

- Literature Force Floating Ball Valve CatalogDocumento16 pagineLiterature Force Floating Ball Valve CatalogJohn Néstor Ramirez CalderónNessuna valutazione finora

- C.I. Single Post Safety Valve Dimensional DataDocumento2 pagineC.I. Single Post Safety Valve Dimensional DataParmasamy SubramaniNessuna valutazione finora

- Sample8 DrawingDocumento1 paginaSample8 DrawingRam Kumar NNessuna valutazione finora

- CAST STEEL GATE VALVES UNDER 40 CHARACTERSDocumento4 pagineCAST STEEL GATE VALVES UNDER 40 CHARACTERSsghinausNessuna valutazione finora

- IFRVT1Documento2 pagineIFRVT1Shilpa SinghNessuna valutazione finora

- #800 Globe SWDocumento1 pagina#800 Globe SWAmit Kumar SharmaNessuna valutazione finora

- Ball ValveDocumento12 pagineBall ValveIdabaNessuna valutazione finora

- PmsDocumento94 paginePmssdk1978100% (1)

- rc61180 b09Documento9 paginerc61180 b09eww08Nessuna valutazione finora

- Tdi 50000 Tpy, GNFCDocumento6 pagineTdi 50000 Tpy, GNFCkrunal panchalNessuna valutazione finora

- Yanbu: Export Refinery ProjectDocumento4 pagineYanbu: Export Refinery ProjectJanakiraman MalligaNessuna valutazione finora

- Alloy and Material Specs for ValvesDocumento0 pagineAlloy and Material Specs for ValvesZoebairNessuna valutazione finora

- GWC Valve International Flanged Floating Ball ValveDocumento16 pagineGWC Valve International Flanged Floating Ball ValveGWC Valve InternationalNessuna valutazione finora

- Valve Qap - IoclDocumento96 pagineValve Qap - Ioclalokgoel_2006Nessuna valutazione finora

- Ewp000 P30 J00 501 - 1H PDFDocumento61 pagineEwp000 P30 J00 501 - 1H PDFOk Oh100% (2)

- 11422Documento10 pagine11422balajivangaruNessuna valutazione finora

- Kitz Gate ValveDocumento28 pagineKitz Gate ValvemohamedfirozNessuna valutazione finora

- Kit 11011Documento28 pagineKit 11011Reza VakilNessuna valutazione finora

- Conn To C-2310 A/N2 10 in RFFE 300Documento1 paginaConn To C-2310 A/N2 10 in RFFE 300Vijay SekharNessuna valutazione finora

- Standards MaterialDocumento1 paginaStandards MaterialFarzad MirzavandNessuna valutazione finora

- Class 61502 Carbon Steel Piping Design LimitsDocumento10 pagineClass 61502 Carbon Steel Piping Design LimitsbalajivangaruNessuna valutazione finora

- Datasheet For Ball ValveDocumento16 pagineDatasheet For Ball ValveDamu JankerboyNessuna valutazione finora

- Petrofac E&C Oman LLC Petroleum Development Oman Datasheet For Globe Valves Rabab Harweel Integrated Project Petrofac Job No.: Es-00002 Pdo Contract No. C311-321Documento21 paginePetrofac E&C Oman LLC Petroleum Development Oman Datasheet For Globe Valves Rabab Harweel Integrated Project Petrofac Job No.: Es-00002 Pdo Contract No. C311-321raj_hp2000Nessuna valutazione finora

- GR-FLY-MEDMGCOC1014 Medical Gas Console Outlet Chemetron Compatible 90 Tubing - 0Documento2 pagineGR-FLY-MEDMGCOC1014 Medical Gas Console Outlet Chemetron Compatible 90 Tubing - 0Héctor ZazuetaNessuna valutazione finora

- High Temp Resistant SteelDocumento14 pagineHigh Temp Resistant SteelrajivashishNessuna valutazione finora

- 1.0 Data Sheet For Sight Glass 1.1 General Requirements: Minimum (HOLD 2)Documento1 pagina1.0 Data Sheet For Sight Glass 1.1 General Requirements: Minimum (HOLD 2)ABDUL KADHARNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_kaNessuna valutazione finora

- G V - B B - F P: Lobe Alves Olted Onnet ULL ORTDocumento1 paginaG V - B B - F P: Lobe Alves Olted Onnet ULL ORTboroumandNessuna valutazione finora

- PCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Documento6 paginePCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Moises Alvarez LeandroNessuna valutazione finora

- 800 1500lb GateValveDocumento1 pagina800 1500lb GateValvePham AnhNessuna valutazione finora

- CI Check ValveDocumento1 paginaCI Check ValveShaik Nizam UddinNessuna valutazione finora

- MPVN BrochureDocumento32 pagineMPVN Brochurefernando_naciamentNessuna valutazione finora

- Yanbu Export Refinery Piping MaterialsDocumento7 pagineYanbu Export Refinery Piping MaterialsJanakiraman MalligaNessuna valutazione finora

- PDS01.11.001 - Wouter Witzel - EVFLDocumento7 paginePDS01.11.001 - Wouter Witzel - EVFLVilius BukysNessuna valutazione finora

- Structural Analysis and Design of Process EquipmentDa EverandStructural Analysis and Design of Process EquipmentNessuna valutazione finora

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDa EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNessuna valutazione finora

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Da EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Valutazione: 3.5 su 5 stelle3.5/5 (3)

- HRD Process Platform Project MC Inspection & Test Record: P03-A Sheet 1 of 1Documento2 pagineHRD Process Platform Project MC Inspection & Test Record: P03-A Sheet 1 of 1gigiphiNessuna valutazione finora

- f3213-6751 - r1 Piping Specialty Item ListDocumento4 paginef3213-6751 - r1 Piping Specialty Item ListgigiphiNessuna valutazione finora

- f3213-61m1.02r1 - Linewise Pipe Mto (4-Inch and Below)Documento13 paginef3213-61m1.02r1 - Linewise Pipe Mto (4-Inch and Below)gigiphiNessuna valutazione finora

- SheetDocumento1 paginaSheetgigiphiNessuna valutazione finora

- Engineering Services Functional Specification for Piping SpecialtiesDocumento25 pagineEngineering Services Functional Specification for Piping Specialtiesgigiphi100% (1)

- F3213-6115a - r0 - Piping Ga (Train-A) Top Deck Elevation View5Documento1 paginaF3213-6115a - r0 - Piping Ga (Train-A) Top Deck Elevation View5gigiphiNessuna valutazione finora

- HRD Process Platform Project MC Inspection & Test Record: Pressure Test Certificate P05-A Sheet 1 of 1Documento1 paginaHRD Process Platform Project MC Inspection & Test Record: Pressure Test Certificate P05-A Sheet 1 of 1gigiphiNessuna valutazione finora

- f3213-6500r0 - General Notes For Piping Support FabricationDocumento11 paginef3213-6500r0 - General Notes For Piping Support FabricationgigiphiNessuna valutazione finora

- F3213-6108.01a - r0 - Piping Ga (Train-A) Top Deck Plan View12 NorthDocumento1 paginaF3213-6108.01a - r0 - Piping Ga (Train-A) Top Deck Plan View12 NorthgigiphiNessuna valutazione finora

- Extract Pages From ASME B16.9 - 2003 - TEE (Factory-Made Wrought Buttwelding Fittings)Documento4 pagineExtract Pages From ASME B16.9 - 2003 - TEE (Factory-Made Wrought Buttwelding Fittings)gigiphiNessuna valutazione finora

- F3213-6107.01a - r0 - Piping Ga (Train-A) Main Deck Plan View11 NorthDocumento1 paginaF3213-6107.01a - r0 - Piping Ga (Train-A) Main Deck Plan View11 NorthgigiphiNessuna valutazione finora

- Weld Profiles - AWS D1.1 D1.1M-2010Documento1 paginaWeld Profiles - AWS D1.1 D1.1M-2010gigiphiNessuna valutazione finora

- s1 Sorter BrochureDocumento8 pagines1 Sorter BrochuregigiphiNessuna valutazione finora

- Welder List For Structure 1Documento7 pagineWelder List For Structure 1gigiphiNessuna valutazione finora

- SmokingDocumento2 pagineSmokinggigiphiNessuna valutazione finora

- Welder List For Structure 2Documento4 pagineWelder List For Structure 2gigiphiNessuna valutazione finora

- HUC Technical Exception (POS Response - 19 Oct 2011) - Rev 1Documento37 pagineHUC Technical Exception (POS Response - 19 Oct 2011) - Rev 1gigiphiNessuna valutazione finora

- PMC - POS Split Scope of WorkDocumento10 paginePMC - POS Split Scope of Workgigiphi100% (1)

- App T8-Tech Excep - 21 Nov - Huc (Pos) - PMC 23nov11Documento2 pagineApp T8-Tech Excep - 21 Nov - Huc (Pos) - PMC 23nov11gigiphiNessuna valutazione finora

- STT PTSC NISCONI L 0xxx Electrical Cable ScheduleDocumento1 paginaSTT PTSC NISCONI L 0xxx Electrical Cable SchedulegigiphiNessuna valutazione finora

- Welding InspectionDocumento137 pagineWelding InspectiongigiphiNessuna valutazione finora

- App T8-Tech Excep - 21 Nov - Huc (Pos) - PMC 23nov11Documento2 pagineApp T8-Tech Excep - 21 Nov - Huc (Pos) - PMC 23nov11gigiphiNessuna valutazione finora

- WeldingDocumento41 pagineWeldinggigiphiNessuna valutazione finora

- Welding InspectionDocumento137 pagineWelding InspectiongigiphiNessuna valutazione finora