Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Working: Figure 5.1 Fabricated Robotic Arm

Caricato da

Khawar RiazTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Working: Figure 5.1 Fabricated Robotic Arm

Caricato da

Khawar RiazCopyright:

Formati disponibili

Chapter 5

Working

The robotic arm was manufactured keeping in view the height and distance from the

conveyor belt. The height of the conveyor belt is 22cm. The pick and place operation was

impossible by using 1 DOF so, 2 DOF were used. Hence, considering the dimensions of

the conveyor belt lengths of the link 1 and link 2 of the manipulator were taken as 33cm

and 30cm. The full stretch length of the manipulator becomes 63cm, which is enough to

sort the objects. The fabricated robotic arm can be observed in figure 5.1.

Figure 5.1 Fabricated Robotic Arm

WORKING

23

As in the figure 5.2 can be observed that the object is passed on the conveyor belt. As

soon as the object enters the field of view of the camera, camera captures an image. The

operation can be observed in figure 5.2.

Figure 5.2 System in Operation

Once the image is captured different image processing techniques are implemented. To remove

the noises from the image median filter is applied. The shapes are identified using the area

analysis. Once the shape is known a signal is sent serially from the Simulink via Arduino UNO

(Microcontroller) to the manipulator. The robotic arm then picks the object from the conveyor

belt and places it in its respective position. The picking operation of the robotic arm could be

observed in the figure 5.3.

AUTONOMOUS OBJECT SORTING ROBOTIC SYSTEM

24

Figure 5.3 Robotic Arm Picking Object

The operation is done once the object is grabbed. and then the elbow joint is actuated and

the object is held up in the air, then the base then rotates and goes to the specific position

where the object lies and releases it in its position. The positions are predefined, and two

boxes are placed at different locations one for each type of object. After placing the

object manipulator returns to its original position and is ready to sort other objects

coming on the conveyor belt. The placing operation by the manipulator can be seen in the

figure 5.4.

WORKING

25

Figure 5.4 Robotic Arm Placing Object

The practical with handling two types of objects circular and rectangular was a success and the

positive thing of this type of system is that the chances of failure are very less, and it works

efficiently.

Potrebbero piacerti anche

- Object-Oriented Magnetic Resonance: Classes and Objects, Calculations and ComputationsDa EverandObject-Oriented Magnetic Resonance: Classes and Objects, Calculations and ComputationsValutazione: 3 su 5 stelle3/5 (1)

- Design and Development of A High Speed Sorting System Based On Machine Vision GuidingDocumento11 pagineDesign and Development of A High Speed Sorting System Based On Machine Vision GuidingMekaTronNessuna valutazione finora

- Experimental Setup of ProjectDocumento7 pagineExperimental Setup of Projectapi-248119294Nessuna valutazione finora

- Pick and Place RobotDocumento3 paginePick and Place RobotShubhamJain100% (1)

- Posteries027 EnglishDocumento1 paginaPosteries027 EnglishKritsada NakthewanNessuna valutazione finora

- 7.mech IJME Manipulator MihirDocumento7 pagine7.mech IJME Manipulator Mihiriaset123Nessuna valutazione finora

- InTech-Improving Greenhouse S Automation and Data Acquisition With Mobile Robot Controlled System Via Wireless Sensor NetworkDocumento27 pagineInTech-Improving Greenhouse S Automation and Data Acquisition With Mobile Robot Controlled System Via Wireless Sensor NetworkJeyhan AgaoNessuna valutazione finora

- Symbiosis of Human and Artifact Y. Anzai, K. Ogawa and H. Mori (Editors) © 1995 Elsevier Science B.V. All Rights ReservedDocumento6 pagineSymbiosis of Human and Artifact Y. Anzai, K. Ogawa and H. Mori (Editors) © 1995 Elsevier Science B.V. All Rights ReservedTrong Nhan DoNessuna valutazione finora

- Walking RobotsDocumento17 pagineWalking RobotsJoemon John KurishumootillNessuna valutazione finora

- Chapter 2Documento19 pagineChapter 2Aung ThikeNessuna valutazione finora

- Lab ManualDocumento9 pagineLab ManualSahil KokitkarNessuna valutazione finora

- Assembly Line Manipulator: Project ReportDocumento9 pagineAssembly Line Manipulator: Project ReportVishal CNessuna valutazione finora

- Sorting of Objects Based On Colour by PiDocumento10 pagineSorting of Objects Based On Colour by PiFarhab Khan FFNessuna valutazione finora

- How To Jog The RobotDocumento6 pagineHow To Jog The RobotzruscicNessuna valutazione finora

- F L8 TA 202 NC Part ProgrammingDocumento4 pagineF L8 TA 202 NC Part ProgrammingAqsa Khanam0% (1)

- Qualitative Vision-Based Mobile Robot Navigation: Zhichao Chen and Stanley T. BirchfieldDocumento7 pagineQualitative Vision-Based Mobile Robot Navigation: Zhichao Chen and Stanley T. BirchfieldJulierme SilvaNessuna valutazione finora

- Lab RoboticsDocumento14 pagineLab RoboticsNurul AdawiyahNessuna valutazione finora

- 05556780Documento6 pagine05556780Hitesh BahetiNessuna valutazione finora

- Design and Development of Automated 3D Visual Tracking SystemDocumento8 pagineDesign and Development of Automated 3D Visual Tracking Systemvinay_2211Nessuna valutazione finora

- Recovery Function For Human Following Robot Losing Target: Masahito OTA Hiroshi HISAHARA Yuki IshiiDocumento5 pagineRecovery Function For Human Following Robot Losing Target: Masahito OTA Hiroshi HISAHARA Yuki IshiiSAGAR JHA 14BEC1074Nessuna valutazione finora

- Gripping Position Detection of A Box-Shaped Object Using A RGB-D Sensor by Tracked Mobile Robot With Two ManipulatorsDocumento5 pagineGripping Position Detection of A Box-Shaped Object Using A RGB-D Sensor by Tracked Mobile Robot With Two ManipulatorsHữu BìnhNessuna valutazione finora

- Ijmerr v3n1 9Documento8 pagineIjmerr v3n1 9KwameOpareNessuna valutazione finora

- Autonomous Lavatory Cleaning SystemDocumento7 pagineAutonomous Lavatory Cleaning SystemAI Coordinator - CSC JournalsNessuna valutazione finora

- On-Line Next Best Grasp Selection For In-Hand Object 3D Modeling With Dual-Arm CoordinationDocumento6 pagineOn-Line Next Best Grasp Selection For In-Hand Object 3D Modeling With Dual-Arm CoordinationAbhishek VermaNessuna valutazione finora

- Object Tracking Using Color ObjectDocumento12 pagineObject Tracking Using Color Objectsunil rathoreNessuna valutazione finora

- Cost Effective Recognition and Classification of Moving Objects Using SimulinkDocumento10 pagineCost Effective Recognition and Classification of Moving Objects Using Simulinknam bachNessuna valutazione finora

- Hand Tracking-Based Motion Control For Robot Arm Using Stereo CameraDocumento5 pagineHand Tracking-Based Motion Control For Robot Arm Using Stereo CameraMaitriya DamaniNessuna valutazione finora

- Presented By: B.Tech (Mechanical Engineering) Mr. K. Sunil Kumar, M.Tech Assistant ProfessorDocumento22 paginePresented By: B.Tech (Mechanical Engineering) Mr. K. Sunil Kumar, M.Tech Assistant Professorsarath chandra satuluriNessuna valutazione finora

- Micro Servo RobotDocumento40 pagineMicro Servo Robotlokesh mahor0% (1)

- Real Time Object Tracking Using Image Based Visual Servo TechniqueDocumento7 pagineReal Time Object Tracking Using Image Based Visual Servo TechniqueSatNessuna valutazione finora

- Person Following Control For A Mobile Robot Based On Color Invariance Corresponding To Varying IlluminationDocumento10 paginePerson Following Control For A Mobile Robot Based On Color Invariance Corresponding To Varying IlluminationIAES International Journal of Robotics and AutomationNessuna valutazione finora

- Bases MiniHumanoide INTERCON2021 v1Documento15 pagineBases MiniHumanoide INTERCON2021 v1KEVIN CUSIHUALLPA HUAMANTTUPANessuna valutazione finora

- Report V1.1.4.finalDocumento17 pagineReport V1.1.4.finalDiego CorreaNessuna valutazione finora

- Humanoid Arm Manipulation Using Binocular Vision: Project ReviewDocumento42 pagineHumanoid Arm Manipulation Using Binocular Vision: Project ReviewLokesh KalyanarajNessuna valutazione finora

- Autonomous Robot OperationDocumento16 pagineAutonomous Robot OperationDiego CorreaNessuna valutazione finora

- Implementation of Cascade Control For Wheeled Mobile Robot Straight Path NavigationDocumento4 pagineImplementation of Cascade Control For Wheeled Mobile Robot Straight Path NavigationVon JinNessuna valutazione finora

- Implementation of An Object-Grasping Robot Arm Using Stereo Vision Measurement and Fuzzy ControlDocumento13 pagineImplementation of An Object-Grasping Robot Arm Using Stereo Vision Measurement and Fuzzy ControlWikipedia.Nessuna valutazione finora

- Prometeo: Beach Cleaner Robot: Oscar Cieza, Carlos Ugarte, Elizabeth Gutiérrez, Javier García, José TafurDocumento4 paginePrometeo: Beach Cleaner Robot: Oscar Cieza, Carlos Ugarte, Elizabeth Gutiérrez, Javier García, José TafurfrafagaNessuna valutazione finora

- Pick and Place RobotsDocumento16 paginePick and Place RobotssvishalnNessuna valutazione finora

- Smart Robot Arm Motion Using Computer VisionDocumento5 pagineSmart Robot Arm Motion Using Computer VisionVienNgocQuangNessuna valutazione finora

- Microcontroller Based Line Following Robot: 25 MARCH, 2018 Balerobe, EthiopiaDocumento10 pagineMicrocontroller Based Line Following Robot: 25 MARCH, 2018 Balerobe, EthiopiaBIniamNessuna valutazione finora

- Autonomous SearchbotDocumento2 pagineAutonomous SearchbotManoj Naik PNessuna valutazione finora

- An Ef Cient Regression Method For 3D Object Localization in Machine Vision SystemsDocumento11 pagineAn Ef Cient Regression Method For 3D Object Localization in Machine Vision SystemsIAES International Journal of Robotics and AutomationNessuna valutazione finora

- RF Based Pick and Place - PowerpointDocumento18 pagineRF Based Pick and Place - PowerpointAshu mishraNessuna valutazione finora

- A Mobile Jack Robot For Rescue Operation: J.Tanaka, K.Suzumori, M.Takata, T.Kanda, and M.MoriDocumento6 pagineA Mobile Jack Robot For Rescue Operation: J.Tanaka, K.Suzumori, M.Takata, T.Kanda, and M.MoriSamael RuizNessuna valutazione finora

- Localization Data Fusion RobotinoDocumento8 pagineLocalization Data Fusion RobotinoAlexandre RibeiroNessuna valutazione finora

- Presented By: Arz Kumar Satsangi & Vineet VermaDocumento26 paginePresented By: Arz Kumar Satsangi & Vineet VermagarunanarasNessuna valutazione finora

- Pick and Place Robotic Arm Implementation Using ArduinoDocumento9 paginePick and Place Robotic Arm Implementation Using Arduinodhinesh dinsNessuna valutazione finora

- Mobile Robot Location Algorithm Based On Image Processing TechnologyDocumento8 pagineMobile Robot Location Algorithm Based On Image Processing Technologycursito laliNessuna valutazione finora

- (Elearnica - Ir) - Robotic Systems Applied To Power Substations - A State-Of-The-Art SurveyDocumento6 pagine(Elearnica - Ir) - Robotic Systems Applied To Power Substations - A State-Of-The-Art SurveyjorjijonNessuna valutazione finora

- Survey of Vision-Based Robot Control: Ezio Malis INRIA, Sophia Antipolis, France, Ezio - Malis@Documento16 pagineSurvey of Vision-Based Robot Control: Ezio Malis INRIA, Sophia Antipolis, France, Ezio - Malis@Saran CoolNessuna valutazione finora

- InTech-Real Time Robotic Hand Control Using Hand GesturesDocumento17 pagineInTech-Real Time Robotic Hand Control Using Hand GesturesGR Techno SolutionsNessuna valutazione finora

- Fibra OpticDocumento39 pagineFibra OpticCristhian Aparcana RomanNessuna valutazione finora

- Chapter 4 Lecture Notes (Joints & End-Effector) - 02 JunDocumento57 pagineChapter 4 Lecture Notes (Joints & End-Effector) - 02 Junakash kahsyapNessuna valutazione finora

- Optimal Tracking A Moving Target For Integrated Mobile Robot-Pan Tilt-Stereo CameraDocumento6 pagineOptimal Tracking A Moving Target For Integrated Mobile Robot-Pan Tilt-Stereo CameraNguyễnĐạtNessuna valutazione finora

- Unit 2 RoboticsDocumento22 pagineUnit 2 RoboticsVishnu PriyanNessuna valutazione finora

- Obstacle Avoidance RobotDocumento40 pagineObstacle Avoidance RobotPraveen ReddyNessuna valutazione finora

- GUI Based Mobile Robot: Prof - Kiran Rathod, Aditi Malgi, Mittal Mehta, Mohanish Mane, Satyendra NishadDocumento3 pagineGUI Based Mobile Robot: Prof - Kiran Rathod, Aditi Malgi, Mittal Mehta, Mohanish Mane, Satyendra NishaderpublicationNessuna valutazione finora

- ELB1502 MajorTest2 S1-2023Documento2 pagineELB1502 MajorTest2 S1-2023Siphamandla CokaNessuna valutazione finora

- Linear Model Predictive Control: Stability and RobustnessDocumento98 pagineLinear Model Predictive Control: Stability and RobustnessKhawar RiazNessuna valutazione finora

- Control System IDocumento12 pagineControl System IKhawar RiazNessuna valutazione finora

- 8 OdesDocumento86 pagine8 Odesprashanthreddy26Nessuna valutazione finora

- Subject: Promotion From Lab Engineer To Lecturer: TH THDocumento1 paginaSubject: Promotion From Lab Engineer To Lecturer: TH THKhawar RiazNessuna valutazione finora

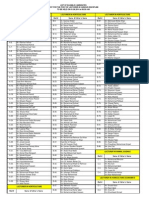

- List of Eligible ApplicantsDocumento13 pagineList of Eligible ApplicantsKhawar RiazNessuna valutazione finora

- Basic Verilog Programming: LAB KDocumento11 pagineBasic Verilog Programming: LAB KKhawar RiazNessuna valutazione finora

- Exp #3: Temperature Transducers: Objectives: To Understand The Operation of Thermistors and Realization of A TemperatureDocumento15 pagineExp #3: Temperature Transducers: Objectives: To Understand The Operation of Thermistors and Realization of A TemperatureKhawar RiazNessuna valutazione finora

- D Section PLC Group'sDocumento2 pagineD Section PLC Group'sKhawar RiazNessuna valutazione finora

- ChecklistkkkllllllDocumento5 pagineChecklistkkkllllllKhawar RiazNessuna valutazione finora

- Datasheet 7400Documento9 pagineDatasheet 7400gab50Nessuna valutazione finora