Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

IWE Subjects

Caricato da

Adnan Rana100%(3)Il 100% ha trovato utile questo documento (3 voti)

1K visualizzazioni2 pagineiwe

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoiwe

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(3)Il 100% ha trovato utile questo documento (3 voti)

1K visualizzazioni2 pagineIWE Subjects

Caricato da

Adnan Ranaiwe

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

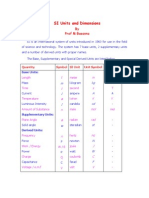

IAB-252-07 Course Title:IWE

Module 1 : Welding processes and equipment

93

1 1-1 General introduction to welding technology 3(3)

2 1-2 Oxy-gas welding and related processes 2(2)

3 1-3 Electrotechnics, a review 2(2)

4 1-4 The Arc 4(4)

5 1-5 Power sources for arc welding 4(4)

6 1-6 Introduction to Gas- shielded arc welding 2(2)

7 1-7 TIG Welding 6(4)

8 1-8 MIG/MAG and Flux Cored Arc Welding 6(4)

9 1-9 MMA Welding 8(4)

10 1-10 Submerged- Arc Welding 6(4)

11 1-11 Resistance Welding 8

12 1-12 Other Welding processes 10

13 1-13 Cutting and other edge preparation processes 4(2)

14 1-14 Surfacing and Spraying 2

15 1-15 Fully mechanised processes and robotics 6

16 1-16 Brazing and soldering 4

17 1-17 Joining processes for plastics 4

18 1-18 Joining processes for ceramics and composites 2

19 1-19 Welding laboratory 10

Module 2 : Materials and their behaviour during welding

111

20 2-1 Manufacture and designation of steels 2(2)

21 2-2 Testing materials and the weld joint 8(4)

22 2-3 Structure and properties of pure metals 4(4)

23 2-4 Alloys and Phase Diagrams 5(5)

24 2-5 Iron-Carbon Alloys 4(4)

25 2-6 Heat treatments of base materials and welded joints 4(4)

26 2-7 Structure of the welded joint 4(4)

27 2-8 Plain Carbon and Carbon-Manganese Steels 6(4)

28 2-9 Fine-grained steels 4(2)

29 2-10 Thermomechanically treated steels (TMCP steels) 4(4)

30 2-11 Cracking phenomena in welded joints 6(2)

31 2-12 Application of structural and high strength steels 2

32 2-13 Low-alloy steels for very low temperature application 4

33 2-14 Low alloy creep resistant steels 4

34 2-15 Introduction to corrosion 6

35 2-16 High-alloyed (stainless) steels 8

36 2-17 Introduction to wear 2

37 2-18 Protective Layers 4

38 2-19 High alloy creep resistant and heat resistant steels 2

39 2-20 Cast irons and steels 2

40 2-21 Copper and copper alloys 4

41 2-22 Nickel and nickel alloys 4

42 2-23 Aluminum and aluminums alloys 6

43 2-24 Other metals and alloys 2

44 2-25 Joining dissimilar materials 4

45 2-26 Metallographic examinations 6

International Welding Engineering (IWE) Subjects

N

o

sec. code Section Time(hr)

IAB-252-07 Course Title:IWE

Module 3 :Construction and Design 64

46 3-1 Basic theory of structural systems 4(4)

47 3-2 Fundamentals of the strength of materials 4(4)

48 3-3 Welded Joint design 4(4)

49 3-4 Basics of weld design 8

50 3-5 Behavior of welded structures under different types of loading 4

51 3-6 Design of welded structures with predominantly static loading 8

52 3-7 Behavior of welded structures under dynamic loading 6

53 3-8 Design of dynamically loaded welded structures 8

54 3-9 Design of welded pressure equipment 6

55 3-10 Design of Aluminum alloys structures 4

56 3-11 Reinforcing-steel welded Joints 2

57 3-12 Introduction to fracture mechanics 6

Module 4 : Fabrication, applications engineering 110

58 4-1 Introduction to quality assurance in welded fabrication 6

59 4-2 Quality control during manufacture 14

60 4-3 Residual Stresses and Distortion 6

61 4-4 Plant facilities, welding jigs and fixtures 4

62 4-5 Health and Safety 4

63 4-6 Measurement, Control and Recording in Welding 4

64 4-7 Non-Destructive Testing 20

65 4-8 Economics 8

66 4-9 Repair-Welding 2

67 4-10 Fitness for Purpose 2

68 4-11 Case Studies 40

69 2-I Pratical Education 60

Total hours 438

N

o

sec. code Section Time(hr)

Potrebbero piacerti anche

- International Welding Engineer Interview QuestionsDocumento2 pagineInternational Welding Engineer Interview QuestionsAnonymous 0rt9KWmN80% (5)

- IWSD M3 - 3 - Introduction To The Design of StructuresDocumento124 pagineIWSD M3 - 3 - Introduction To The Design of StructuresPourya NouryNessuna valutazione finora

- Paper 5qa 002 Sa2Documento12 paginePaper 5qa 002 Sa2Siva Kumar100% (1)

- Iws Materials and Their Behaviour PDFDocumento282 pagineIws Materials and Their Behaviour PDFkatfy1Nessuna valutazione finora

- CWEng SampleQuestionsDocumento8 pagineCWEng SampleQuestionsSungJun ParkNessuna valutazione finora

- Module 1 16 - IIWDocumento1.119 pagineModule 1 16 - IIWsree100% (1)

- Welding Processes and EquipmentDocumento167 pagineWelding Processes and EquipmentTAF150850Nessuna valutazione finora

- International Welding Engineer IWE CVDocumento4 pagineInternational Welding Engineer IWE CVlaz_k50% (2)

- DAC3 March 2012Documento319 pagineDAC3 March 2012John Boran100% (1)

- Iws Materials and Their Behaviour PDFDocumento282 pagineIws Materials and Their Behaviour PDFscott2355100% (8)

- Welding IiwDocumento6 pagineWelding IiwletsmakeithappenNessuna valutazione finora

- 15.welding Engineering PDFDocumento15 pagine15.welding Engineering PDFEmad A.Ahmad100% (2)

- IIW World OverrviewDocumento4 pagineIIW World OverrviewAnonymous hBBam1nNessuna valutazione finora

- IIW IWE Syllabus PDFDocumento27 pagineIIW IWE Syllabus PDFசுரேஷ் பாலமுருகன்100% (1)

- WPE2 Course Notes PDFDocumento356 pagineWPE2 Course Notes PDFQuoc Vinh100% (2)

- International Welding Engineer - Model PaperDocumento23 pagineInternational Welding Engineer - Model Paperrohit mathanker100% (2)

- Welding Processes ANB IIWDocumento273 pagineWelding Processes ANB IIWAsad Bin Ala Qatari100% (5)

- IWE ModuleGuide 15crDocumento39 pagineIWE ModuleGuide 15crAbigail TrevinoNessuna valutazione finora

- Iws Fabrication Application PDFDocumento245 pagineIws Fabrication Application PDFScott Trainor100% (1)

- Minimum Requirements IweDocumento52 pagineMinimum Requirements IweIonutz TelteuNessuna valutazione finora

- Wtia Iiw Iwe V3 - 0 PDFDocumento2 pagineWtia Iiw Iwe V3 - 0 PDFRizwan NazirNessuna valutazione finora

- The Indian Institute of WeldingDocumento11 pagineThe Indian Institute of WeldingNnamdi Celestine NnamdiNessuna valutazione finora

- Course Fully Sponsored By: (W International Institute of Welding (IIW) Diploma of International Welding Specialist (IWS)Documento8 pagineCourse Fully Sponsored By: (W International Institute of Welding (IIW) Diploma of International Welding Specialist (IWS)SanthaKumar Muthu ThankaveluNessuna valutazione finora

- IIW Diploma - WPE1 Course NotesDocumento300 pagineIIW Diploma - WPE1 Course NotesBilly Tan100% (12)

- Welding Essential Variables - en ISO 15614Documento2 pagineWelding Essential Variables - en ISO 15614NS QCNessuna valutazione finora

- Demoversion IWE 2011Documento47 pagineDemoversion IWE 2011Burag HamparyanNessuna valutazione finora

- Duplex Ss WPSDocumento8 pagineDuplex Ss WPSVinu Raveendran100% (1)

- Material BehaviorDocumento111 pagineMaterial BehaviorFajar LuqmanNessuna valutazione finora

- WeldingDocumento15 pagineWeldingJacob Green100% (1)

- Construction and DesignDocumento2 pagineConstruction and DesignAnthony AbelNessuna valutazione finora

- Certified International Welding Engineer PDFDocumento2 pagineCertified International Welding Engineer PDFSridharan ChandranNessuna valutazione finora

- Guideline For IWE and IWT TrainingDocumento6 pagineGuideline For IWE and IWT TrainingAnil KulkarniNessuna valutazione finora

- Welding 11-14%Cr IIW Document - Part 1Documento20 pagineWelding 11-14%Cr IIW Document - Part 1Manuel CarreñoNessuna valutazione finora

- GSI SLV Duisburg - International Welding Engineer-2015Documento2.485 pagineGSI SLV Duisburg - International Welding Engineer-2015yutwelding83% (12)

- Iwt Book PDFDocumento1.196 pagineIwt Book PDFsree100% (1)

- Wtia Iiw Iwe V3 - 0Documento2 pagineWtia Iiw Iwe V3 - 0Rizwan NazirNessuna valutazione finora

- Welding QuestionnairesDocumento2 pagineWelding Questionnairesasif712100% (2)

- IIW Diploma - DAC1 Course Notes PDFDocumento243 pagineIIW Diploma - DAC1 Course Notes PDFTan Billy100% (3)

- 04 Briony Holmes - TWI PDFDocumento32 pagine04 Briony Holmes - TWI PDFSupratim Biswas100% (2)

- Sandeep Kumar CV - Welding Engineer-Welding InspectorDocumento4 pagineSandeep Kumar CV - Welding Engineer-Welding InspectorWeld Bro Sandeep100% (1)

- Old Questions IWEDocumento7 pagineOld Questions IWErohit mathankerNessuna valutazione finora

- 1143 EWF IIW Diploma Overview - August 2013Documento2 pagine1143 EWF IIW Diploma Overview - August 2013Sean ฌอนNessuna valutazione finora

- IWSD 2012-M4 - 4 Design Against Brittle FractureDocumento29 pagineIWSD 2012-M4 - 4 Design Against Brittle FracturePourya NouryNessuna valutazione finora

- Welders Training Program ManualDocumento140 pagineWelders Training Program ManualAlmario Sagun100% (1)

- IIW-India ANB Brochure JulyDocumento6 pagineIIW-India ANB Brochure JulyMahesh JetuNessuna valutazione finora

- CE Marking of StructuralDocumento31 pagineCE Marking of StructuralRavi ValiyaNessuna valutazione finora

- BS en 439 94 PDFDocumento12 pagineBS en 439 94 PDFDario RamljakNessuna valutazione finora

- Responsible Welding CoordinatorDocumento637 pagineResponsible Welding Coordinatorscott2355100% (5)

- Multiple PQR QualificationDocumento4 pagineMultiple PQR QualificationKarthikeyan ShanmugavelNessuna valutazione finora

- IIW SyllabusDocumento31 pagineIIW SyllabusAbhishek AnandNessuna valutazione finora

- Paper - 5QA 002 SA1Documento12 paginePaper - 5QA 002 SA1kreksomukti5508100% (1)

- Reinforced C Vol - IDocumento6 pagineReinforced C Vol - IIgnacio Luis Reig Mataix42% (12)

- Unit 1 - Introduction To Welding and OxyfuelDocumento2 pagineUnit 1 - Introduction To Welding and OxyfuelKamarul NizamNessuna valutazione finora

- Materials 13 02022 v2Documento16 pagineMaterials 13 02022 v2Nathanael Basana HisarNessuna valutazione finora

- Piping Codes, Standards, and Specifications 1Documento5 paginePiping Codes, Standards, and Specifications 1Manish KumarNessuna valutazione finora

- Special Metals Joining (WeldingWorld) PDFDocumento52 pagineSpecial Metals Joining (WeldingWorld) PDFاکبر کرمیNessuna valutazione finora

- Manufacturing Processes For Engineering MaterialsDocumento10 pagineManufacturing Processes For Engineering Materialsrmsamy125% (37)

- StandardsDocumento7 pagineStandardsMoch Rafi AnugrahNessuna valutazione finora

- Zoznam NoriemDocumento4 pagineZoznam NoriemPeter TvardzíkNessuna valutazione finora

- In Partial Fulfillment For The Award of The Degree ofDocumento11 pagineIn Partial Fulfillment For The Award of The Degree ofKumar DneshNessuna valutazione finora

- TWI-ADS-FRM-003-00, Request For Providing Goods From StoreDocumento2 pagineTWI-ADS-FRM-003-00, Request For Providing Goods From StoreAdnan RanaNessuna valutazione finora

- Twi PK: TotalDocumento1 paginaTwi PK: TotalAdnan RanaNessuna valutazione finora

- CP3 - 1-09 Tube Welding 2nd Edition July 2015 PDFDocumento19 pagineCP3 - 1-09 Tube Welding 2nd Edition July 2015 PDFAdnan RanaNessuna valutazione finora

- Criteri For AffiliationDocumento6 pagineCriteri For AffiliationAdnan RanaNessuna valutazione finora

- TWI ADS FRM 005 00, Goods Services Supply RecordsDocumento2 pagineTWI ADS FRM 005 00, Goods Services Supply RecordsAdnan RanaNessuna valutazione finora

- Twi PK: Administration Section List of Approved Suppliers Document Code: TWI-ADS-FRM-001-00Documento1 paginaTwi PK: Administration Section List of Approved Suppliers Document Code: TWI-ADS-FRM-001-00Adnan RanaNessuna valutazione finora

- 15 - Nde Rev 011Documento32 pagine15 - Nde Rev 011Adnan RanaNessuna valutazione finora

- TWI ITS FRM 001 00, Equipment ListDocumento2 pagineTWI ITS FRM 001 00, Equipment ListAdnan RanaNessuna valutazione finora

- An Introduction To:: Centrifugal Pumps - API 610 BasedDocumento11 pagineAn Introduction To:: Centrifugal Pumps - API 610 BasedAdnan RanaNessuna valutazione finora

- Muhammad Farhad Ghouri: ObjectiveDocumento2 pagineMuhammad Farhad Ghouri: ObjectiveAdnan RanaNessuna valutazione finora

- 2016 Detail CalendarDocumento15 pagine2016 Detail CalendarAdnan RanaNessuna valutazione finora

- Api 570Documento1 paginaApi 570Adnan Rana100% (1)

- P&ID and PFD DevelopmentDocumento5 pagineP&ID and PFD DevelopmentAdnan RanaNessuna valutazione finora

- Pakistan 1113 Visual Welding Inspector - January 2016Documento1 paginaPakistan 1113 Visual Welding Inspector - January 2016Adnan RanaNessuna valutazione finora

- TWI Technology Engineering (PVT) LTD: Training Calendar 2016Documento3 pagineTWI Technology Engineering (PVT) LTD: Training Calendar 2016Adnan RanaNessuna valutazione finora

- Mechanical Engineering Drawing: SR KaleDocumento22 pagineMechanical Engineering Drawing: SR KaleAdnan RanaNessuna valutazione finora

- Asme b31.3 Process Piping Code SimplifiedDocumento1 paginaAsme b31.3 Process Piping Code SimplifiedAdnan Rana0% (1)

- Objective: The P&ID: Reading and Interpretation Course Is Designed ForDocumento2 pagineObjective: The P&ID: Reading and Interpretation Course Is Designed ForAdnan RanaNessuna valutazione finora

- Piping & Instumentation Diagram (P&Id) Engineering Drawings InterpretationDocumento1 paginaPiping & Instumentation Diagram (P&Id) Engineering Drawings InterpretationAdnan RanaNessuna valutazione finora

- Wall - Penstock - 200x200 1200x1200Documento2 pagineWall - Penstock - 200x200 1200x1200Mohamed RamadanNessuna valutazione finora

- 16-CONSERVATION OF LINEAR MOMENTUM - 01-TheoryDocumento15 pagine16-CONSERVATION OF LINEAR MOMENTUM - 01-TheoryRaju SinghNessuna valutazione finora

- Variational MethodDocumento4 pagineVariational Methodletter_ashish4444Nessuna valutazione finora

- Industry 4.0 4Documento23 pagineIndustry 4.0 4Mandhara KsNessuna valutazione finora

- Fact Sheet MerichemDocumento4 pagineFact Sheet Merichemsureshbabu7374Nessuna valutazione finora

- Energy Management System Using Particle Swarm Optimization For MicrogridDocumento2 pagineEnergy Management System Using Particle Swarm Optimization For MicrogridNellis BlancoNessuna valutazione finora

- Standard For Overhead LinesDocumento23 pagineStandard For Overhead LinesHappi Gwegweni0% (1)

- ABB LTB 145 D1B 1HSB429954-3en - 20120511Documento214 pagineABB LTB 145 D1B 1HSB429954-3en - 20120511Daniel Buitrago Ramirez100% (6)

- Engine Report Sriwantha PDFDocumento14 pagineEngine Report Sriwantha PDFSriwantha HewageNessuna valutazione finora

- Samsung Frontier WasherDocumento88 pagineSamsung Frontier Washerpetre333Nessuna valutazione finora

- Enst Renewable Energy Syllabus 2015 1Documento6 pagineEnst Renewable Energy Syllabus 2015 1api-303214818Nessuna valutazione finora

- Mli Nov Dec 2022Documento40 pagineMli Nov Dec 2022huseyinNessuna valutazione finora

- ME6603 FEA AL AMEEN1 Lecture NotesDocumento155 pagineME6603 FEA AL AMEEN1 Lecture Notesl8o8r8d8s8i8v8Nessuna valutazione finora

- GS Ep PVV 000 enDocumento9 pagineGS Ep PVV 000 ensenthil muruganNessuna valutazione finora

- Lecture 4 Water Pipe Sizing PDFDocumento26 pagineLecture 4 Water Pipe Sizing PDFAlchea Aldeguer100% (1)

- Lab 5 - Sync GeneratorDocumento4 pagineLab 5 - Sync GeneratorzawirNessuna valutazione finora

- SI Units and Dimensions: by Prof M BasannaDocumento4 pagineSI Units and Dimensions: by Prof M Basannaembi76Nessuna valutazione finora

- Year 1, Course CH158: Foundations of Chemistry Section A3 Basics of Organic ChemistryDocumento40 pagineYear 1, Course CH158: Foundations of Chemistry Section A3 Basics of Organic ChemistryVina DwitaNessuna valutazione finora

- Helix HX7 10W 40 TdsDocumento2 pagineHelix HX7 10W 40 TdsDery AlfianNessuna valutazione finora

- Transformer NameplateDocumento2 pagineTransformer NameplateHamza AliNessuna valutazione finora

- 998-21327565 DVR Ebro GMADocumento24 pagine998-21327565 DVR Ebro GMACata CatalinNessuna valutazione finora

- Thesis ProposalDocumento42 pagineThesis ProposalHarvey M. OrongNessuna valutazione finora

- Science Curriculum Guide Grades 3-10 December 2013Documento64 pagineScience Curriculum Guide Grades 3-10 December 2013api-252270937Nessuna valutazione finora

- CURICULUM VITAE - Koko SantanaDocumento2 pagineCURICULUM VITAE - Koko SantanaRiesky FirdyanNessuna valutazione finora

- BLDC 1500 2018 BC Building Code-Part 9 Single Family Dwelling BuildingsDocumento12 pagineBLDC 1500 2018 BC Building Code-Part 9 Single Family Dwelling BuildingsHamza TikkaNessuna valutazione finora

- The lEE Regulations, BS 7671 and This Guide PDFDocumento259 pagineThe lEE Regulations, BS 7671 and This Guide PDFatramanathanNessuna valutazione finora

- Omid Beik PHD ThesisDocumento333 pagineOmid Beik PHD ThesisMuhammad Sohaib ShahidNessuna valutazione finora

- RefacDocumento5 pagineRefacknight1729Nessuna valutazione finora

- Informe2 - Ing - ElectricaDocumento24 pagineInforme2 - Ing - ElectricaCarlos Coral TaipeNessuna valutazione finora

- Human Activity and The Environment: 2. Liquid WasteDocumento3 pagineHuman Activity and The Environment: 2. Liquid WasteDanellNessuna valutazione finora