Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A Proposed Integrated Transport Terminal For Barbaza, Antique

Caricato da

RubyFaithEspinosa0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

1K visualizzazioni172 pagineComplete project study of a proposed terminal in Barbaza, Antique

Titolo originale

A Proposed Integrated Transport Terminal for Barbaza, Antique

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoComplete project study of a proposed terminal in Barbaza, Antique

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

1K visualizzazioni172 pagineA Proposed Integrated Transport Terminal For Barbaza, Antique

Caricato da

RubyFaithEspinosaComplete project study of a proposed terminal in Barbaza, Antique

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 172

A PROPOSED INTEGRATED TRANSPORT TERMINAL

FOR BARBAZA, ANTIQUE

A Project Study

Submitted in Partial Fulfillment of the Requirements

for the Course CE 5102 Civil Engineering Project by:

Ruby Faith D. Espinosa

Mark B. Kho Yute

Charles C. Suobiron

Engr. Erwin L. Rizardo

Adviser

Civil Engineering Department

College of Engineering

Central Philippine University

Jaro, Iloilo City

October 2013

ACKNOWLEDGMENT

We would like to thank the following:

Engr. Erwin Rizardo, our adviser, and Engr. Shevanee Ruth Dela Cruz, the

coordinator of the course subject, for helping us throughout the making of the study.

Engr. Mary Earl Daryl Grio and Engr. Gerardo Gepulango, faculty of CPU Civil

Engineering Department, for sharing their knowledge to us every time we seek technical

advice; Also, Engr. Vitini Edhard Idemne, faculty of CPU Electronics and

Communications Engineering, for helping us in our electrical estimates;

Engr. Emmanuel Juanitas, Municipal Engineer of Barbaza, for becoming our

main consultant in Antique. Former Mayor Faith Francisco, the municipal officials, and

residents of Barbaza for responding to our data gathering;

CPU Math and Physics Department for helping us in the analysis of our data;

Department of Public Works and Highways and Ceres Liner Maintenance

Department for providing us the necessary information for the study;

Our families and friends who warmly supported us throughout the making of this

project study; Kho Yutes family who always welcomed us to their residence which

became the major place in the making of the study;

Our classmates, CPU Civil Engineering Batch 2014, for helping us in many

different ways, from sharing their knowledge and resources to simply encouraging us.

Above all, the Almighty God, whom by His grace made all these things possible.

The Research Team

TABLE OF CONTENTS

TITLE PAGE ..

APPROVAL SHEET ..

ACKNOWLEDGMENT .

TABLE OF CONTENTS

LIST OF FIGURES AND TABLES .......

ABSTRACT

CHAPTER I: INTRODUCTION ....

1.1 Background and Rationale of the Study ..

1.2 Problem Definition ..

1.3 Ultimate Objective ..

1.4 Specific Objectives ..

1.5 Operational Variable and Key Terms ..

1.6 Significance of the Study ....

1.7 Scope and Limitation ..

CHAPTER II: REVIEW OF RELATED LITERATURE ......

2.1 The Function of Transport Terminals .

2.2 Design of Transport Terminals ...

CHAPTER III: METHODOLOGY

3.1 Data Gathering

3.2 Data Analysis ..

3.3 Resources and Facilities ..

i

ii

iii

iv

vi

viii

1

1

6

8

9

9

10

11

12

12

14

15

15

16

18

CHAPTER IV: PROJECT AREA ...

4.1 Physical Features .

4.2 Infrastructure Resources ..

4.3 Economic Structure .

4.4 Proposed Site of the Transport Terminal

CHAPTER V: THE PROPOSED PROJECT ..

5.1 Project Description ..

5.2 Architectural Plans ..

5.3 Structural Plans ...

5.4 Electrical Plans ....

5.5 Plumbing Plans

5.6 Traffic Design .

5.7 Construction Specifications .

5.8 Project Cost and Work Schedule .

CHAPTER VI: PROJECT IMPLEMENTATION ..

CHAPTER VII: CONCLUSIONS AND RECOMMENDATIONS ...

REFERENCES ....

APPENDICES .....

Appendix A Structural Design and Analysis ...

Appendix B Detailed Estimates ..

Appendix C Topographic Survey

Appendix D Questionnaire Survey ..

19

19

24

25

27

29

29

29

31

32

32

33

67

74

79

80

81

84

84

149

158

163

LIST OF FIGURES AND TABLES

List of Figures

Figure 1.1 Map of Philippines showing the location of Antique .....

Figure 1.2 Map of Panay Island showing the location of Barbaza ..

Figure 1.3 Map of Panay Island showing its towns .

Figure 1.4 National road along Barbaza ..

Figure 1.5 Bus unloading a passenger along the national road ...

Figure 1.6 Tricycles parking along the national road ..

Figure 4.1 Slope map ...

Figure 4.2 Soil map .

Figure 4.3 Location of the proposed terminal (right view) .

Figure 4.4 Location of the proposed terminal (left view)

List of Tables

Table 1.1 Tourist destinations .

Table 1.2 Types and number of registered vehicles

Table 4.1 Slope distribution .

Table 4.2 Soil type distribution ...

Table 5.1 Summary of estimates .

Table 5.2 Work schedule .

2

2

3

5

7

8

21

23

27

28

4

6

20

22

67

68

A PROPOSED INTEGRATED TRANSPORT TERMINAL FOR

BARBAZA, ANTIQUE

ABSTRACT

A terminal may be defined as any facility where passengers and

freight are assembled or dispersed. Terminals are central and intermediate locations in the

movements of passengers and a necessary part of any transport system. By using

schedule of services and a common loading and unloading area for public vehicles,

terminals generally provide comfort, speed, and efficiency to passengers.

An integrated transport terminal is proposed at Brgy. Poblacion, Barbaza, Antique

to address problems of delays, missed trips, and inconvenience caused by uncertainty of

travel schedule and loading of passengers along the highway. The transport terminal will

cater services for nearby municipalities and can accommodate four different modes of

land transportation: bus (local and RORO bus), public utility jitney (PUJ), van (PUV),

and tricycle.

The project study is supported with architectural, structural, electrical and

plumbing plans, construction specifications, cost estimates, and work schedule. The

structure was designed using the codes and specifications of the National Structural Code

of the Philippines (NSCP 2010). Ultimate Stress Design and Allowable Stress Design

methods were used in designing concrete and steel members respectively.

The project cost is estimated to 15,314,438.45 with 82 working days to finish.

The project will be funded by the Municipality of Barbaza through the Department of

Finance in Manila.

Chapter I

INTRODUCTION

This chapter presents the background, rationale, objectives, significance of the study of

the study, and scope and limitations of the study

1.1 Background and Rationale of the Study

Terminals are a necessary part of any transport system. It may be defined as any

facility where passengers and freight are assembled or dispersed. Terminals are designed

to insure a continuity of the flows that will generally provide comfort, speed, and

efficiency. Transportation terminals are also focal points of economic activity.

Transportation terminals are also focal points of economic activity. The traffic

flowing through terminals and the need to transfer freight between the modes gives

opportunities to other activities to use locational advantages. Manufacturing firms can

locate near terminals. Also, terminals are linked with the service sector because terminal

activity creates demands for a very wide range of transport services.

Barbaza is a 4th Class municipality located at the central part of the province of

Antique in Region VI (Western Visayas). Barbaza is situated along the Philippine

National Highway linking the four provinces of Panay Island. The total population of

Barbaza as of 2010 is 21,775. Previous censuses of population show a continual increase

in number since 1970. By the year 2022, Barbaza has a projected population of 27,425.

2

Figure 1.1 Map of Philippines Showing the Location of Antique

Figure 1.2 Map of Panay Island Showing the Location of Barbaza

3

Figure 1.3 Map of Panay Island Showing its Towns

Barbaza is an agricultural and coastal community. It is the 3

rd

largest rice-

producing municipality in the province of Antique and exports rice to provincial and

regional markets. Barbazas geographical location and nearness to different economic

centers such as Kalibo, Aklan, Roxas City, Passi City, and Iloilo City makes the

municipality within reach to a variety of economic investments.

4

Tourism in Barbaza relies on nature spots and on historical sites and structures.

Coral reefs, beaches, forest parks, waterfalls, caves, and spring abound for tourism

development. Macalbag Water Falls in Brgy. Mablad and Cadiao Falls in Brgy. Cadiao

are sites where people visit during summer time. Caves can be found in Brgy. Mablad

and Brgy. Esparar. They are abodes of limestone where intricate stalactite and stalagmite

are found.

Historical

Jinalinan Plaza (the site of the peace treaty between Gen. Fullon and the

American Forces in Panay Island)

Natural

Esparar Cave

Makalbag Falls

Mablad Caves

Cadiao Falls

Batabat Coral Reef

Religious Barbaza Catholic Church

Man-Made

Kaigangan Diversion Dam

Villa Alianza Resort

Welbeck Inland Resort

Table 1.1Tourist Destinations

Barbaza is known for its Abaca Fiber being declared by FIDA as a world class

fiber which can be found in the upland barangays of the municipality. Being the largest

producer of Abaca Fiber in the province, the product serves as the theme of the annual

agro-industrial fair being celebrated every 2nd week of March named as Kigihan

Festival. The festival brings back Barbaza balikbayans bringing with them their foreign

friends.

5

Figure 1.4 National Road Along Barbaza

Transportation services in Barbaza are generally provided by tricycles, public

utility jitneys (PUJs), public utility vans (PUVs), and buses. The public utility vehicles

are used to transport passengers from Barbaza to Kalibo, San Jose, and Iloilo or vice

versa. Tricycle, on the other hand, is the common means of transportation to most

barangays. There are also daily buses available going back and forth to Manila that pass

by the town via the roll-on/roll-off (RORO) nautical highway. A total of 647 motor

vehicles are accounted for in the Municipality of Barbaza.

6

Type of vehicle Number Type of vehicle Number

Jitney 20 Owner-type jeep 47

Private

Public

17

3

Private

Public

46

1

Automobile 28 Truck 18

Private

Government

26

2

Private

Government

16

2

Motorcycle 87 Bus 4

Tricycle 321 Van 11

Private

Public

17

302

Private

Public

2

9

Ambulance 2 TOTAL 647

Table 1.2Types and Number of Registered Vehicles

1.2 Problem Definition

The municipality has no terminal for public utility jitneys, tricycles, and

motorcycles. At present, the existing parking area or terminal for public utility jitneys

and tricycles is located in front of the public market which becomes more crowded with

the increasing number of utility vehicles operating every year.

A site visit and opinion survey of the residents of Barbaza resulted in the

following identification of problems:

Passengers in Barbaza purchase tickets through ticketing businesses (e.g. Dimple

Stars) found on different sari-sari stores and they are given estimated time of arrival of

the RORO buses. Delays are usually encountered by the passengers. There are also

cases where they miss the bus due to the wrong estimation of arrival time. In the case of

other public vehicles that do not use a ticketing system, like buses of Ceres Liners and

tricycles, waiting passengers do not have the assurance that there are available and not

fully occupied vehicles to ride on at specific times of day. These uncertainty problems

7

with regard to arrival time of RORO buses and availability of vehicles are most important

to be considered for the safety of the passengers who travel during the night. These

problems also result to inefficient use of time and effort of the passengers.

Current transportation system in Barbaza shows an unsafe and disorganized traffic

flow. Public vehicles load and unload passengers anytime and anywhere along the

national road of the town. Because of the narrow highway, buses load and unload the

passengers on the vehicle lane. With the absence of designated loading and unloading

area, accidents are more probable to take place. Moreover, PUJs and tricycles usually

park in front of the market and the school which becomes more crowded with the

increasing number of utility vehicles operating every year.

Figure 1.5 Bus Unloading a Passenger Along the National Road

8

The present tricycle system of Barbaza is not organized. Tricycles comprise

majority of the public vehicles yet there is no terminal to organize their services and load

the passengers properly. Thus, drivers tend to compete in picking the passengers. Also,

since they roam around the municipality looking for passengers, it results to high

consumption of gasoline, and ultimately to a low profit.

Figure 1.6 Tricycles Parking Along the National Road

1.3 Ultimate Objective

The ultimate objective of this study is to design an integrated transport terminal

for Barbaza, Antique.

9

1.4 Specific Objectives

To achieve the ultimate objective, the following specific objectives were met:

1. Coordinated with the Municipality Engineer;

2. Obtained necessary data from the municipality regarding the project

area like population census and registered vehicles;

3. Conducted visual inspection of the site and surveyed the area;

4. Interviewed municipal officials, drivers, passengers, vendors and other

residents regarding the existing transportation system; and

5. Prepared complete plans, detail specifications, work program, and cost

estimates.

1.5 Operational Variable and Key Terms

A terminal is any facility where passengers and freight are assembled or

dispersed in the transportation process.

A tricycle is a 3-wheeled vehicle propelled by a motor. It is often used for public

transportation.

Public Utility Van (PUV) is a multipurpose enclosed motor vehicle having a

boxlike shape, rear or side doors, and side panels (often with windows) used for public

transportation.

Public Utility Jitney (PUJ) is a vehicle smaller than a bus that carries passengers

over a regular route on a flexible schedule and is available for use by the general public.

Buses are large motor vehicles designed to carry passengers usually along a fixed

route according to a schedule.

10

The Roll-on, Roll-off, popularly known as RORO, is an inter-island system of

transportation that involves the driving of a motorized land vehicle in and out of an inter-

island ferry or cargo ship. It is basically a mode of transportation designed to carry

wheeled vehicles such as cars, trucks, cargo trucks, trailers, etc. over a body of water.

Some RORO vessels also transport passengers.

Ceres Liner is a bus line under Vallacar Transit Inc., the largest public land

transportation company in the island of Negros, Philippines. It operates bus transport

service to the whole island of Negros from Bacolod City to Panay, Cebu and Samar-

Leyte islands.

A municipality is a local government unit in the Philippines. Municipalities are

also called towns.

1.6 Significance of the Study

The construction of the terminal will provide an organized system of

transportation in Barbaza. It will provide the passengers a more convenient and efficient

transportation service while preventing loss of their time and effort.

Because of the scheduling of services and continuity of transport services, the

terminal will provide public vehicle drivers the assurance of having passengers in their

trips, and help the tricycle drivers reduce their high fuel consumption caused by roaming

around, looking for passengers. The terminal, therefore, will help increase the income of

PUJ and tricycle drivers in Barbaza in a time-efficient manner.

11

The terminal will help decrease the accident rates in Barbaza by providing a

separate loading area for public vehicles and a safe waiting area for passengers that

would mostly benefit the night-time travelers.

The terminal will improve the economic status of Barbaza by increasing the

employment rate through hiring necessary people for the needed terminal services. It will

also bring locational advantages like the operation of different businesses in the vicinity.

An organized system of transportation through terminals will also bring good

accommodation for tourists and therefore boost the tourism of the municipality.

1.7 Scope and Limitation

This study includes all architectural, structural, electrical, and plumbing plans,

structural analysis and details, construction specifications, project cost and estimates, and

work schedule of the proposed integrated transport terminal. The actual construction,

implementation and maintenance of the project are not included in the study. The study

does not include any view regarding the administration and management of the terminal

and the assessment regarding its environmental impacts.

Chapter II

REVIEW OF RELATED LITERATURES

This chapter presents the review of literature and other related studies

2.1 The Function of Transport Terminals

2.1.1 The Nature of Transport Terminals

Terminals are a necessary part of any transport system. A terminal may be

defined as any facility where passengers and freight are assembled or dispersed. Both

cannot travel individually, but in batches. Terminals may be points of interchange

involving the same mode of transport. They may also be points of interchange between

different modes of transportation. Transport terminals are central and intermediate

locations in the movements of passengers and freight. They often require specific

facilities and equipment to accommodate the traffic they handle.

2.1.2 Economic Advantages of Transport Terminals

Transportation terminals are focal points of economic activity. The traffic

flowing through terminals and the need to transfer freight between the modes gives

opportunities to other activities to use locational advantages. There have been long

standing advantages for certain types of manufacturing to locate near terminals. Also,

terminals are linked with the service sector. Terminal activity creates demands for a very

wide range of transport services. These include activities as diverse as locomotive repair,

kitchens, warehousing, duty free stores, and freight forwarders. Together they comprise

13

an important business sector that contributes to the overall effectiveness of the terminal.

In addition to the linkages with manufacturing and the service sector, terminals are major

employers in their own right. In order to operate a major terminal requires a wide range

of employee skills. Terminals, therefore, is a source of employment and benefit regional

economic activities, notably by providing accessibility to suppliers and customers. They

become foci of economic activity because they generate links to other sectors of the

economy. Terminals are frequently considered as growth poles.

2.1.3 Terminal Costs

Because they jointly perform transfer and consolidation functions, terminals are

important economically because of the costs incurred in carrying out these activities.

Terminal costs represent an important component of total transport costs. They are fixed

costs that are incurred regardless of the length of the eventual trip, and vary significantly

between the modes. They can be considered as:

1. Infrastructure costs. Include construction and maintenance costs of structures.

2. Transshipment costs. The costs of loading and unloading passengers or

freight.

3. Administration costs. Many terminals are managed by institutions.

Administration costs are incurred.

A truck or a passenger bus can be loaded much more quickly, and hence the

terminal costs for road transport are the lowest.

14

2.2 Design of Transport Terminals

An important factor which determines the level of transportation service is the

design of a transport terminal. Apart from comfort, speed, and efficiency in trunk

movement, what contributes to passenger satisfaction is the planning of the terminal in

such a manner that its internal layout minimizes the possible disorientation of a passenger

as he alights from his vehicle and rushes into the terminal building desiring that he be

enabled to proceed to the destination without undue loss of time.

Layouts and activities taking place in passenger terminals tend to be simple and

require relatively little equipment. This is because individual mobility is the means by

which passengers access buses, ferries or trains. They may appear congested at certain

times of the day, but the flows of people can be managed successfully with good design

of platforms and access points, and with appropriate scheduling of arrivals and

departures. The amount of time passengers spend in such terminals tends to be brief.

Transport terminal facilities may include: arrival and departure lanes; traffic

control facilities; terminal administration areas; terminal operations, maintenance, safety,

and security areas; parking areas for terminal personnel, customers, and visitors; and

transport vehicle servicing areas.

Chapter III

METHODOLOGY

This chapter presents the methodology of the study, specifically the site visit, data

gathering, surveying, architectural plans, and structural design and analysis

3.1 Data Gathering

3.1.1 Site Visit

Site visits were conducted to investigate the present situation around the vicinity.

Informal interviews with the Mayor, the municipal officials, and the residents were

conducted regarding their opinion and ideas about the current transportation system of

Barbaza.

With the help of the Municipal Engineer, the proposed site of the terminal was

inspected visually and observations were noted regarding the flow of traffic, and the

characteristics of the site and its surroundings. The boundaries for the proposed project

were also located.

3.1.2 Questionnaire Survey

To determine the acceptability of the residents on the proposed project,

questionnaires were made and distributed to 50 drivers and 50 passengers by convenience

sampling. The sample questionnaire and the summary of the results are found in

Appendix E.

16

3.1.3 Topographic Survey

The site was surveyed using inclined sights. Different points were located within

the proposed site, its boundaries, and its surroundings. The values obtained, the detailed

computations, and the resulting topographic map are found in Appendix D.

3.2 Data Analysis

3.2.1 Development of Plans

Architectural plans were conceptualized using the data on the registered vehicles

of Barbaza. The dimensions of the design vehicle for the bus lane was based on the

largest RORO bus that passes by Barbaza (data obtained from the Maintenance

Department of Ceres Liner at Buhang, Jaro).

Architectural, electrical, and plumbing plans were aided by able professionals.

3.2.2 Structural Design and Analysis

Details were prepared with utmost simplicity, accuracy, and clarity for easy

understanding in construction. Beams are designed to have uniform dimensions for

aesthetic and economic purposes.

3.2.2.1 Material Properties and Data Specifications

Compressive strength of concrete (fc) and yield stress of steel (fy) used were

based on the usage of the structure and availability of materials in the market. Unit

weight of soil was based on construction practices in Antique.

17

For beams and slabs, fc = 28 MPa

For columns, fc = 21 MPa

For all structural members, fy = 275 MPa

Weight of concrete, Wc = 23.5 KN/m

3

Allowable soil bearing capacity, qa = 50 kPa

Unit weight of soil = 15.7 KN/m

3

3.2.2.2 Design Code, Standards, and Method

The structure was designed using the codes and specifications of the National

Structural Code of the Philippines (NSCP 2010). The design for terminal slabs was

based on the standards set by the Department of Public Works and Highway. The

properties of steel are based on ASEP Steel Manual.

Ultimate Stress Design (USD) method was used in the design and analysis of

reinforced concrete members. While Allowable Stress Design (ASD) method was used

for steel. Throughout the design of structural members, all columns and footings are

assumed to be axially loaded.

3.2.2.3 Design Load Specifications

Roofing (arched beam)

Dead load: G.I. sheet = 0.08 KPa

Roofing (diagonal beam)

Dead load: G.I. sheet = 0.08 KPa

18

Roofing (minor structure)

Dead loads:

Acoustical fiber board = 0.05 KPa

Mechanical duct allowance = 0.20 KPa

Water-proofing membranes (liquid applied) = 0.03 KPa

Insulation (1 cm fiber board) = 0.028 KPa

3.3 Resources and Facilities

Background information of the project area was taken from the two

Comprehensive Land Use Plans of Barbaza (2004-2014 and 2012-2022) obtained at the

Office of the Municipality. The CLUP contains the record of the registered local

vehicles, maps, physical features of Barbaza, and its human resources and economic

structure. Reference books, online articles, and past project studies of CPU Civil

Engineering Department were also used to support the study.

Theodolite and stadia rods were used in the topographic survey.

AutoCAD software was used to draft all plans and the topographic map.

Spreadsheet software Microsoft Office Excel (MS Excel) was used in the computation of

elevations, structural analysis, and cost estimates. Statistical Product and Service

Solutions (SPPS) tool was used in analyzing the results of the questionnaire survey.

Cameras were used to document opinion surveys and pictures of the site. Laptops

were used to secure all data and prepare all required reports.

Chapter IV

PROJECT AREA

This chapter profiles the project area of the proposed project plan

4.1 Physical Features

4.1.1 Land Area

Barbaza is located in the central part of Antique. It has a total land area of

15,436.333 hectares, of which 9,207.964 (60%) hectares are timberland and 5,674.951

(40%) hectares, alienable and disposable lands.

4.1.2 Geographic Location

The municipality is located at 11 11 48 855 N latitude 122 0214 191 E

longitude. It is bounded in the north by the municipality of Tibiao, on the east by the

municipality of Tapaz, Capiz, on the south by the municipality of Laua-an, and the Cuyo

East Pass on the west. It is 60 kilometers away from San Jose de Buenavista, the

provincial capital and 160 kilometers away from Iloilo City.

4.1.3 Political Subdivision

Barbaza is one of the 18 municipalities in the Province of Antique. It is

composed of 39 barangays, which are divided into two categories, the lowland and the

upland areas.

20

4.1.4 Geology

The underlying rocks of the Municipality of Barbaza are mostly igneous. These

rocks are metamorphic and igneous rock in nature and mostly found on the eastern

section of the municipality. The parent materials of these rocks belong to Lumboyan

Formation, Baloy Volcanics and Qauternary Alluvium. Aside from this basalt formation,

coralline limestone rock deposits are also found in Barbaza and are mostly concentrated

in the hills of the southern and eastern parts of the municipality.

4.1.5 Elevation and Slope

The municipality has the highest elevation of 2,325m found in Mt. Nangtud,

Barangay Mayabay. The 0-3% slope which is equal to 2,375.70 hectares is considered to

be alienable and disposable area based on the topographic map of National Mapping and

Research Institute Agency (NAMRIA). The slope 18% and above accounts for

12,282.97 hectares. These areas include the proclaimed timberland (9,207.96 has.).

Range Land Area (ha) % Distribution

0-3% (Level to Nearly Level) 2,375.70 15.39

3%- 18 % ( Gently to Undulating) 777.34 5.04

18-30% ( Strongly Sloping to Moderate Steep) 508.40 3.29

30-50% (Steep Hills & Mountainous) 1,193.12 7.73

50% & Above (Very Steep Hills & Mountainous) 10,581.45 68.55

TOTAL 15,436.33 100%

Table 4.1Slope Distribution

Figure 4.1 Slope Map

4.1.6 Soils

There are five soil types found in the Municipality of Barbaza namely:

Alimodian Sandy Loam, Umingan Sandy loam, San Manuel Clay, Beach Sand and

Mountain Soil Undifferentiated.

Soil Type Land Area (has) % Distribution

Alimodian Sandy Clay 6,599.47 42.75

Umingan Sandy Loam 729.05 4.72

San Manuel Clay 1,013.11 6.56

Beach Sand 129.29 0.84

Mountain Undifferentiated Soils 6,932.49 44.91

River sand 32.6 0.21

TOTAL 15,436.01 100.00

Table 4.2Soil Type Distribution

4.1.7 Mineral Resources

The mountainous area of the municipality are rich in Manganese, Copper, Gold

and Marble which can be found in the upland barangays of Mayabay, Lombuyan,

Marigne, Mablad, Idao, Igpalge and Esparar. Other mineral deposits such as limestone

can be found in Esparar. Sand and gravel is being extracted in identified rivers and is

being used for infrastructure projects.

4.1.8 Water Resources

The main river, Dalanas River is 43 kilometers long, 23 kilometers falls under the

jurisdiction of the municipality. A substantial number of rivers, creeks and small

tributaries lead to Dalanas River. Six of them are within the jurisdiction of Barbaza.

Figure 4.2 Soil Map

Natural springs and ground water, which are common sources for potable water,

abound in different barangays in the municipality. The Barbaza Water District (gravity

type serving 10 barangays) is taking its source from natural springs in Sitio Atabay and

Sitio Bay-ang, and a pumping station in Bantayan, Brgy. Gua. There are other natural

springs in the municipality which are also sources of potable water and irrigation system.

4.2 Infrastructure Resources

4.2.1 Roads

The Municipality of Barbaza is linked to the adjacent municipalities of Laua-an

on the south and Tibiao on the north through the national highway. The provincial road

has a total length of 52.60 kilometers. The municipal road can be found in Poblacion and

Jinalinan and these cover 3.834 kilometers. Barangay roads have a total length of 69.93

kilometers.

4.2.2 School Buildings

Barbaza School District has 18 elementary schools. There are 16 public and 2

private schools. It has two secondary schools, one private and one public. All secondary

schools, Barbaza National High School and Saint Anthonys High School are

strategically located along the national highway. Most of the barangays have Day Care

Centers except for some remote barangays.

4.2.3 Health Services

There is a municipal hospital being managed by the Antique Provincial Health

24

Office in Brgy. Lisub admitting patients for consultations and confinement. Barbaza

Rural Health Unit is in Poblacion, where basic services can be availed of. Ten Barangay

Health Stations are located in catchment barangays.

A government dentist is available at the municipal hospital. Private dental

practitioners are also available, one in the Poblacion, one in Sitio Aligtos,

Barangay Igpalge, and two in Brgy. Capoyu-an.

4.2.4 Public Building & Facilities

Barbaza has a municipal building for 200 employees, a covered court, and a PNP

building housing 24 PNP personnel.

4.2.5 Utilities

Antique Electric Cooperative (ANTECO) provides power services for the 27

barangays. Town based information and communication facilities are made up of the

Philippine Postal Office, Globe, Smart and Sun cellular sites. Other courier companies

service the municipality, although their offices are based in other towns in the province.

4.3 Economic Structure

4.3.1 Public Markets

There are two public markets in the municipality. The Poblacion Daily Market, in

Poblacion, is along the national highway, and Palma Public Market with Bagsakan Center

located in Brgy. Palma leading to the northern part of Antique.

25

4.3.2 Industry

Barbaza is known for its Abaca Fiber being declared by FIDA as a world class

fiber. Dalanas River is a major source of aggregates and identified by the Provincial

Engineering District DPWH-Antique as one of the two main sources of gravel, boulders

and sand in the province. Several quarry operators are operating in the area, exporting

aggregates to other parts of the country.

One multi-pass and five mobile rice mills are operating in the locality. Two

hollow blocks producers and three bakeries are situated within the lowland area. Two

wood-furniture makers, one bamboo craft producer, and one noodles fruit processing

plant in Brgy. Esparar. All these, including the chain saw operators, comprise the various

industries in the municipality.

There are approximately 230 commercial wholesale and retail establishments,

recreational parlors, hollow block factory, refilling stations, warehouses and shops

operating in the entire municipality.

4.3.3 Agriculture

Barbaza is the 3rd leading rice producing municipality in the province of Antique.

Four thousand five hundred forty four hectares (4,544 or 29.44 %) of its land is fertile

agricultural land planted to different crops.

4.3.4 Employment

Farming and fishing are the occupation of the majority of Barbazeos. To

estimate the monetary value of per diems of an ordinary farmer or laborer, this cannot

26

augment the daily operating expenses of one household with a member of five. The same

scenario was also revealed during the National Household Targeting System for Poverty

Reduction, conducted by the DSWD, which they have identified 35.54% (1,520) of the

total households belong to poor households during their assessment last 2008.

4.4 Proposed Site of the Transport Terminal

The site is located along the plaza area and near the national road. Majority of the

land is vacant but a part is currently being rented by local eateries made of nipa and

bamboo. The land is legally owned by the municipality of Barbaza.

Figure 4.3 Location of the Proposed Terminal (right view)

27

Figure 4.4 Location of the Proposed Terminal (left view)

Chapter V

THE PROPOSED PROJECT

This chapter presents the project description, architectural plans, structural plans,

electrical plans, plumbing plans, traffic design, and construction specifications

5.1 Project Description

The proposed project is a transportation terminal with an administration office,

public rest rooms, waiting area, storage room, and guardhouse. The transport terminal is

located at Poblacion, Barbaza, Antique. The proposed project has an area of 800 square

meters (m

2

), 40 meters by 20 meters. It is expected to accommodate four different modes

of transportation: 4 buses (RORO and local buses), 3 public utility jitneys (PUJs) or vans

(PUVs), and 18 tricycles. Vehicles have separate lanes for parking. The administration

office will serve as the information center of passengers and the office for over-all

administrator. The storage room may be used for janitorial supplies.

5.2 Architectural Plans

The architectural plans include the perspective, the vicinity map and site

development plan, the elevations of the terminal, the schedule of doors and windows and

details of gate, and the ground floor plan indicating the traffic flow and positions of

vehicles in the terminal.

Site

Church

Saint Anthony's

High School

Pharmacy

Plaza

Municipal Hall

National Road going North

VICINITY MAP

SCALE : N.D.T.S.

31

5.3 Structural Plans

Structural plans include the foundation plan, roof framing plans, and structural

details of beams, columns, and footings. Detailed computations for the structural

analysis and design are found on Appendix B.

5.3.1 Design of Purlins

Purlins are used over the arched and inclined wide-flange beams of the roof. The

purlins are C 8 x 13.5. Weld is E 60 XX Electrode (4.76 mm or 3/16 in) with the length

of 224.4 mm.

5.3.2 Design of Slabs

5.3.2.1 Roof slab

One-way slab design is used for the waiting area. One-way slab has a thickness

of 165 mm. Two-way slabs are used for the office, comfort room, storage room, and the

guard house. These slabs have thickness of 125 mm.

5.3.2.2 Floor slab

Floor slabs of the terminal have thickness of 150 mm with 12 mm diameter

reinforcing bars spaced at 750 mm based on DPWH standard for terminal slabs.

5.3.3 Design of Beams

The beams of the roof (arched, inclined, and horizontal) are wide-flange beams.

The beams are W 10 x 15. The beams for the minor structure are reinforced concrete

32

with dimensions of 330 x 150 mm.

5.3.4 Design of Columns

The columns of major structure are composite members of steel and concrete

joined with base plates. The columns are W 6 x 12 joined with reinforced concrete

columns with dimensions of 250 x 250 mm. Base plates have dimensions of 200 x 200 x

10 mm. The long wide-flange columns are W 6 x 12. The columns of minor structure

are reinforced concrete with dimensions of 150 x 150 mm.

5.3.5 Design of Footing

All footings are designed as square footings. Footings under the composite

columns have dimensions of 1.6 m x 1.6 m and 1.4 m x 1.4 m. Footings for the

reinforced concrete columns of the minor structure have dimensions of 1.2 m x 1.2 m.

5.3.6 Design of Bolts and Stirrups

Design of bolts and stirrups with detailed computations are found in Appendix B.

5.4 Electrical Plans

The electrical plans include the electrical layout, schedule of loads, and design

analysis.

5.5 Plumbing Plans

The plumbing plans include the plumbing layout, septic vault detail, and catch

33

basin detail.

5.6 Traffic Design

5.6 1 Parking space

Length of 11.5 meters and width of 3.5 meters are provided for each bus.

Dimensions of 7.5 meters by 2.5 meters are provided for each PUJ/PUV, while 2 meters

by 2 meters are provided for each tricycle.

5.6.2 Pavement

The surface will be paved with concrete. The pavement will have a 2% slope.

Slope in the pavement is necessary to drain water and prevent it from staying at the center

of pavement.

5.6.3 Lights

Lights are provided for guidance and safety of drivers and passengers.

ARCHITECTURAL PLANS

PERSPECTIVE

FRONT ELEVATION

SCALE : N.D.T.S.

1 2 3 4 5

EXIT

ENTRANCE

11.56 m

11.50 m

1

1

.8

7

m

5

.

5

0

m

3

.

0

0

m

2

.

3

5

m

1

1

.

2

0

m

0

.

3

0

m

3

.

4

5

m

2

.

7

5

m

3

.

0

0

m

2

.

3

0

m

SEE BLOW UP A

3 5 2 1 4

REAR ELEVATION

SCALE :

1

1

.

2

0

m

2

.

0

0

m

3

.

9

0

m

3

.

0

0

m

2

.

3

0

m

N.D.T.S.

LEFT ELEVATION

SCALE : N.D.T.S.

A B C

0

.

3

0

m

3

.

1

5

m

2

.

7

5

m

3

.

0

0

m

1

.

3

0

m

1

1

.

2

0

m

SEE BLOW UP B

A B C

RIGHT ELEVATION

SCALE : N.D.T.S.

3

.

1

5

m

2

.

7

5

m

2

.

6

0

m

1

.

3

0

m

0

.

3

0

m

1

1

.

2

0

m

WAITING AREA

OFFICE

STORAGE

3 2 1

GUARDHOUSE

SCALE : N.D.T.S.

R O A D

ENTRY EXIT

PROPERTY LINE

PROPERTY LINE

P

R

O

P

E

R

T

Y

L

IN

E

P

R

O

P

E

R

T

Y

L

IN

E

1 2 3 4 5

A

A'

A''

B

B'

B''

C

A

D1

D1

D2

D2

D3

D3

D3

W1

W2

W2

W3

W4

W4

10.00 m 10.00 m 10.00 m 10.00 m

3

.

6

0

m

3

.

4

0

m

3

.

0

0

m

4

.

5

0

m

3

.

0

0

m

2

.

5

0

m

3.00 m 5.00 m 5.00 m

1

0

.

0

0

m

1

0

.

0

0

m

3.30 m

GROUND FLOOR PLAN

BUS LANE

JEEPNEY LANE

TRICYCLE LANE

SEE BLOW UP A OF

GROUND FLOOR PLAN

SCALE : N.D.T.S.

R O A D

ENTRY EXIT

PROPERTY LINE

PROPERTY LINE

P

R

O

P

E

R

T

Y

L

I

N

E

P

R

O

P

E

R

T

Y

L

I

N

E

1 2 3 4 5

A

B

C

10.00 m 10.00 m 10.00 m 10.00 m

5.00 m

1

0

.

0

0

m

1

0

.

0

0

m

TRAFFIC FLOW DIAGRAM

BUS LANE

JEEPNEY LANE

TRICYCLE LANE

1

0

.

0

0

m

1

0

.

0

0

m

5.00 m

40.00 m

3 2 1

SCALE : N.D.T.S.

P

R

O

P

E

R

T

Y

L

I

N

E

1

A

A'

A''

B

B'

B''

C

D1

D1

D2

D2

D3

D3

D3

W1

W2

W2

W3

W4

W4

3

.

6

0

m

3

.

4

0

m

3

.

0

0

m

4

.

5

0

m

3

.

0

0

m

2

.

5

0

m

3.00 m

3.30 m

BLOW UP A OF GROUND FLOOR PLAN

GUARD HOUSE

OFFICE

WAITING AREA

COMFORT ROOM

STORAGE ROOM

D1 D2 D3 W1 W2 W3 W4

0.73 0.68

1.40 2.90

0.60 0.60

1.20

0.50 0.80 0.70 0.50

FINISH OFFICE FLOOR LINE

SCHEDULE OF DOORS

MARK DESCRIPTION

D - 1 SOLID WOOD KD PANEL DOOR

HEIGHT

2.10

WIDTH

0.80

NO. OF SETS

2

D - 2 2.10 0.70 2

SCHEDULE OF WINDOWS

MARK DESCRIPTION HEIGHT WIDTH NO. OF SETS

W - 1 1.20 2.90 1 6MM THK. FIXED GLASS WINDOW ON ALUM. FRAME

SOLID WOOD KD PANEL DOOR

D - 3 2.10 0.50 3 PVC DOOR W/ LOUVER

W - 2 1.20 1.40 2 6MM THK. SLIDING GLASS WINDOW ON ALUM. FRAME

W - 3 1.20 1.20 1 6MM THK. SLIDING GLASS WINDOW ON ALUM. FRAME

W - 4 .50 .50 2 6MM THK. AWNING GLASS WINDOW ON ALUM. FRAME

SCHEDULE OF DOORS & WINDOWS

SCALE : N.D.T.S.

BLOW UP A

SCALE :

BLOW UP B

SCALE :

GATE DETAIL

SCALE : NDTS

BRICKS

ROAD LINE

FINISH TERM. FLOOR LINE

TOP OF SQUARE BAR

TOP OF SQUARE BAR POST

1/4" THK X 4" SQUARE TUBE

1/4" THK. X 2" SQUARE TUBE

1/4 " THK X 6" SQUARE TUBE

2.35 2.36

4.71

TOP OF FENCE

1.92 1.97

3.89

1/4" THK. X 1" ANGLE BAR

2.45 2.45

0.15 1.35 0.10

0.70

0.15 0.15 1.35 0.10

0.70

0.15

1/4" THK. X 2" SQUARE TUBE

NDTS

NDTS

STRUCTURAL PLANS

1 2 3 4 5

A

B

C

FOUNDATION PLAN

SCALE N.D.T.S.

C1F1 C3F2

C1F1

C1F1

C2F3

C2F3 C2F3

C2F3

C2F3

C2F3 C2F3

C2F3 C2F3

10.00m 10.00m 10.00m

C3F2

C3F2

C3F2

C3F2

C3F2

C3F2

C3F2

C3F2

C3F2

C3F2

C3F2

C2F3

WF1

WF1

WF1

WF2

WF2

WF2

WF2

WF2 WF1 WF1 WF1

WF1 WF1 WF1 WF1

WF2

WF2

WF2

WF2

WF1

WF1

WF1

WF1

WF1

WF1

7.00m 3.00m

1

0

.

0

0

m

1

0

.

0

0

m

2

.

5

0

m

3

.

0

0

m

4

.

5

0

m

3

.

0

0

m

3

.

4

0

m

3

.

6

0

m

3.30m

8 - 16mm

O.C.B.W.

NGL

0

.

8

0

m

4 - 16mm RSB

w/ 10mm LAT.

TIES @

2 - 0.05m,.

2-0.10m.,

@ 0.15m., O.C.

8 - 16mm

O.C.B.W.

4 - 16mm

1

.

6

0

m

0.25 m

DETAIL OF C1F1

SCALE N.D.T.S.

5 - 16mm

O.C.B.W.

NGL

0

.

8

0

m

3 - 16mm

O.C.B.W.

NGL

0

.

8

0

m

0

.

2

4

m

1

.

4

0

m

0.25 m

DETAIL OF C3F2

SCALE N.D.T.S.

DETAIL OF C2F3

SCALE N.D.T.S.

0

.

1

8

m

1

.

1

0

m

0.25 m

8 - 16mm

O.C.B.W.

8 - 16mm

O.C.B.W.

4 - 16mm

4 - 16mm

0

.

2

8

m

250 mm x 250 mm Column 250 mm x 250 mm Column 250 mm x 250 mm Column

4 - 16mm RSB

w/ 10mm LAT.

TIES @

2 - 0.05m,.

2-0.10m.,

@ 0.15m., O.C.

4 - 16mm RSB

w/ 10mm LAT.

TIES @

2 - 0.05m,.

2-0.10m.,

@ 0.15m., O.C.

0

.

2

5

m

0.40m

0

.

6

0

m

Finish Grade Line

10mm RSB @ 0.6m O.C.B.W.

WALL FOOTING FOR 100mm AND 150mm CHB WALL

SCALE N.D.T.S.

ROOF FRAMING PLAN

SCALE : N.D.T.S.

1 2 3 4 5

A

B

C

Purlins

11.50 m

10.20 m

11.50 m

10.20 m

INCLINED WIDE FLANGE

INCLINED WIDE FLANGE

ARCHED WIDE FLANGE ARCHED WIDE FLANGE HORIZONTAL WIDE FLANGE HORIZONTAL WIDE FLANGE

10.00 m 10.00 m 10.00 m 10.00 m

1

0

.

0

0

m

1

0

.

0

0

m

1

.

0

0

m

1

.

0

0

m

1.12 m 1.12 m

1.12 m 1.12 m

ROOF BEAM FRAMING PLAN (ARCHED AND INCLINED BEAM)

SCALE N.D.T.S.

1 2 3 4 5

A

B

C

C5 B6 B7

40.00 m

10.00 m 10.00 m 10.00 m 10.00 m

1

0

.

0

0

m

1

0

.

0

0

m

B6

B6

B6

B6

B6

B7

B7 B7

B7 B7

C5

C5 C4

C4

C4

C4

C4

C4

C4

C4

C4

C4

C4

C4

1.12 m 1.12 m

ROOF BEAM FRAMING PLAN AT C5

SCALE N.D.T.S.

1 2 3 4 5

A

B

C

B8

40.00 m

10.00 m 10.00 m 10.00 m 10.00 m

40.00 m

10.00 m 10.00 m 10.00 m 10.00 m

1

0

.

0

0

m

1

0

.

0

0

m

C4

C4

C4

C4

C4

C4

C4

C4

C4

C4

C4

C4

C5

C5

C5

B8

B8

B8

B8

B8

B8

B8

B8

B8

B8

B8

B8

B8

B8

B8

B8

B8

B8

B8

B8

B8

B2

B2

B3

B3

B2

B3

B1

B1

B1

B4

B5

B4

B5

B1

B4

B5

C1

C2

C2 C2

C2 C2

C2 C2

C2

C2

C1

C1

C3

C3

ROOF BEAM FRAMING PLAN (MINOR STRUCTURE)

SCALE N.D.T.S.

C3

1 2 3 4 5

A

A'

A''

B

B'

B''

C

S2

S3

S1

S4

S5

B1

40.00 m

10.00 m 10.00 m 10.00 m 10.00 m

3.30 m

C3

C3

C3

C3

C3

C3

C3

C3

C3

C2

3.00 m

3

.

6

0

m

3

.

4

0

m

3

.

0

0

m

4

.

5

0

m

3

.

0

0

m

2

.

5

0

m

Scale

0.15mm

BEAM DETAILS

N.D.T.S.

0.33 mm

Vertical Stirrups 10mm, 4 @ 80mm, 5 @ 120mm and rest @ 160mm

2-16mm Top Bars

2-16mm Bottom Bars

0

.

0

7

5

m

12 mm Straight Bars @ 150 mm O.C.

10 mm Shrinkage and Temperature Bars

@ 175 mm O.C.

0

.

0

7

5

m

3.30 m

7

.

5

0

m

WAITING AREA ONE-WAY ROOF SLAB

Scale N.D.T.S.

170mm thk Concrete Slab

0

.

0

7

5

m

3

.

4

m

0

.

0

7

5

m

12 mm Bent @ Straight Bars @ 200 mm O.C.

12 mm Straight Bars @ 200 mm O.C.

12 mm Bent @ Straight Bars @ 200 mm O.C.

12 mm Straight Bars @ 200 mm O.C.

0.075 m

0

.

0

8

m

3

.

6

0

m

3.00 m

12 mm Bent @ Straight Bars @ 200 mm O.C.

12 mm Straight Bars @ 200 mm O.C.

12 mm Bent @ Straight Bars @ 200 mm O.C.

125 mm thk Concrete Slab

Scale N.D.T.S.

OFFICE AND GUARD HOUSE TWO-WAY ROOF SLAB

3

.

0

0

m

0

.

0

7

5

m

3.30 m

2

.

5

0

m

0.075 m

12 mm Bent @ Straight Bars @ 200 mm O.C.

12 mm Straight Bars @ 200 mm O.C.

12 mm Bent @ Straight Bars @ 200 mm O.C.

12 mm Straight Bars @ 200 mm O.C.

Scale N.D.T.S.

STORAGE ROOM AND COMFORT ROOM TWO-WAY ROOF SLAB

125 mm thk Concrete Slab

ELECTRICAL PLANS

WAITING AREA

MECHANICS RM.

3 2 1

ELECTRICAL LAYOUT

SCALE : NDTS

ENTRY EXIT

PROPERTY LINE

P

R

O

P

E

R

T

Y

L

I

N

E

P

R

O

P

E

R

T

Y

L

I

N

E

S3 ABC

E

A

B

C

C

B B

S1 D

D

S3 EFG

F

G

S1 H

S1 I

S1 J

H

I

J

H

I

S3 KLM

S2 NO

K

L M

N O

S3 PQR

S3 STU

O

O

P P

Q

S

Q

R R S

T

T U U V

V W W X X

S3 VWX

C.O. POWER LINE

L.O. POWER LINE

13W PINLIGHT

CIRCUIT HOMERUN

PANEL BOARD

DUPLEX SWITCH

TRIPLEX SWITCH CONVENIENCE OUTLET

SINGLE POLE SWITCH

S1

S2

S3

30W ELDFL FLOOD LIGHT

32W CIRCULAR LIGHT

LEGEND:

22W DOME TYPE REFLECTOR

W

A

I

T

I

N

G

A

R

E

A

M

E

C

H

A

N

I

C

S

R

M

.

3

2

1

PROPERTY LINE

S

3

A

B

C

E

A

B

C

C

B

B

S

1

D

D

S

3

E

F

G

F

G

S

1

H

S

1

I

S

1

J

H

I

J

H

I

S

3

K

L

M

S

2

N

O

S

3

P

Q

R

S

3

S

T

U

S

3

V

W

X

SECTION A OF ELECTRICAL LAYOUT

SCALE : N.D.T.S.

DESIGN ANALYSIS:

C1 : LIGHT OUTLET

I = 20(30W)+5(22)+6(40)+9(16.25)

= 750+137.50+240+146.25=1,273.75/230

= 5.53 A

Ic = 5.53 A x 1.25 = 6.91 A

USE: 2 - 3.5mm THWN STRANDED

20mm UPVC

15A 2PCB BOLT-ON

C2 : CONVENIENCE OUTLET

I = 6(180)= 1,080 / 230 = 4.69 A

Ic = 4.69 A x 1.25 = 5.86 A

USE: 2 - 3.5mm THWN STRANDED

20mm UPVC FLEX. CONDUIT

20A 2PCB BOLT-ON

C2,& C3:SPARE

I = 500 VA

2.17AmP

MAIN BREAKER:

IT =3,353.75VA

I LOAD = 3,353.75/230=14.58A

= 14.58 A

USE: 2 - 14mm THWN

60A 2P C.B. BOLT-ON

30 mm RSC

1

LOAD DESCRIPTION

LIGHT OUTLETS

S1 L.O. EF EL SP

AMPERE

CIRCUIT

PROTECTION

SIZE & TYPE

& STRANDED

CU CONDUCTOR

SIZE OF CONDUIT

UPVC

20mm UPVC

OUTLETS

SCHEDULE OF LOADS

15A

2

3

4

CIRCUIT

NO.

V/A SWITCHES

SPARE

500.00

S2 S3 C.O.

5.53

4.69

SPARE

20A

15A

2.17

2.17

1080

2-3.5mm THWN

S3W

14.56

40

6

2-14mm THWN 30mm RSC 60A 40 6 2 TOTAL

1,273.75

3,353.75

CONVENIENCE OUTLETS

MAIN

20mm UPVC flex

20mm UPVC

2-3.5mm THWN

2-3.5mm THWN 500.00

1

1

SINGLE LINE DIAGRAM

15 A

2 - 3.5 mm THWN

C1 C2

2 - 14 mm THWN

SERVICE ENTRANCE

220V

60Hz

1

CO

2 - 3.5 mm THWN

20 A

30 mm RSC

2PCB THWN

LO

C9 C10

60 A

SPARE SPARE

PLUMBING PLANS

PLUMBING LAY-OUT

SCALE : N.D.T.S.

ENTRY EXIT

PROPERTY LINE

P

R

O

P

E

R

T

Y

L

I

N

E

P

R

O

P

E

R

T

Y

L

I

N

E

1 2 3 4 5

A

A'

A''

B

B'

B''

C

C.O.

URI.URI.

LAV.

LAV.

W.C.

W.C.

W.C.

FD.

100 rr0 30Ll0 PlPE LlNE

50 rr0 wA3TE PlPE LlNE

100 rr0 30lL PlPE LlNE 150 mm DRAINAGE SYSTEM

TO STREET

DRAINAGE

TO STREET

DRAINAGE

TO STREET

DRAINAGE

FD.

FD.

FD.

FD.

FD.

SOLID, WASTE ,SOIL & WATER PIPE LINE

50 rr0 wATER PlPE LlNE

GV.

GV.

150 mm DRAINAGE SYSTEM

FD.

SEPTIC VAULT

50 rr0 v3TR

CB

CB

CB

CB

CB

CB

CB CB

CB

CB

CB

CB

CB

CB

SEE BLOW UP OF CR

PLUMBING LAYOUT

BLOW UP OF CR PLUMBING LAYOUT

SCALE : N.D.T.S.

A'

A''

C.O.

URI.URI.

LAV.

LAV.

W.C.

W.C.

W.C.

FD.

100 rr0 30Ll0 PlPE LlNE

50 rr0 wA3TE PlPE LlNE FD.

FD.

FD.

FD.

FD.

50 rr0 wATER PlPE LlNE

GV.

GV.

FD.

50 rr0 v3TR

CB

BLOW UP OF CR ISOMETRIC PLUMBING LAYOUT

SCALE : N.D.T.S.

2000 1000 1000

4000

750 500 750

MANHOLE

250 500 250 250 500 250

10mm REINF. BARS

AT 200 O.C. B.W.

MANHOLE MANHOLE

500 500 500 500

100 X 200 X 400 CHB

10mm HOR.

BARS @ 600 O.C.

10mm VERTICAL

BARS @ 600 O.C.

4" PVC

INLET

4" PVC

OUTLET

DIGESTIVE CHAMBER LEACHING CHAMBER LEACHING CHAMBER

600X600

MANHOLE

600X600

MANHOLE

600X600

MANHOLE

2000 1000 1000

4000

750 500 750

MANHOLE

250 500 250 250 500 250

MANHOLE MANHOLE

10mm REINF. BARS

AT 200 O.C. B.W.

PLAN

N.G.L. N.G.L.

1 % SLOPE

4" PVC

INLET

SEPTIC VAULT DETAIL

SCALE : N.D.T.S.

10mm REINF. BARS

AT 200 O.C. B.W.

100 X 200 X 400 CHB

600

SECTION

PLAN

10mm REINF. BARS

AT 100 O.C. B.W.

6" CONC. PIPE

6" CONC. PIPE

6" CONC. PIPE

6" CONC. PIPE

CATCH BASIN DETAIL

SCALE : N.D.T.S.

67

5.7 Construction Specifications

5.7.1 Site Work

The work shall include furnishing of all labor, materials, equipment, and other

facilities and satisfactory performance of all work necessary to complete all the site work.

5.7.2 Preparation of the Site

5.7.2.1. Alignments

1. Lines must be staked out correctly.

2. Reference marks shall not be disturbed or moved on wrong alignment during the

construction.

5.7.2.2. Excavation

1. The volume of embankment shall be 1950 m

3

.

2. The specific depth of embankment shall be levelled before concrete is placed.

5.7.3 Concrete and Masonry Works

5.7.3.1 Material

1. The mixture for all classes of concrete shall be designed and approved by the

Engineer to obtain concrete having a compressive strength of 28 MPa for beams

and slabs, and 21 MPa for columns, at the age of 28 days.

2. Cement shall conform to the requirements of the standard specification and test

for Portland cement (ASTM C-150).

68

3. Water used for mixing shall be clean and potable, free from organic materials and

acids.

4. Aggregates must be hard, tough, durable, uncoated particles, generally rounded or

cubical and free from organic materials.

a. Fine aggregates shall be natural sand, clean, free from injurious amount of

clay, loam, and vegetables matter.

b. Coarse aggregates shall be river run gravel or crushed stone. The minimum

size shall be 38 mm and do not exceed 50 mm. It should be washed gravel.

5. All the mortar to be used for cement plaster shall be mixed.

6. Concrete Hollow Block units shall conform to the latest requirements of ASTM

C-129. They shall be non-load bearing with minimal sizes of 100-150mm thick.

Hollow block units shall be true size, without cracks, splits or other defects, which

may impair the strength and durability.

5.7.3.2 Proportioning and Mixing

All materials shall be proportioned as followed:

Class A (1:2:4) cement, sand, gravel

Mortar (1:3)

5.7.3.3 Forms

1. Forms shall be sufficient in strength to withstand the pressure resulting from

placement and vibration of concrete, and shall be maintained rigidly in correct

position.

69

2. Removing of forms shall be done after the concrete has attained its strength to

prevent the concrete from damage.

5.7.3.4 Conveying and Placing of Concrete

1. Concrete shall be conveyed from the mixer to the place of final deposit that will

prevent segregation of materials.

2. In placing of concrete it shall be tamped or vibrated to minimize the air voids that

will develop after the hardening of the concrete.

5.7.3.5. Curing

1. Fresh placed concrete shall be protected from harmful action of the sun and rain.

2. Curing must be started as soon as free water has disappeared from the surface of

the concrete.

3. Maintain all forms containing concrete in a wet condition until all forms are

removed. All concrete shall be moist cured for a period of not less than 7 days by

an approved method.

5.7.3.6 Finishing

Exposed concrete surfaces shall present a smooth finished appearance except for

minor defects which can easily be repaired with patching of cement mortar.

70

5.7.3.7 Concrete Hollow Block Wall

All concrete hollow block walls shown on the drawings shall have 10mm

vertical reinforcing bars spaced at 40cm o.c. and 10mm horizontal reinforcing bars at

every three layers. All holes of the blocks shall be filled with mortar. CHB walls shall be

plain finished unless otherwise indicated in the plans.

5.7.4 Structural Steel Works

1. The work included are the furnishing, erection, and installation of all bolts and

other structural steel works indicated in the plan.

2. All steel reinforcement shall be structural grade, new billet stock conforming to

ASTM Designation A-15 and deformed in accordance with ASTM Designation

A-305. It shall conform to the ASTM-36 Latest Revision (Specification for

Structural Steel), for rolled and built-up sections.

3. 16 mm diameter bars for beams with 10 mm diameter stirrups shall be provided.

4. Steel reinforcement shall be provided with all necessary tie wires to properly

install the rebar in correct location.

5. All welding electrodes shall conform to the requirements of the American

Welding Society (Specifications for Iron and Steel Arc-welding Electrodes).

6. Surfaces to be welded shall be free from loose scale, rust, grease, paint, and other

foreign materials. Joint surfaces shall be free from fins and tears.

7. Finished members shall be true to line and free from twists, bends, and open

joints. Erection shall include the setting of all structural steel as called for by the

71

plans and specifications and shall be in accordance with good engineering

practice. Erection procedure shall be approved by the Engineer.

5.7.5 Electrical Works

1. The work included in electrical works shall consist of furnishing of all labor,

materials, lighting fixtures, equipment, tools, and safety devices. And to make

ready for the operations of electrical power and lighting as specified.

2. All works shall be done in accordance with the latest edition of the Philippine

Electrical Code, the rules and regulation of the local enforcing authorities, and

with the requirements of the electric utility company.

3. All materials and equipment to be used shall be of approved standard.

4. Nature of services shall be 220 V, single phase, 60 Hz.

5. Type of wiring shall be THW C, wire in rigid metal conduit for service entrance,

and THHN Cu for circuit and switch lines in non-metallic conduit concealed on

ceiling and embedded on concrete walls and slabs.

6. Mounting heights for the following shall be not less than as follows:

MTS/Panelboard .1.20 m AFFL

Pole switches ...............................1.40 m AFFL

Duplex convenience outlet.. 0.30 m AFFL

Counter height D.C.O. .... 0.30 m AFFL

Others ...as indicated in the plan

7. All work shall be done under the direct supervision of a duly registered Electrical

Engineer or Master Electrician.

72

5.7.6 Plumbing Works

1. All plumbing works shall conform to the provisions of R.A.1378, National

Plumbing Code of the Philippines 1985 and the rules and regulations of the local

health office.

2. All materials shall be brand new and applicable for approved location.

3. All plumbing fixtures, pipes, fittings, and accessories shall be approved quality,

free from all defects and deformations.

4. All vent thru roof pipes shall be extended from roofing at least 300 mm.

5. Septic vault shall be constructed watertight or waterproofed to eliminate seepage

and located at the safe distance from an existing water supply well.

6. Outflow from septic vault shall be supplied from existing municipal or city water

works system as per section 102, chapter 9 of the national building code.

7. All plumbing works shall be by experienced plumbers under the direct

supervision of a registered Master Plumber or Sanitary Engineer.

5.7.7. Roofing & Ceiling

1. G.I. sheets shall be used in covering of the roof of the arched beam.

2. Use C 8 x 13.75 on the I-beams of roof.

3. Gypsum board shall be used for the roofing of the minor structure. 1 cm fiber

board shall be provided for insulation.

73

5.7.8. Doors & Windows

1. 6 mm glass windows on aluminium frame shall be used. Sliding doors shall be

used in the entrance to the mechanics room and the office.

2. PVC door with louver shall be used for the cubicles in the rest rooms.

3. Solid wood panel doors shall be used for other doors.

5.7.9 Painting Works

1. All painting materials shall meet the requirements of the standard specification as

approved for use by the Institute of Science and Technology.

2. All paints shall be delivered at the job site in their original containers, with labels

intact and seals unbroken. All pints shall be specified by its brand manufacturer.

3. Surfaces to be painted shall be clean, dry, smooth, and free from dust, rust, grease

or oils.

4. Skilled painters shall do all the work in a workmanlike manner. All paints shall be

evenly applied, free from crawling and other defects.

5. All exterior works shall receive three coatings.

6. All metal works shall be coated with lead primer before applying the topcoat.

7. Concrete surfaces shall be treated with a coat of zinc sulphate then a coat of

concrete paint to finish.

8. Paint shall be thoroughly dried before the succeeding coat is to be applied. Allow

24 hours or more between coats.

9. Colour shall be in accordance with the colour schemes to be supplied by the

Engineer.

74

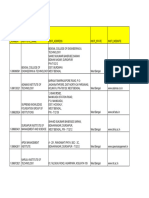

5.8 Project Cost and Work Schedule

The total cost of materials was estimated based on the unit cost of each material

and the quantity required. The estimated cost for the project is 15,314,438.45. Project

cost is subject to change because of the changes in prices of materials and cost of labor.

The contingencies, which include the amount agreed for equipment, tools, temporary

materials, and other miscellaneous count to 10% of the total cost. See Appendix C for

detailed estimates.

General Requirements 24,600

Site Development 156,556.44

Earthworks 388,598.00

Structural Works 11,088,908.99

Civil Works and Architectural 512,541.70

Electrical 80,022.48

Plumbing 166,103.60

Contingency, 10%

1,243,053.12

VAT, 12%

1,640,854.12

TOTAL

15,314,438.45

Table 5.1Summary of Estimates

The Critical Path Method (CPM) was used for work scheduling of the project. It

includes the activities and the duration of the activity from the start up to the completion

of the project. The project has a duration of 82 working days. The critical path is

indicated in the CPM diagram. A Gannt chart is also provided to guide the construction

with activities to finish each day.

75

Activity Duration Cost

Weight

in %

A General Requirements 1 24,600.00 0.11

B Site Development Works under Demolition 4 13,200.00 3.13

C Earthworks 7 388,598.00 1.08

D Footing 5 134,079.01 0.27

E Concrete Columns 7 33,059.83 3.92

F Steel Columns 5 486,887.42 18.13

G Steel Beams 10 2,253,539.90 29.33

H Steel Purlins 3 3,645,600.00 26.84

I GI-Sheet 2 3,336,952.67 5.60

J Concrete Floor Slab 7 696,518.39 1.09

K Concrete Beams 7 135,442.48 0.39

L Walls 7 47,876.59 1.31

M Concrete Roof Slabs 7 162,968.13 0.60

N Doors and Windows 5 75,088.00 0.25

O Septic Vault 10 31,360.26 0.64

P Electrical Works 5 80,022.48 1.34

Q Plumbing and Sanitary Works 5 166,103.60 0.32

R Ceiling (Gypsum Board) 7 39,966.51 0.66

S Grates: Wall and Roof 7 82,566.66 0.34

T Gates 5 42,057.66 1.70

U Finishing, Plastering and Tiling Works 7 210,982.01 1.50

V Painting Works 14 186,505.18 1.26

W Site Development Works under Landscaping 7 156,556.44

Contingency, 10% 1,243,053.12

VAT, 12% 1,640,854.12

TOTAL 15,314,438.45

100%

Table 5.2Work Schedule

A B C D E

Duration =82 days

Critical Path: A-B-C-D-E-F-G-H-I-O-R-S-V-W

CONSTRUCTION PROJ ECT MANAGEMENT DIAGRAM

SCALE N.D.T.S.

F G H I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

1 4 7 5 7 5 10 3 2

7

7

7

7

5

10

5

5

7

7

5

7

14

7

GANTT CHART

Duration Cost Weight in %

A General Requirements 1 24,600.00 0.20

B Site Devlopment Works under Demolition 4 13,200.00 0.11

C Earthworks 7 388,598.00 3.13

D Footing 5 134,079.01 1.08

E Concrete Columns 7 33,059.83 0.27

F Steel Columns 5 486,887.42 3.92

G Steel Beams 10 2,253,539.90 18.13

H Steel Purlins 3 3,645,600.00 29.33

I GI-Sheet 2 3,336,952.67 26.84

J Concrete Floor Slab 7 696,518.39 5.60

K Concrete Beams 7 135,442.48 1.09

L Walls 7 47,876.59 0.39

M Concrete Roof Slabs 7 162,968.13 1.31

N Doors and Windows 5 75,088.00 0.60

O Septic Vault 10 31,360.26 0.25

P Electrical Works 5 80,022.48 0.64

Q Plumbing and Sanitary Works 5 166,103.60 1.34

R Ceiling (Gypsum Board) 7 39,966.51 0.32

S Grates: Wall and Roof 7 82,566.66 0.66

T Gates 5 42,057.66 0.34

U Finishing, Plastering and Tiling Works 7 210,982.01 1.70

V Painting Works 14 186,505.18 1.50

W Site Development Works under Landscaping 7 156,556.44 1.26

TOTAL 100.00

Contingency, 10% %Complete

VAT, 12%of Sumof Total Amount with Contingency %Cumulative

Projected

Cumulative

Critical Path

Non-Critical Path

Float

LEGEND

Activity

1.20

56.15 19.57 7.91 4.66 3.86 1.20 96.24 94.87

11.66 3.25 0.80 2.66 3.41 33.57 36.58 1.96 1.38 1.74 0.90 0.90

93.12 89.72 99.10 98.20 100.00

148,828.00 216,636.69 423,494.01 4,172,581.92 4,547,015.96 1,449,501.43 403,678.44 111,826.03

480,029.61 11,575,640.11 11,152,146.09 12,207,365.77 11,963,411.75 11,792,276.80

99,338.74 331,201.61

983,046.78 579,368.34

111,339.40 243,954.02 171,134.95

Week 2 Week 1 Week 13 Week 12 Week 11 Week 10 Week 7 Week 6 Week 5 Week 4 Week 3 Week 9 Week 8

TOTAL VALUE PHP 15,314,438.45

PHP 12,430,531.21

PHP 1,243,053.12

PHP 1,640,854.12

12,430,531.21 12,318,705.18 148,828.00 6,979,564.17 2,432,548.21

`

Chapter VI

PROJECT IMPLEMENTATION

This chapter presents the project implementation and construction management

The project study will be presented to the Local Government Unit of Barbaza.

Upon their approval, the LGU will loan from the Department of Finance in Manila. The

LGU of Barbaza will then publish an invitation to bid at the website of Philippine

Government Electronic Procurement System (PHILGEPS) for interested bidders. The

project study shall undergo the bidding before it can be implemented.

Proper supervision shall be implemented and supervised by the Municipal

Engineering Office throughout the project. A representative of the Municipal Engineers

Office may be assigned to monitor the contractor and the workers whether they comply

with the conditions agreed on the contract.

CHAPTER VII

CONCLUSIONS AND RECOMMENDATIONS

A Proposed Integrated Transport Terminal for Barbaza, Antique will provide a

common loading area of public vehicles for Barbaza and nearby towns. The terminal is

able to provide loading spaces for the four different modes of public transportation

available in Antique: bus, van, jeep, and tricycle. The project cost is within the budget

recommended by the municipality. Statistically-analyzed results of the questionnaire

survey shows the approval of both the drivers and passengers regarding the project.

Opinion surveys of the residents and municipal officials also yielded positive responses.

It is recommended that the transport terminal will be a priority project of Barbaza

to avoid inflation of prices since the project is estimated using prices of commercially

available materials on the year 2013. Traffic control devices like signs and markings are

recommended for safety. It is recommended that an organizational chart should be

provided for an orderly management. It is also recommended that a security personnel

will be assigned at the terminal.

81

REFERENCES

Beral, E., Macavinta, N., Tumale, F.J. (2010). A Proposed Bus and Shuttle Vans

Terminal in Dalipe, San Jose, Antique. Civil Engineering Department, College of

Engineering, Central Philippine University, Iloilo, PH.

Escoderos, M.P., Gico, P.T., Nolido, A.R. (2011). A Proposed Constuction of Jeepney

Transport Terminal in San Miguel, Iloilo. Civil Engineering Department, College

of Engineering, Central Philippine University, Iloilo, PH.

Gallo, R., Mata, P., Tabera, G.I., Timbas, K.L. (2011). A Proposed Transport Terminal in

the Municipality of Jordan, Guimaras. Civil Engineering Department, College of

Engineering, Central Philippine University, Iloilo, PH.

Gillesania, D.I.T. (2006). Fundamentals of Structural Steel Design with Theory of

Structures.

Gumapon, F. (2012). PPA bares major RO-RO routes. Philippine Information Agency.

Retrieved on 03-26-2013. Available:

[http://www.pia.gov.ph/news/index.php?article=1431337066034]

Litman, T.A. (2012). Evaluating Accessibility for Transportation Planning: Measuring

Peoples Ability to Reach Desired Goods and Activities. Victoria Transport

Policy Institute. Retrieved on 03-26-2013. Available:

[http://www.vtpi.org/access.pdf]

82

Modak, S. K., Patkar, V.N. (1984). Transport Terminal Design and Passenger

Orientation. Retrieved on 03-26-2013. Available:

[www.tandfonline.com/doi/pdf/10.1080/03081068408717275]

Municipality of Barbaza, Antique (2012). Comprehensive Land Use Plan.

Official Antique Website (2012). Barbaza. Retrieved on 03-26-2013. Available:

[http://www.antique.gov.ph/barbaza/]

Panay (2012). Discover the Wonders of Panay Island: Barbaza. Retrieved on 03-26-2013.

Available: [http://www.panay.org/barbaza/]

Rodrigue, J. (1999). Globalization and the Synchronization of Transport Terminals.