Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sono Koya Training Filel

Caricato da

Vegeta12527Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Sono Koya Training Filel

Caricato da

Vegeta12527Copyright:

Formati disponibili

TRAINING REPORT

AT

QUALITY DEPARTMENT,

SONA KOYO STEERING SYSTEM LTD.

MALPURA, DHARUHERAIII

HARYANA (INDIA)

SUBMITTED TO SUBMITTED BY

M.E.DEPT. MANJEET SINGH

BREMCET ROLL NO-10ME-4764

ME-8

TH

SEM

Certificate

To whom it may concern

This is to certify that Mr. Manjeet Singh,

a student of B.Tech.8

th

sem.of BRCMCET Bahal (Bhiwani) has

successfully completed his 5 month industrial training from

10

th

January 2013 to 10

th

June 2013 in Sona Koyo Steering

System Ltd, Dharuhera. . He is a very punctual and sincere

trainee who keeps interest in the assigned department. The most

appreciable quality that he possesses is his ability to analyze

technical problems and provides possible solutions. His overall

performance during the training has been outstanding.

We wish him all the best for his bright future.

Division Head

(Quality Department)

ACKNOWLEDGEMENT

I wish to thanks Mr. K.S. Yadav - GM ( HR Department)

for endowing me with an opportunity to work in such a prestigious Company for

being a candid link between Sona Koyo Steering Systems Ltd.

I would like to thank my training supervisor Mr. Umed Singh

Yadav for his valuable guidance throughout my training. I would also like to thank

the entire Production Department, especially Mr. Anuj Singh for the help extended to

me through the course of my training.

Special thanks to Mr. Kamal for helping me adjust to the environment of the

organization and taking keen interest in me.

Finally, I would also like to thank the entire

Sona Family for helping and guiding me as and when required.

Manjeet Singh

Sona Koyo Steering Systems Ltd. Dharuhera-III

A joint venture between

Maruti Udyog Ltd., Sona Steering and Koyo Seiko (Japan), the

company is into the manufacturing of steering systems and

other driveline products for passenger cars and light commercial

vehicles. The company is DEMING PRIZE WINNER in 2003, TPM

EXCELLENCE AWARDED in 2007 & UDYOG RATNA AWARD in

2012 and also ISO 9001, TS 16949 & ISO 14001 certified.

Sona Koyo Steering Systems Ltd. Dharuhera-III plant

is machaning plant in which various types of component is

manufacturing such as rack bar, valve housing, cap differential,

pinion housing,integrating housing etc.

Sona Koyo Steering Share Holding

COMPANY POLICIES

QUALITY POLICY

Commitment to defect prevention and

continuous improvement while meeting or exceeding customer

requriments at all times.

TPM POLICY

Renovate the manufacuturing system to achive high efficiency

production through zero failure and zero defects.

Improve the work place environment through zero- accident

and zero pollution.

Develop skills of employees through eduction and training.

CUSTOMER

DIRECT CUSTOMER

Sona Koyo Steering System Ltd. Dharuhera Plant I

Sona Koyo Steering System Ltd. Dharuhera Plant II

Sona Koyo Steering System Ltd. Gurgaon Plant

INDIRECT CUSTOMER

Maruti

Hyundai

Mahindra

John Deer

PRODUCTS

Rack Bar

Top Cover

Cap Differential

Pinion Differential

Gear Differential

Valve Housing

Pinion Housing

Integrated Housing

Senser Housing

HPS

CEPS& UPPER SHAFT

WHAT IS QUALITY:-

QUALITY IS THE DEGREE OF SATISFACTION

OF THE CUSTOMER BY A PARTICULAR

PRODUCT

DIFFIRENT PROCESSES TO MEASURE

QUALITY:-

MATERIAL TESTING

PRODUCTION LINE INSPECTION

FINAL INSPECTION

QUALITY CONTROL

MEASURING INTRUMENTS&

TOOLS:-

MEASURING INSTRUMENTS:-

VERNIER CALLIPER

MICROMETER

FILLER GAUGE

HEIGHT GAUGE

QUALITY CONTROLLING TOOL:-

5-S (HOUSEKKEEPING)

3-C

7-QC TOOLS

14

SEVEN QC TOOLS

Check Sheets

Pareto Diagram

Histogram.

Scatter Diagram

Cause and Effect Diagram

Graphs

Control Charts

15

How to Collect Data

1. Have Clear Defined Objectives

Controlling and monitoring the production process

Analysis of non-conformance

Inspection

2. What Is Your Purpose

Collecting as per strata

Collecting in Pairs (correlation)

3. Are Measurements Reliable

4. Find Right Ways to Record Data

Arrangement

Data sheet

16

Mark defect by

S N C la s s M e a n Va lue T a lly M a rk s T o ta l

1 950-955 952.5 IIII 4

2 955-960 957.5 IIII III 8

3 960-965 962.5 IIII IIII IIII 15

4 965-970 967.5 IIII IIII 10

5 970-975 972.5 IIII I 6

Diagram type check sheet

Frequency check sheet

Sn P ar am et er Spec J u dgem ent R em ar k

1 2 3 4 5

P ar t N o : P r o ces s : Machi ne:

Sam pl e N o

Inspection check sheet

Check Sheet

17

Pareto Analysis

What: A bar chart that helps to prioritize actions by

arranging

elements in descending order of occurrence. Sorts

out the vital few from the trivial many.

Why :

To prioritize actions needed to solve complex

problems.

To separate important from non-important

causes contributing to a problem.

When :

18

Contd Pareto

100%

A B C D E

75%

50%

25%

Defect Code

Nos.

n=150

19

Types of Pareto Diagrams

1. Pareto Diagrams by Phenomenon

Quality: defects, faults, failure, complaints, RW etc.

Cost: amount of loss, expenses

Delivery: delay in delivery, stock shortages etc

Safety: accidents, mistakes, breakdowns etc

2. Pareto Diagrams by Causes

Operator: shift, group, age, experience, skill etc

Machine: machines, equipments, tools, instruments etc.

Material: manufacturer, plant, lot, kind etc

Process: conditions, orders, arrangements,methods etc.

20

Cause & Effect Diagram

What:

A graphic tool used to represent the relationship

between an effect and the cause that influence

it.Why:

Identifies various causes affecting a process.

Helps groups in reaching a common

understanding of a problem.

Helps reduce incidence of subjective decision

making.

When:

Looking for all potential causes of problem.

Cause and Effect Diagram

Nurses

Many patients

Long waiting

time after

completion of

ultrasonic scan

Methods Environment

People

Reception

work

Medical charts hard to tell

apart

Many charts to input

Shortage of

numbers

Inexperience

Patients

Two or more booked

in at same time

Record

findings

Charts all

returned

together

Handling

Data input

takes time

Calculation

of bill

Charts from all

departments

come together

Test

Rooms

Far away

Busy

Computer

terminal

slow

Reception

22

Scatter Diagram

What:

A tool used to study the possible relationship

between two variables.

Why:

To test for possible causes and effect

relationships.

Though it cannot prove that one variable causes

the other, the diagram does make it clear

whether a relationship exists and shows the

strength of that relationship.

23

Histogram

What: A bar chart that displays the variation within

the process. Also called a frequency distribution

because the frequency of occurrence of any given

value is represented by the height of the bars.

Why:

Allows one to quickly visualize whats going on

within a large amount of data.

Provides clues to causes of problems.

Maybe be used to show the relationship between

the engineering tolerance and the capabilities of

the process.

24

0.5 5.5 10.5 15.5 20.5 25.5 30.5

5

10

15

20

5

25

Histogram...

How.contd..

25

Graphs

Graphs are among the simplest and best techniques to analyse and

display data for easy communication.

Various types of graphs generally used are shown below which are

self explanatory.

Y e a r R e j C o s t

1 9 9 6 5 0

1 9 9 7 4 5

1 9 9 8 7 0

0

2 0

4 0

6 0

8 0

1 9 9 6 1 9 9 7 1 9 9 8

Y e a r

R

e

j

.

c

o

s

t

M o n t h R e j

A p r 0 . 2

M a y 0 . 6

J u n 0 . 2

J u l 0 . 2

A u g 0 . 1 5

S e p 0 . 2

0

0 . 2

0 . 4

0 . 6

0 . 8

A p r Ma y J u n J u l A u g S e p

M o nth

R

e

j

e

c

t

i

o

n

%

a

g

e

R e j

Bar chart Trend chart

26

O T H E R S

5 . 5 6 %

R B S S T R G .

A S S Y .

1 0 . 8 3 %

R & P A S S Y .

1 7 . 6 2 %

P O W E R

S T R G .

4 . 9 2 %

A X L E A S S Y .

2 8 . 6 7 %

P R O P . S H A F T

A S S Y .

6 . 1 5 %

C O L U M N

A S S Y .

2 6 . 2 5

Pie-chart

Graphs

27

Control Charts

WHAT:

A control chart is a line graph used to display

variation on time ordered fashion. A centerline and

control limits are placed on the graph to help

analyse the pattern of the data.

WHY:

To separate common causes from special causes of

variation.

To help assign causes of variation.

When : Measuring control characteristics.

Where: At the earliest possible point in the

manufacturing process.

BEKIDO RATE

The rate how much

production the line can do

without stopping the

machine .

Bekido rate of line is calculate based upon

NMCT ( Neck machine cycle time)

NMCT = highest / bottleneck machine cycle

time of line ( including loading & unloading

of part)

Bekido Rate

Bekido Rate =

NMCT x OK Production

Available Time (in sec.)

x100

It is ratio of finished

products exiting a line to

total raw material entering

in the line.

OR

First Pass Goods Rate

Chokko Rate

Chokko Rate calculation

Chokko Rate = 1

st

Pass OK Goods Quantity

Total Production

Chokko Rate

It is ratio of Not Good (NG)

parts quantity to total parts

machined quantity.

Scrap Rate

Scrap Rate calculation

Scrap Rate = NG Parts Quantity

Total Production

Scrap Rate

Basic Idea of TPM

..

Pursuit of Economical Efficiency,

Reducing

Accidents to Zero

Breakdowns to Zero

Complaints to Zero

Defects to Zero

Environmental Friendly

Failures to Zero

Maximizing plant effectiveness involves bringing

the plant to Peak operating conditions and then

keeping it there by eliminating or at least minimizing

any factors such as failures,defects or problems that

might diminish Its performance .

Overall Plant Effectiveness

Equipment Failure

Loss

Losses Obstructing Equipment Efficiency

DOWN TIME LOSSES

Scheduled Downtime

Losses

Un Scheduled Downtime

Losses

Production

Adjustment

Loss

Shutdown Loss

Process Failure

Loss

1

2

3

4

Time lost when production stops for planned annual shutdown

maintenance or periodic servicing.

Ex: shutdown work, Periodic servicing, Statutory

inspection, Autonomous inspections, General

inspection work etc.

1. Shutdown Losses

The plants continuous operation can be extended

by curtailing its shutdown periods and improving

The efficiency of shutdown maintenance work.

Shutting down part of the plant for repair, servicing

must also be carefully planned to make themmore

efficient.

Time lost when changes in supply and demand require

adjustments to production plans.

Ex: Production-adjustment shutdown ,

Inventory reduction shutdown etc.

2. Production Adjustment Losses

A company can minimize adjustment losses, however, if it maintains

a strong lead in Quality , Cost , Delivery and Continually stimulates

demand by improving its product lineup & developing new products

.This will naturally increase the plants overall effectiveness.

Time lost when equipment suddenly looses

its specified functions .There are 2 types of

equipment related losses

a. Function reduction loss

b. Function failure loss

Ex: Pump fails , Motor burns,

Bearing seizes, shaft breaks

3. Equipment Failure Losses (Hours)

F

T

Time lost in shut down due to external factors such

as changes in chemical or physical properties of materials

being processed,operating

errors , defective raw materials etc.

Ex: Leaks, Spills, Blocks, corrosion, erosion , dust scatter, miss

operation

4. Process Failure Losses (Hours)

Process failures will decrease only when their sources are

stamped out.Such problems should be distinguished and dealt

with separately from sudden equipment failure.

Abnormal

Production Loss

(Low-load, Low-speed

Loss)

Losses Obstructing Equipment Efficiency

Performance Loss

Normal

Production Loss

(Start-up Loss)

5 6

Production rate reductions during warm up period after startup,

cool down period before shutdown and product changeover.

Ex: Rate & time losses at plant startup , shutdown

or changeover.

5. Normal Production Losses (Hours)

This loss can be minimized by introducing

systematic vertical startup procedures

(immediate trouble free Startup). The same

applies to the cool down period.Also reducing internal setup

and using external setup techniques to prepare in advance

can minimize changeover losses.

Production rate reductions , when plant under performs due to

malfunctions and abnormalities.

Ex: Low - load operation , Low speed operation,

Operation at below standard production rate

5. Abnormal Production Losses (Hours)

The difference between the standard and actual

production rates is the abnormal production loss.

Reprocessing

Loss

Losses Obstructing Equipment Efficiency

Quality Loss

Quality Defect

Loss

7 8

Losses due to producing reject able product , physical loss o f

rejected product ,Financial losses due to product downgrading

Ex: Physical and time losses due to making

product that fails to meet quality standards.

7. Quality Defect Losses (Hours,Tons, $)

Quality defects can have many causes.Some may arise when

production conditions are set incorrectly due to Instrument

malfunction or operating errors; others arise from external factors

such as failures,problems with raw

Materials or contamination.

Recycling losses due to passing material back through the process

Ex: Recycling non confirming product from the

final process to the starting process to make

it acceptable

In some industries , reprocessing or reworking is impossible, here they

are treated as Quality losses only.Recycling is a significant loss and

wastes time, materials and Energy.

8. Reprocessing Losses (Hours,Tons, $)

Principles of Measurement

The Principle of linear measurement is essentially a

comparison of the piece under test with a known standard.

Ensure instruments are maintained in a serviceable condition:

-Keep instruments clean, avoid misuse.

- Return instruments to cases when not in use.

- Keep the inside of the cases clean.

- Do not attempt to dismantle an instrument.

CONDITIONS FOR INSPECTION

* MEASURING INSTRUMENT &

JOB

* BASED UPON CHARACTERISTIC AND TOLERANCE SELECT

MEASURING INSTRMENT / GAUGE AND ITS LEAST COUNT.

* CONTACT AREA OF GAUGE AND JOB SHOULD BE

CLEAN

* REFERENCE MUST BE TRUE / FULLY

ALIGNED

LEAST COUNT

* SMALLEST UNIT ON SCALE OF MEASURING

INSTRUMENT

* LEAST COUNT OF THE MEASURING INSTRUMENT

SHOULD BE 1/10TH OF THE TOLERANCE.

A surface is a boundary that separates an object from another object

or substance.

Dimensions are the macroscopic sizes of a part, e.g.

diameter or length.

Tolerance

A tolerance is an allowable range for a dimension to take, a specified

interval of dimensions where the part will still function acceptably

Roughness

Roughness includes the finest irregularities of a surface. Roughness

generally results from a particular production process or material

condition.

Surface

Dimension

SYMBOLS OF MEASUREMENT

* STRAIGHTNESS / FLAGHTNESS

* CYLINDERICITY

* CIRCULARITY

* ACCURACY OF SURFACE PROFILE

* PARALLELISM

* PERPENDICULARITY

* ANGULARITY

* CONCENTRICITY

* SYMMETRY

Gauges

Feeler Gauges

NB: Feeler gauges should be wiped with a clean cloth before

and after use. If grease or dirt is trapped, a false reading may

be given.

Feeler Gauges are manufactured from accurately rolled shims and are

used to measure gap sizes from 0.05mm up to about 1.25mm (0.002 to

0.050 inches). The numbers are marked on the gauge to give the

thickness and thus the gap width.

Feeler

Gauges

PRINCIPAL OFSURFACE FINISH TESTER

* ROLE OF SURFACE FINISH / TEXTURE

* BETTER THE SURFACE CONDITION / TEXTURE , ACCURATE THE

INSPECTION RESULTS

* BETTER THE SURFACE CONDITION / TEXTURE , BETTER THE

REPEATIBILITY / REPRODUCABILITY OF INSPECTION RESULTS

INSPECTION RESULTS

* BETTER THE SURFACE CONDITION / TEXTURE , BETTER THE LIFE

OF THE PARTS PRODUCED . ( COMPONENTS )

* IN ALL THE MEASURING INSTRUMENTS SURFACE CONDITION /

TEXTURE IS CONTROLED TO A VERY CLOSE DEGREE OF ACCURACY

HENCE NEEDS TO BE HANDLED VARY CAREFELLY.

HOW TO SET AN AIR GAUGE

RANGE SETTING

OPEN BOTH THE ADJUSTERS FULLY

CHECK THE GAUGE WITH SETTING

MASTERS FOR RANGE

*

IF RANGE IS LESS TIGHT THE RIGHT ADJUSTER

*

IF RANGE IS MORE TIGHT THE LEFT ADJUSTER

*

FOR SETTING ZERO PRESS OR LIFT THE DIAL

THANKS

Potrebbero piacerti anche

- Presentation Guidelines: Case Study - Zero Defect Drive by Laxmikant MishraDocumento28 paginePresentation Guidelines: Case Study - Zero Defect Drive by Laxmikant MishrapiyushNessuna valutazione finora

- Tolerance Manual For Precast and Prestressed Concrete MNL-135-00Documento192 pagineTolerance Manual For Precast and Prestressed Concrete MNL-135-00John Cartagena CondorNessuna valutazione finora

- Critical quality control sheetDocumento22 pagineCritical quality control sheetazadsingh1Nessuna valutazione finora

- Rotating Equipment MeasurementDocumento15 pagineRotating Equipment MeasurementAndinata SitepuNessuna valutazione finora

- Quality CricleDocumento22 pagineQuality CricleQSSD ENTERPRISESNessuna valutazione finora

- ZED PresentationDocumento13 pagineZED PresentationSatbir SinghNessuna valutazione finora

- Planned Maintenance Guide for Equipment ReliabilityDocumento97 paginePlanned Maintenance Guide for Equipment ReliabilityMAngesh GadeNessuna valutazione finora

- GD&TDocumento5 pagineGD&Travindra_2011Nessuna valutazione finora

- Work Instruction For Operator (English)Documento1 paginaWork Instruction For Operator (English)PRAMODNessuna valutazione finora

- Sterling Generators: Submitted in Partial Fulfillment For The Award of The Degree ofDocumento63 pagineSterling Generators: Submitted in Partial Fulfillment For The Award of The Degree ofNivesh KumarNessuna valutazione finora

- Servo Adjustment Manual 640mDocumento37 pagineServo Adjustment Manual 640malexandre100% (1)

- Heater Catalog 0618Documento576 pagineHeater Catalog 0618abasakNessuna valutazione finora

- Training On Core Tools For Iatf 16949 2016Documento2 pagineTraining On Core Tools For Iatf 16949 2016AnkurNessuna valutazione finora

- White Belt PPT Slides - Six Sigma PH - 13SEP2020Documento18 pagineWhite Belt PPT Slides - Six Sigma PH - 13SEP2020Dos LimNessuna valutazione finora

- Tata Motors Case StudyDocumento35 pagineTata Motors Case StudyGokulraju Rangasamy100% (2)

- BS 4429 PDFDocumento24 pagineBS 4429 PDFbich100% (1)

- Problem Solving Techniques: 7 QC ToolsDocumento54 pagineProblem Solving Techniques: 7 QC Toolssaghirhassan61Nessuna valutazione finora

- Kobetsu Kaizen: Maintenance ManagementDocumento34 pagineKobetsu Kaizen: Maintenance ManagementMohammed Rushnaiwala100% (1)

- Case Study - NCQC19 Recur-17Documento48 pagineCase Study - NCQC19 Recur-17Bibhudutta mishraNessuna valutazione finora

- Resume - Shashank BipinbhaiDocumento2 pagineResume - Shashank BipinbhaiFinQuest Consulting ServicesNessuna valutazione finora

- AAL-ICQCC-2021, Team PragathiDocumento42 pagineAAL-ICQCC-2021, Team PragathiAnirudh Shenoy KNessuna valutazione finora

- Quality Circle (Hindi) 14 - 05 - 2011 (Read-Only)Documento40 pagineQuality Circle (Hindi) 14 - 05 - 2011 (Read-Only)Atul Sharma100% (1)

- 08.DM Pillar FCDocumento67 pagine08.DM Pillar FCashutoshpal21Nessuna valutazione finora

- Electric Wire PDFDocumento102 pagineElectric Wire PDFGoswami kinjalNessuna valutazione finora

- Sae J409 - 1995-02Documento9 pagineSae J409 - 1995-02Cristian RodeghelNessuna valutazione finora

- 3b.pika PikaDocumento15 pagine3b.pika PikaAnand Azad100% (1)

- Kaizen improvements for machine cleaning and lubricationDocumento2 pagineKaizen improvements for machine cleaning and lubricationAzaly BuangNessuna valutazione finora

- SAIL CatalogueDocumento37 pagineSAIL Cataloguekoushikdey_20110% (1)

- Quality Circle - EM58M - AUQCCDocumento75 pagineQuality Circle - EM58M - AUQCCpverma02Nessuna valutazione finora

- 4M ManagementDocumento5 pagine4M ManagementSachin YadavNessuna valutazione finora

- 2K Clear Coat / Top Coat Basecoat Primer Substrate Treatement SubstrateDocumento51 pagine2K Clear Coat / Top Coat Basecoat Primer Substrate Treatement SubstrateVenkatesanNessuna valutazione finora

- BS en 476 General Requirements For Components Used in Discharge Pipes, Drains and Sewers For Gravity SystemsDocumento14 pagineBS en 476 General Requirements For Components Used in Discharge Pipes, Drains and Sewers For Gravity SystemsShameel PtNessuna valutazione finora

- Progress at TPM: Newsletter From CII TPM Club IndiaDocumento18 pagineProgress at TPM: Newsletter From CII TPM Club IndiamurilocabriniNessuna valutazione finora

- Iso 554 1976Documento4 pagineIso 554 1976vateshNessuna valutazione finora

- Astm B 124Documento5 pagineAstm B 124Teymur Regenmaister100% (1)

- Xfmea Pfmea PDFDocumento8 pagineXfmea Pfmea PDFvinidesoNessuna valutazione finora

- Rejection Analysis Procedure PDFDocumento7 pagineRejection Analysis Procedure PDFsmartsatish100% (1)

- 5 S and Six SigmaDocumento19 pagine5 S and Six SigmaAnandraj004Nessuna valutazione finora

- LP LA N: Control PlanDocumento26 pagineLP LA N: Control PlanSyed ShabbirNessuna valutazione finora

- Ebook - 9 & 10 Ogos 2022 - Seminar Dan Coaching Intervensi KKP Di Tempat KerjaDocumento127 pagineEbook - 9 & 10 Ogos 2022 - Seminar Dan Coaching Intervensi KKP Di Tempat KerjaAfrina DamyaNessuna valutazione finora

- Anand Kumar ResumeDocumento3 pagineAnand Kumar ResumeArun ShishodiaNessuna valutazione finora

- Meenakshi Polymers rework inspection reportDocumento1 paginaMeenakshi Polymers rework inspection reportKaran MalhiNessuna valutazione finora

- Sona KoyoDocumento26 pagineSona Koyosandhyayadav88Nessuna valutazione finora

- Controlling The Defects of Paint Shop PDFDocumento4 pagineControlling The Defects of Paint Shop PDFRahul SasidharanNessuna valutazione finora

- 5 S For Shop Floor 01Documento52 pagine5 S For Shop Floor 01sachinNessuna valutazione finora

- 01.sundram Fasteners LTDDocumento60 pagine01.sundram Fasteners LTDTapash Kumar PalNessuna valutazione finora

- Lucas-TVS-SQA Manual PART A 23.04.2011final New 1Documento133 pagineLucas-TVS-SQA Manual PART A 23.04.2011final New 1Purushothama Nanje Gowda0% (2)

- Key Skills: Sunil Kumar DalalDocumento3 pagineKey Skills: Sunil Kumar DalalAvinashBatraNessuna valutazione finora

- Specific Gravity in Rubber CompoundingDocumento1 paginaSpecific Gravity in Rubber CompoundingBharat ChatrathNessuna valutazione finora

- Bajaj AutoDocumento30 pagineBajaj AutoJOYSON NOEL DSOUZANessuna valutazione finora

- National Counsil of Quality Control 2019 Knowledge Test - 5S Practice PaperDocumento3 pagineNational Counsil of Quality Control 2019 Knowledge Test - 5S Practice PaperRajesh SharmaNessuna valutazione finora

- UntitledDocumento19 pagineUntitledSuresh KumarNessuna valutazione finora

- What Are QC Circle Activities?: TQM Study ProgrammeDocumento62 pagineWhat Are QC Circle Activities?: TQM Study ProgrammeMd Saiful islam BhuiyanNessuna valutazione finora

- Corrective Actions For Not Ok Charcteristics: Months - July13Documento1 paginaCorrective Actions For Not Ok Charcteristics: Months - July13shobha shelarNessuna valutazione finora

- Lean ProductionDocumento17 pagineLean ProductionTahir Naeem JattNessuna valutazione finora

- ABC Type DefectsDocumento17 pagineABC Type DefectsMayank Dadhich100% (2)

- Spatter Reduction ReportDocumento77 pagineSpatter Reduction ReportaabhimittalNessuna valutazione finora

- Six Sigma - Reduction of Downtime - RE Mill-2 - NewDocumento76 pagineSix Sigma - Reduction of Downtime - RE Mill-2 - NewKiruthiga VelmuruganNessuna valutazione finora

- Vendor Selection and E-Nagare at Maruti - 123735014Documento25 pagineVendor Selection and E-Nagare at Maruti - 123735014akankshag_13100% (1)

- MT QM PillarDocumento71 pagineMT QM Pillarazadsingh1Nessuna valutazione finora

- Sanden Glitters (Productivity Improvement)Documento19 pagineSanden Glitters (Productivity Improvement)Anonymous Y5cnLVYMGNessuna valutazione finora

- JBM Group 12 Pillar Internal Auditor Exam 2022-23Documento30 pagineJBM Group 12 Pillar Internal Auditor Exam 2022-23Ravi javaliNessuna valutazione finora

- Defects Reduction in A Pump Manufacturing Industry Using Six Sigma MethodologiesDocumento7 pagineDefects Reduction in A Pump Manufacturing Industry Using Six Sigma MethodologiesInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Sona GroupDocumento56 pagineSona GroupbrindatammaNessuna valutazione finora

- Difference Between APQP and PPAPDocumento2 pagineDifference Between APQP and PPAPshankarNessuna valutazione finora

- Summer Training Presentation E.R AutoDocumento15 pagineSummer Training Presentation E.R AutoRobin ChhabraNessuna valutazione finora

- Tamil Nadu - 15th Fin Fund MvkmuthuDocumento160 pagineTamil Nadu - 15th Fin Fund MvkmuthuNirmal kumarNessuna valutazione finora

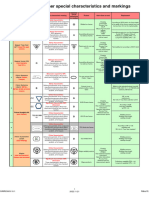

- Customer Special CharacteristicsDocumento1 paginaCustomer Special Characteristicspundhir12898Nessuna valutazione finora

- Application of Six-Sigma For Productivity Improvement in A Manufacturing UnitDocumento35 pagineApplication of Six-Sigma For Productivity Improvement in A Manufacturing UnitPiu KunduNessuna valutazione finora

- Six Sigma DMAICDocumento25 pagineSix Sigma DMAICgurwantNessuna valutazione finora

- IX Igma - : AbstractDocumento10 pagineIX Igma - : AbstractViswanath TurlapatiNessuna valutazione finora

- Appendix B - Limits and Fits (Final)Documento14 pagineAppendix B - Limits and Fits (Final)helix90Nessuna valutazione finora

- Fundermax Exterior Technic 2011gb WebDocumento88 pagineFundermax Exterior Technic 2011gb WebarchpavlovicNessuna valutazione finora

- ASME Y14.5 M - 1994 - Dimensioning and TolerancingDocumento12 pagineASME Y14.5 M - 1994 - Dimensioning and TolerancingDimitri MantauNessuna valutazione finora

- BS en 00683-3 1997 (En)Documento10 pagineBS en 00683-3 1997 (En)Emanuele MastrangeloNessuna valutazione finora

- Indian Gen Const SpecsDocumento154 pagineIndian Gen Const SpecsjungzkiNessuna valutazione finora

- Glycodur F A ENDocumento52 pagineGlycodur F A ENmarc_albertoNessuna valutazione finora

- 2003 04 NewsletterDocumento4 pagine2003 04 NewslettergurugoodrichNessuna valutazione finora

- 3e Ut Blocks PDFDocumento2 pagine3e Ut Blocks PDFAbdi Wirawan AnggaweNessuna valutazione finora

- App A, Pls HDBK PDFDocumento186 pagineApp A, Pls HDBK PDFpadmanabanNessuna valutazione finora

- DummyDocumento5 pagineDummysatishNessuna valutazione finora

- OS Mechanics L4Documento65 pagineOS Mechanics L4mulualemNessuna valutazione finora

- Carbon Steel Forgings, Class 2: Corporate Purchase Specification AA 193 31 Rev. No. 11 Preface SheetDocumento7 pagineCarbon Steel Forgings, Class 2: Corporate Purchase Specification AA 193 31 Rev. No. 11 Preface Sheetraghav248Nessuna valutazione finora

- Technology and Livelihood Education 8: Republic of The Philippines Region 4-A Calabarzon Division of San Pablo CityDocumento3 pagineTechnology and Livelihood Education 8: Republic of The Philippines Region 4-A Calabarzon Division of San Pablo CityKissarah B. VillanuevaNessuna valutazione finora

- Acceptance Criteria of ConcreteDocumento26 pagineAcceptance Criteria of ConcretevempadareddyNessuna valutazione finora

- Config Options Complete PTCDocumento40 pagineConfig Options Complete PTCrafafranca2Nessuna valutazione finora

- 2010 AMD3 Reff2021Documento24 pagine2010 AMD3 Reff2021Roushan KumarNessuna valutazione finora

- Profile, Curve Form and Profile CalypsoDocumento4 pagineProfile, Curve Form and Profile Calypsomike sNessuna valutazione finora

- ICU Bed Bid DocumentDocumento7 pagineICU Bed Bid DocumentCE CERTIFICATENessuna valutazione finora

- Specification For Steel Wheelbarrows (Single-Wheel Type) : (First Revision)Documento12 pagineSpecification For Steel Wheelbarrows (Single-Wheel Type) : (First Revision)Devesh Kumar PandeyNessuna valutazione finora