Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pressure Vessel Nozzle Calc - ASME VIII Div 1

Caricato da

aauppal100%(1)Il 100% ha trovato utile questo documento (1 voto)

2K visualizzazioni20 pagineNozzle design calculation for ASME BPVC Section VIII Div 1 Pressure Vessels

Copyright

© © All Rights Reserved

Formati disponibili

XLSX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoNozzle design calculation for ASME BPVC Section VIII Div 1 Pressure Vessels

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

2K visualizzazioni20 paginePressure Vessel Nozzle Calc - ASME VIII Div 1

Caricato da

aauppalNozzle design calculation for ASME BPVC Section VIII Div 1 Pressure Vessels

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLSX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 20

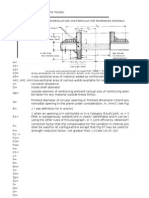

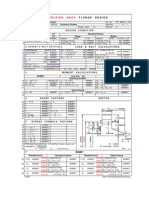

Nozzle N1/B

Nozzle name: Air Inlet

Applicable rules (UG-37 or 1-9 or 1-10 or UG-39 or App 14)

Nozzle location Top Head

Material Spec.

Nozzle size NPS

Nozzle orienation (deg)

Liquid Static Head H

s

(mm)

P

s

bar(g)

Hill side opening

Size of finished opening (UG-36(a)) d (mm)

Corrosion Allowance (nozzle) CA

n

(mm)

Corrosion Allowance (shell) CA (mm)

Shell course inside diameter D (mm)

Joint Efficiencies (UG-36(a)) E

(UG-36(a)) E

1

Flange size NPS

Flange material spec.

Flange rated MDMT (UCS-66(b)(1)(b))

0

C

ASME B16.5 Flange rating MAWP bar(g)

ASME B16.5 Flange rating MAP bar(g)

ASME B16.5 Flange hydrotest bar(g)

Static head on flange H

s

(mm)

P

s

bar(g)

Bolt material

Nozzle neck thickness:

Design Pressure Internal P bar(g)

Design Pressure External P

ext

bar(g)

Nozzle outside diameter d

0

(mm)

Nozzle thickness (assumed) (mm)

Nozzle inside diamter d

n

(mm)

Nozzle inside radius R

n

(mm)

Vessel inside diameter D (mm)

Nozzle allowable stress S

n

Mpa

Vessel allowable stress S Mpa

Nozzle thickness (UG-27( c )(1) t

a

(mm)

Vessel thickness (UG-37(a)( c ) t

b1

(mm)

Vessel thickness t

b2

(mm)

Nozzle thickness t

b3

(mm)

Nozzle thickness t

b

(mm)

Nozzle neck thickness t

UG-45

(mm)

Nozzle neck thickness t

UG-45

(mm)

Standard pipe wall thickness t

st

(mm)

Required Nozzle thickness (UG-27( c )(1) t

rn

(mm)

Required thickness of shell (UG-37(a)( c ) t

r

(mm)

Nozzle nominal wall thickess t

n

(mm)

Nozzle UCS-66 governing thickness (mm)

Nozzle rated MDMT

0

C

Nozzle reinforcement check:

Pad material

Pad diameter D

p

(mm)

Pad is split

Pad UCS-66 governing thickness (mm)

Pad rated MDMT

0

C

(pad impact test exemption temperature from Fig. UCS-66M Curve D)

Specified vessel thickness t (mm)

Thickness of re-pad t

e

(mm)

Nominal thick. Of int. proj. t

i

(mm)

Required thickness of smls nozzle wall t

rn

(mm)

Internal design pressure P bar(g)

Internal radius of nozzle R

n

(mm)

Internal radius of shell course R (mm)

Spherical radius factor K

1

Nozzle projection from inside vessel wall h (mm)

Length of projection L (mm)

Diameter of finished opening d (mm) =dn

Parallel limits of reinf. UG-40 L

R

(mm)

Outer Normal limits of reinf. UG-40 L

H

(mm)

Allowable Stress in tension S (MPa)

Allowable Stress in nozzle S

n

(MPa)

Allowable Stress in vessel S

v

(MPa)

Allowable Stress in pad S

p

(MPa)

Correction Factor Fig UG-37 F

Strenght reduction factor(s) f

r

f

r1

f

r2

f

r3

f

r4

Total load carried by attach. Weld W

Area of reinf. Required (UG-37) A

mm

2

(UG-37)

mm

2

(UG-39)

mm

2

Area available in shell A

1a

mm

2

A

1b

mm

2

A

1

mm

2

Area available in outward nozzle A

2a

mm

2

A

2b

mm

2

A

2

mm

2

Area available in inward nozzle A

3a

mm

2

A

3b

mm

2

A

3b

mm

2

A

3

mm

2

Outward nozzle weld leg L

41

mm

Re-in element weld leg L

42

mm

Inward nozzle weld leg L

43

mm

Area available in outward nozzle welds A

41

mm

2

A

41

mm

2

Area available in reinf. element welds A

42

mm

2

Area available in inward nozzle welds A

43

mm

2

Area available in welds A

4

mm

2

Area available in reinf element A

5

mm

2

Total Available Area A

av

mm

2

Is A

av

>= A Yes

Allowable Stresses in weld joints (UG-45 and UW-15( c ))

Groove weld in tension S

g

MPa

Nozzle wall in shear S

ns

MPa

Inner fillet weld in shear S

i

MPa

Outer fillet weld in shear S

o

MPa

Upper groove weld in tension S

g

MPa

Fillet weld size check (UW-16( c )(2))

Outer fillet weld t

min

(mm)

t

c (req)

(mm)

leg (mm)

t

c (actual)

(mm)

Outer element weld t

min

(mm)

t

w (req)

(mm)

leg (mm)

t

w (actual)

(mm)

Inner fillet weld t

min

(mm)

t

w (req)

(mm)

leg (mm)

t

w (actual)

(mm)

Strength of weld joints

Groove weld in tension N

Nozzle wall in shear N

Inner fillet weld in shear N

Outer fillet weld in shear N

Upper groove weld in tension N

Loading on welds (UG-41(b)(1))

W

W

1-1

W

2-2

W

3-3

(UG-37 or 1-9 or 1-10 or UG-39 or App 14)

SA 312 TP 316L (Smls pipe)

12 Sch 80S DN 300

0

850

0.082 0.008 Mpa

No

0.5

0.5

1

1 (=0.85 if nozzle passes thru weld cat A, C, D)

12 Class 150 Type WNRF

SA 182 F316L

-48

11.16 @ 203

0

C

15.9 @ 21.11

0

C

24 @ 21.11

0

C

0

0

SA 193 B8

10.3 1.044 Mpa

1.03 0.104 Mpa

323.85

12.7 (based on Sch 80S)

298.45

149.225

631

134

109

2.0 =(P*R

n

/(S

n

*E - 0.6*P)+ CA)/0.875

3.6 =(P+P

s

)*R/(S*E -0.6*P) + CA

9 =External pressure thickness + CA

8.84 =Table UG-45 + CA

8.84 = min (t

b3

, max(t

b1

, t

b2

)

2.0 =t

a

(for inspection and access opening)

8.8 =max (t

a,

t

b

) (for all other nozzles)

12.7

1.5 =P*R

n

/(S

n

*E - 0.6*P) (without C.A.)

3.1 =(P+P

s

)*R/(S*E -0.6*P) (without C.A.)

(seamless shell, E=1; check also if UG-37 is applicable)

10.61 (for other than pipe, thickness without forming allowance)

-105 (UCS-66(b)(3)) [coincident ratio: ]

SA 240 TP316L

700

No

-48 (UCS-66(b)(2)) [coincident ratio: ]

9

9

0

1.5

10.3

149.225

315.5

0 (no credit for projection outside limit of re-inf)

136.7 (thickened portion of integral re-inf of nozzle neck beyond

vessel outside surface)

298.45

298.45 =max(d, R

n

+(t

n

-CA

n

) + (t-CA)

21.25 =min(2.5*(t-CA), 2.5*(t

n

-CA

n

) + t

e

)

109

134

109

109

1

1.23 =S

n

/S

v

1.00 =min(1, S

n

/S

v

)

1.00 =min(1, S

n

/S

v

)

1 =min(f

r2

, S

p

/S

v

)

1 =min(1, S

p

/S

v

)

914.02 = dt

r

F+2t

n

t

r

F(1-f

r1

) (internal pressure)

= 0.5*dt

r

F+2t

n

t

r

F(1-f

r1

) (external pressure)

= 0.5*dtF+2tt

r

F(1-f

r1

) (flat head)

1772.03 =d*(E

1

*t-F*t

r

)-2*t

n

*(E

1

*t-F*t

r

)*(1-f

r1

)

232.90 =2*(t+t

n

)*(E

1

*t-F*t

r

)-2*t

n

*(E

1

*t-F*t

r

)*(1-f

r1

)

1772.03 =max(A

1a

, A

1b

)

411.69 =5*(t

n

-t

rn

)*f

r2

*t

=5*(t

n

-t

rn

)*t

n

*f

r2

(without re-inf. Pad)

4369.02 =2*(t

n

-t

rn

)*(2.5*t

n

*t

e

)*f

r2

(with re-inf. Pad)

411.69 =min(A

2a

, A

2b

)

0 =5*(t

*

t

i

)*f

r2

0 =5*(t

i*

t

i

)*f

r2

0 =2*(h

*

t

i

)*f

r2

0 =min(A

3a

, A

3b

, A

3b

)

9

9

0

=(leg)

2

*f

r2

(without re-inf. Pad)

81 =(leg)

2

*f

r3

(with re-inf. Pad)

81 =(leg)

2

*f

r4

0 =(leg)

2

*f

r2

162 =(A

41

+ A

42

+ A

43

)

3422.925 =(D

p

-d-2*t

n

)*t

e

*f

r4

5768.64 =(A

1

+ A

2

+ A

3

+A

4

+A

5

)

i.e. Reinforcement is adequate.

80.66 = 0.74 * S

v

93.8 = 0.70 * S

n

53.41 = 0.49 * S

v

65.66 = 0.49 * S

n

99.16 = 0.74 * S

v

12.70 = min (19, t

n

, t

e

)

6 = min (6, 0.7*t

min

)

0 = actual leg size

0 = 0.7*leg

9.00 = min (19, t

, t

e

)

6 = 0.5*t

min

9 = actual leg size

6.3 = 0.7*leg

19.00 = min (19, t

n

, t

e

)

6 = 0.5*t

min

0 = actual leg size

0 = 0.7*leg

= (/2)*Nozzle OD*t

w

* S

g

= (/2)*Mean Nozzle OD*t

n

* S

ns

= (/2)*Nozzle OD*leg* S

i

= (/2)*Pad OD*leg* S

o

= (/2)*Nozzle OD*t

w

* S

g

=[A-A

1

+2*t

n

*f

r1

*(E

1

*t-F*t

r

)]*S

v

=(A

2

+ A

5

+ A

41

+A

42

)*S

v

=(A

2

+ A

3

+ A

41

+A

43

+2*t

n

*t*f

r1

)*S

v

=(A

2

+ A

3

+ A

5

+A

41

+A

42

+A

43

+2*t

n

*t*f

r1

)*S

v

Potrebbero piacerti anche

- Body Flange Design-Appx-2Documento4 pagineBody Flange Design-Appx-2Matthieu100% (1)

- Section VIII CalDocumento19 pagineSection VIII CalPradeep Kothapalli100% (1)

- Asme Viii CalcsDocumento20 pagineAsme Viii CalcsSriram VjNessuna valutazione finora

- ASME Code VIII Div. I Edition 2004Documento4 pagineASME Code VIII Div. I Edition 2004Akshat JainNessuna valutazione finora

- Nozzle ReinforcementDocumento8 pagineNozzle ReinforcementHafizi HZnumismatic0% (1)

- Cone dimensions and calculationsDocumento4 pagineCone dimensions and calculationsanil4u29100% (1)

- Rectangular TankDocumento4 pagineRectangular Tankknsaravana0% (1)

- Pressure Vessel Design CalculationsDocumento2 paginePressure Vessel Design CalculationsMohan VarkeyNessuna valutazione finora

- Calcu Nozzle NeckDocumento15 pagineCalcu Nozzle Necksachmaya0% (1)

- Small Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFDocumento6 pagineSmall Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFhussamammarNessuna valutazione finora

- Saddle Calc PD5500Documento4 pagineSaddle Calc PD5500rsubramaniNessuna valutazione finora

- Rectangular Vessel Stress CalculationDocumento2 pagineRectangular Vessel Stress Calculationpastyl100% (1)

- Shell CalculationsDocumento3 pagineShell CalculationsBaher Elsheikh100% (7)

- Nozzle Design Tool AnalysisDocumento2 pagineNozzle Design Tool AnalysisArt G. EnziNessuna valutazione finora

- Saddle AnalysisDocumento17 pagineSaddle AnalysisPEJU0007Nessuna valutazione finora

- Pressure Vessel CalculationsDocumento1 paginaPressure Vessel Calculationsmoonstar_dme100% (3)

- Design of Pressure Vessel NewDocumento200 pagineDesign of Pressure Vessel NewneelNessuna valutazione finora

- API Calcs Rev1 (Version 2)Documento112 pagineAPI Calcs Rev1 (Version 2)Jake Sparrow100% (1)

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocumento30 pagineWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersmishtinilNessuna valutazione finora

- ASME VIII CalculationDocumento14 pagineASME VIII CalculationWan Wei100% (1)

- Anchor Flange Design CalculationDocumento6 pagineAnchor Flange Design CalculationJohakim974Nessuna valutazione finora

- Nozzle Reinf Calc (Rough)Documento12 pagineNozzle Reinf Calc (Rough)Sajal Kulshrestha100% (1)

- Reinforcement Pad DesignDocumento3 pagineReinforcement Pad DesignAkshat JainNessuna valutazione finora

- Pressure Vessel FormulaDocumento9 paginePressure Vessel FormulaNasir Khan JadoonNessuna valutazione finora

- Sight Glass Selection Guide PDFDocumento7 pagineSight Glass Selection Guide PDFani_datNessuna valutazione finora

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDocumento5 pagineNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- SHELL VESSEL DESIGNDocumento22 pagineSHELL VESSEL DESIGNaauppalNessuna valutazione finora

- Vessel Thickness CalculationDocumento60 pagineVessel Thickness CalculationSaurabh SinghNessuna valutazione finora

- Heat Exchanger DesignDocumento7 pagineHeat Exchanger Designsiva sankarNessuna valutazione finora

- Tube Sheet CalculationDocumento3 pagineTube Sheet CalculationAbhay UpadhyayNessuna valutazione finora

- Agitator Nozzle Load Data SheetDocumento1 paginaAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBENessuna valutazione finora

- Saddle CalculationDocumento10 pagineSaddle Calculationpharis_chrisNessuna valutazione finora

- Design Calculations For Pressure VesselsDocumento73 pagineDesign Calculations For Pressure Vesselsshani5573Nessuna valutazione finora

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocumento4 pagineBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNessuna valutazione finora

- Flange CalculationsDocumento5 pagineFlange CalculationsswapnavattemNessuna valutazione finora

- Pipe Insulation THK CalculationDocumento6 paginePipe Insulation THK Calculationnitin_bir100% (2)

- ASME Section VIII, Division 2: Pressure Vessel Stress and Fatigue AnalysisDocumento17 pagineASME Section VIII, Division 2: Pressure Vessel Stress and Fatigue AnalysisBernacleboy IDNessuna valutazione finora

- Welded Beam CalculationDocumento2 pagineWelded Beam CalculationVeenoyNessuna valutazione finora

- Thickness Calculation of Pressure Vessel ShellDocumento22 pagineThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- Api 620 - 2002Documento12 pagineApi 620 - 2002ductaiutc100% (1)

- Pressure VesselDocumento507 paginePressure Vesselpradip11100% (1)

- Fiber elongation calculations for pressure vesselsDocumento1 paginaFiber elongation calculations for pressure vesselsJ.SIVIRA100% (1)

- Vent Sizing - SpreadsheetDocumento2 pagineVent Sizing - SpreadsheetPradip ShindeNessuna valutazione finora

- CAESAR II Training Overview PDFDocumento5 pagineCAESAR II Training Overview PDFJesus MaestreNessuna valutazione finora

- Cone DevelopmentDocumento2 pagineCone DevelopmentpandiangvNessuna valutazione finora

- Weight Estimation of Vessels AppsDocumento28 pagineWeight Estimation of Vessels AppsAlvin Smith60% (5)

- Asme Viii Shell & Se HeadDocumento5 pagineAsme Viii Shell & Se HeadSnr George RaczNessuna valutazione finora

- Nozzle Design Under Internal PressureDocumento1 paginaNozzle Design Under Internal PressurenamasralNessuna valutazione finora

- Internal CoilDocumento2 pagineInternal CoilwhngomjNessuna valutazione finora

- ASME VIII Corroded Nozzle - Shell With Repad - UG-45 - UG-37 CalcDocumento32 pagineASME VIII Corroded Nozzle - Shell With Repad - UG-45 - UG-37 CalcIonut FloricaNessuna valutazione finora

- New - Reinforcement of NozzleDocumento31 pagineNew - Reinforcement of NozzleNithin ZsNessuna valutazione finora

- Mud Gas Separator CalculationDocumento16 pagineMud Gas Separator CalculationErwin Gomop-asNessuna valutazione finora

- Shell Inputs: Use Asme Code Section-8 Division I (Ug-37)Documento34 pagineShell Inputs: Use Asme Code Section-8 Division I (Ug-37)Bashu PoudelNessuna valutazione finora

- Mud Gas Separator CalculationDocumento16 pagineMud Gas Separator CalculationErwin Gomop-as100% (2)

- Mathcad - 539900-050-130 Padeye Pulling Skid 9.5 TDocumento7 pagineMathcad - 539900-050-130 Padeye Pulling Skid 9.5 TPablo Diego Didoné100% (1)

- Calculo de Brida Segun ASMEDocumento29 pagineCalculo de Brida Segun ASMEakarcz6731Nessuna valutazione finora

- Ist Stage Cooler Process and Mechanical DetailsDocumento2 pagineIst Stage Cooler Process and Mechanical DetailsjnmanivannanNessuna valutazione finora

- Asme BPVC Code Viii Div. I Edition 2015, Nozzle Neck Thickness Calculation Nozzle SizeDocumento2 pagineAsme BPVC Code Viii Div. I Edition 2015, Nozzle Neck Thickness Calculation Nozzle SizeAnil GhildiyalNessuna valutazione finora

- New - Reinforcement of NozzleDocumento31 pagineNew - Reinforcement of Nozzlehardik5818Nessuna valutazione finora

- Branch Reinforcement Pad Requirement CalculationDocumento2 pagineBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Wind Calculation SheetDocumento32 pagineWind Calculation SheetaauppalNessuna valutazione finora

- Zick AnalysisDocumento12 pagineZick AnalysisrksahayNessuna valutazione finora

- Stored Energy CalculationDocumento4 pagineStored Energy Calculationaauppal0% (1)

- ANSI Bolt Thread Sizes ChartDocumento1 paginaANSI Bolt Thread Sizes ChartaauppalNessuna valutazione finora

- Wind Engineering Latest ToolsDocumento3 pagineWind Engineering Latest ToolsaauppalNessuna valutazione finora

- Refractory EngineeringDocumento3 pagineRefractory EngineeringaauppalNessuna valutazione finora

- M.ed. Style Guide 2011Documento33 pagineM.ed. Style Guide 2011opabalekeNessuna valutazione finora

- Microstructure WRC DiagramDocumento3 pagineMicrostructure WRC DiagramaauppalNessuna valutazione finora

- Bolt Torque CalculatorDocumento9 pagineBolt Torque Calculatoraauppal100% (3)

- Wind Speed Table For Conversion of Knots, Beaufort, M/s and KM/HDocumento4 pagineWind Speed Table For Conversion of Knots, Beaufort, M/s and KM/HaauppalNessuna valutazione finora

- Basics of Corrosion ControlDocumento9 pagineBasics of Corrosion ControlSenad Senna MuratovicNessuna valutazione finora

- Haste LoyDocumento16 pagineHaste LoybitanjungNessuna valutazione finora

- Piping Stress AnalysisDocumento51 paginePiping Stress Analysissandygo100% (4)

- Tin 46 T out 36 delta T 10 V 54 m 54000 54 vel 2 7200 A 0.0075 D 97.720 4 C 4.2 ρ 1000 Q 2268000 630 179 COP 4Documento2 pagineTin 46 T out 36 delta T 10 V 54 m 54000 54 vel 2 7200 A 0.0075 D 97.720 4 C 4.2 ρ 1000 Q 2268000 630 179 COP 4aauppalNessuna valutazione finora

- Beam Deflection FormulaeDocumento2 pagineBeam Deflection Formulae7575757575100% (6)

- Words in Applied Statistics BookDocumento1 paginaWords in Applied Statistics BookaauppalNessuna valutazione finora

- Wind Speed EstimationDocumento13 pagineWind Speed EstimationaauppalNessuna valutazione finora

- Numerical Analysis PDFDocumento15 pagineNumerical Analysis PDFaauppalNessuna valutazione finora

- Steel TableDocumento14 pagineSteel TablensriitmNessuna valutazione finora

- GRE High Freq Words by AADocumento15 pagineGRE High Freq Words by AAaauppalNessuna valutazione finora

- Haste LoyDocumento16 pagineHaste LoybitanjungNessuna valutazione finora

- RAL ChartDocumento1 paginaRAL ChartaauppalNessuna valutazione finora

- Numerical Analysis PDFDocumento15 pagineNumerical Analysis PDFaauppalNessuna valutazione finora

- Tank CalibrationDocumento12 pagineTank Calibrationmohamedyoussef1100% (2)

- Material SelectionDocumento8 pagineMaterial SelectionaauppalNessuna valutazione finora

- Solution: WE1 12 Nov 2008Documento9 pagineSolution: WE1 12 Nov 2008aauppalNessuna valutazione finora

- Bro Spiral WoundDocumento47 pagineBro Spiral WoundaauppalNessuna valutazione finora

- Introduction To C++ ProgrammingDocumento47 pagineIntroduction To C++ Programmingryan ong89% (9)

- Material SelectionDocumento8 pagineMaterial SelectionaauppalNessuna valutazione finora

- BioTime 7.0 Installation Guide V1.1 APR 2018Documento13 pagineBioTime 7.0 Installation Guide V1.1 APR 2018Muhammad Rizwan WaliNessuna valutazione finora

- Teac Ad-600 PDFDocumento50 pagineTeac Ad-600 PDFAnonymous Pr8IgKeNessuna valutazione finora

- Dokumen - Tips Simple Trusses The Method of Joints Zero Force Mikecp1170noteschapter06methodofjointspdfDocumento34 pagineDokumen - Tips Simple Trusses The Method of Joints Zero Force Mikecp1170noteschapter06methodofjointspdfWyaette NhengoNessuna valutazione finora

- Railway Overhead Conductors CatalogDocumento14 pagineRailway Overhead Conductors CatalogsudhakarrrrrrNessuna valutazione finora

- CSE Application ChecklistDocumento4 pagineCSE Application ChecklistArfan HaiderNessuna valutazione finora

- Seabed Worker DatasheetDocumento2 pagineSeabed Worker DatasheetAnthonyNessuna valutazione finora

- Quality Test Bank 2Documento16 pagineQuality Test Bank 2Behbehlynn100% (4)

- UntitledDocumento346 pagineUntitledDr Luis e Valdez ricoNessuna valutazione finora

- Test-4 SomDocumento42 pagineTest-4 SomVivekMishraNessuna valutazione finora

- Proposal For UreaDocumento24 pagineProposal For UreaUmar ZamanNessuna valutazione finora

- Instruction Manual of Gravity Destoner: Zhengzhou Chinatown Grain Machinery Co., LTDDocumento9 pagineInstruction Manual of Gravity Destoner: Zhengzhou Chinatown Grain Machinery Co., LTD(Doc - Bto) Renato Alejandro Andara EscalonaNessuna valutazione finora

- 160 88-CL2Documento6 pagine160 88-CL2vanthe140591Nessuna valutazione finora

- AML Biodiesel 1500 TPDDocumento14 pagineAML Biodiesel 1500 TPDREALLY ?Nessuna valutazione finora

- QuotationDocumento14 pagineQuotationMiko AbiNessuna valutazione finora

- 250 42aECDocumento35 pagine250 42aECniknenadNessuna valutazione finora

- LPCBDocumento3 pagineLPCBhomaNessuna valutazione finora

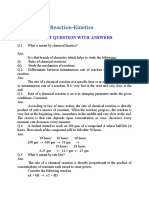

- Chapter 11 .Reaction-Kinetics: Short Question With AnswersDocumento6 pagineChapter 11 .Reaction-Kinetics: Short Question With AnswersAasim AliNessuna valutazione finora

- Backlash (Engineering) - Wikipedia, The Free EncyclopediaDocumento4 pagineBacklash (Engineering) - Wikipedia, The Free EncyclopediadarkruseNessuna valutazione finora

- 5 Sol To s2 Phy PressureDocumento7 pagine5 Sol To s2 Phy PressureShreyan KhetaniNessuna valutazione finora

- Manual Moto Rev 125Documento33 pagineManual Moto Rev 125Mario Recio LoríaNessuna valutazione finora

- Company Profile Traya Lintas PersadaDocumento24 pagineCompany Profile Traya Lintas PersadaAyu Catra KastaraNessuna valutazione finora

- Knauf OnBoards External CeilingsDocumento2 pagineKnauf OnBoards External CeilingsScott FullerNessuna valutazione finora

- Maya Shortcut KeysDocumento7 pagineMaya Shortcut KeysYogesh RathiNessuna valutazione finora

- Sr. No. Description Material Grade Length (MM) Weight (KG)Documento4 pagineSr. No. Description Material Grade Length (MM) Weight (KG)Shriniwas NaikNessuna valutazione finora

- Замена проявки Xerox - WC - 7855FDocumento12 pagineЗамена проявки Xerox - WC - 7855FkuharskiyvsNessuna valutazione finora

- Confirm Receipt TroubleshootingDocumento1 paginaConfirm Receipt TroubleshootingMahmoud Ibrahim ElatafawyNessuna valutazione finora

- MPMC 32 Bit PDFDocumento29 pagineMPMC 32 Bit PDFashok1683Nessuna valutazione finora

- Belt Conveyor Systems and ComponentsDocumento87 pagineBelt Conveyor Systems and Componentskasim leeNessuna valutazione finora

- SJ Asphalt 1Documento8 pagineSJ Asphalt 1Estêvão MayrerNessuna valutazione finora

- Physics! Unit 07 Packet ETM 2012Documento16 paginePhysics! Unit 07 Packet ETM 2012Kelly O'Shea80% (5)