Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

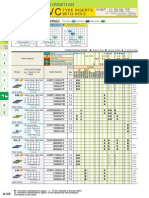

Type Inserts With Hole: VNMG 16 04 02-FH

Caricato da

TungstenCarbideTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Type Inserts With Hole: VNMG 16 04 02-FH

Caricato da

TungstenCarbideCopyright:

Formati disponibili

A088

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

E

6

0

3

5

U

H

6

4

0

0

M

C

7

0

1

5

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

T

F

1

5

FH

VNMG 160402-FH 0.2 a [ a a a

C018

020

E015

E042

160404-FH 0.4 a [ a a a

160408-FH 0.8 a [ a a a a

FS

VNMG 160404-FS 0.4 [ a

C018

020

E015

E042

160408-FS 0.8 [ a

FJ

VNGG 1604V5-FJ 0.05 a a

C018

020

E015

E042

160401-FJ 0.1 a a

160402-FJ 0.2 a a

R/L-F

VNGG 160402R-F 0.2 a a a a

C018

020

E015

E042

160402L-F 0.2 a a a a

160404R-F 0.4 a a a a

160404L-F 0.4 a a a a

LP

VNMG 160404-LP 0.4 a a a a

C018

020

E015

E042

160408-LP 0.8 a a a a

LM

VNMG 160404-LM 0.4 a a a

C018

020

E015

E042

160408-LM 0.8 a a a

SH

VNMG 160404-SH 0.4 a a [ a a a

C018

020

E015

E042

160408-SH 0.8 a a [ a a a

NEW

NEW

VNMG 16 04 02- FH

VN

35

P K

N

E

W

N

E

W

N

E

W

N

E

W

N

E

W

P M

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

3

2

1

0

0.1 0.2 0.3 0.4

4

3

2

1

0

0.1 0.3 0.5

3

2

1

0

0.1 0.2 0.3 0.4

8

7

6

5

4

3

2

1

0

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7 0.1 0.3 0.5 0.7

MA

4

3

2

1

0

0.1 0.3 0.5

4

3

2

1

0

0.1 0.3 0.5

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

FH

MP

LP

MM

LM

FS MA

NEG

TURNI NG I NSERTS

[

NEGATI VE

]

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

Size Thickness Corner Radius

*

Please refer to page A002.

WITH

HOLE

Finish Cutting

Finish Cutting

Finish Cutting

Finish Cutting

Light Cutting

Light Cutting

Light Cutting

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Carbon Steel Alloy Steel

Mild Steel

Diffcult-to-Cut Materials

a

p

(

m

m

)

a

p

(

m

m

)

a

p

(

m

m

)

f (mm/rev)

f (mm/rev)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

TYPE I NSERTS

WI TH HOLE

Chip Breaker

CHIP CONTROL RANGE FOR WORK MATERIALS

Mild Steel Cast Iron (<350MPa)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev) Feed (mm/rev)

Standard

Flat Top

Finish Cutting Light Cutting MediumCutting Rough Cutting Heavy Cutting

Stainless Steel

a

p

(

m

m

)

f (mm/rev)

a : Inventory maintained in Japan.

[ : Inventory maintained in Japan. To be replaced by new products.

(10 inserts in one case)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel (180280HB) Stainless Steel (<200HB)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev) Feed (mm/rev)

A089

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

E

6

0

3

5

U

H

6

4

0

0

M

C

7

0

1

5

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

T

F

1

5

MJ

VNMG 160404-MJ 0.4 a a a a

C018

020

E015

E042

160408-MJ 0.8 a a a a

160412-MJ 1.2 a a a

MJ

VNGM 160404-MJ 0.4 a a

C018

020

E015

E042

160408-MJ 0.8 a a

MP

VNMG 160404-MP 0.4 a a a [ a a

C018

020

E015

E042

160408-MP 0.8 a a a [ a a

160412-MP 1.2 a a a [ a

MM

VNMG 160408-MM 0.8 a a a

C018

020

E015

E042

GM

VNMG 160404-GM 0.4 a a a

C018

020

E015

E042

160408-GM 0.8 a a a

MA

VNMG 160404-MA 0.4 a a a [ a a [ a a a a

C018

020

E015

E042

160408-MA 0.8 a a a [ a a a [ a a a a

MH

VNMG 160404-MH 0.4 a a [ a

C018

020

E015

E042

160408-MH 0.8 a a [ [ a

VNMG 160404 0.4 a a a [ a a a a a a a a

C018

020

E015

E042

160408 0.8 a a a [ a a a a a a a a

160412 1.2 a a a a a

MS

VNMG 160404-MS 0.4 a [ a a a a a

C018

020

E015

E042

160408-MS 0.8 a [ a a a a a a

NEW

NEW

N

E

W

N

E

W

N

E

W

N

E

W

N

E

W

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

5

4

3

2

1

0

0.1 0.3 0.5

4

3

2

1

0

0.1 0.3 0.5

NEG

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

WITH

HOLE

Light Cutting

Light Cutting

Medium Cutting

Medium Cutting

Medium Cutting

Medium Cutting

Medium Cutting

Standard

Medium Cutting

Medium Cutting

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Diffcult-to-Cut Materials

Carbon Steel Alloy Steel

Carbon Steel Alloy Steel

a

p

(

m

m

)

a

p

(

m

m

)

a

p

(

m

m

)

f (mm/rev)

f (mm/rev)

f (mm/rev)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel

f (mm/rev)

a

p

(

m

m

)

Stainless Steel

a

p

(

m

m

)

f (mm/rev)

Stainless Steel

a

p

(

m

m

)

f (mm/rev)

Diffcult-to-Cut Materials

a

p

(

m

m

)

f (mm/rev)

CHIP BREAKERS A040

GRADES A030

IDENTIFICATION A002

Diffcult-to-Cut Materials

A090

P

M

K

N

S

Re

U

E

6

1

0

5

U

E

6

1

1

0

M

C

6

0

2

5

U

E

6

0

2

0

U

E

6

0

3

5

U

H

6

4

0

0

M

C

7

0

1

5

M

C

7

0

2

5

M

P

7

0

3

5

U

S

7

0

2

0

U

S

7

3

5

U

S

9

0

5

U

C

5

1

0

5

U

C

5

1

1

5

V

P

0

5

R

T

V

P

1

0

R

T

V

P

1

5

T

F

U

P

2

0

M

N

X

2

5

2

5

N

X

3

0

3

5

M

P

3

0

2

5

A

P

2

5

N

V

P

2

5

N

U

T

i

2

0

T

H

T

i

0

5

T

H

T

i

1

0

R

T

9

0

1

0

T

F

1

5

R/L

VNGG 160404R 0.4 a a a a

C018

020

E015

E042

160404L 0.4 a a a

VNGA 160404 0.4 a a

C018

020

E015

E042

160408 0.8 a a

VN

35

N

E

W

N

E

W

N

E

W

N

E

W

N

E

W

P M P K

VNGG 16 04 04 R

5

4

3

2

1

0

0.1 0.3 0.5

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

FH

MP

LP

MM

LM

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

FS

8

6

4

2

0

0.1 0.3 0.5 0.7

8

7

6

5

4

3

2

1

0

0.1 0.3 0.5 0.7

MA MA

NEG

TURNI NG I NSERTS

[

NEGATI VE

]

T

U

R

N

I

N

G

I

N

S

E

R

T

S

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

Size Thickness Corner Radius

*

Please refer to page A002.

WITH

HOLE

Medium Cutting

Flat Top

Work Material

Steel

Stainless Steel

Cast Iron

Non-ferrous Metal

Heat-resistant Alloy, Titanium Alloy

Shape

Chip Control Range

ap : Depth of Cut

f : Feed

Order Number

Corner R Coated Cermet

Coated

Cermet

Carbide

A

p

p

l

i

c

a

b

l

e

H

o

l

d

e

r

P

a

g

e

(mm)

Cast Iron

a

p

(

m

m

)

f (mm/rev)

TYPE I NSERTS

WI TH HOLE

CHIP CONTROL RANGE FOR WORK MATERIALS

Finish Cutting Light Cutting MediumCutting Rough Cutting Heavy Cutting

a : Inventory maintained in Japan.

[ : Inventory maintained in Japan. To be replaced by new products.

(10 inserts in one case)

Carbon Steel Alloy Steel

a

p

(

m

m

)

f (mm/rev)

Carbon Steel Alloy Steel (180280HB) Stainless Steel (<200HB)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev) Feed (mm/rev)

Mild Steel

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Cast Iron (<350MPa)

D

e

p

t

h

o

f

C

u

t

(

m

m

)

Feed (mm/rev)

Standard

Flat Top

Chip Breaker

Potrebbero piacerti anche

- Machine Design Short Answers GuideDocumento184 pagineMachine Design Short Answers GuideHew LetNessuna valutazione finora

- Electronic Circuit Design Ideas: Edn Series for Design EngineersDa EverandElectronic Circuit Design Ideas: Edn Series for Design EngineersValutazione: 5 su 5 stelle5/5 (2)

- 1.lesson Plan Welding Basic Metals - 0 - 0Documento6 pagine1.lesson Plan Welding Basic Metals - 0 - 0Romel A. De GuiaNessuna valutazione finora

- Aws D3.5-93PV PDFDocumento8 pagineAws D3.5-93PV PDFwalter091011Nessuna valutazione finora

- Bolt Grip Length PDFDocumento1 paginaBolt Grip Length PDFmatthewwalls4386100% (2)

- Fundamentals of Machine Design 3252Documento509 pagineFundamentals of Machine Design 3252greenwind007100% (1)

- Gate Valve Parts CatalogueDocumento12 pagineGate Valve Parts CatalogueLeandroNessuna valutazione finora

- Controlled Bolt Tightening ChecklistDocumento10 pagineControlled Bolt Tightening Checklistanjangandak2932Nessuna valutazione finora

- STP 550-1986Documento58 pagineSTP 550-1986Anonymous pSozzNFcNessuna valutazione finora

- Effect of Grain Size on Mechanical Properties of High Strength Low Alloy SteelsDocumento42 pagineEffect of Grain Size on Mechanical Properties of High Strength Low Alloy SteelsDeepak PatelNessuna valutazione finora

- Classification of Steel PDFDocumento11 pagineClassification of Steel PDFkart_rl100% (2)

- Filtros Por Modelos Massey FergunsonDocumento10 pagineFiltros Por Modelos Massey FergunsonRafael CamejoNessuna valutazione finora

- Type Inserts With Hole: DNMG 15 04 02-FHDocumento5 pagineType Inserts With Hole: DNMG 15 04 02-FHTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: VCMT 11 03 02-FPDocumento2 pagineType Inserts With Hole: VCMT 11 03 02-FPTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: TCMT 09 02 02-FPDocumento2 pagineType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNessuna valutazione finora

- CPDocumento1 paginaCPTungstenCarbideNessuna valutazione finora

- CCDocumento2 pagineCCTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: WNMG 08 04 04-FHDocumento4 pagineType Inserts With Hole: WNMG 08 04 04-FHTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocumento1 paginaType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocumento1 paginaType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: SCMT 09 T3 04-FPDocumento2 pagineType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: WCGT 02 01 02 RDocumento1 paginaType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNessuna valutazione finora

- Profit Center Ledger ReportDocumento1.043 pagineProfit Center Ledger ReportVergaraJuan0% (1)

- Type Inserts With Hole: RCGT 08 03 M0-AZDocumento1 paginaType Inserts With Hole: RCGT 08 03 M0-AZTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: DEGX 15 04 02 R-FDocumento1 paginaType Inserts With Hole: DEGX 15 04 02 R-FTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: VBMT 11 03 04 - SVDocumento2 pagineType Inserts With Hole: VBMT 11 03 04 - SVTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: TPMH 08 02 02-FVDocumento3 pagineType Inserts With Hole: TPMH 08 02 02-FVTungstenCarbideNessuna valutazione finora

- Tru P1-C 1 - Tubes 1 - 2 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Tru P1-C 1 - Tubes 2 - 3 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16Documento12 pagineTru P1-C 1 - Tubes 1 - 2 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Tru P1-C 1 - Tubes 2 - 3 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16hboespnNessuna valutazione finora

- Type Inserts With Hole: XCMT 15 03 02-SVXDocumento1 paginaType Inserts With Hole: XCMT 15 03 02-SVXTungstenCarbideNessuna valutazione finora

- Stock ListDocumento22 pagineStock ListIthink'bree-mahana Anak'sintua Lau'gunungs-shimalemnari Prnmbeh'ningen-prpusuhNessuna valutazione finora

- Kyocera Fs-6900 Parts ManualDocumento28 pagineKyocera Fs-6900 Parts ManualNic CowpeNessuna valutazione finora

- Denison Calzoni Type MRT Mrte MRTFDocumento24 pagineDenison Calzoni Type MRT Mrte MRTFSilvio RomanNessuna valutazione finora

- VB VCC Ho VB VCC HoDocumento2 pagineVB VCC Ho VB VCC HounnidigiNessuna valutazione finora

- VB VCC Ho VB VCC HoDocumento2 pagineVB VCC Ho VB VCC HounnidigiNessuna valutazione finora

- BHEL Auxiliary Systems DesignationsDocumento13 pagineBHEL Auxiliary Systems Designationssuleman247Nessuna valutazione finora

- Weld ExportDocumento4 pagineWeld ExportDhowre AliNessuna valutazione finora

- Type Inserts With Hole: TEGX 16 03 02 RDocumento1 paginaType Inserts With Hole: TEGX 16 03 02 RTungstenCarbideNessuna valutazione finora

- GE Multilin 489 Generator Management Relay MODBUS Memory MapDocumento29 pagineGE Multilin 489 Generator Management Relay MODBUS Memory MapArturo NeiraNessuna valutazione finora

- Thermal Expansion Valves GuideDocumento3 pagineThermal Expansion Valves GuidercbandeiraNessuna valutazione finora

- Technical Manual: Stereo Integrated AmplifierDocumento11 pagineTechnical Manual: Stereo Integrated AmplifierIordan Dan FfnNessuna valutazione finora

- Packing List - P932: Item Cant Description Hoja #72 72 72Documento11 paginePacking List - P932: Item Cant Description Hoja #72 72 72Anonymous CpWhwdC7sNessuna valutazione finora

- FC-M591 FC-M591: DEORE Front ChainwheelDocumento1 paginaFC-M591 FC-M591: DEORE Front Chainwheelarag60Nessuna valutazione finora

- A Pi Ring Joint Flange DataDocumento2 pagineA Pi Ring Joint Flange DataSusin LimNessuna valutazione finora

- List of Equipment ReportDocumento5.113 pagineList of Equipment ReportBetty RosalinaNessuna valutazione finora

- Obl - NXTDocumento3 pagineObl - NXTKumar DevvratNessuna valutazione finora

- Resultats Tsi Ga AdoDocumento5 pagineResultats Tsi Ga AdoKamal Hassani AlaouiNessuna valutazione finora

- Weld ExportDocumento4 pagineWeld ExportDhowre AliNessuna valutazione finora

- L6004DDocumento8 pagineL6004DmaldomattNessuna valutazione finora

- Regal Furnace ManualDocumento44 pagineRegal Furnace Manualali khaddoumaNessuna valutazione finora

- Tabela ABB - BT 2015 - 02.03.15Documento1.802 pagineTabela ABB - BT 2015 - 02.03.15Shadi AbdelsalamNessuna valutazione finora

- Quoizel PDF Sku ListDocumento40 pagineQuoizel PDF Sku ListA_tenksNessuna valutazione finora

- Base enDocumento31 pagineBase enTrần Thanh HoàngNessuna valutazione finora

- Bustan City Phase-12 Project DetailsDocumento1 paginaBustan City Phase-12 Project DetailssaaNessuna valutazione finora

- ZTE180 POs NOVAS NOKIA 2019 2020 GRI CL4 CMF 6010 ESGUP08Documento247 pagineZTE180 POs NOVAS NOKIA 2019 2020 GRI CL4 CMF 6010 ESGUP08Young VisionNessuna valutazione finora

- MES id and package dataDocumento25 pagineMES id and package dataamirulamirNessuna valutazione finora

- Bang Gia Thiet Bi Dien Mitsubishi 01-04-2020Documento422 pagineBang Gia Thiet Bi Dien Mitsubishi 01-04-2020Kien Nguyen TrungNessuna valutazione finora

- Type Inserts With Hole: SPMT 09 03 04Documento1 paginaType Inserts With Hole: SPMT 09 03 04TungstenCarbideNessuna valutazione finora

- Onbongo - FinalDocumento10 pagineOnbongo - FinalMKT_RGBNessuna valutazione finora

- Insert Stock Statement For The Mont of April-2017Documento12 pagineInsert Stock Statement For The Mont of April-2017Abhijeet AnkushNessuna valutazione finora

- File - YANMAR ItalyDocumento22 pagineFile - YANMAR ItalyEdisonNainggolanNessuna valutazione finora

- R 390Documento5 pagineR 390MiticaVladNessuna valutazione finora

- Sectors 5-7 document codesDocumento2 pagineSectors 5-7 document codesAsher Grimaldi HannoverNessuna valutazione finora

- Al Plate Heat Ex ChangersDocumento686 pagineAl Plate Heat Ex ChangersMario Mendoza33% (3)

- Pricelist Ahm Maret 02-03-2015Documento1.155 paginePricelist Ahm Maret 02-03-2015momoNessuna valutazione finora

- Iiic Ble5Documento4 pagineIiic Ble5Haze Garcia HechanovaNessuna valutazione finora

- Guide to Miniature Tube Fittings & ConnectorsDocumento34 pagineGuide to Miniature Tube Fittings & ConnectorsBrant AkkanNessuna valutazione finora

- ULTEGRA Cassette Sprocket: 11-SpeedDocumento1 paginaULTEGRA Cassette Sprocket: 11-SpeedLucaNessuna valutazione finora

- Through Holes Steam Oxide External Cooling: Series 4402Documento8 pagineThrough Holes Steam Oxide External Cooling: Series 4402TungstenCarbideNessuna valutazione finora

- Any Size Kits Are All $400.00: Steel ApplicationsDocumento2 pagineAny Size Kits Are All $400.00: Steel ApplicationsTungstenCarbideNessuna valutazione finora

- CC CC: Type Inserts With HoleDocumento4 pagineCC CC: Type Inserts With HoleTungstenCarbideNessuna valutazione finora

- Gy2g0200d020n-Mf VP10RTDocumento6 pagineGy2g0200d020n-Mf VP10RTTungstenCarbideNessuna valutazione finora

- Nnmu200608zen-Hk MC5020Documento1 paginaNnmu200608zen-Hk MC5020TungstenCarbideNessuna valutazione finora

- CBN InsertsDocumento27 pagineCBN InsertsTungstenCarbideNessuna valutazione finora

- VFX5UR0203CA10Documento3 pagineVFX5UR0203CA10TungstenCarbideNessuna valutazione finora

- CCMXDocumento1 paginaCCMXTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: WCGT 02 01 02 RDocumento1 paginaType Inserts With Hole: WCGT 02 01 02 RTungstenCarbideNessuna valutazione finora

- AOMT 123602 PEER-M VP15TF Mitsubishi CarbideDocumento2 pagineAOMT 123602 PEER-M VP15TF Mitsubishi CarbideTungstenCarbideNessuna valutazione finora

- Cpmt1205zpen-M2 VP15TFDocumento1 paginaCpmt1205zpen-M2 VP15TFTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: WNMG 08 04 04-FHDocumento4 pagineType Inserts With Hole: WNMG 08 04 04-FHTungstenCarbideNessuna valutazione finora

- Aemw150304er Up20mDocumento1 paginaAemw150304er Up20mTungstenCarbideNessuna valutazione finora

- Aemw150304er Up20mDocumento1 paginaAemw150304er Up20mTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: XCMT 15 03 02-SVXDocumento1 paginaType Inserts With Hole: XCMT 15 03 02-SVXTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: VBMT 11 03 04 - SVDocumento2 pagineType Inserts With Hole: VBMT 11 03 04 - SVTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: WPGT 04 02 04 R-FSDocumento1 paginaType Inserts With Hole: WPGT 04 02 04 R-FSTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: WBGT 02 01 V3 L-FDocumento1 paginaType Inserts With Hole: WBGT 02 01 V3 L-FTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: SPMT 09 03 04Documento1 paginaType Inserts With Hole: SPMT 09 03 04TungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: VPET 08 02 01 R-SRFDocumento1 paginaType Inserts With Hole: VPET 08 02 01 R-SRFTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: VDGX 16 03 02 RDocumento1 paginaType Inserts With Hole: VDGX 16 03 02 RTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: SCMT 09 T3 04-FPDocumento2 pagineType Inserts With Hole: SCMT 09 T3 04-FPTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: TEGX 16 03 02 RDocumento1 paginaType Inserts With Hole: TEGX 16 03 02 RTungstenCarbideNessuna valutazione finora

- Type Inserts With Hole: TPMH 08 02 02-FVDocumento3 pagineType Inserts With Hole: TPMH 08 02 02-FVTungstenCarbideNessuna valutazione finora

- TNDocumento6 pagineTNTungstenCarbideNessuna valutazione finora

- Type Inserts Without Hole: Posi 6ºDocumento1 paginaType Inserts Without Hole: Posi 6ºTungstenCarbideNessuna valutazione finora

- SNDocumento4 pagineSNTungstenCarbideNessuna valutazione finora

- Page 1 of 78Documento78 paginePage 1 of 78Wilfharry billyNessuna valutazione finora

- Chemical Composition Limit (Cast Analysis, %) Tempering Temperature Property Class Material and Heat TreatmentDocumento1 paginaChemical Composition Limit (Cast Analysis, %) Tempering Temperature Property Class Material and Heat TreatmentAhmed Saber NassarNessuna valutazione finora

- Tool Materials PDFDocumento34 pagineTool Materials PDFAvadhoot RajurkarNessuna valutazione finora

- Sec11 LowAlloy WebDocumento68 pagineSec11 LowAlloy WebAshvin GaikwadNessuna valutazione finora

- Pop A Plug MaterialDocumento2 paginePop A Plug MaterialHijau Auliya Keramat Al-qadiryNessuna valutazione finora

- Classification of SteelsDocumento9 pagineClassification of SteelsrajbhushanbhattNessuna valutazione finora

- Astm A209 A209mDocumento3 pagineAstm A209 A209msantoshNessuna valutazione finora

- API 6a Valves LomisaDocumento5 pagineAPI 6a Valves LomisaJulio CNessuna valutazione finora

- Metal Solid IronDocumento48 pagineMetal Solid IronVinoth SangNessuna valutazione finora

- Is 2707-1982Documento12 pagineIs 2707-1982Sumit ShyamalNessuna valutazione finora

- AI I 4145 Allo Teel (UN G41450) : Topics CoveredDocumento3 pagineAI I 4145 Allo Teel (UN G41450) : Topics CoveredUmerNessuna valutazione finora

- ABNT NBR 6330 2020 - General Purpose Carbon Steel Wire RodDocumento12 pagineABNT NBR 6330 2020 - General Purpose Carbon Steel Wire RodElton Felipe Gularte dos SantosNessuna valutazione finora

- "Twist Off" Type Tension Control Structural Bolt/Nut/Washer Assemblies, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthDocumento8 pagine"Twist Off" Type Tension Control Structural Bolt/Nut/Washer Assemblies, Steel, Heat Treated, 120/105 Ksi Minimum Tensile StrengthkrutikNessuna valutazione finora

- PFI ES-11-1975 (R1990) Permanent Marking On Piping MaterialsDocumento3 paginePFI ES-11-1975 (R1990) Permanent Marking On Piping MaterialsThao NguyenNessuna valutazione finora

- Asme Sa 209 Grade T1a TubesDocumento1 paginaAsme Sa 209 Grade T1a TubesFerroPipENessuna valutazione finora

- ISO - TR - 15608 - Welding Guide Line PDFDocumento10 pagineISO - TR - 15608 - Welding Guide Line PDFDacher DanielNessuna valutazione finora

- Nof0849384523 ch1Documento90 pagineNof0849384523 ch1sujit_sekharNessuna valutazione finora

- Aisi 4140 Alloy Steel (Uns g41400)Documento4 pagineAisi 4140 Alloy Steel (Uns g41400)Deepak ChaurasiaNessuna valutazione finora

- ESAB Lesson 1Documento35 pagineESAB Lesson 1Shahid HussainNessuna valutazione finora

- CUTTING TOOLS GUIDE: DRILLS, REAMERS, ENDS MILLSDocumento10 pagineCUTTING TOOLS GUIDE: DRILLS, REAMERS, ENDS MILLSnanang arifNessuna valutazione finora

- 1448110077lecture 02 (Ferrous Metallurgy)Documento18 pagine1448110077lecture 02 (Ferrous Metallurgy)Ariffuzzaman TipuNessuna valutazione finora

- Physical Metallurgy 21 TH Lecture: MS&E 410 D.Ast Dast@ccmr - Cornell.edu 255 4140Documento55 paginePhysical Metallurgy 21 TH Lecture: MS&E 410 D.Ast Dast@ccmr - Cornell.edu 255 4140Manikandan VijayanNessuna valutazione finora