Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

API 650 Tank Design Calculation

Caricato da

mail_younes6592Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

API 650 Tank Design Calculation

Caricato da

mail_younes6592Copyright:

Formati disponibili

Sheet 1 of 1

(English Units)

1

2

3

4

5

6

7

8

9

10

11

12

13 Ft

14

15 Ft

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30 F

31

32

33

34 F

35 F

36

37

38

39

40

41

42

43

44

45

46

47

48 %

49 lb lb

50

51

52

Rev Date Description By Chk. Rev Date Description By Chk.

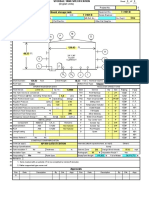

STORAGE TANK SPECIFICATION

Stress Relieve ? Yes

Plot Plan No. : P&ID No.

psig

oz/in.2 Set @

Shell Manway

Flush Cleanout MW

CONSTRUCTION/FABRICATION

Sump

Internals (attach separate sheet, as req'd):

Design Wind Velocity

Design Specifications:

No

Paint Spec. Fireproofing ? Yes

F. F.

85 Radiograph Inspection Req'd ? Yes Hot

API 650 LATEST EDITION

in.

1

OPERATING/DESIGN DATA

oz/in.2

NOZZLES/CONNECTIONS

0.7900 Sp. Gr. : Size Rating Qty

4"

8"

3/4"

3/4"

4"

2"

F. F.

F. F.

R. F.

API

48"x48"

1"

10"

150#

8"

30"

Shell & Bottom

Roof L. J.

R. F.

R. F.

F. F.

L. J.

API

L. J.

R. F.

K

Operating Design

P

M

H

Emergency Vacuum Design ?

METALLURGY

Remarks

Service :

Location :

Model :

Unit :

F

G

Barrels Feet 11,191

Sloped

PID115-EPF-01-112A1

32.00

Bottom Floor Type:

Manufacturer :

1952.000

Fluid Stored : CRUDE OIL

0.50

Flash Point (Closed Cup) :

150#

Mark

A

0

Remarks

Project No.

Service

Cone

50.00

Nominal Volume :

For Inquiry

1. Items marked with an asterisk (*) to be completed by Vendor/Fabricator.

2. Fixed cone roof with internal floating roof.

Appr.

Mixer Manway

Vapor Pressure @ Max. Operating Temperature psia

Two

CA, in.

----

Minimum Fluid Temperature

(Hydro)test Pressure expressed in Psig

0.0.3

Fill Nozzle

Sample Tap

Stilling Vent

Temperature Indicator

Outlet Nozzle

Positive Pressure

Yes

Material

200

-25

Component

150#

150#

Maximum Fluid Temperature

Roof Nozzle

N1

N2

Water Draw Nozzle

Top Center Vent

0.1250

0.1250

for:

57370 Normalized

Normalized

API Lining/Coating 1 Spare

D

Others:

mph 100 Thickness :

150#

150#

Face

Feet

5.5

Sample Tap

I

J

L

1

1

1

2

2

1

1

1

1

1

Design Engineer :

T-400 & T-405 Equipment No. :

No. Req'd :

Other Ref. Dwg No. :

CRUDE OIL Storage

Kirwin

1

1

Mfr Ref. No. :

24"

24"

6"

Roof Manway

E

This Tank Service is considered: Cyclic

Roof Type :

Shell Diameter : 50.00 Shell Height : 32.00

Approvals

125#

125#

125#

150#

150#

150#

150#

150#

Negative Pressure

150#

150#

API

API

516 Grade 55

0.00

1.00 2.00

Appr.

Tank Insulation ?

Insulation Type:

Code (as appl.):

EmptyTank Weight Full of Water

Seismic Zone 3

R

e

v

.

N

o

.

48" X 48"

FLUSH

CLEANOUT

F

A

M

P

G

K

D

E

L

E

H

N

2

N

1

J I

Art Montemayor API 650 Storage Tank March 12, 2002

Rev: 0

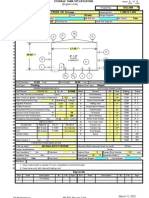

API 650 Design Calculations

50.00

32.00

0.174 in. Wall Thickness

t

d

= 0.224

1

23,200

0.85%

24,900

0.0625

For First Course (Bottom) 516-60 Plate 0.236

0.189

0.230

50.00

32.00

1

Sd = allowable Stress for Design condition 21,300

E = joint efficiency 0.85%

S

t

= allowable stress516-60 Hydro Test 24,000

CA = Corrosion Allowance 0.0625

For Second Course 516-60 Plate 0.5000

t

d

= 2.6(D)(H -1)(G)/S

d

= 0.165

t

d

=t

d

/ t

t

= 2.6(D)(H-1)/(S

t

)

t

d

= Miniumum shell thickness, in inches 0.209

D = Normal tank diameter , in feet 50.00

H = depth of tank , in feet 28

G = design Specific gravity of liquid 1

Sd = allowable Stress for Design condition 21,300

E = joint efficiency 0.85%

S

t

= allowable stress 516-60 Hydro Test 24,000

CA = Corrosion Allowance 0.0625

For Third Course 516-60 Plate 0.3750

H = depth of tank , in feet =

G = design Specific gravity of liquid =

CA = Corrosion Allowance

t

d

= 2.6(D)(H -1)(G)/S

d

=

t

d

=t

d

/ t

t

= 2.6(D)(H-1)/(S

t

) =

t

d

= Miniumum shell thickness, in inches =

E = joint efficiency

t

d

= 2.6(D)(H -1)(G)/S

d

=

Miniumum shell thickness, in inches, t

d

= t

d

/ t

t

= 2.6(D)(H-1)/(S

t

)

in. (Includes Corrosion Allowance)

S

t

= allowable stress 516-60 Hydro Test

D = Normal tank diameter , in feet =

D = Normal tank diameter , in feet

H = depth of tank , in feet

G = design Specific gravity of liquid

Sd = allowable Stress for Design condition

Shell Design : FROM ( BOTTOM COURSE) PLATE TO (TOP COURSE) PLATE

Page 2 of 8

FileName: 230781857.xls.ms_office

WorkSheet: Steel Design

Art Montemayor API 650 Storage Tank March 12, 2002

Rev: 0

API 650 Design Calculations

Shell Design :

0.196

0.2365 inches

D = Normal tank diameter , in feet 94.5

H = depth of tank , in feet 18

G = design Specific gravity of liquid 1

Sd = allowable Stress for Design condition 21,300

E = joint efficiency 0.85%

S

t

= allowable stress 516-60 Hydro Test 24,000

CA = Corrosion Allowance 0.0625

For Fourth Course 516-60 Plate 0.2500

t

d

= 2.6(D)(H -1)(G)/S

d

= 0.081

t

d

=t

d

/ t

t

= 2.6(D)(H-1)/(S

t

)

t

d

= Miniumum shell thickness, in inches 0.1342

D = Normal tank diameter , in feet 94.5

H = depth of tank , in feet 8

G = design Specific gravity of liquid 1

Sd = allowable Stress for Design condition 21,300

E = joint efficiency 0.85%

S

t

= allowable stress 516-60 Hydro Test 24,000

CA = Corrosion Allowance 0.0625

For Fifth Course 516-60 Plate 0.2500

Annular Bottom Plate Thickness 0.3750

D = Diameter in Feet 50.00

H = Height in Feet 32.00

V = Volume in Cubic Feet

p*D*H = 5,027 Ft

2

of Shell surface area

p*D

2

/4 = 1,963 Ft

2

of Roof Area (estimated)

p*D

2

/4 = 1,963 Ft

2

of Bottom Floor area

Tank Roof surface =

Tank Floor surface =

t

d

= Miniumum shell thickness =

t

d

= 2.6(D)(H -1)(G)/S

d

=

t

d

=t

d

/ t

t

= 2.6(D)(H-1)/(S

t

) =

Tank Shell surface =

Page 3 of 8

FileName: 230781857.xls.ms_office

WorkSheet: Steel Design

Art Montemayor API 650 Storage Tank March 12, 2002

Rev: 0

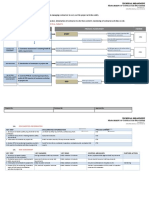

Seismic Zone; 3

Zone Coefficient Z = 0.3

Importance Factor I = 1.0

Diameter of Tank D = 94.5

Height of Liquid Content (Design) H = 44.5

Shell Height Hs = 48

Design Specific Gravity G = 0.79

Thickness of Bottom PL Under Shell t

b

= 0.3750

Yeild Strength of Bottom PL F

by

= 36,000 PSI

Weight of Shell Ws = 221 Kips

Weight of Roof + Live Load = 107.4 + 210.4 Wy = 317.8 Kips

Weight of Product PI()/4(94.5)

2

(44.5)(.79)(62.4) Wt = 15,386 Kips

Xs = 19.685 Ft

C

1

= 0.60

D/H = 2.12

W

1

/ W

t

= 0.535 W

1

= 8,231

W

2

/ W

t

= 0.45 W

2

= 6,924

X

1

/H = 0.375 X

1

= 16.7

X

2

/H = 0.59 X

2

= 26.3

Per Fig. E-4

K = 0.6

Lateral Force Coefficients: E-3.3

T =K (D

0.5

) =.6 *(94.5

0.5

) = 5.83 Seconds

If Greater Than 4.5 seconds 3.375 (s/T

2

) = 3.375*1.5/5.83

2

= 0.149 Seconds

DATA GIVEN:

Per Fig. E-3

CALCULATIONS:

Seismic Coefficients:

FOUNDATION DESIGN:

Per API 650 (Appendix E)

Per Fig. E-2

Tank is unanchored, use equations pertaining to unanchored tanks,

for seismic loading.

Page 4 of 8

FileName: 230781857.xls.ms_office

WorkSheet: Foundation Design - 1

Art Montemayor API 650 Storage Tank March 12, 2002

Rev: 0

Seismic Loads:

M = (Z)(I) { (C

1

)(Ws)(Xs)+(C

1

)(Wr)(Ht)+(C

1

)(W)(X)+(C

2

)(W

2

)(X

2

)}

(0.3)*(1.0)[ 0.6(221)(19.685)+ 0.6(317.8)(48.0)+ 0.6(8232)(16.7)+ 0.149(6924)(26.3)]

0.3 2610 9155 82485 27133 36415 Ft-Kips

V = (Z)(I) {(C1)(Ws)+(C1)(Wr)(Ht)+(C1)(W)(X)+(C2)(W2)(X2)}

(0.3)*(1.0)[ 0.6(221)+ 0.6(317.8)+ 0.6(8232)+ 0.149(6924)]

0.3 132.6 190.68 4939.2 1031.676 1888 kips

Reistance to Overturning:( E.4.1) API 650

W

L

= 7.9t

b

F

by

G H

(G18)*(G16)*(G14)/(G13)

2

)

3,333 # / ft

1265580 1125

Constant = 7.9

3,333 # / ft Not to exceed 1.25*GHD 4153 # / ft

USE 4153 # / ft

Shell Compression: Per E-5

M = 36415 ft-kips

Wt + W

L

= 583.8 / (PI()*94.5) + 4.153 6 Kips

M / D

2

(Wt + W

L

)

(G76)/(G13)

2

(6.12)

36415 54653 0.666 > 0.785

b = 1.815+1.273*36415/94.5^2 b = 7.0

Max. Longitudinal Compressive Force 7.0

UnAnchored Longitudinal Compressive Stress

7000 / 6 1167

Allowable Longitudinal Compressive Stress

GHD

2

/t

2

1.255 * 10

6

= Fa=10

6

(t) / D = 5.29 Kips

Anchorage Not Required

FOUNDATION DESIGN:

Page 5 of 8

FileName: 230781857.xls.ms_office

WorkSheet: Foundation Design - 1

Art Montemayor API 650 Storage Tank March 12, 2002

Rev: 0

Max. Overturning Moment Due To Seismic Loads. 36,415 Kips

Compression or Tension Due To Moment: 5.19 kpf

Seismic Base Shear: 0.27 kips

RINGWALL DESIGN:

Use Following Weight Values for Materials

Wt. of Steel 490lb/ft

3

Wt. Of Compacted Soil 110 lb/ft

3

Wt. Of Concrete Wall 150 lb/ft

3

Wt. Of Product in Tank 50 lb/ft

3

Horizontal Pressure on Ring Wall:

F=Kah(g*p*H+1/2 soh)+270

0.3*6.0[(50*44.5+0.5*110*6.0)]+270 4,869 kips

Hoop Tension:

1/2FD= 1/2(4869)(94.5) 230 kips

As= 231/24.0 10 in.

USE - 6 # 9 Bars Ea. Face

USE - # 4 Bars at 12" on Center

Minimum RingWall Thickness:

T = 2W / g *p*h - 2h ( gc - gso) W = 1100

(2)(1100)/50(44.5)-2(6.0)(150-110) 1.26

FOUNDATION DESIGN:

Use 16" Thick Concrete Wall

12"

48"

12"

Top of Ground Elevation

16"

Page 6 of 8

FileName: 230781857.xls.ms_office

WorkSheet: Foundation Design - 2

Art Montemayor API 650 Storage Tank March 12, 2002

Rev: 0

Concrete Tensile Stress:

f

ct

= c(Es)(As)+T / Ac + n (As)

.0003(29*10

6

)(10)+231000/(16*72)+(9*10)

318000 1242 256 psi

.15(3000) 450 psi

OK

Soil Bearing:

Try 3'- 6" Footing

Weight. of Wall = 1.33*5.0*.150 1.0 kips

Weight of Footing = 3.5*1.0*.150 0.525 kips

Weight of Fill = 2.17*4.0*.110 0.95 kips

2.48 kips

Case 1

Load from Shell + Roof + Live Load = 1.1 kips

Weight of Wall +Footing + Fill = 2.48 kips

Bearing Pressure = 3.58/3.50 1.0 kips

Case 2

Dead + Live Load + Earthquake Load =

P = 3.58 + 5.19 = 8.77 kips

H = 0.270 kips

Moment at Base of Footing = .270(6.0) 1.62 kips

Bearing Pressure Under Footing =

8.77/3.5*1 2.51 kips

2.51+.79 3.30 kips

Allowable Pressure = 3.0*1.33 3.99

OK

USE -4 # 9 Bars in Footing

USE - # 4 Bars at 12" Horizontal

Page 7 of 8

FileName: 230781857.xls.ms_office

WorkSheet: Foundation Design - 2

Art Montemayor API 650 Storage Tank March 12, 2002

Rev: 0

NOTES:

DETAILED FOUNDATION DESIGN:

4. Maximum Deiation to be less than 1/4" overall:

3. Top of concrete to be smooth and level with 1/8" +/- in any 30 feet of circumferential length:

1. Oiled sand to be mixture of sand and liquid asphalt (mc70):

2. Use 10 gallons of asphalt per cubic yard of sand:

3' - 6"

(4) # 9 Bars Eq. Spaced

Center Line of Tank

47" - 3"

Slope 1" per ft.

10" Pad of Sand

Well-Compacted Gravel

95% Compacted

50 / 100 % Passing # 4 Sieve

95 % Compacted Subgrade or fill Material

10"

6

#

9

B

a

r

s

E

a

c

h

F

a

c

e

E

q

.

4

'

-

0

"

12"

1

2

"

1'-4" Wall

# 4 Bars 12" O/C Each Face

Page 8 of 8

FileName: 230781857.xls.ms_office

WorkSheet: Foundation Design - 3

Potrebbero piacerti anche

- API 650 Tank Design 1Documento5 pagineAPI 650 Tank Design 1Fabian Nuñez Diaz100% (1)

- Process Intensification for Sustainable Energy ConversionDa EverandProcess Intensification for Sustainable Energy ConversionNessuna valutazione finora

- API 650 Tank Design 1foot MethodDocumento4 pagineAPI 650 Tank Design 1foot Methodjakjak67% (3)

- API 650 Tank Design CalculationDocumento8 pagineAPI 650 Tank Design CalculationNorazlan Shah Mahadi100% (1)

- Industrial Chemistry of Oxides for Emerging ApplicationsDa EverandIndustrial Chemistry of Oxides for Emerging ApplicationsNessuna valutazione finora

- API 650 Tank Design CalculationsDocumento8 pagineAPI 650 Tank Design CalculationsVinoth Rajendra50% (4)

- API 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)Documento25 pagineAPI 650 Storage Tank Load Computations With Ring Wall Foundation Design (8.7-m Diameter X 9.0-m Height)AVBP100% (3)

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityDa EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNessuna valutazione finora

- API 650 Tank Design 5Documento44 pagineAPI 650 Tank Design 5Inamullah Khan93% (14)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsDa EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNessuna valutazione finora

- API 650 Tank DesignDocumento29 pagineAPI 650 Tank DesignBerk Koç100% (11)

- Southern Marine Engineering Desk Reference: Second Edition Volume IDa EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INessuna valutazione finora

- API 650 Tank Design 1Documento5 pagineAPI 650 Tank Design 1robertantoreni100% (9)

- Steel Storage Tanks Excel Sheet (API 650-2009) Free-09122209467Documento42 pagineSteel Storage Tanks Excel Sheet (API 650-2009) Free-09122209467Hamid Mansouri100% (5)

- TD3 DIESEL API 650 Calculation ReportDocumento72 pagineTD3 DIESEL API 650 Calculation ReportDaniel Gómez100% (3)

- Storage Tank CALC Api 650Documento10 pagineStorage Tank CALC Api 650kuselanml100% (3)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDa EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNessuna valutazione finora

- Calculation API 650Documento78 pagineCalculation API 650jamil93% (14)

- Pressure Vessel and Stacks Field Repair ManualDa EverandPressure Vessel and Stacks Field Repair ManualValutazione: 4 su 5 stelle4/5 (4)

- API 620 Tank CalculationsDocumento11 pagineAPI 620 Tank CalculationsPrashant Malve64% (11)

- API 650 Tank CalculationDocumento30 pagineAPI 650 Tank Calculationsachin8389100% (2)

- Tank Calc SheetDocumento3 pagineTank Calc SheetHarrys Manalu100% (4)

- B ABJ 5000 2 API 650 Calculation ReportDocumento46 pagineB ABJ 5000 2 API 650 Calculation ReportSalamaNessuna valutazione finora

- Api 620 - 2002Documento12 pagineApi 620 - 2002ductaiutc100% (1)

- API 650 Design TanksDocumento34 pagineAPI 650 Design TanksSyedZainAli100% (13)

- Calculation Sheet For Tank - API 620 12th EdDocumento48 pagineCalculation Sheet For Tank - API 620 12th EdHamid Mansouri71% (17)

- API-650 Design Procedure ExampleDocumento21 pagineAPI-650 Design Procedure Examplegdwvcd92% (13)

- API 650 Tank Design CalculationDocumento8 pagineAPI 650 Tank Design Calculationbhavanamadhuri itapu100% (1)

- API 650 Tank Design CalculationsDocumento8 pagineAPI 650 Tank Design CalculationsMohammed EljammalNessuna valutazione finora

- API 650 Tank Design CalculationDocumento8 pagineAPI 650 Tank Design Calculationlecongdinh100% (1)

- TangkiDocumento8 pagineTangkiCarey Rich67% (3)

- API 650 Tank Design CalculationsDocumento8 pagineAPI 650 Tank Design Calculationsツ ツNessuna valutazione finora

- API 650 Tank Design CalculationDocumento8 pagineAPI 650 Tank Design CalculationHoracio RodriguezNessuna valutazione finora

- API 650 Tank Design CalculationDocumento9 pagineAPI 650 Tank Design CalculationSunday PaulNessuna valutazione finora

- API 650 Tank Design 1Documento5 pagineAPI 650 Tank Design 1Jose Ortiz100% (1)

- CalDocumento19 pagineCalpandiangv100% (1)

- FinalDocumento12 pagineFinalchompink6900Nessuna valutazione finora

- API 650 Tank Design 1Documento5 pagineAPI 650 Tank Design 1Nguyễn Thành Trung100% (1)

- Hfo Service Tank - ht003 Data Sheet r1 PDFDocumento4 pagineHfo Service Tank - ht003 Data Sheet r1 PDFsocomenin2013Nessuna valutazione finora

- Storage Tanks CalculationsDocumento21 pagineStorage Tanks Calculationsjimallen21288% (26)

- API 650 Tank Design 1 1Documento5 pagineAPI 650 Tank Design 1 1samy7354100% (1)

- Design Calculation TankDocumento28 pagineDesign Calculation Tankibiceng100% (4)

- Foot Design (Amine Absorber) Rev.0Documento9 pagineFoot Design (Amine Absorber) Rev.0taz_taz3Nessuna valutazione finora

- API 650 Design Calculations: D D D D T TDocumento2 pagineAPI 650 Design Calculations: D D D D T TChristian ReyesNessuna valutazione finora

- Total Middle East New Bitumen Terminal in TlbuDocumento25 pagineTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- Maximum PressureDocumento83 pagineMaximum Pressureanhhung80Nessuna valutazione finora

- Ash Water Recovery Sump & Settling Tank-Design Report: Doc. No.: REL-BGCPP-VES-144-R-00813 & - R-00820Documento18 pagineAsh Water Recovery Sump & Settling Tank-Design Report: Doc. No.: REL-BGCPP-VES-144-R-00813 & - R-00820Akhilesh KajarekarNessuna valutazione finora

- Tank Calc - Api650Documento90 pagineTank Calc - Api650kamleshyadavmoney100% (3)

- Design Tanks Menurut API 650Documento80 pagineDesign Tanks Menurut API 650irbar.darmansyah.alwiNessuna valutazione finora

- Thickness Cal. Fo DM Water Storage Tank-API 650Documento15 pagineThickness Cal. Fo DM Water Storage Tank-API 650Jose Rodriguez50% (2)

- Grade Slab ACI-150thkDocumento7 pagineGrade Slab ACI-150thkMUTHUKKUMARAM100% (1)

- E4.5 Flange Cover CalcDocumento10 pagineE4.5 Flange Cover CalcTanCM100% (1)

- Shear Wall DesignDocumento1 paginaShear Wall DesignCarlos Valverde Portilla100% (1)

- Charges InadapteesDocumento1 paginaCharges Inadapteesmail_younes6592Nessuna valutazione finora

- CPR Saves LivesDocumento1 paginaCPR Saves Livesmail_younes6592Nessuna valutazione finora

- Commissioning Area Work Permit: (For Construction Works)Documento2 pagineCommissioning Area Work Permit: (For Construction Works)mail_younes6592100% (2)

- Steel GradesDocumento8 pagineSteel GradesSanket Arun MoreNessuna valutazione finora

- Steel EquivalentDocumento2 pagineSteel Equivalentmail_younes6592Nessuna valutazione finora

- Commissioning Area Work Permit: (For Construction Works)Documento2 pagineCommissioning Area Work Permit: (For Construction Works)mail_younes6592100% (2)

- Commissioning Area Work Permit: (For Construction Works)Documento2 pagineCommissioning Area Work Permit: (For Construction Works)mail_younes6592100% (2)

- Ipe DimensionsDocumento3 pagineIpe Dimensionsmail_younes6592Nessuna valutazione finora

- Carbon Arc Cutting PDFDocumento44 pagineCarbon Arc Cutting PDFMark InnesNessuna valutazione finora

- F MAC 11 - Planning Annuel Des AuditsDocumento3 pagineF MAC 11 - Planning Annuel Des Auditsmail_younes6592Nessuna valutazione finora

- GougingDocumento4 pagineGougingmail_younes6592Nessuna valutazione finora

- Weldingguide ENGDocumento518 pagineWeldingguide ENGBoris Kozjan0% (1)

- Carbon Arc Cutting PDFDocumento44 pagineCarbon Arc Cutting PDFMark InnesNessuna valutazione finora

- Inspection and Test Plan ITP For Monorail Hoist IDocumento3 pagineInspection and Test Plan ITP For Monorail Hoist Imail_younes6592Nessuna valutazione finora

- Welding VocabularyDocumento35 pagineWelding Vocabularymail_younes6592Nessuna valutazione finora

- Normes AciersDocumento2 pagineNormes Aciersmail_younes6592Nessuna valutazione finora

- 02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical ApplicationsDocumento12 pagine02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical Applicationsivanmatijevic100% (1)

- Sample of TS BOLTDocumento12 pagineSample of TS BOLTmail_younes6592Nessuna valutazione finora

- API 650 Tank Design CalculationDocumento8 pagineAPI 650 Tank Design Calculationmail_younes659283% (29)

- ASME - How To Get Certified by ASMEDocumento2 pagineASME - How To Get Certified by ASMEmail_younes6592Nessuna valutazione finora

- Prepared by Seo Seung-Ho at The 17th of October 2005 (Dong-Il Industrial and Const' Co.)Documento17 paginePrepared by Seo Seung-Ho at The 17th of October 2005 (Dong-Il Industrial and Const' Co.)mail_younes6592Nessuna valutazione finora

- Iso GD&TDocumento39 pagineIso GD&TSanjay Kumar SinghNessuna valutazione finora

- API 650 Storage Tank Design CalculationDocumento12 pagineAPI 650 Storage Tank Design Calculationmail_younes6592Nessuna valutazione finora

- Monorail HoistDocumento3 pagineMonorail Hoistmail_younes6592Nessuna valutazione finora

- Welding VocabularyDocumento35 pagineWelding Vocabularymail_younes6592Nessuna valutazione finora

- PU410-K0000 JL56-ITP-M017IFC R0 2 Inspection and Test Plan ITP For Buckstay InstallaDocumento3 paginePU410-K0000 JL56-ITP-M017IFC R0 2 Inspection and Test Plan ITP For Buckstay Installamail_younes6592Nessuna valutazione finora

- Tank Design (API 650)Documento21 pagineTank Design (API 650)deddod96% (25)

- Wps Follow Chart PDFDocumento2 pagineWps Follow Chart PDFmail_younes6592100% (1)

- Post Weld Heat Treatment Procedure: Doc Ref: Isb/PwhtDocumento13 paginePost Weld Heat Treatment Procedure: Doc Ref: Isb/PwhtMahtemeselasie Tesfamariam Hailu100% (4)

- Format HIRADocumento1 paginaFormat HIRAAndi Tri Octavian75% (4)

- Laboratory 3 EER Modelling and Transformation: Step ER-Model Relational ModelDocumento12 pagineLaboratory 3 EER Modelling and Transformation: Step ER-Model Relational ModelHamza QasimNessuna valutazione finora

- Management of Contractors ProcedureDocumento2 pagineManagement of Contractors ProcedurednmuleNessuna valutazione finora

- LCPC Assessment Form 001 ADocumento1 paginaLCPC Assessment Form 001 ABarangay MukasNessuna valutazione finora

- Summative 3-4Documento5 pagineSummative 3-4Wilmar EspinosaNessuna valutazione finora

- Project Based Lab Report On MEASURING TEDocumento23 pagineProject Based Lab Report On MEASURING TERaja VenkateshNessuna valutazione finora

- Mmbth10 (SMD 3em Sot-23) Transistor NPN Vhf-UhfDocumento4 pagineMmbth10 (SMD 3em Sot-23) Transistor NPN Vhf-UhfJesus Hung RodriguezNessuna valutazione finora

- Example 4 (Minimization Problem) Unique and Optimum Solution Refer - OR by J K Sharma Page 123 Ex 4.9Documento7 pagineExample 4 (Minimization Problem) Unique and Optimum Solution Refer - OR by J K Sharma Page 123 Ex 4.9Aman PaniyaNessuna valutazione finora

- Central Flying School Volume - 12 - HelicoptersDocumento163 pagineCentral Flying School Volume - 12 - HelicoptersuserNessuna valutazione finora

- Combining Inductive and Analytical LearningDocumento6 pagineCombining Inductive and Analytical LearningDr B AnjanadeviNessuna valutazione finora

- Kyplot Research PDFDocumento10 pagineKyplot Research PDFTakkas FernandoNessuna valutazione finora

- Chapter 4Documento35 pagineChapter 4hailomNessuna valutazione finora

- Distillation - Session 4Documento8 pagineDistillation - Session 4atif irshadNessuna valutazione finora

- Pal007a DatasheetDocumento1 paginaPal007a DatasheetCarlos Iran Benítez MedinaNessuna valutazione finora

- 2.5 Solar Energy Advantages & DisadvantagesDocumento6 pagine2.5 Solar Energy Advantages & DisadvantagesKamran HameedNessuna valutazione finora

- ASVAB Word Knowledge Practice Test 5Documento5 pagineASVAB Word Knowledge Practice Test 5ASVABTestBankNessuna valutazione finora

- Motherboard Flow Chart TroubleshootingDocumento1 paginaMotherboard Flow Chart TroubleshootingKubeta AkihiroNessuna valutazione finora

- Flexsim 5.0 ManualDocumento684 pagineFlexsim 5.0 ManualMaryC Marchosky100% (2)

- A Study On Consumer Buying Behavior Towards Online and Offline ShoppingDocumento94 pagineA Study On Consumer Buying Behavior Towards Online and Offline ShoppingARAVINDNessuna valutazione finora

- 02-Digital Representation of InformationDocumento39 pagine02-Digital Representation of InformationBarnabas FantahunNessuna valutazione finora

- Basic Cal. ReviewerDocumento4 pagineBasic Cal. Reviewerkristine0% (1)

- Business Process Modelling: Operations and Information Management DR Maria Kutar & DR Yun Chen August 2021Documento21 pagineBusiness Process Modelling: Operations and Information Management DR Maria Kutar & DR Yun Chen August 2021Hamdan MonNessuna valutazione finora

- CTX-10 User's Manual FINAL Less Block Diagram Rev H 1-18-2021Documento48 pagineCTX-10 User's Manual FINAL Less Block Diagram Rev H 1-18-2021Bob MartinNessuna valutazione finora

- Messko Mtrab - Maintenance-Free Dehydrating Breather of The Premium Series Twice As Reliable and Simply EffectiveDocumento6 pagineMessko Mtrab - Maintenance-Free Dehydrating Breather of The Premium Series Twice As Reliable and Simply Effectivengvc87Nessuna valutazione finora

- Microsoft Lumia 950 XL - Unlocked (Black)Documento8 pagineMicrosoft Lumia 950 XL - Unlocked (Black)Dawood AhmedNessuna valutazione finora

- MOT - Week 14 - Assignment - Group 7Documento10 pagineMOT - Week 14 - Assignment - Group 7vian100% (2)

- LS-9101 Ancillary Card Cage For Locomotive/Rail ApplicationsDocumento2 pagineLS-9101 Ancillary Card Cage For Locomotive/Rail ApplicationsMijo SvirčevićNessuna valutazione finora

- Analyze A Phenomenon Based On Theories in InformaticsDocumento57 pagineAnalyze A Phenomenon Based On Theories in InformaticsHelen Ansah GyamfuahNessuna valutazione finora

- Tugas 1 (GDD)Documento2 pagineTugas 1 (GDD)febri hansyahNessuna valutazione finora

- A Survey On The Use of ICT in Teaching Learning Practices in College Level MathematicsDocumento5 pagineA Survey On The Use of ICT in Teaching Learning Practices in College Level MathematicsAndrea Espino Kipad ReidNessuna valutazione finora

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Da EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Valutazione: 4 su 5 stelle4/5 (3)

- Artificial Intelligence: From Medieval Robots to Neural NetworksDa EverandArtificial Intelligence: From Medieval Robots to Neural NetworksValutazione: 4 su 5 stelle4/5 (3)

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsDa EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsValutazione: 5 su 5 stelle5/5 (3)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Da EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Valutazione: 4 su 5 stelle4/5 (5)

- A Welder’s Handbook to Robotic ProgrammingDa EverandA Welder’s Handbook to Robotic ProgrammingValutazione: 5 su 5 stelle5/5 (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDa EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNessuna valutazione finora

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDa EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureValutazione: 4.5 su 5 stelle4.5/5 (2)

- Romantic Automata: Exhibitions, Figures, OrganismsDa EverandRomantic Automata: Exhibitions, Figures, OrganismsNessuna valutazione finora

- Dark Aeon: Transhumanism and the War Against HumanityDa EverandDark Aeon: Transhumanism and the War Against HumanityValutazione: 5 su 5 stelle5/5 (1)

- The Heart and the Chip: Our Bright Future with RobotsDa EverandThe Heart and the Chip: Our Bright Future with RobotsNessuna valutazione finora

- Evil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityDa EverandEvil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityValutazione: 4.5 su 5 stelle4.5/5 (3)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceDa EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceValutazione: 5 su 5 stelle5/5 (9)

- Arduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Da EverandArduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Valutazione: 3 su 5 stelle3/5 (1)

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityDa EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityValutazione: 3.5 su 5 stelle3.5/5 (22)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkDa EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkValutazione: 5 su 5 stelle5/5 (1)

- How to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionDa EverandHow to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionValutazione: 3.5 su 5 stelle3.5/5 (129)

- Artificial You: AI and the Future of Your MindDa EverandArtificial You: AI and the Future of Your MindValutazione: 4 su 5 stelle4/5 (3)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsDa EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNessuna valutazione finora

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessDa EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNessuna valutazione finora

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationDa EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationValutazione: 4.5 su 5 stelle4.5/5 (2)

- Create Profitable Side Hustles with Artificial IntelligenceDa EverandCreate Profitable Side Hustles with Artificial IntelligenceNessuna valutazione finora

- ChatGPT: The Future of Intelligent ConversationDa EverandChatGPT: The Future of Intelligent ConversationValutazione: 3.5 su 5 stelle3.5/5 (8)

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesDa EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesValutazione: 2.5 su 5 stelle2.5/5 (3)

- Collection of Raspberry Pi ProjectsDa EverandCollection of Raspberry Pi ProjectsValutazione: 5 su 5 stelle5/5 (1)

- Robotics: Designing the Mechanisms for Automated MachineryDa EverandRobotics: Designing the Mechanisms for Automated MachineryValutazione: 4.5 su 5 stelle4.5/5 (8)