Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

UTP Student Industrial Project Report

Caricato da

rooparn28391Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

UTP Student Industrial Project Report

Caricato da

rooparn28391Copyright:

Formati disponibili

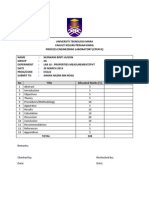

STUDENT INDUSTRIAL PROJECT REPORT

JANUARY 2014 APRIL 2014

MODELING AND SIMULATION OF STEADY STATE FLOW

ASSURANCE STUDY ON OFFSHORE PIPELINES USING

PIPESIM SOFTWARE

at

BERACHAH GROUP SDN. BHD.

by

MOHANA ROOPARN A/L KALAICHELVAN

15338

CHEMICAL ENGINEERING PROGRAMME

II

VERIFICATION STATEMENT

I hereby verify that this report was written by Mohana Rooparn A/L Kalaichelvan,

15338 and all information regarding this company and the projects involved are NOT

confidential.

Host Company Supervisors

Signature & Stamp

Name:

Designation:

Host Company:

Date:

III

ACKNOWLEDGEMENT

First and foremost, the author would like to express his utmost gratitude

towards his parents, for it was them who had given the author the guidance and moral

support required throughout the industrial training totalling up to 7 months at Berachah

Group Sdn. Bhd. The author would also like to take this opportunity to extend his

appreciation towards all other individuals, both family and friend that have cheered

and supported the author during this internship period.

Many thanks the author bids to his host company Berachah Group Sdn. Bhd.

for providing the opportunity to undertake the industrial training with them and also

to the supervisors, Pipeline Engineer Mr. Krishna Kumar and Flow Assurance

Engineers Ms. Prasana Seharan, for their vital encouragement, support and guidance

in the authors learning process throughout training period here.

The author also wishes to convey his deepest gratitude towards all members of

staff and engineers of Berachah Group Sdn. Bhd., for all of their supports and training

given to the author during the industrial training. Special thanks to Mr. Samuel John,

Senior Project Manager for his valuable inputs and guidance throughout this project.

The experiences shared with the engineers provided a much needed insight towards

the working environment.

Last but not the least, the author wishes to thank his supervisor from Universiti

Teknologi PETRONAS (UTP), Dr. Khor Cheng Seong, who was ever willing to spend

his time providing support during the entire training period to ensure the author is able

to achieve the objectives of the Student Industrial Internship Program.

IV

TABLE OF CONTENTS

VERIFICATION STATEMENT ............................................................................... II

ACKNOWLEDGEMENT ......................................................................................III

TABLE OF CONTENTS ....................................................................................... IV

LIST OF TABLES ............................................................................................... VI

LIST OF FIGURES ............................................................................................. VII

LIST OF GRAPHS ............................................................................................ VIII

CHAPTER 1: INTRODUCTION .............................................................................. 1

1.1. PURPOSE OF STUDENT INDUSTRIAL PROJECT .................................................... 2

1.2. OBJECTIVES OF STUDENT INDUSTRIAL PROJECT ................................................ 3

1.3. TRAINING APPROACH ........................................................................................ 4

1.4. HOST COMPANY ................................................................................................ 5

1.4.1. Berachah Group Sdn. Bhd........................................................................................... 5

1.4.2. Business & Expertise .................................................................................................. 6

1.4.2.1. Flow Assurance Team ....................................................................................... 6

CHAPTER 2: PROJECT INTRODUCTION ................................................................. 7

2.1. PROBLEM STATEMENT ....................................................................................... 8

2.2. OBJECTIVES ........................................................................................................ 9

2.3. SCOPE OF STUDY ................................................................................................ 9

2.4. RELEVANCY OF THE PROJECT ............................................................................10

CHAPTER 3: LITERATURE REVIEW ..................................................................... 11

3.1. MULTIPHASE FLOW ..........................................................................................12

3.2. FLOW CORRELATIONS .......................................................................................16

3.2.1. Hagedorn & Brown Correlation ................................................................................ 16

V

3.2.1.1. Elevation Pressure Drop .................................................................................. 17

3.2.1.2. Frictional Pressure Drop .................................................................................. 20

3.2.1.3. Acceleration Pressure Drop ............................................................................. 22

3.2.2. Lockhart& Martinelli Correlation .............................................................................. 23

3.2.3. Beggs & Brill Correlation .......................................................................................... 27

3.2.3.1. Flow Regime ................................................................................................... 28

3.2.3.2. Elevation Pressure Drop .................................................................................. 28

3.2.3.3. Frictional Pressure Drop .................................................................................. 30

3.2.3.4. Acceleration Pressure Drop ............................................................................. 31

3.3. HYDRATES .........................................................................................................32

3.4. CO

2

CORROSION ...............................................................................................34

3.4.1. Mechanism of CO

2

Corrosion.................................................................................... 34

3.4.2. Parameters Affecting CO

2

Corrosion ......................................................................... 35

CHAPTER 4: METHODOLOGY ............................................................................ 37

4.1. PROJECT FLOW .................................................................................................38

4.2. CASE STUDY ......................................................................................................39

4.2.1. Design and Operating Data....................................................................................... 39

4.2.2. Environmental Data ................................................................................................. 41

4.2.3. Simulation Parameters ............................................................................................. 41

4.3. TOOLS & SOFTWARE .........................................................................................43

4.4. GANTT CHART ...................................................................................................44

CHAPTER 5: RESULTS & DISCUSSION ................................................................. 45

5.1. PIPESIM MODEL ................................................................................................46

5.2. PRESSURE VARIATION AMONG FLOW CORRELATION.......................................47

5.3. PIPELINE SIZE OPTIMISATION ...........................................................................50

5.4. HYDRATE CONTROL ..........................................................................................53

5.5. CORROSION STUDY ...........................................................................................56

CHAPTER 6: CONCLUSION & RECOMMENDATION .............................................. 58

REFERENCES ................................................................................................... 61

VI

LIST OF TABLES

Table 1: Horizontal Flow Regime Limits ................................................................28

Table 2: Constants for Liquid Holdup Calculation...................................................29

Table 3: Design and operating conditions ................................................................39

Table 4: Pipeline design data ...................................................................................40

Table 5: Riser design data .......................................................................................40

Table 6: Environmental data ...................................................................................41

Table 7: Simulation parameters used .......................................................................42

VII

LIST OF FIGURES

Figure 1: Company Logo ......................................................................................... 5

Figure 2: Some of the aspects of flow assurance. ...................................................... 6

Figure 3: Gas hydrates plug removal from pipeline. ................................................. 6

Figure 4: European gas pipeline network. ................................................................. 8

Figure 5: Flow Regime Map Based on Superficial Velocities ..................................13

Figure 6: Flow Patterns for Vertical Two-Phase Flows............................................14

Figure 7: Flow Patterns for Horizontal Two-Phase Flows........................................15

Figure 8: Holdup Factor Correlation .......................................................................18

Figure 9: Correlation for Viscosity Number Correlation ..........................................18

Figure 10: Correlation for Secondary Correction Factor ..........................................19

Figure 11: Moody Diagram .....................................................................................21

Figure 12: Lockhart& Martinelli Friction Correction ...............................................24

Figure 13: Horizontal FlowPatterns of Beggs & Brill Correlation ...........................27

Figure 14: Simple molecular structure of methane hydrate ......................................32

Figure 15: Simplified schematic representation of CO2 corrosion mechanism .........35

Figure 16: Project Flowchart ...................................................................................38

Figure 17: Sarawak offshore gas fields ....................................................................39

Figure 18: Seabed elevation profile .........................................................................41

Figure 19: PIPESIM interface .................................................................................43

Figure 20: PIPESIM model .....................................................................................46

VIII

LIST OF GRAPHS

Graph 1: Horizontal flow correlation comparison ....................................................47

Graph 2: Vertical flow correlation comparison ........................................................48

Graph 3: Vertical flow correlation comparison - Riser F14 .....................................48

Graph 4: Vertical flow correlation comparison - Riser F23 .....................................49

Graph 5: Pressure drop for various pipe sizes ..........................................................50

Graph 6: Pressure drop for various pipe sizes, Outlet = 92 bara ...............................51

Graph 7: Fluid velocity for various pipe sizes, Outlet = 92 bara ..............................52

Graph 8: Phase envelope plot ..................................................................................53

Graph 9: Phase envelope plot - operation line .........................................................54

Graph 10: Phase envelope plot - 5 mm insulation ....................................................54

Graph 11: Phase envelope plot - 10 mm insulation ..................................................55

Graph 12: CO2 corrosion rate .................................................................................56

Graph 13: CO2 corrosion rate - adjusted composition .............................................57

1

CHAPTER 1: INTRODUCTION

This report is prepared to record all the relevant activities that contributed towards the

completion of the authors study on his industrial project throughout the internship

period at Berachah Group Sdn. Bhd. This chapter gives a brief description on the host

company, the purpose of the industrial project, followed by the objectives and training

approach applied.

2

1.1. PURPOSE OF STUDENT INDUSTRIAL PROJECT

The main purpose of the Student Industrial Project (SIP) is to provide exposure

to Universiti Teknologi PETRONAS (UTP) students to the real working environment

and in doing so they would be able to relate theoretical knowledge learned in the

university with appropriate application in the industry. The SIP program will also aid

the students in the development of their skills set such as in safety practices, work

ethics, communication and management. UTP also aims to achieve closer relationships

with the industry through the SIP program.

The SIP is an opportunity for UTP students to build a solid understanding of

the fundamentals of business and organization performance such as economic models

of business, competitive positioning and strategy execution. In this real life

environment, students will be able to develop their ability to assess performance,

interpret trends, explore the consequences of change and make better decisions as

engineers.

3

1.2. OBJECTIVES OF STUDENT INDUSTRIAL PROJECT

There are a number of learning outcomes of which the students doing the SIP

are required to accomplish by the end of the training. These learning outcomes would

become the main objectives of the SIP, which are:

a) Integrate theoretical knowledge in the industry.

The SIP provides students with the opportunity to implement the theoretical

knowledge learnt in the university into real-world situations. Through this

hands-on experience working with the industrial practitioners, the students will

have better understanding of the knowledge learnt.

b) Analyse complex engineering/technical projects or problems.

During SIP, students will be assigned projects and tasks by their host company

supervisors. This will expose them to the real engineering working

environment where they would work with other engineers or independently to

investigate and study the engineering/technical part of the projects and tasks

assigned.

c) Evaluate and propose solutions for given complex project or problems.

Upon investigating the project or task assigned to them and identifying the

problems involved, the student would then have to propose a solution for it.

Working with other engineers of various engineering background, the students

will gain valuable knowledge and experience on how to overcome such

engineering problems.

d) Communicate effectively on complex engineering/technical activities.

During the SIP period in the host company, students will able to demonstrate

their practical, communication and technical skills gained throughout the

internship. The students will be able to present their findings to fellow

engineers and professionals and with excellent performance and testimonies

will even be able to secure placement at the host company and launch their

career there upon graduation.

4

1.3. TRAINING APPROACH

The training approach used for all tasks, assignments and projects undertaken

at the host company applied the following topics:

Hands-on training

Real project-based assignments

Research-based activities

Team-work activities

Leadership and management skills

Safety awareness

For SIP, the suggested training areas applicable for the students of the

Chemical Engineering programme are, but not limited to:

Research and Development

Health, Safety and Environment

Statistical Process Control

Process Design & Unit Operation

Process & Instrumentation Control

Plant Process/Maintenance

Process Analysis

Thermal System Design

Management & Administration

Production Planning

Computer Application

5

1.4. HOST COMPANY

1.4.1. Berachah Group Sdn. Bhd.

Figure 1: Company Logo

Berachah Group Sdn. Bhd. (BGSB), incorporated in 27

th

August 2007 offers

engineering and project management services for the offshore and onshore oil and gas

pipeline industry with a team of specialists and engineers spanning various disciplines.

BGSBs main office is located in the Wisma Goldhill office tower in Jalan Raja

Chulan, which is part of the Golden Triangle business district in Kuala Lumpur.

BGSB currently has strength of 31 personnel with active plans for expansion

in progress. The companys staffs consists of professional engineers and specialists

coming from various backgrounds with extensive skills in engineering design and

project management with up to 25 years or so of experience in the offshore and onshore

oil and gas industry. Due to their vast experience and knowledge of the industry, BGSB

is able assemble its team of engineers to understand the uniqueness of each client and

the associated projects; therefore adapting and providing tailored solutions to meet the

clients needs.

BGSB has a standing reputation in the industry with a broad client base

consisting of key players of the oil and gas industry in Malaysia and even in the South-

East Asia region. Some of the clients BGSB frequently works with include:

PETRONAS Carigali Sdn. Bhd.

Petrofac (Malaysia) Limited

Sarawak Shell Bhd.

Brunei Shell Petroleum Company Sdn. Bhd.

Talisman Malaysia Limited

6

1.4.2. Business & Expertise

BGSBs expertise lies in providing a wide range of engineering and design

solutions to cater for its clients in the oil and gas industry. The main expertises of

BGSB are in offshore pipelines and risers, onshore pipelines and facilities, flow

assurance and operability, marine terminals and subsea production. The scope of

engineering, design and project management services provided include Conceptual

Design, Front End Engineering Design (FEED), Detailed Engineering and Design,

Construction and Installation Engineering and Construction Management and project

Management.

1.4.2.1. Flow Assurance Team

As mentioned previously, one of BGSBs expertise lies in the field of flow

assurance. Flow assurance is the design, strategies and principles for ensuring that

there is an uninterrupted hydrocarbon production flowing from the reservoir to the

point of sale through the pipeline. A flow assurance study for a pipeline can mostly be

performed with the aid flow simulations such as network modelling, multiphase steady

state and transient modelling, but besides that it also involves tackling other

complications of a pipeline flow such as gas hydrate deposits, wax, asphaltene and

scaling.

Figure 2: Some of the aspects of flow assurance.

Figure 3: Gas hydrates plug removal from

pipeline.

Since flow assurance is based on fluid flow and its inherent properties, the

BGSB Flow Assurance Team, is led by and comprised mainly of chemical engineers

due to their specialisation in these topics. The author was also a member of this team

and therefore this project is based upon the flow assurance studies undertaken during

the authors SIT in the previous semester.

7

CHAPTER 2: PROJECT

INTRODUCTION

This chapter provides a simple introduction of the project by expressing the problem

statement, highlighting the projects objective followed by discussing the scope of

study and finally defining the relevancy of the project.

8

2.1. PROBLEM STATEMENT

In the present age, the global demand for energy is limitless and grows

annually. Majority of this energy is generated via fossil fuel or petroleum. To maintain

supply, energy companies worldwide actively search for new oil wells, be it onshore

or offshore, or try to maximise production in an already existing ones. The raw

petroleum or natural gas is then transported to onshore refineries and processing

facilities via a network of pipelines. With the discoveries of new wells and production

increases from already existing wells, newer pipelines are designed and constructed as

part of the overall network to handle these higher production volumes.

Figure 4: European gas pipeline network.

However, the task of designing and constructing such pipelines are not to be

taken lightly. One of the factors of the utmost importance to be taken into consideration

when designing pipelines is flow assurance which are the design strategies

implemented to achieve uninterrupted flow of product in the pipeline. Thus, to achieve

this uninterrupted flow, various calculations and modelling have to be performed to

9

study all major problems that might arise in the pipeline. Some of the factors that have

to be considered include:

Pressure drops

Temperature variations

Corrosion

Hydrate formation

Slugging

Performing the required calculations and modelling is not an easy task either, mainly

due to the vast length of the pipeline and the complex numerical methods employed in

the modelling.

2.2. OBJECTIVES

Some of the main objectives identified for carrying out this project include the

following:

a) To identify the important aspects of flow assurance.

b) To model steady state fluid flow conditions with the aid of computer software

simulations using data obtained from the field.

c) To identify and analyse problem found in the end result of the simulations.

d) To suggest solutions designed to nullify the problems.

e) To propose a design for an offshore pipeline based on the findings of the steady

state flow simulations and the solutions implemented.

2.3. SCOPE OF STUDY

The scopes of studies covered by the author in this particular project are as per

following:

a) Understanding the many aspects involved in flow assurance.

10

b) Studying the different types of fluid flow such as liquid flow, gas flow and

multiphase flow and flow regimes involved in such flows.

c) Studying the theories used in the modelling of steady state flow conditions such

as flow correlations, assumptions and applicability of these correlations.

d) Understanding the application and capabilities of the steady state flow

simulation software used in this project.

e) Providing design inputs for an overall design of an offshore pipeline based on

findings.

2.4. RELEVANCY OF THE PROJECT

Designing and constructing a pipeline without properly considering these

factors will pose serious risks such as clogging due to hydrate plugs, leaking from

corroded joints and even explosions caused from excessive pressure. This will then

lead to severe downtime for maintenance and repair works and the costs incurred will

be too high.

Therefore, in this project, the author, with the aid of advanced software, will

attempt to model and simulate the flow of well fluids using specific fluid

compositional data and environmental data from the field. With the generated results,

the author will then address the flow assurance factors and propose control methods

and solutions to finalize a basic design input for the pipeline in study.

With these suggested modifications to the pipeline design, the pipeline would

have a better chance of operating flawlessly under the simulated conditions and

unnecessary damage and downtime can be avoided.

11

CHAPTER 3: LITERATURE

REVIEW

In this chapter is mainly based upon the engineering and technical aspects of fluid flow

simulations. The author discusses the themes addressed in this report such as

multiphase flows, hydrates and etc. with available literature and past researches. The

final study will be based upon the literature discussed in this chapter.

12

3.1. MULTIPHASE FLOW

Multiphase flow is commonly referred to as any fluid flow consisting of more

than one phase or component. In many cases, the two main phases are vapour and

liquid. Many other combinations are possible too, such as solid-gas, solid-liquid and

two immiscible liquids. In this context however, a 3-phase fluid flow is considered

which consists of gas, water and oil. To this date, multiple methods have been applied

for the studying and modelling of the multiphase flow regime. The true predictions of

fluid flow are only available for single-phase laminar flows and very low Reynolds

number flows in simplified geometries. When there is an increase in the Reynolds

number however, to values of real applications, the true predictions can no longer be

valid and therefore the only practical means is by applying empiricism. This proves

that multiphase flows with deformable interfaces take upon virtually an infinite

number of flow configurations which present an intractable problem. For example,

laminar flow over a basic geometric shape such as an isolated spherical particle, bubble

or droplet, yield analytical solutions to the conservation equations. This is particularly

true given that in the vast majority of cases multiphase flows are turbulent in nature.

This goes to show that the study and modelling of multiphase flow regimes put upon

a heavy emphasis on empirical methods and the predictions resulting from it can only

be as reliable as the empirical relationships which they are based upon (Brill &

Mukherjee, Multiphase Flow in Wells, Monograph Volume 17, 1999).

From the numerous observations and experiments performed over past years,

it was found necessary for the flow patterns or flow regimes observed to be defined

and categorized accordingly. Pickering, Hewitt, Watson, & Hale, 1992 provide an

introductory discussion of flow patterns and states that these can themselves be

categorized into three main types which are dispersed flow, separated flow and

intermittent flow. In dispersed flows, flow regimes are characterized as one phase is

distributed uniformly in another continuous phase as rough spherical elements (Beggs

& Brill, 1973). For example, bubble flow in which small gas bubbles are dispersed

through a continuous liquid phase and mist flow where small droplets of liquid are

carried along in a vapour stream. Separated flows consist of immiscible phases. One

of it stratified flow where the heavier liquid phase flows at the base of the pipe and the

lighter gas phase on the above. Another variant is annular flow where the liquid flows

13

around the periphery of the pipe as a thin film with a gas core flowing internally.

Finally, there is the intermittent flow made up of non-uniformly distributed phases. An

example of intermittent flow is the slug flow. This flow regime creates massive

amounts of turbulence at the front of the slug. The slug flow exerts a high sheer stress

on the walls of the pipe due to the constant impact and collapse of the slug upon the

pipe wall which in turn leads to corrosion.

Figure 5: Flow Regime Map Based on Superficial Velocities

The figure above classifies some of the main flow regimes based on the

superficial velocities of the liquid and gas phases involved. The fluid mean velocity

for a single phase flow regime can be obtained by dividing the volumetric flow rate

with the cross sectional area. However, when multiphase flow is involved, a better way

to define the velocities would be through superficial velocities using the volumetric

flow rates of the liquid phase and gas phase respectively. For a simple 2-phase flow

consisting of a single liquid phase and single gas phase, the corresponding superficial

velocities are:

:

sL

=

q

I

(n4)J

2

:

sg

=

q

g

(n4)J

2

(Palmer & King, 2008)

14

It can be seen, at very low superficial velocities, the flow is rather laminar or

stratified. As the superficial velocities of both phases increase, the flow becomes wavy

and finally at very high superficial velocities it develops into an annular flow. At lower

gas superficial velocities, the flow transitions from the wavy-stratified flow into a slug

flow and upon reaching high liquid superficial velocities compared fairly lower gas

superficial velocities the flow becomes a bubble flow with gas bubbles entrained

within a continuous liquid phase. For the opposite conditions, where the gas superficial

velocities are fairly higher compared to the liquid superficial velocities, the flow

becomes a mist flow containing liquid droplets in carried in a gas phase. Although

very useful, it is important to note that the superficial velocities do not represent the

actual velocity of which the phase is moving as it is based on the relative flow rates

and cross sectional areas of the flowing phase.

Figure 6: Flow Patterns for Vertical Two-Phase Flows

Even though the identification and classification of flow regimes into specific

flow patterns is subjective, it has become a rather useful method in the modelling of

multiphase flows. This is mainly due to the significant differences in the pressure drops

and phase hold-ups of one flow pattern compared with another and therefore the

predictions of the multiphase flow will benefit from the knowledge of the flow pattern

and an appropriate model which is unique to the flow pattern being studied. The

models which offer the best predictions for such multiphase flows rather accurately

are the phenomenological models. These models function by first indentifying the flow

pattern being studied and then applying a very specific and unique model for the flow

pattern in study. For example, considering a slug flow, the traditional Eulerian solution

of a two-phase model which specifies a stationary spatial grid over which the partial

15

differential equations are discretised, presents certain difficulties associated with the

unphysical dispersion of discontinuities, for example, the noses and tails of slugs.

These problems can be partly alleviated using complex adaptive grid techniques which

allow the spatial nodes to bunch in order to resolve discontinuities. However, perhaps

the only robust solution will come from a Langrangian phenomenological model

where individual slugs are followed throughout the system and appropriate

correlations are employed for entrainment of bubbles at the nose and shedding of liquid

from the tail (Date, 2005).

Figure 7: Flow Patterns for Horizontal Two-Phase Flows

16

3.2. FLOW CORRELATIONS

A general and simplified equation used to calculate the pressure gradient can

be written as:

Jp

JZ

= _

Jp

JZ

]

cI

+ _

Jp

JZ

]

]

+_

Jp

JZ

]

ucc

This equation takes into account three main factors that cause the pressure drop, which

are the elevation, friction factor and fluid acceleration. The pressure drop arising from

the elevation variations is mainly due to the changing density of the two-phase fluid.

This would be usually calculated using a liquid holdup value. This component also

causes the main pressure drop in vertical flows unless for conditions of high flow

velocities. The second component is the pressure drop due to frictional losses and this

is obtained through the computation of a two-phase fluid friction factor. Finally, there

is the pressure loss caused by the acceleration of the fluids. This is neglected in most

cases unless it involves high flow velocities.

Over the past years, many semi-empirical flow correlations have been

developed for the purpose of predicting the pressure gradients in two-phase flows. All

these flow correlations differ in the sense of their approach used to calculate the three

components of the total pressure gradient mentioned previously. Certain correlations

assume a no-slip condition where the velocities of both the liquid phase and gas phase

are the same for evaluating the mixture density and evaluate only a friction factor

empirically. Unfortunately, this approach is rather inaccurate. Other developed

methods calculate both liquid holdup and friction factor of the flow and even divide

the flow conditions into patterns and regimes and apply different correlations for

different flow regimes (Brill & Beggs, 1991).

3.2.1. Hagedorn & Brown Correlation

The Hagedorn & Brown flow correlation was developed using data obtained

from a 1500 ft. experimental well with pipe sizes ranging from 1 in. to 4 in., applicable

for vertical flows only. This correlation takes into account slippage between the phases

due to velocity differences but not the different flow regimes that may occur in the

pipe. However, the liquid holdup calculated using this correlation is not actually the

17

true measure of the portion of the pipe retained with liquid but is rather a correlating

parameter to satisfy the measured pressure gradient arising from friction losses and

fluid acceleration.

3.2.1.1. Elevation Pressure Drop

For calculating pressure losses due to elevation variations, a value liquid

holdup must be established. Several dimensionless parameters need to be used in order

to obtain the liquid holdup value. The parameters are:

N

L

= 1.9S8 :

sL

_

p

L

o

L

4

Liquid Velocity Number

N

g

= 1.9S8 :

sg

_

p

L

o

L

4

Gas Velocity Number

N

d

= 12u.872 J

_

p

L

o

L

Pipe Diameter Number

N

L

= u.1S726 p

L

_

1

p

L

o

L

3

4

Liquid Viscosity Number

The units used for the given equations are rather specific and commonly referred to as

oil field units, which are:

vsL = liquid superficial velocity, ft/s

vsg = gas superficial velocity, ft/s

L = liquid density, lbm/ft

3

L = interfacial tension, dynes/cm

L = liquid viscosity, cp

d = pipe internal diameter, ft

For a liquid stream made up of an oil-water mixture, the properties of the fluid can be

represented as:

o

=

q

o

q

o

+q

w

onJ

w

= 1

o

=

q

w

q

o

+ q

w

p

L

= p

o

o

+ p

w

w

o

L

= o

o

o

+o

w

w

18

p

L

= p

o

o

+p

w

w

With the dimensionless parameters calculated, the liquid holdup can now be obtained

with the aid of the following correlations, shown in the figures below.

Figure 8: Holdup Factor Correlation

Figure 9: Correlation for Viscosity Number Correlation

19

Figure 10: Correlation for Secondary Correction Factor

The steps taken to calculate the liquid holdup and the final pressure drop due

to elevation are:

1. Obtain viscosity number, CNL and secondary correction factor, from the

graphs in Figure 9 and Figure 10 respectively using dimensionless parameters

NLv, Ngv, Nd and NL calculated earlier.

2. Use obtained CNL value to calculate for holdup factor,

H

L

is from Figure 8.

3. Multiply

H

L

by to obtain liquid holdup, HL.

4. Input HL and the other relevant values in the following equation to obtain the

elevation pressure drop component:

_

Jp

JZ

]

cI

=

g

g

c

|p

L

E

L

+ p

g

(1 E

L

)]

20

3.2.1.2. Frictional Pressure Drop

The pressure drop due to friction between the fluid and the pipe wall can be

computed using the following equation:

_

Jp

JZ

]

]

=

:

m

2

p

]

2 g

c

J

However, the expression derived by Hagedorn and Brown, which incorporates mass

flow rate is given as:

_

Jp

JZ

]

]

=

w

2

2.96S2 1u

11

p

s

J

5

Where:

w = mass flow rate, lbm/day

s = liquid holdup density, lbm/ft

3

= p

L

E

L

+ p

g

E

g

, E

g

= 1 E

L

d = internal diameter of pipe, ft

f = friction factor

The fluid Reynolds number is calculated to obtain the friction factor either from

the Moody Diagram in Figure 11, or using an equation as mentioned below.

N

Rc

=

p

n

:

m

J

p

s

Reynolds number

:

m

= :

sL

+:

sg

Mixture velocity

p

s

= p

L

H

L

p

g

H

g

Mixture viscosity

= u.uuSS_1 +_2 1u

4

e

J

+

1u

6

N

Rc

_

1

3

_ Friction factor equation

Figure 11: Moody Diagram

3.2.1.3. Acceleration Pressure Drop

The pressure gradient arising from acceleration of the fluids in the pipe is

neglected in most cases unless there are high flow velocities involved. The governing

equation of this pressure gradient is:

_

Jp

JZ

]

ucc

=

p

s

(:

m

2

)

2 g

c

JZ

Where:

(:

m

2

) = :

m

2

(p

1

, I

1

) :

m

2

(p

2

, I

2

)

And Ek is defined as:

E

k

=

JZ

Jp

_

Jp

JZ

]

ucc

=

p

s

(:

m

2

)

2 g

c

Jp

Therefore, the total pressure drop arising from elevation variations, friction

between fluid and pipe wall and fluid acceleration can be calculated from the following

equation:

Jp

JZ

=

[

dp

dz

cI

+ [

dp

dz

]

1 E

k

23

3.2.2. Lockhart& Martinelli Correlation

The Lockhart& Martinelli correlation applies for fluid flow along horizontal

pipes, therefore pressure loss due to elevation variations are disregarded. This

correlation does not follow the usual friction factor analogy but takes it into account

the two-phase flow as a single phase with a correction factor. The pressure gradient

due to acceleration is also ignored in this flow correlation.

The general pressure drop equation for horizontal flows is:

Jp

JX

= _

Jp

JX

]

]

+_

Jp

JX

]

ucc

or

Jp

JX

=

:

m

2

p

]

2 g

c

J

+

p :

m

J:

m

g

c

JX

Note the absence of the elevation pressure drop component from the equation.

However, since the Lockhart& Martinelli disregards the acceleration component, the

equation is reduced to:

Jp

JX

=

g

2

_

Jp

JX

]

g

=

L

2

_

Jp

JX

]

L

_

Jp

JX

]

g

=

g

:

sg

2

p

g

2 g

c

J

_

Jp

JX

]

L

=

L

:

sL

2

p

L

2 g

c

J

Where: Subscripts:

f = friction factor

vs = superficial velocity

= density

gc = gravitational constant (for conversion of lbm to

lbf)

g = gas

L = liquid

24

d = pipe internal diameter

The friction factors can be determined from the Moody diagram or the equation

by calculating the Reynolds number of the flow as mentioned previously.

The two-phase correction factors used are correlated with a parameter defined

as following:

X = __

Jp

JX

]

L

_

Jp

JX

]

g

_ _

0.5

This correlation is shown in the graph in Figure 12, where different curves are

used for each depending on the Reynolds number of each phase. Laminar flow is

considered for phases with Reynolds number less than 1000.

Figure 12: Lockhart& Martinelli Friction Correction

The lower case subscripts t and v represent either turbulent or laminar flow

with the first one designated for the liquid phase and the second one for the gas phase.

For example, the factor Gvt is the correction factor applied to the single phase gas

pressure gradient when the liquid phase is in laminar flow and the gas phase is in

turbulent flow.

25

26

The steps taken to calculate the pressure drop using the Lockhart& Martinelli

correlation are:

1. Calculate Reynolds number for gas phase, NReg and liquid phase, NReL and

obtain the corresponding friction factor values, fg and fL.

2. Determine the pressure gradients for the liquid phase,[

dp

dX

L

and gas phase,

[

dp

dX

g

.

3. Calculate for parameter X.

4. Use the obtained X value to determine the correction factors for the liquid

phase, L and gas phase, g, based on the Reynolds number calculated earlier.

5. Multiply the correction factors with their respective pressure gradients to

obtain the final pressure drop.

27

3.2.3. Beggs & Brill Correlation

The Beggs & Brill correlation was developed from small scale test facility

experiments consisting of 1 in. and 1.5 in. acrylic pipes with a length of 90 ft. which

could be inclined at any angle. The parameters studied for the development of this

correlation include:

gas flow rate (0-300 MMSCFD)

liquid flow rate (0-30 gal/min)

average system pressure (35-95 psia)

pipe diameter (1-1.5 in.)

liquid holdup (0-0.87)

pressure gradient (0-0.8 psi/ft)

inclination angle (-90

o

to +90

o

)

horizontal flow patterns (segregated, intermittent and distributed, Figure 13)

This flow correlation is one of the most widely used in the industry due to

versatility where it can be applied to both horizontal and vertical flows. The liquid

holdup and pressure gradient was measured at angles of 0

o

(horizontal) and varied up

to plus minus 5

o

, 10

o

, 15

o

, 20

o

, 35

o

, 55

o

, 75

o

and 90

o

. A total of 584 tests were

conducted to develop this correlation and therefore it has a high degree of accuracy

(Brill & Beggs, Two-phase flow in pipes, 1991).

Figure 13: Horizontal FlowPatterns of Beggs & Brill Correlation

28

3.2.3.1. Flow Regime

To determine the flow regime of the fluid inside the pipe, first, the following

parameters are calculated:

N

PR

=

:

m

2

g J

z

L

=

:

sL

:

m

I

1

= S16 z

L

0.302

I

2

= u.uuu92S2 z

L

-2.468 4

I

3

= u.1u z

L

-1.4516

I

4

= u.S z

L

-6.7 38

The parameters are then compared with the limits mentioned below to identify the flow

patterns involved:

Flow Patterns Limits

Segregated

L< 0.01 and NFR< L1

or

L 0.01 and NFR< L2

Transition L 0.01 and L2 NFR L3

Intermittent

0.01 L< 0.4 and L3< NFR L1

or

L 0.4 and L3< NFR L4

Distributed

L< 0.4 and NFR L1

or

L 0.4 and NFR> L4

Table 1: Horizontal Flow Regime Limits

3.2.3.2. Elevation Pressure Drop

As mentioned previously, to calculate for pressure drop caused by elevation,

the liquid holdup must be calculated.

E

L()

= E

L(0)

29

E

L(0)

=

o z

L

b

N

PR

c

Where:

= correction factor to account for inclination

HL(0) = liquid holdup for horizontal pipe

Flow Regime a b c

Segregated 0.98 0.4846 0.0868

Intermittent 0.845 0.5351 0.0173

Distributed 1.065 0.5824 0.0609

Table 2: Constants for Liquid Holdup Calculation

The inclination correction factor, is calculated from:

= 1 +C|sin(1.8 0) u.SSS sin

3

(1.8 0)]

C = (1 z

L

) ln (J z

L

c

N

Lv

]

N

PR

g

)

Where:

= angle of inclination

Flow Regime d' e f g

Segregated uphill 0.011 -3.768 3.539 -1.614

Intermittent uphill 2.96 0.305 -0.4473 0.0978

Distributed uphill No correction necessary

Downhill (all flow

patterns)

4.70 -0.3692 0.1244 -0.5056

However, when a transition flow patterns is involved, its liquid holdup is

calculated via interpolation of the liquid holdups of segregated and intermittent flow:

E

L

(trons) =

I

3

N

PR

I

3

I

2

E

L

(sgt) + _1

I

3

N

PR

I

3

I

2

] E

L

(int)

Once the liquid holdup is obtained, the elevation pressure drop can then be

calculated via:

30

_

Jp

JZ

]

cI

=

g

g

c

|p

L

E

L

+ p

g

(1 E

L

)]

3.2.3.3. Frictional Pressure Drop

Equation used to calculate the frictional pressure drop:

_

Jp

JZ

]

]

=

tp

p

n

:

m

2

2 g

c

J

where:

p

n

= p

L

z

L

+p

g

z

g

and

tp

=

n

c

s

The friction factor fn, is obtained from the Moody diagram or the given equation, using

the Reynolds number of the flow, calculated via:

N

Rc,n

=

p

n

:

m

J

p

n

where:

p

n

= p

L

z

L

+ p

g

z

g

The correction factor, s, applied to the normal friction factor to obtain the two-phase

friction factor can be obtained from:

s =

ln (x)

u.uS2S +S.182 ln(x) u.872S |ln (x)]

2

+ u.u18SS |ln (x)]

4

s = ln(2.2 x 1.2), for 1 < x < 1.2

where:

x =

z

L

(E

L()

)

2

31

3.2.3.4. Acceleration Pressure Drop

The pressure drop due acceleration of the fluids is very small unless for high

velocity flows though it can be included in the calculation for better accuracy. The

governing equation is:

_

Jp

JZ

]

ucc

=

p

s

:

m

:

sg

g

c

p

Jp

JZ

The acceleration term is defined as:

E

k

=

p

s

:

m

:

sg

g

c

p

Therefore, the total pressure loss is represented as:

Jp

JZ

=

[

dp

dz

cI

+ [

dp

dz

]

1 E

k

32

3.3. HYDRATES

Hydrate formation is a major hindrance in the transportation of oil and gas

through offshore pipelines. The multiphase mixture consisting of oil, gas and water

produced at the wellhead will normally be of high pressure and temperatures. The

mixture, as it is flowing through the offshore pipelines cools down gradually and at

certain points sometimes even rapid cooling occurs. With this, the mixture enters the

hydrate formation region which will eventually lead to flow restriction or even

blockage.

Gas hydrates or better known as clathrate hydrates are crystalline water-based

solids which physically resemble ice and are formed when small non-polar molecules,

typically gases are trapped within "cages" of water molecules which are hydrogen

bonded. Clathrates and ice share rather similar properties with the main difference

being the formation of the clathrates occurring at temperatures above the freezing point

of water at elevated pressure conditions. Water molecules through hydrogen bonding

can form a lattice-like structure which becomes stable when filled with suitable size

gas molecules known as hydrate former. Some of the common hydrate formers

include natural gases such as, methane, ethane, propane, isobutene, nitrogen, hydrogen

sulphide and carbon dioxide. These gas hydrates can be formed at temperature well

above the triple point of water (Sloan, 1998).

Figure 14: Simple molecular structure of methane hydrate

33

As mentioned previously, conditions favouring gas hydrates formation are low

temperatures and high pressures. As temperature falls, the rapid movement and

vibrations of liquids and gas tend to slow down and since this vibration causes fluids

to flow and take the shape of the container. This removal of thermal energy allows

most fluids to freeze into solid crystalline structure and at higher pressures warmer

fluids can freeze due to the tendency of the pressure to push molecules into the

crystalline structure (Masoudi, Tohidi, Anderson, Burgass, & Yang, 2004).

Other phenomena that induce formation of hydrates are such as turbulence,

nucleation sites and free-water. Hydrate formation is favoured in high fluid flow

velocity regions. Therefore, choke valves are particularly susceptible to hydrate

formation. When natural gas undergoes compression through a valve, there is usually

a significant temperature drop in accordance with the Joule-Thomson effect leading to

hydrate formation and the velocity is also increased when it flows through the

narrowing in the valve. Nucleation site is also favoured since it is a point where phase

transition occurs from a fluid phase to solid phase. These nucleation sites generally

include imperfections along the pipeline such as a weld spot or a fitting.

In order to prevent the formation of hydrates and the problems that may follow

in subsea production systems, several methods can be used. Firstly, the freezing point

of the water phase or the formation conditions of the hydrates can be altered by

injecting large volumes of chemicals such as methanol. Small volumes of additives

can also be injected into the pipeline to inhibit the formation of bigger hydrate plugs

occurring through agglomeration of hydrate crystals. Finally, the pipeline can be

insulated or under demanding conditions, even heated to maintain the flowing mixture

outside the hydrate formation region. In the petroleum industry, methods have been

developed to determine the volume of freezing point depressant required, the volume

of additive required, and the insulation and degree of heating required (Masoudi,

Tohidi, Anderson, Burgass, & Yang, 2004).

34

3.4. CO2 CORROSION

CO2 corrosion or sweet corrosion as it is widely called is recognized as a major

problem in production and transportation of petroleum over the years. It is a major

source of concern in the application of carbon steel in the industry. This result from

the fact that an aqueous phase is normally associated with the oil and gas production

systems which promote an electrochemical reaction between carbon steel and the

contacting aqueous phase. CO2 is very soluble in water but has a greater solubility in

hydrocarbon fluids produced in the oil and gas production systems. Although it does

not cause the catastrophic failure mode of cracking associated with H2S or sour

corrosion, its presence can nevertheless result in very high corrosion rate particularly

localized corrosion.

3.4.1. Mechanism of CO2 Corrosion

Dry carbon dioxide gas by itself is not corrosive. It has to be dissolved in an

aqueous phase through which it can promote an electrochemical reaction between steel

and the aqueous phase. Various mechanisms have been proposed for the sweet

corrosion process, all of which involve either carbonic acid, H2CO3 or the bicarbonate

ion, HCO3 formed on dissolution of carbon dioxide in water. The basic reaction for

sweet corrosion occurs as follows:

CO2(g)+ H2O CO2(aq)

CO2(aq) + H2O H2CO3 H

+

+ HCO3

The corrosion mechanism:

H2CO3 + e

-

H + HCO3

2H H2

Reaction of steel:

Fe Fe

2+

+ 2e

-

Overall reaction:

CO2 + H2O + Fe FeCO3 + H2

(de Waard & Milliams, Carbonic Acid Corrosion of Steel, 1975)

35

The significance of FeCO3 formation is that it drops out of the solution as a

precipitate due to its limited solubility. This precipitate has the potential to form

passive films or scale on the surfaces of carbon steel which hinders further corrosion.

Figure 15: Simplified schematic representation of CO2 corrosion mechanism

3.4.2. Parameters Affecting CO2 Corrosion

There are several parameters that affect the rate at which the corrosion due to

carbon dioxide occurs. Some of the main parameters which have a significant effect

on the corrosion rate include:

a) CO2 Partial Pressure

CO2 corrosion occurs when the steel surface of the pipe reacts with carbonic

acid formed via the solution of CO2 in an aqueous phase. The CO2aqueous

phase concentration is directly related to the partial pressure of CO2 in the gas

in equilibrium with the aqueous phase. Thus, in CO2 corrosion, estimates of

corrosion rate are primarily based on the partial pressure of CO2 in the gas

phase.

b) Temperature

The rate of corrosion of carbon steel via aqueous CO2increases with

temperature and this leads to the formation of iron carbonate as a reaction

product. However, at significantly high temperatures, around 80C, the

solubility iron carbonate falls and it begins to precipitate and form a protective

36

FeCO3 film. This scale as it is commonly referred to hinder further corrosion

of the pipe wall.

c) pH

The pH value is an important parameter in corrosion of carbon steel. The pH

affects both the electrochemical reactions and the precipitation of corrosion

products. Under certain production conditions the associated aqueous phase

can contain salts which will buffer the pH. This tends to decrease the corrosion

rate and lead to conditions under which the precipitation of protective FeCO3

film layers is more likely.

d) Scaling

Scaling occurs when the product of the sweet corrosion, FeCO3 is not able to

dissolve any further as it has reached saturated levels. This leads to the

precipitation of the FeCO3 and this precipitate builds up and forms a layer of

scale on the pipe wall. This scale hinders corrosion by blocking the wall from

further attack by the ions. However, at high flow velocities, the scale begins to

break away from wall and corrosion progresses (de Waard, Lotz, & Dugstad,

Influence of Liquid Flow Velocity on CO2 Corrosion: A Semi-Empirical

Model, 1995).

37

CHAPTER 4: METHODOLOGY

This chapter discusses the methods and procedures taken in carrying out this project.

In this chapter, the author also introduces the tools used in this project and provides

descriptions on the functionality of the mentioned tools. Finally, a Gantt chart

highlighting the progress of the project is given at the end of the chapter.

38

4.1. PROJECT FLOW

The flow chart below represents the general procedures taken in carrying out

this project:

Analyse and discuss upon the collected results

Gather and compile results of all performed simulations

Perform further simulation for sensitivity analyses and optimisation of results

Collect results from simulation

Perform preliminary simulation in PIPESIM

Build model based on data on hand

Gather and compile pipeline design and operating data

Selection of an appropriate case study

Figure 16: Project Flowchart

39

4.2. CASE STUDY

The selected case study is a design for a20 in. 30 km pipeline connecting the

F14 gas field and the F23 production facilities offshore of Sarawak. The pipeline is

part of an overall development project of the mentioned gas field and therefore is fairly

recent. The approximate location of the pipeline is shown in the figure below.

Figure 17: Sarawak offshore gas fields

4.2.1. Design and Operating Data

PARAMETER UNIT VALUE

Operating Pressure bara 100

Design Pressure bara 153

Operating Temperature C 86

Design Temperature C Max: 96, Min: -20

Table 3: Design and operating conditions

40

DESIGN PARAMETER UNIT VALUE

Nominal Pipe Size in 20

Outer Diameter mm 508

Inner Diameter mm 476

Wall Thickness mm 16

Absolute Roughness mm 0.045

Approximate Length km 30

Concrete Coating mm 60

Table 4: Pipeline design data

DESIGN PARAMETER UNIT VALUE

Nominal Pipe Size in 20

Outer Diameter mm 508

Inner Diameter mm 457.2

Wall Thickness mm 25.4

Absolute Roughness mm 0.045

Height

Profile

Dry Zone

m

12

Splash Zone 12.2

Submerged

Zone

F14 101.1

F23 87.7

External

Corrosion

Coating

Dry Zone (GFE)

mm

0.5

Splash Zone (EPDM) 12.7

Submerged Zone

(3LPP)

10

Table 5: Riser design data

Tables 3, 4 and 5 show the operating and design conditions, design data for the

pipeline and the design data for riser respectively. The concrete coating on the pipeline

is necessary for ensuring the stability on the pipeline on the sea floor whereas the

coatings on the riser are to prevent the riser from corroding externally.

41

4.2.2. Environmental Data

Environmental data input is required for PIPESIM simulations. Therefore,

recent data has been collected at the time of the project from meteorological and

oceanographic surveys as shown in the following page.

PARAMETER UNIT VALUE

Average Water

Depth

F14

m

105.3

F23 91.9

Average Air Temperature C 27.2

Seawater Surface Temperature C 27.2

Seabed Temperature C 19.1

Underwater Current Velocity m/s 1.31

Air Velocity m/s 43.4

Table 6: Environmental data

Figure 18: Seabed elevation profile

4.2.3. Simulation Parameters

ITEM PARAMETER

Fluid Model Compositional

42

Thermodynamic Package Multiphase

Equation of State Peng-Robinson

Table 7: Simulation parameters used

To perform a simulation in the PIPESIM environment, a model of the pipeline

system has to be built first. It is built using the pipeline and riser and the environmental

input data provided above. It then requires simulation parameter which will provide

the basis for the PIPESIM engine to simulate the model. The table above shows a

summary of the parameters used to run this PIPESIM simulation.

The fluid model is required to identify the properties of the fluid being

simulated. For general purposes, the black oil model is can be used. This model uses

bulk properties such as watercut, specific gravity, API gravity and gas-to-oil ratio to

simulate the flow. The results generated using the black oil can be less accurate due to

the fact that these bulk properties are based on averages. For more accurate results,

compositional models can be used where the user inputs the molar fraction of all the

species found in the fluid being modelled. PIPESIMs compositional modelling engine

can also generate and model pseudo-components which are used for heavy petroleum

fractions.

To generate the properties of the species in the composition, the software uses

a thermodynamic package which is a form of database and calculation engine for the

thermodynamic properties. The thermodynamic package used in this simulation is the

MULTIFLASH package developed by Infochem. MULTIFLASH is able to carry out

multiphase equilibrium calculations using the selected equation of state to model the

phase envelope, PVT behaviour, entropy, enthalpy and internal energy of the fluid

mixture. It is also required for modelling hydrate formations.

43

4.3. TOOLS & SOFTWARE

In BGSB, the primary simulation software available for pipeline flow

assurance study is the PIPESIM software developed by Schlumberger. PIPESIM is a

very applicable tool capable of modelling single phase and multiphase flows from the

reservoir through the production facilities to the final delivery point. In facilities

modelling, PIPESIM can also be used to design systems by varying key system

parameters, thus enabling optimal pipeline and equipment sizes to be determined.

Some of the typical applications of PIPESIM include:

Multiphase flow in flowline and pipelines.

Point by point generation of pressure and temperature profiles.

Transportation pipeline design and flow rate calculation.

Flowline & equipment performance modelling (system analysis).

Hydrate modelling.

Sweet corrosion & erosional corrosion modelling.

Wax deposition modelling.

Figure 19: PIPESIM interface

4.4. GANTT CHART

No. Activities Category

Week

1 2 3 4 5 6 7 8 9 10 11 12 13 14

1 Determine problem statement and objectives.

Planning

2 Identifying a proper case study.

3 Research on literature related to project.

Research

4 Determine methods to test case study.

5 Prepare model and run simulations. Execution

6 Collect and analyse the generated results. Results

7 Prepare report.

Reporting

8 Conduct presentation on project.

9 Submission of SIP report.

10 Submission of logbook summary.

11 End of SIP

CHAPTER 5: RESULTS &

DISCUSSION

This chapter compiles the collected data from the simulations conducted and the

subsequent analysis of the data. This followed by the findings regarding the project

based on the engineering and technical review done on the second chapter.

46

5.1. PIPESIM MODEL

The above diagram shows the basic model built using the pipeline and riser

data provided. This model is then subjected to various inputs based on the parameter

being studied and simulated to obtain the desired data.

Figure 20: PIPESIM model

47

5.2. PRESSURE VARIATION AMONG FLOW CORRELATION

The following simulation was carried out to compare between the different

pressure drops arising from the use of different flow correlations. This study is

generally done to observe the accuracy of the flow correlations being studied. The

inputs used for this simulation are as follows:

Inlet pressure : 100 bara

Inlet temperature : 86 C

Gas flowrate : 200 MMSCFD

Nominal Pipe Diameter : 20 inch

There are two outputs generated of this simulation, which are for the

comparison of horizontal flow correlations followed by the comparison of vertical

flow correlations. The following is the output for the horizontal flow correlations

comparison:

Graph 1: Horizontal flow correlation comparison

The graph shows the pressure drop variation between the Lockhart &

Martinelli, Beggs & Brill Original and the Beggs & Brill Revised horizontal flow

correlations. Note the pressure drop variation only happens along the main line and

not at the edges. This is because the correlations being varied are for horizontal flow

and not vertical flow as in with the riser sections at the edges. It can be also seen that

the pressure drops for the Lockhart & Martinelli and Beggs & Brill Original

correlations are rather similar whereas for the Beggs & Brill Revised correlation it is

much steeper. This is mainly due to the fact that the Lockhart & Martinelli and Beggs

48

& Brill Original were developed without taking pipe surface roughness into

consideration. When the Beggs & Brill correlation was originally formulated, it only

considered for smooth pipe flow with an absolute roughness of 0.0015 mm. It was later

on revised and formulated into the Beggs & Brill Revised correlation which has a

provision for surface roughness and therefore a carbon steel pipe with an absolute

roughness of 0.045 mm exhibits a larger pressure drop compared to the other two.

Graph 2: Vertical flow correlation comparison

This graph shows the pressure drop variation between the Hagedorn & Brown,

Beggs & Brill Original and the Beggs & Brill Revised vertical flow correlations. The

variation cannot be seen clearly here because it only occurs in sections involving

vertical flow, in this case the risers. Therefore, zooming in towards the riser sections,

the different pressure gradients are more visible.

Graph 3: Vertical flow correlation comparison - Riser F14

49

Graph 4: Vertical flow correlation comparison - Riser F23

These two graphs also highlight the effect of the surface roughness on the

overall pressure drop. It is also observed that the pressure gradients of both the original

and revised Beggs & Brill overlap. This is due to the liquid holdup calculation which

is similar for both and the elevation pressure drop contributed by it.

50

5.3. PIPELINE SIZE OPTIMISATION

This study is performed to obtain an optimum pipe size or diameter for the

main flowline connecting the F14 and F23 risers. The main factors considered for

sizing a pipeline are the pressure requirements, the fluid flow velocity and the pipeline

design pressure. This is a sensitivity study where fluid flow is simulated against the

various pipe sizes available and compared against one another. The inputs used in this

simulation are:

Inlet pressure : 100 bara

Inlet temperature : 86 C

Gas flowrate : 200 MMSCFD

Nominal Pipe Diameter : - 20 inch

- 18 inch

- 16 inch

- 14 inch

- 12 inch

- 10 inch

The pressure drop profile obtained for the current simulation with the given

pipe sizes are as follows:

Graph 5: Pressure drop for various pipe sizes

51

Based on the graph, it is observed that the light blue, red and green lines

representing the 10 inch, 12 inch and 14 inch pipes are cut off before travelling the

total pipeline distance of 30 km. This shows clearly that an inlet pressure of 100 bara

is insufficient to deliver the required flowrate of 200 MMSCFD of gas across the

pipeline at mentioned diameters.

The input of the simulation is altered slightly with the outlet pressure being

fixed now at 92 bara which would be the required topside pressure. The output

generated is:

Graph 6: Pressure drop for various pipe sizes, Outlet = 92 bara

From this graph, it can be seen that the required inlet pressures for the 10 inch

pipe and the 12 inch pipe are 225 bara and 160 bara respectively. However, these two

pressures are higher than the given design pressure for the pipeline, thus cannot be

implemented. Therefore, this leads to the 14 inch pipe to be the optimum size with an

inlet pressure of 135 bara.

52

Graph 7: Fluid velocity for various pipe sizes, Outlet = 92 bara

Another graph is plotted to observe the variations in the velocity of the fluid

flowing in the pipes of differing sizes. The reason behind this being the possibility of

erosion occurring at velocities higher than 20 m/s for a gas flowline. From the graph,

it can be seen that the maximum velocity exhibited is at an excess of 10 m/s for the 10

inch pipe which is still within limits. Therefore, the initial optimum pipe size selection

of 14 inch is still maintained for its required inlet pressure is within the design pressure

and the fluid velocity is within the erosional velocity limit.

53

5.4. HYDRATE CONTROL

Hydrates as mentioned in the previous chapters, pose a serious threat for gas

pipelines operating in low temperatures. Although operating in a tropical region, the

pipeline studied here still faces the risk as minimum sea water temperatures can drop

up 19C. This study is done to identify the possibility of hydrates forming in the

pipeline and providing sufficient control if necessary. This simulation uses the

following inputs:

Inlet pressure : 100 bara

Inlet temperature : 86 C

Gas flowrate : 200 MMSCFD

Nominal Pipe Diameter : 20 inch

Graph 8: Phase envelope plot

The graph above shows the phase envelope plot which is specific to the

composition of the gas used. The red and green lines on the phase envelope plot are

the hydrate curves which represent the phase boundary to the hydrate formation region.

The region towards the left of the green line is the stable hydrate region where the

formation of hydrates is inevitable and the region between the red and green lines is

the meta-stable region where hydrates form and dissolve spontaneously. To prevent

hydrate formation, the operating conditions must be in the region towards the right of

the red hydrate line.

54

Graph 9: Phase envelope plot - operation line

This graph shows the same phase envelope plot but with the added operation

line which traces pressure and temperature operating conditions along the pipeline. It

can be clearly seen that the operation line intersects the first hydrate curve and enters

the meta-stable region. This shows that along the pipeline, conditions exist for the

formation of hydrate crystals. To avoid this, the operation line needs to be shifted to

the right towards temperatures higher than 20 C. This can be done by applying

insulation to the pipeline to prevent heat loss and subsequent temperature drop.

Graph 10: Phase envelope plot - 5 mm insulation

55

Graph 11: Phase envelope plot - 10 mm insulation

By applying an insulation of 3 Layer Poly-Propylene (3LPP) of 5 mm thickness, it can

be seen that the operation line is slightly nudged towards higher temperatures but still

falls in the meta-stable region. Increasing the 3LPP insulation thickness to 10 mm

effectively moves the operation line completely out of the meta-stable region and thus

blocking the hydrate formation completely.

Therefore, an insulation of 3LPP of 10 mm thickness is required input in the

overall design of the pipeline to prevent excess heat lose and temperature drop which

will lead to hydrate formation.

56

5.5. CORROSION STUDY

Another major problem occurring in pipelines is corrosion, not just external

corrosion due to seawater but also in the internals. Two main forms of corrosion are

the CO2 or sweet corrosion and the H2S or sour corrosion depending on the type of

service. This pipeline is a sweet service pipeline carrying natural gas mixed

predominantly with CO2. To predict the corrosion rate along the pipeline in PIPESIM,

the following inputs were used:

Inlet pressure : 100 bara

Inlet temperature : 86 C

Gas flowrate : 200 MMSCFD

Nominal Pipe Diameter : 20 inch

Amount of CO2 : 1.8811 mol%

Amount of H2O : 19.938 mol%

Graph 12: CO2 corrosion rate

The graph above shows the corrosion rate predicted by the deWaard-Milliam

model along the entire length of the pipeline. The corrosion rate values fluctuate due

to the many factors involved in the calculation but mainly varying pressures, densities

and temperatures, however it averages at approximately 3.1 mm/year. This corrosion

rate is still considered high and control methods have to be implemented to reduce it

such as injection of corrosion inhibitors into the gas stream, dehydration and CO2

removal.

57

The composition of the gas stream is now altered slightly to simulate a

dehydrated and CO2 removed gas. The corrosion rate predicated is as follows:

Graph 13: CO2 corrosion rate - adjusted composition

It is observed now that the corrosion rate is significantly lower compared to the

previous with an average rate of around 1.3 mm/year. By removing water an CO2 from

the gas stream, the concentration of the HCO3

-

ion which attacks metal surface of the

pipe has be reduced and therefore an reduction in the overall corrosion rate.

58

CHAPTER 6: CONCLUSION &

RECOMMENDATION

With this chapter, the author finally draws a conclusion on the project based on the

objectives laid out and the reported findings. The author also suggested a few

recommendations to further improve upon the findings of the project for better

understanding.

59

UTP Student Industrial Project (SIP) is an effective medium designed to allow

engineering students to make use of their knowledge obtained in the classroom and

during the initial training and apply them in real world project to gain vital insight and

experiences. With the exposure during the 14-weeks of project undertaking period, the

author was able to fulfil the objectives set for the SIP, which are:

a) Integrate theoretical knowledge in the industry.

b) Analyse complex engineering/technical projects or problems.

c) Evaluate and propose solutions for given complex project or problems.

d) Communicate effectively on complex engineering/technical activities.

It can be also brought to conclusion that the objectives and the corresponding

scope of study for the undertaken project have been also fulfilled. The objectives laid

out for the project were:

a) To identify the important aspects of flow assurance.

Some of the major aspects of flow assurance studied were the multiphase flow

conditions, natural gas hydrates and sweet corrosion.

b) To model steady state fluid flow conditions with the aid of computer

software simulations using data obtained from the field.

A case study on a proposed pipeline project was selected and its design data

was used to build a model in the PIPESIM and simulated under steady state

conditions.

c) To identify and analyse problem found in the end result of the simulations.

Simulation was performed in PIPESIM and the output generated was analysed

to identify the problem associated with it.

d) To suggest solutions designed to nullify the problems.

Several control methods were proposed to overcome the problems identified in