Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Taibah University PDF Calc. 2013-07-04

Caricato da

Anju KlCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Taibah University PDF Calc. 2013-07-04

Caricato da

Anju KlCopyright:

Formati disponibili

STRUCTURAL CALCULATIONS

TAIBAH UNIVERSITY

B01-MAIN BUILDING

JUNE 2013

DESIGN CRITERIA

DESIGN CODES:

1. FOR LOAD VALUES AND LATERAL LOAD CALCULATIONS BUILDING CODE REQUIREMENTS FOR REINFORCED CONCRETE UBC 97

2. FOR LOAD COMBINATIONS AND DESIGN OF CONCRETE STRUCTURES UNIFORM BUILDING CODE ACI 318-08

UNITS:

SI UNIT SYSTEM.

MATERIAL PROPERTIES:

NORMAL WIEGHT CONCRETE DENSITY = 2.4 t. /m

3

.

NORMAL WEIGHT BLOCKS DENSITY = 1.2 t. /m

3

.

CONCRETE SHALL HAVE A MIN 28 DAYS CYLINDER STRENGTH OF 400 kg/cm

2

FOR ALL MEMBERS

REINFORCING STEEL SHALL HAVE MIN YIELD STRENGTH OF 4200 kg/cm

2

LOADING ASSUMPTIONS:

DEAD LOADS:

FLOORING = 0.250 t. /m

2

.

PARTIONS = 0.300 t. /m

2

.

LIVE LOADS:

1. ROOF = 0.50 t. /m

2

.

2. TYPICAL FLOORS = 0.20 t. /m

2

.

3. CORRIDOORS & STAIRS = 0.48 t. /m

2

.

CASES OF LOADINGS

1. DEAD LAODS (DEAD)

2. LIVE LOADS (LIVE)

3. WIND LAODS (Wx-Wy)

4. EARTHQUAKE (Ex-Ey)

LOAD COMBINATIONS

1. Working ( WORKING VL LOADS) =DEAD*1+LIVE *1

2. Ultimate ( ULTIMATE VL LOADS ) = 1.2* DEAD +1.6*LIVE

3. OTHER CASES FROM DEFAULT DESIGN COMBINATIONS DEFINED BY PROGRAMES ACCORDING TO UBC 97 .

COMPUTER PROGRAMES:

ETABS 9SAFE 12

MECHANICAL EQUIPMENTS LOADS

PART 1

ETABS v9.7.4 - File: B001 Part 1 Phase I 3013-05-08 - May 8,2013 10:09

3-D View - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 1 Phase I 3013-07-01 - J uly 2,2013 14:22

3-D View Column P-M-M Interaction Ratios (ACI 318-05/IBC 2003) - Ton-m Units

Microsoft

ETABS

0.00 0.50 0.70 0.90 1.00

ETABS v9.7.4 - File: B001 Part 1 Phase I 3013-07-01 - J uly 2,2013 13:17

Plan View - GR - Elevation 0 Shear Force 2-2 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 1 Phase I 3013-07-01 - J uly 2,2013 13:17

Plan View - GR - Elevation 0 Moment 3-3 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 1 Phase I 3013-05-08 - May 8,2013 10:21

Plan View - MZ - Elevation 6.6 Moment 3-3 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 1 Phase I 3013-05-08 - May 8,2013 10:23

Plan View - MZ - Elevation 6.6 Shear Force 2-2 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 1 Phase I 3013-05-08 - May 8,2013 10:22

Plan View - ROOF - Elevation 10 Moment 3-3 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 1 Phase I 3013-05-08 - May 8,2013 10:22

Plan View - ROOF - Elevation 10 Shear Force 2-2 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

PART 2

ETABS v9.7.4 - File: B001 Part 2 Phase II only 3013-05-08 - May 8,2013 10:12

3-D View - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 2 Phase II only 3013-07-01 - J uly 2,2013 15:27

3-D View Column P-M-M Interaction Ratios (ACI 318-05/IBC 2003) - Ton-m Units

Microsoft

ETABS

0.00 0.50 0.70 0.90 1.00

ETABS v9.7.4 - File: B001 Part 2 Phase II only 3013-07-01 - J uly 2,2013 13:27

Plan View - GR - Elevation 0 Moment 3-3 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 2 Phase II only 3013-07-01 - J uly 2,2013 13:28

Plan View - GR - Elevation 0 Shear Force 2-2 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 2 Phase II only 3013-05-08 - May 8,2013 10:25

Plan View - MZ - Elevation 6.6 Moment 3-3 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 2 Phase II only 3013-05-08 - May 8,2013 10:27

Plan View - MZ - Elevation 6.6 Shear Force 2-2 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 2 Phase II only 3013-05-08 - May 8,2013 10:26

Plan View - ROOF - Elevation 10 Moment 3-3 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 2 Phase II only 3013-05-08 - May 8,2013 10:26

Plan View - ROOF - Elevation 10 Shear Force 2-2 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

PART 3

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-04-28 - May 8,2013 10:12

3-D View - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-07-01 - J uly 2,2013 15:29

3-D View Column P-M-M Interaction Ratios (ACI 318-05/IBC 2003) - Ton-m Units

Microsoft

ETABS

0.00 0.50 0.70 0.90 1.00

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-07-01 - J uly 2,2013 14:18

Plan View - BASE - Elevation 0 Moment 3-3 Diagram (U2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-07-01 - J uly 2,2013 14:19

Plan View - BASE - Elevation 0 Shear Force 2-2 Diagram (U2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-04-28 - May 8,2013 10:28

Plan View - MZ - Elevation 6.6 Moment 3-3 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-04-28 - May 8,2013 10:30

Plan View - MZ - Elevation 6.6 Shear Force 2-2 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-04-28 - May 8,2013 10:28

Plan View - ROOF - Elevation 10 Moment 3-3 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-04-28 - May 8,2013 10:29

Plan View - ROOF - Elevation 10 Shear Force 2-2 Diagram (DCON2) - Ton-m Units

Microsoft

ETABS

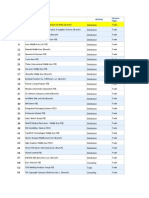

DESIGN OF FOOTINGS

DESIGN OF ISOLATED FOOTING ACCORDING TO ACI 318M 08

MD-1139 B001

fc'= 350 kg/cm

2

d

L

= t - 7 cm Round to nearest 10 cm 1.10 1.00

fy= 4200 kg/cm

2

d

W

= t - 7 cm min # bars /m 5 bar Reduce Foot. ow by soil ow 1.00

NET B.C.= 6.00 kg/cm

2

max # bars /m 9 bar consider soil Den 1.8 t/m

3

P

working TYP. Typ

CHK OF

PUNCH.

CHECK of

SHEAR

P is fact. by for rft.=

Col

Dim. ( m.)

Reinforced conc

Dim. ( m.)

STRESS

ON SOIL

REINFORCEMENT

As / m' As total

P is fact. by for B/C.=

Note

Footings_BC 6.00 For PDF Only 1 7/2/20136:03 PM

Lc Wc L W H (kg/cm2) FOS L W

FOS(L) FOS(W)

F1 150 0.8 0.4 2 1.6 0.5 4.72

1.27

1.7

3.5 3.5 5.8 14 min 5.8 14 min 13 14 11 14 F1

F2 360 1 0.8 3 2.8 0.6 4.33

1.39

1.1

1.7 1.7 8.2 16 req 8.2 16 req 26 16 24 16 F2

F3 460 1 0.8 3.4 3.2 0.7 4.28

1.41

1.1

1.7 1.7 6.2 20 req 6.2 20 req 23 20 21 20 F3

F4 660 1 0.8 3.8 3.6 0.9 4.89

1.23

1.1

2.0 2.0 7.3 20 req 7.3 20 req 29 20 28 20 F4

F5 680 1.65 1 4.1 3.5 0.8 4.79

1.25

1.2

2.0 1.9 6.5 20 req 6.3 20 req 28 20 23 20 F5

F6 890 1.65 1 4.7 4.1 1 4.69

1.28

1.3

2.2 2.1 7.7 20 req 7.4 20 req 38 20 32 20 F6

F7 895 1 0.8 4.5 4.3 1.1 4.70

1.28

1.1

2.0 2.0 8.9 20 req 8.9 20 req 41 20 40 20 F7

short steel ( W dir.) long steel ( L dir.) short (W) long (L)

Note

Footings_BC 6.00 For PDF Only 1 7/2/20136:03 PM

MOMENT CALCULATIONS

r %

min

=

0.18 %

r %

max

=

2.66 %

b= 0.85

depth con- Moment LONG SHORT

TYP. P d d tact M M As.

Min

r % As.

Req

As.

Choosen

r % As.

Req

As.

Choosen

Footings_BC 6.00 For PDF Only 2 7/2/20136:03 PM

des. L W stress L W cm

2

/ m' req. cm

2

/ m' cm

2

/ m' req. cm

2

/ m' cm

2

/ m'

F1 150 0.43 0.43 46.88 8.4 8.4 9.00 0.183 7.89 9.00 0.183 7.89 9.00

F2 360 0.53 0.53 42.86 21.4 21.4 10.80 0.309 16.40 16.40 0.309 16.40 16.40

F3 460 0.63 0.63 42.28 30.4 30.4 12.60 0.311 19.60 19.60 0.311 19.60 19.60

F4 660 0.83 0.83 48.25 47.3 47.3 16.20 0.278 23.06 23.06 0.278 23.06 23.06

F5 680 0.73 0.73 47.39 35.6 37.0 14.40 0.270 19.70 19.70 0.281 20.53 20.53

F6 890 0.93 0.93 46.19 53.7 55.5 18.00 0.251 23.33 23.33 0.259 24.11 24.11

F7 895 1.03 1.03 46.25 70.8 70.8 19.80 0.270 27.82 27.82 0.270 27.82 27.82

Footings_BC 6.00 For PDF Only 2 7/2/20136:03 PM

SHEAR & PUNCHING CALCULATIONS

as= 40

Acting Ult. Max. Ult. Upward Punch Conc. Resistance in

TYP. Shear Shear d Load Load bc bo Punching (ult.) fVc

Footings_BC 6.00 For PDF Only 3 7/2/20136:03 PM

L W L W ave. (t.) ult. (t.) (m) V c (a) V c (b) V c (d) ult.

F1 12.0 12.0 42.4 42.4 0.43 47.9 153 2 4.12 349 539 349 262

F2 30.2 30.2 52.3 52.3 0.53 87.2 409 1.25 5.72 777 853 598 448

F3 36.1 36.1 62.1 62.1 0.63 98.5 542 1.25 6.12 988 1163 760 570

F4 41.3 41.3 81.8 81.8 0.83 143.9 774 1.25 6.92 1472 1925 1133 849

F5 35.2 37.0 72.0 72.0 0.73 195.1 727 1.65 8.22 1309 1643 1183 888

F6 41.2 43.0 91.7 91.7 0.93 230.0 990 1.65 9.02 1830 2533 1654 1241

F7 50.0 50.0 101.6 101.6 1.03 171.8 1085 1.25 7.72 2038 2876 1568 1176

Footings_BC 6.00 For PDF Only 3 7/2/20136:03 PM

DESIGN OF ISOLATED FOOTING ACCORDING TO ACI 318M 08

MD-1139 B001

FOOTING

FOOTING CHEDULE

DIMENSIONS (mm) SHORT STEEL LONG STEEL

Footings_BC 6.00 For PDF Only 4 7/2/20136:03 PM

MARK L W H

F1 2000 1600 500 13 T 14 4 T 12 11 T 14 4 T 12

F2 3000 2800 600 26 T 16 4 T 12 24 T 16 4 T 12

F3 3400 3200 700 23 T 20 4 T 12 21 T 20 4 T 12

F4 3800 3600 900 29 T 20 4 T 12 28 T 20 4 T 12

F5 4100 3500 800 28 T 20 4 T 12 23 T 20 4 T 12

F6 4700 4100 1000 38 T 20 4 T 12 32 T 20 4 T 12

F7 4500 4300 1100 41 T 20 4 T 12 40 T 20 4 T 12

BOT. BARS TOP BARS BOT. BARS TOP BARS

Footings_BC 6.00 For PDF Only 4 7/2/20136:03 PM

DESIGN OF WATER TANK

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-06-19 - J une 24,2013 10:59

Elevation View - Y1 Resultant M22 Diagram (ENVE) - Ton-m Units

Microsoft

ETABS

-93.5 -85.0 -76.5 -68.0 -59.5 -51.0 -42.5 -34.0 -25.5 -17.0 -8.5 0.0 8.5 17.0

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-06-19 - J une 24,2013 11:01

Elevation View - Y1 Resultant F22 Diagram (ENVE) - Ton-m Units

Microsoft

ETABS

-93.5 -85.0 -76.5 -68.0 -59.5 -51.0 -42.5 -34.0 -25.5 -17.0 -8.5 0.0 8.5 17.0

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-06-19 - J une 24,2013 10:56

Elevation View - Y2 Resultant M22 Diagram (ENVE) - Ton-m Units

Microsoft

ETABS

-48. -36. -24. -12. 0. 12. 24. 36. 48. 60. 72. 84. 96. 108.

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-06-19 - J une 24,2013 10:58

Elevation View - Y2 Resultant F22 Diagram (ENVE) - Ton-m Units

Microsoft

ETABS

-65.0 -58.5 -52.0 -45.5 -39.0 -32.5 -26.0 -19.5 -13.0 -6.5 0.0 6.5 13.0 19.5

MD-1139 Taibah University-1200 mm thick wall VL RFT check

Structure Exposure Environmental Conditions Upper mid room

1. Normal Ph 5 or Sulphate Solution 1000

Z = 115 (Kips/inch)

w = 0.01 (inch) (Crack Width)

0.25 (mm)

2. Severe Ph > 5 or Sulphate Solution > 1000

Z = 95 (Kips/inch)

w = 0.009 (inch) (Crack Width)

0.23 (mm)

Z = fs (dc .A)

(1/3)

(Kips/inch) Eqn (10.5)

w = 7.60x 10

(-5)

. B . Z (inch) B = 1.35 for floor slabs

B = 1.2 (for Beams)

According to the designed case choose the relevant condition

Z = 95 (Ki /i h)

Check of Water Section according to ACI

ACI 350-01 R - Environmental Structure Code and Commentry

Clause (10.6.4)

Z = 95 (Kips/inch)

w = 0.009 (inch)

0.23 (mm)

B = 1.35

From Eq (10.5)

t = 1200 mm

dc = 70 mm

S = 62.5 mm

A = 13.5625

Z = 87.72 (Kips/inch) Safe

fs = 26.24 ksi

= 180.90 Mpa

= 1808.96 kg/cm

2

Straining Actions

Mw = 102 m.t Vertical Direction

Nw = -44 t/m +ve tension -ve Comp

Required Area of Steel

Aw = 43.2819 cm

2

/ m

Bar Area = 2.70512 cm

2

T 19

Eng. Mahmoud Hassan

MD-1139 Taibah University-800 mm thick wall VL RFT check

Structure Exposure Environmental Conditions Upper mid room

1. Normal Ph 5 or Sulphate Solution 1000

Z = 115 (Kips/inch)

w = 0.01 (inch) (Crack Width)

0.25 (mm)

2. Severe Ph > 5 or Sulphate Solution > 1000

Z = 95 (Kips/inch)

w = 0.009 (inch) (Crack Width)

0.23 (mm)

Z = fs (dc .A)

(1/3)

(Kips/inch) Eqn (10.5)

w = 7.60x 10

(-5)

. B . Z (inch) B = 1.35 for floor slabs

B = 1.2 (for Beams)

According to the designed case choose the relevant condition

Z = 95 (Ki /i h)

Check of Water Section according to ACI

ACI 350-01 R - Environmental Structure Code and Commentry

Clause (10.6.4)

Z = 95 (Kips/inch)

w = 0.009 (inch)

0.23 (mm)

B = 1.35

From Eq (10.5)

t = 800 mm

dc = 70 mm

S = 125 mm

A = 27.1251

Z = 87.72 (Kips/inch) Safe

fs = 20.82 ksi

= 143.58 Mpa

= 1435.77 kg/cm

2

Straining Actions

Mw = 18 m.t Vertical Direction

Nw = -17 t/m +ve tension -ve Comp

Required Area of Steel

Aw = 13.1618 cm

2

/ m

Bar Area = 1.64522 cm

2

T 14

Eng. Mahmoud Hassan

MD-1139 Taibah University-600 mm thick wall VL RFT check

Structure Exposure Environmental Conditions Upper mid room

1. Normal Ph 5 or Sulphate Solution 1000

Z = 115 (Kips/inch)

w = 0.01 (inch) (Crack Width)

0.25 (mm)

2. Severe Ph > 5 or Sulphate Solution > 1000

Z = 95 (Kips/inch)

w = 0.009 (inch) (Crack Width)

0.23 (mm)

Z = fs (dc .A)

(1/3)

(Kips/inch) Eqn (10.5)

w = 7.60x 10

(-5)

. B . Z (inch) B = 1.35 for floor slabs

B = 1.2 (for Beams)

According to the designed case choose the relevant condition

Z = 95 (Ki /i h)

Check of Water Section according to ACI

ACI 350-01 R - Environmental Structure Code and Commentry

Clause (10.6.4)

Z = 95 (Kips/inch)

w = 0.009 (inch)

0.23 (mm)

B = 1.35

From Eq (10.5)

t = 600 mm

dc = 70 mm

S = 125 mm

A = 27.1251

Z = 87.72 (Kips/inch) Safe

fs = 20.82 ksi

= 143.58 Mpa

= 1435.77 kg/cm

2

Straining Actions

Mw = 19 m.t Vertical Direction

Nw = -14 t/m +ve tension -ve Comp

Required Area of Steel

Aw = 22.8674 cm

2

/ m

Bar Area = 2.85842 cm

2

T 19

Eng. Mahmoud Hassan

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-06-19 - J une 24,2013 11:00

Elevation View - Y1 Resultant M11 Diagram (ENVE) - Ton-m Units

Microsoft

ETABS

-84.0 -77.0 -70.0 -63.0 -56.0 -49.0 -42.0 -35.0 -28.0 -21.0 -14.0 -7.0 0.0 7.0

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-06-19 - J une 24,2013 11:01

Elevation View - Y1 Resultant F11 Diagram (ENVE) - Ton-m Units

Microsoft

ETABS

-36.0 -30.0 -24.0 -18.0 -12.0 -6.0 0.0 6.0 12.0 18.0 24.0 30.0 36.0 42.0

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-06-19 - J une 24,2013 10:57

Elevation View - Y2 Resultant M11 Diagram (ENVE) - Ton-m Units

Microsoft

ETABS

-104. -91. -78. -65. -52. -39. -26. -13. 0. 13. 26. 39. 52. 65.

ETABS v9.7.4 - File: B001 Part 3 Phase I 3013-06-19 - J une 24,2013 10:58

Elevation View - Y2 Resultant F11 Diagram (ENVE) - Ton-m Units

Microsoft

ETABS

-19.5 -13.0 -6.5 0.0 6.5 13.0 19.5 26.0 32.5 39.0 45.5 52.0 58.5 65.0

MD-1139 Taibah University-1200 mm thick wall HL RFT check

Structure Exposure Environmental Conditions Upper mid room

1. Normal Ph 5 or Sulphate Solution 1000

Z = 115 (Kips/inch)

w = 0.01 (inch) (Crack Width)

0.25 (mm)

2. Severe Ph > 5 or Sulphate Solution > 1000

Z = 95 (Kips/inch)

w = 0.009 (inch) (Crack Width)

0.23 (mm)

Z = fs (dc .A)

(1/3)

(Kips/inch) Eqn (10.5)

w = 7.60x 10

(-5)

. B . Z (inch) B = 1.35 for floor slabs

B = 1.2 (for Beams)

According to the designed case choose the relevant condition

Z = 95 (Ki /i h)

Check of Water Section according to ACI

ACI 350-01 R - Environmental Structure Code and Commentry

Clause (10.6.4)

Z = 95 (Kips/inch)

w = 0.009 (inch)

0.23 (mm)

B = 1.35

From Eq (10.5)

t = 1200 mm

dc = 70 mm

S = 62.5 mm

A = 13.5625

Z = 87.72 (Kips/inch) Safe

fs = 26.24 ksi

= 180.90 Mpa

= 1808.96 kg/cm

2

Straining Actions

Mw = 70 m.t Vertical Direction

Nw = -20 t/m +ve tension -ve Comp

Required Area of Steel

Aw = 32.5215 cm

2

/ m

Bar Area = 2.03259 cm

2

T 16

Eng. Mahmoud Hassan

MD-1139 Taibah University-800 mm thick wall HL RFT check

Structure Exposure Environmental Conditions Upper mid room

1. Normal Ph 5 or Sulphate Solution 1000

Z = 115 (Kips/inch)

w = 0.01 (inch) (Crack Width)

0.25 (mm)

2. Severe Ph > 5 or Sulphate Solution > 1000

Z = 95 (Kips/inch)

w = 0.009 (inch) (Crack Width)

0.23 (mm)

Z = fs (dc .A)

(1/3)

(Kips/inch) Eqn (10.5)

w = 7.60x 10

(-5)

. B . Z (inch) B = 1.35 for floor slabs

B = 1.2 (for Beams)

According to the designed case choose the relevant condition

Z = 95 (Ki /i h)

Check of Water Section according to ACI

ACI 350-01 R - Environmental Structure Code and Commentry

Clause (10.6.4)

Z = 95 (Kips/inch)

w = 0.009 (inch)

0.23 (mm)

B = 1.35

From Eq (10.5)

t = 800 mm

dc = 70 mm

S = 62.5 mm

A = 13.5625

Z = 87.72 (Kips/inch) Safe

fs = 26.24 ksi

= 180.90 Mpa

= 1808.96 kg/cm

2

Straining Actions

Mw = 50 m.t Vertical Direction

Nw = -23 t/m +ve tension -ve Comp

Required Area of Steel

Aw = 35.7132 cm

2

/ m

Bar Area = 2.23207 cm

2

T 17

Eng. Mahmoud Hassan

MD-1139 Taibah University-600 mm thick wall HL RFT check

Structure Exposure Environmental Conditions Upper mid room

1. Normal Ph 5 or Sulphate Solution 1000

Z = 115 (Kips/inch)

w = 0.01 (inch) (Crack Width)

0.25 (mm)

2. Severe Ph > 5 or Sulphate Solution > 1000

Z = 95 (Kips/inch)

w = 0.009 (inch) (Crack Width)

0.23 (mm)

Z = fs (dc .A)

(1/3)

(Kips/inch) Eqn (10.5)

w = 7.60x 10

(-5)

. B . Z (inch) B = 1.35 for floor slabs

B = 1.2 (for Beams)

According to the designed case choose the relevant condition

Z = 95 (Ki /i h)

Check of Water Section according to ACI

ACI 350-01 R - Environmental Structure Code and Commentry

Clause (10.6.4)

Z = 95 (Kips/inch)

w = 0.009 (inch)

0.23 (mm)

B = 1.35

From Eq (10.5)

t = 600 mm

dc = 70 mm

S = 48.78 mm

A = 10.5853

Z = 87.72 (Kips/inch) Safe

fs = 28.50 ksi

= 196.47 Mpa

= 1964.75 kg/cm

2

Straining Actions

Mw = 8 m.t Vertical Direction

Nw = -6 t/m +ve tension -ve Comp

Required Area of Steel

Aw = 7.00928 cm

2

/ m

Bar Area = 0.34191 cm

2

T 7

Eng. Mahmoud Hassan

MD-1139 Taibah University-400 mm thick wall HL RFT check

Structure Exposure Environmental Conditions Upper mid room

1. Normal Ph 5 or Sulphate Solution 1000

Z = 115 (Kips/inch)

w = 0.01 (inch) (Crack Width)

0.25 (mm)

2. Severe Ph > 5 or Sulphate Solution > 1000

Z = 95 (Kips/inch)

w = 0.009 (inch) (Crack Width)

0.23 (mm)

Z = fs (dc .A)

(1/3)

(Kips/inch) Eqn (10.5)

w = 7.60x 10

(-5)

. B . Z (inch) B = 1.35 for floor slabs

B = 1.2 (for Beams)

According to the designed case choose the relevant condition

Z = 95 (Ki /i h)

Check of Water Section according to ACI

ACI 350-01 R - Environmental Structure Code and Commentry

Clause (10.6.4)

Z = 95 (Kips/inch)

w = 0.009 (inch)

0.23 (mm)

B = 1.35

From Eq (10.5)

t = 400 mm

dc = 70 mm

S = 100 mm

A = 21.7

Z = 87.72 (Kips/inch) Safe

fs = 22.43 ksi

= 154.66 Mpa

= 1546.63 kg/cm

2

Straining Actions

Mw = 8 m.t Vertical Direction

Nw = -6 t/m +ve tension -ve Comp

Required Area of Steel

Aw = 15.4762 cm

2

/ m

Bar Area = 1.54762 cm

2

T 14

Eng. Mahmoud Hassan

FOUNDATION DESIGN OF STEEL TANK

Potrebbero piacerti anche

- American App Examples 2007 CompleteDocumento388 pagineAmerican App Examples 2007 CompleteJay NatoNessuna valutazione finora

- Quantify Dead Loads Acting On StructureDocumento41 pagineQuantify Dead Loads Acting On StructureAnju KlNessuna valutazione finora

- RC17 Column01Documento25 pagineRC17 Column01Bhim Prasad DahalNessuna valutazione finora

- Analysis and Design of A Multi-Storey Reinforced ConcreteDocumento61 pagineAnalysis and Design of A Multi-Storey Reinforced ConcreteAnju KlNessuna valutazione finora

- Staad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1Documento17 pagineStaad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1kardels100% (14)

- Analysis and Design of Three Storey Framed BuildingDocumento74 pagineAnalysis and Design of Three Storey Framed BuildingUsman Afzal100% (1)

- Trane Product GuideDocumento249 pagineTrane Product GuideAnju Kl75% (4)

- RCC DesignsDocumento925 pagineRCC DesignsEmad Elhussieny100% (3)

- ETABS-Example-RC Building Seismic Load - Time HistoryDocumento59 pagineETABS-Example-RC Building Seismic Load - Time HistoryMauricio_Vera_5259100% (15)

- Moment Distribution MethodDocumento7 pagineMoment Distribution MethodAnju KlNessuna valutazione finora

- RCC DesignsDocumento925 pagineRCC DesignsEmad Elhussieny100% (3)

- Civil Engineering CompaniesDocumento1 paginaCivil Engineering CompaniesAnju KlNessuna valutazione finora

- Etabs Steel DesignDocumento60 pagineEtabs Steel DesignChayanon Hansapinyo100% (2)

- Primaver p3 Manual 3Documento47 paginePrimaver p3 Manual 3ramgavisNessuna valutazione finora

- 1Documento25 pagine1Anju KlNessuna valutazione finora

- Shedule of Bars 1Documento2 pagineShedule of Bars 1Anju KlNessuna valutazione finora

- IntroductionDocumento100 pagineIntroductionAnju KlNessuna valutazione finora

- Design of Through Type Plate GirderDocumento9 pagineDesign of Through Type Plate GirderAnju Kl0% (1)

- EstimationDocumento5 pagineEstimationAnju KlNessuna valutazione finora

- IntroductionDocumento100 pagineIntroductionAnju KlNessuna valutazione finora

- Deep BeamDocumento8 pagineDeep BeamShashikant Gaur0% (1)

- Dubai AirportFreezone Company ListDocumento50 pagineDubai AirportFreezone Company ListAnju Kl50% (6)

- ContentDocumento8 pagineContentAnju KlNessuna valutazione finora

- IntroductionDocumento100 pagineIntroductionAnju KlNessuna valutazione finora

- Calorie Chart For Indian FoodDocumento7 pagineCalorie Chart For Indian FoodAnju Kl100% (1)

- 1Documento25 pagine1Anju KlNessuna valutazione finora

- 1Documento25 pagine1Anju KlNessuna valutazione finora

- CementDocumento1 paginaCementAnju KlNessuna valutazione finora

- DM Condition & Specification of BuildingDocumento24 pagineDM Condition & Specification of BuildingAnju KlNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- CHAPTER 9 - FluidsDocumento26 pagineCHAPTER 9 - FluidsJanine Jade SetiasNessuna valutazione finora

- Citation510 MustangDocumento62 pagineCitation510 MustanglocoboeingNessuna valutazione finora

- AC 43-9-1 Amdt 0Documento15 pagineAC 43-9-1 Amdt 0Harry NuryantoNessuna valutazione finora

- SL 413Documento2 pagineSL 413Tim CuypersNessuna valutazione finora

- Airframe CARDocumento8 pagineAirframe CARChaaaNessuna valutazione finora

- Diffusion WeldingDocumento41 pagineDiffusion WeldingCool Sash S100% (3)

- EET-200E Encoder Emulator User Manual: Trans-Cal Industries, IncDocumento34 pagineEET-200E Encoder Emulator User Manual: Trans-Cal Industries, IncReginaldoNessuna valutazione finora

- 0Documento3 pagine0Brian NolascoNessuna valutazione finora

- Supersonic Combustion of Hydrogen Using AnDocumento14 pagineSupersonic Combustion of Hydrogen Using AnArun G NairNessuna valutazione finora

- Accessories: More of What You Need To Work Smarter, Faster, and Better. Visit The-Minute Accessory SelectionsDocumento32 pagineAccessories: More of What You Need To Work Smarter, Faster, and Better. Visit The-Minute Accessory SelectionsPartsGopher.comNessuna valutazione finora

- CWPHDocumento3 pagineCWPHVijay Kumar SiripurapuNessuna valutazione finora

- Gov Mock Congress BillDocumento2 pagineGov Mock Congress Billapi-303081350Nessuna valutazione finora

- Staubli RX170Documento3 pagineStaubli RX170JorgeValdzNessuna valutazione finora

- Sortie 129 (PFL, Steep Turns Revision)Documento12 pagineSortie 129 (PFL, Steep Turns Revision)Ethan PoonNessuna valutazione finora

- FMC Manual 747 PMDGDocumento56 pagineFMC Manual 747 PMDGanonymous100% (6)

- RAI LG LeverDocumento15 pagineRAI LG LeverAminur PahlawanNessuna valutazione finora

- SEMM1911 Case Study 2 2022Documento2 pagineSEMM1911 Case Study 2 2022Ruby RoseNessuna valutazione finora

- SanskardhamDroneAcademy BrochureDocumento11 pagineSanskardhamDroneAcademy BrochurePragnendra RahevarNessuna valutazione finora

- 37 Operational Emergency and Abnormal ProceduresDocumento40 pagine37 Operational Emergency and Abnormal ProceduresLucian Florin ZamfirNessuna valutazione finora

- Augmented Spark Gap Igniter For Propellants: Descr Mouser Part NumberDocumento3 pagineAugmented Spark Gap Igniter For Propellants: Descr Mouser Part NumberFrançois LeroyNessuna valutazione finora

- Earth's Rotation and Revolution (Grade 6) - Free Printable Tests and WorksheetsDocumento2 pagineEarth's Rotation and Revolution (Grade 6) - Free Printable Tests and WorksheetsCarl Maramag100% (7)

- FinalDocumento17 pagineFinalTonyNessuna valutazione finora

- Traffic Alert and Collision Avoidance System (TCAS II)Documento17 pagineTraffic Alert and Collision Avoidance System (TCAS II)Adil KhNessuna valutazione finora

- Sonic BoomDocumento43 pagineSonic BoomsubineeeNessuna valutazione finora

- Old SyllabusDocumento2 pagineOld Syllabusajd.nanthakumarNessuna valutazione finora

- Jeppesen 021 - 03 - PowerplantDocumento274 pagineJeppesen 021 - 03 - PowerplantSadcat97% (29)

- Aerospace: A View of The Earth's Atmosphere With The Moon BeyondDocumento5 pagineAerospace: A View of The Earth's Atmosphere With The Moon Beyondfriends_isNessuna valutazione finora

- Arch BridgeDocumento133 pagineArch BridgeLau Kim Hwa100% (2)

- FlightGroup HZS517-HZS518 RPLL-VHHH-RPLC STD122030 STD120001Documento37 pagineFlightGroup HZS517-HZS518 RPLL-VHHH-RPLC STD122030 STD120001Lavern SipinNessuna valutazione finora

- Flight Trajectory of A Golf Ball For A Realistic Game: Seongmin Baek and Myunggyu KimDocumento5 pagineFlight Trajectory of A Golf Ball For A Realistic Game: Seongmin Baek and Myunggyu KimKevinNessuna valutazione finora