Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

7a. Steel Pipeline Fitting

Caricato da

amaliabdulkaderCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

7a. Steel Pipeline Fitting

Caricato da

amaliabdulkaderCopyright:

Formati disponibili

CGD STEEL PIPELINE PROJECT

VOLUME II OF II - TECHNICAL

Bid Document No.:110299/WGI /GSPC GAS/ / 01-R0

SECTION 2

PIPING

GSPC GAS COMPANY LIMITED

CITY GAS DISTRIBUTION PROJECT

CLIENT JOB NO. -

PIPING MATERIAL SPECIFICATION

TOTAL SHEETS 18

DOCUMENT NO 11 0299 02 08 02 001

0 06/02/10 ISSUED FOR TENDER AS DDS PKS

A 04/02/10 ISSUED FOR IDC AS DDS PKS

REV DATE DESCRIPTION PREP CHK APPR

Document No. Rev

11-0299-02-08-02-001 0 PIPING MATERIAL SPECIFICATION

SHEET 2 of 18

TABLE OF CONTENT

CONTENT PAGE No.

GENERAL NOTES 3

DEFINITIONS 3

CODES AND STANDARDS 3

ABBREVIATIONS 4

PIPING CLASS DESCRIPTION 6

PIPING CLASS 1A1 7

PIPING CLASS 3A1 11

PIPING CLASS 6A1 15

Document No. Rev

11-0299-02-08-02-001 0 PIPING MATERIAL SPECIFICATION

SHEET 3 of 18

1.0 GENERAL NOTES

This specification describes the minimum requirements for the design, furnishing of materials,

fabrication, and inspection and testing of pipes, fittings and valves.

All material shall confirm to ASTM, API or BS standards. Design and fabrication shall confirm to

ASME for pressure piping, ASME B 31.3 Chemical Plant and petroleum Refinery Piping, and

ASME B 31.8 Gas transmission and Distribution piping system.

2.0 DEFINITIONS

Shall : This verbal form indicates requirements strictly to be followed in order

to confirm to the standards and from which no deviation is permitted.

Should : This verbal form indicates that among several possibilities one is

particularly suitable without mentioning or excluding others or that a

certain course of action is preferred but not necessarily required.

May : This verbal form indicates a course of action permissible within the

limits of this standard.

Can : This verbal form is used for statements of possibility & capability,

whether material, physical or casual.

3.0 CODES AND STANDARDS

The latest revision of the following shall be considered as part of this specification.

ASME B 16.5 Steel Pipe Flanges and Flanged Fittings

ASME B 16.9 Factory made Wrought Steel Butt welding Fittings

ASME B 16.10 Face to Face/ End to End dimension of valves.

ASME B 16.11 Forged Steel Fittings, Socket Welding and Threaded.

ASME B 16.20 Metallic Gaskets for Pipe Flanges.

ASME B 16.21 Non-Metallic Flat Gasket for Pipe Flanges

ASME B 16.47 Large Diameter Steel Flanges (26 throu 60)

ASME B 31.3 Process Piping

ASME B 31.4 Pipeline Transportation system for Liquid hydrocarbons & other Liquids

ASME B 31.8 Gas Transmissions and Distribution Piping System

ASME B 36.10 Welded and Seamless Wrought Steel Pipe

ASME B 46.1 Surface Texture

API 5L Line Pipe

Document No. Rev

11-0299-02-08-02-001 0 PIPING MATERIAL SPECIFICATION

SHEET 4 of 18

API 6D Pipeline Valves

API 590 Steel Line Blank

API 600 Steel Gate Valves Flanges and Butt welding Ends

API 602 Compact Steel Gate Valves

MSS SP 44 Steel Pipe line Flanges

MSS SP 75 Specification for High Test Wrought Butt Welding Fittings

MSS SP 97 Integrally Reinforced Forged Branch Outlet Fitting Socket Welding,

Threaded and Butt welding Ends

ASTM A 105 Forging, Carbon Steel for Piping Components

ASTM A 193 Alloy Steel and Stainless Steel bolting Materials for High temp Service.

ASTM A 194 Carbon and Alloy Steel Nuts for Bolts for High Pressure and High

Temperature Service

ASTM A 320 Standard Specification for Alloy Steel and Stainless Steel Bolting

Materials

ASTM A 216 Steel Casting, Carbon, Suitable for Fusion Welding, for High

Temperature Service.

ASTM A 234 Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate

and Elevated Temperature

ASTM A 694 Forging, Carbon and Alloy Steel, for Pipe Flanges, Fitting, Valves and

Parts for High Pressure Transmission Service.

ASTM A 333 Low temperature service seamless pipe.

ASTM A 350 Forged Carbon and Low Alloy Steel requiring Notch Toughness Testing

for Piping Components

ASTM A 420 Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low

Temperature Service.

ASTM A 860 Standard Specification for Wrought High Strength Low Alloy Steel Butt

Welding Fittings

4.0 ABBREVIATIONS

4.1 Flange Facing

RTJ - Ring Type Joint

FF - Flat Face

RF - Raised Face

Document No. Rev

11-0299-02-08-02-001 0 PIPING MATERIAL SPECIFICATION

SHEET 5 of 18

4.2 Fittings

PE - Plain End

BE - Bevel End

BW - Butt Weld

PBE - Plain Both End

POE - Plain One End

TBE - Threaded Both End

TOE - Threaded One End

LR - Long Radius

SR - Short Radius

4.3 Connections

BW - Butt-Weld

FLGD - Flanged

SCRD - Screwed

SO - Slip-On

SW - Socket Weld

THRD - Threaded

WN - Weld Neck

4.4 Wall Thickness

SCH - Schedule in accordance with ASME B 36.10 or B 36.19

STD - Standard Weight Wall Thickness

XS - Extra Strong Wall Thickness

XXS - Double Extra Strong Wall Thickness

4.5 Valve Description

BC - Bolted Cap

BB - Bolted Bonnet

ES - Extension Stem

FB - Full Bore

MO - Motor Operated

GO - Gear Operated

NRS - Non-Rising Stem (with inside screw)

OS&Y - Outside Screw and Yoke

RB - Reducer Bore

RS - Rising Stem

SC - Screwed Cap

UB - Union Bonnet

UC - Union Cap

WB - Welded Bonnet

4.6 Pipes Description

BE - Beveled End

CS - Carbon Steel

ERW - Electric Resistance Welded

EFW - Electric Fusion Welded

FS - Forged Steel

HFI - High Frequency Induction

KCS - Killed Carbon Steel

KFS - Killed Forged Steel

Document No. Rev

11-0299-02-08-02-001 0 PIPING MATERIAL SPECIFICATION

SHEET 6 of 18

OH - Open Hearth

SAW - Submerged Arc Welded

SMLS - Seamless

5.0 PIPING CLASSES DESCRIPTION

Piping Classes assigned for the project are based on the following 2-digit system.

First Digit

Numerical, denoting the basic system rating or flange class

i.e. 1 = ASME Class 150

3 = ASME Class 300

6 = ASME Class 600

9 = ASME Class 900

Second Digit

Letter, denoting the material

A - Carbon Steel

C - Stainless Steel

F - Fiberglass Reinforced plastic/epoxy (FRP)

G - Galvanized

P - Plastic (PEHD)

S - Stainless Steel

V - PVC

Third Digit

Sequential number to differentiate two or more piping classes of the same rating and same

material but presenting some difference related to the handled fluid.

Fourth Digit

Letter, denoting the aboveground and underground

U = Underground

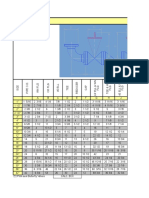

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL

CODE FROM- AND/OR STANDARD

THRU SCHED.

PIPELINE PL 4"-8" BE 6.4 mm API 5L API 5L Gr. X42

10" BE 6.4 mm API 5L API 5L Gr. X52

PIPES P 0.50" - 1.50" PE, SEAMLESS S160 ASME B36-10 ASTM A 106 Gr.B

2" BE, SEAMLESS S80 ASME B36-10 ASTM A 106 Gr.B

3" - 16" BE, SEAMLESS S40 ASME B36-10 ASTM A 106 Gr.B

ELBOWS 90 LR E 0.50" - 1.50" SW

3000#

ASME B16.11 ASTM A105

2" - 16" BW, 1.5D, 3D M ASME B16.9 ASTM A 234 Gr WPB

ELBOWS 45 LR E45 0.50" - 1.50" SW

3000#

ASME B16.11 ASTM A105

2" - 16" BW, 1.5D, 3D M ASME B16.9 ASTM A 234 Gr WPB

LR Bends 90 LR B 4-16" BW, 3D M ASME B16.9 ASTM A 234 Gr WPB

LR Bends 45 LR B 45 4-16" BW, 3D M ASME B16.9 ASTM A 234 Gr WPB

REDUCERS RC 2" - 16" BW - ASME B16-25 M X M ASME B16-9 ASTM A 234 Gr WPB

CONCENTRIC

REDUCERS RE 2" - 16" BW - ASME B16-25 M X M ASME B16-9 ASTM A 234 Gr WPB

ECCENTRIC

TEES EQUAL T 0.50" - 1.50" SW

3000#

ASME B16.11 ASTM A105

2" - 16" BW M ASME B16.9 ASTM A 234 Gr WPB

TEES RED TR 0.50" - 1.50" SW

3000#

ASME B16.11 ASTM A105

2" - 16" BW M X M ASME B16.9 ASTM A 234 Gr WPB

SOCKOLET S 0.50" - 1.50" SW

3000#

MSS-SP 75 ASTM A105

WELDOLETS W 2" - 16" BW - ASME B16-25 M X M MSS-SP 75 ASTM A105

CAPS C 0.50" - 1.50" SCRF

3000#

ASME B16.11 ASTM A105

2" - 16" BW M ASME B16-9 ASTM A 234 Gr WPB

NIPPLES NA 0.50" - 1.50" PBE, SEAMLESS M ASME B36-10 ASTM A 106 Gr.B

FULL

COUPLINGS FC 0.50" - 1.50" SW 3000#

ASME B16-11 ASTM A105

HALF HC 0.50" - 1.50" SW 3000#

COUPLINGS

NOTE: M=THICKNESS TO MATCH PIPE WALL THICKNESS

Rev

0

RATING 150#

CODE ANSI B 31.8

BASIC MATERIAL

CORROSION ALL. 0.5 mm

PIPING SPECIFICATION

GSPC GAS COMPANY LIMITED

1A1

TEMPERATURE ( 0 TO 60 C)

PRESSURE (18.75 bar g)

REMARKS

4"-6" :Seamless

8" :Electric Welded

Electric Welded

Document No.

11-0299-02-08-02-001

PIPING MATERIAL SPECIFICATION

ASME B16-11 ASTM A105

Sheet 7 of 18

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL

CODE FROM- AND/OR STANDARD

THRU SCHED.

WN FLANGES FW 0.50"-16" RF,125 AARH 150# ASME B16-5

BLIND FB 0.50"-16" RF,125 AARH 150# ASMEB16-5

FLANGE

FLANGES FF 0.5" - 16" RF,125 AARH 150# ASME B16-48

FIG 8

SPCR & FSB 16" RF,125 AARH 150# ASME B16-48

BLND

STUD BOLTS B 0.5" - 16" ASME B18-2 Bolt: A193 B7

Nut: A194 Gr.2H

GASKETS G 0.5" - 16" 150#, SPIRAL B-16.20 - SP. WND

SPIRAL ASME B16.5

metallic with

Graphite Filler

WOUND (5 mm thick)

GATE VG 0.50 - 1.50 SW , B16.11 800# API 602 ASTM A105

VALVE 2''-16''

FLG, B16.5,

RF/125 AARH 150# API 600 ASTM A 216 Gr WCB

0.50 - 1.50 SW,BS-5353 800# ASME B16.10 ASTM A105

2''-16'' FLG/BW,API6D 150# ASME B16.10 ASTM A 216 Gr WCB

NOTE: M=THICKNESS TO MATCH PIPE WALL THICKNESS

Rev.

0

ASTM A105

ASTM A105

ASTM A105

ASTM A105

Sheet 8 of 18

PIPING MATERIAL SPECIFICATION

Document No.

11-0299-02-08-02-001

GSPC GAS COMPANY LIMITED

PIPING SPECIFICATION

1A1

TEMPERATURE( 0 TO 60 C)

PRESSURE (18.75 bar g)

RATING 150#

CODE ANSI B 31.8

BASIC MATERIAL

CORROSION ALLOWANCE 0.5 mm

REMARKS

PLUG

VALVE

PV

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL

CODE FROM- AND/OR STANDARD

THRU SCHED.

BALL VBA 0.50'' - 1.50'' SW:ASME B16-11 800# ASME B16-10 BODY:

VALVES ASTM A105

BALL:

SS 316

2"-3" BW:ASME B16-5 150# ASME B16-10 BODY:

ASTM A216 Gr. WCB

BALL:

(A 216 Gr. WCB)

+ 0.003" ENP

4"-16" BW:ASME B16-5 150 # ASME B16-10 BODY:

ASTM A216 Gr. WCB

BALL:

(A 216 Gr. WCB)

+ 0.003" ENP

GLOBE VGL 0.50'' - 1.50'' SW 800# ASME B16-10 BODY:

VALVES ASME B16-11 ASTM A 105

TRIM:

ASTM A182 F6

2" - 16" FLGD RF 150# ASME B16-10 BODY:

ASME B16-5 ASTM A 216 Gr. WCB

TRIM:

ASTM A182 F6

LIFT CHECK 0.50'' - 1.50'' SW 800# ASME B16-10 BODY:

VALVES ASME B16-11 ASTM A 105

TRIM:

ASTM A182 F6

2"-16" FLGD RF 150# ASME B16-10 BODY:

ASME B16-5 ASTM A 216 Gr. WCB

TRIM:

ASTM A182 F6

NOTE: M=THICKNESS TO MATCH PIPE WALL THICKNESS

Document No. Rev.

Sheet 9 of 18

HORIZONTAL INSTALLATION

VERTICAL INSTALLATION FLOW

UPWARDS

11-0299-02-08-02-001 0

FIRE SAFE

HORIZONTAL INSTALLATION

FIRE SAFE

HANDWHEEL

FIRE SAFE

GEAR OPERATED.

HANDWHEEL

FIRE SAFE

WRENCH OPERATED.

FULL BORE

FIRE SAFE

WRENCH OPERATED.

FULL BORE

REMARKS

FULL BORE

PIPING MATERIAL SPECIFICATION

PIPING SPECIFICATION

1A1

TEMPERATURE ( 0 TO 60 C)

SWING CHECK

VALVE

VCH

RATING 150#

CODE ANSI B 31.8

PRESSURE (18.75 bar g)

GSPC GAS COMPANY LIMITED

BASIC MATERIAL

CORROSION ALLOWANCE 0.5 mm

B R A N C H S I Z E

1/2" 3/4" 1" 1.1/2" 2" 3" 4" 6" 8" 10" 12" 14" 16"

1/2" T

3/4" T T

H 1" T T T

E 1.1/2" T T T T

A 2" S T T T T

D 3" S S S S T T

E 4" S S S S T T T

R 6" S S S S W T T T

8" S S S S W W T T T

S 10" S S S S W W T T T T

I 12" S S S S W W W T T T T

Z 14" S S S S W W W T T T T T

E 16" S S S S W W W T T T T T T

LEGEND

T : TEE

S: SOCKOLET - SW

W : WELDOLET - BW

Rev.

0

PIPING MATERIAL SPECIFICATION

Sheet 10 of 18

Document No.

11-0299-02-08-02-001

RATING 150#

CORROSION ALW 0.5 mm

CODE ANSI B 31.8

BRANCH TABLE

BASIC MATERIAL

GSPC GAS COMPANY LIMITED

PIPING SPECIFICATION

1A1

TEMPERATURE ( 0 TO 60 C)

PRESSURE (18.75 bar g)

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL REMARKS

CODE FROM- AND/OR STANDARD

THRU SCHED.

PIPELINE PL 4"-8" BE 6.4 mm API 5L

API 5L Gr. X42

10" BE 6.4 mm API 5L

API 5L Gr. X52

PIPES P 0.50" - 1." PE, SEAMLESS S160 ASME B36-10 ASTM A 106 Gr.B

1.5" PE, SEAMLESS S80 ASME B36-10 ASTM A 106 Gr.B

2" BE, SEAMLESS S80 ASME B36-10 ASTM A 106 Gr.B

3" - 16" BE, SEAMLESS S40 ASME B36-10 ASTM A 106 Gr.B

ELBOWS 90 LR E 0.50" - 1.50" SW 3000# ASME B16.11 ASTM A105

2" - 16" BW, 1.5D, 3D M ASME B16.9 ASTM A 234 Gr WPB

ELBOWS 45 LR E45 0.50" - 1.50" SW 3000# ASME B16.11 ASTM A105

2" - 16" BW, 1.5D, 3D M ASME B16.9 ASTM A 234 Gr WPB

LR Bends 90 LR B 4-16" BW, 3D M ASME B16.9 ASTM A 234 Gr WPB

LR Bends 45 LR B 45 4-16" BW, 3D M ASME B16.9 ASTM A 234 Gr WPB

REDUCERS RC 2" - 16" BW - ASME B16-25 M X M ASME B16-9 ASTM A 234 Gr WPB

CONCENTRIC

REDUCERS RE 2" - 16" BW - ASME B16-25 M X M ASME B16-9 ASTM A 234 Gr WPB

ECCENTRIC

TEES EQUAL T 0.50" - 1.50" SW 3000# ASME B16.11 ASTM A105

2" - 16" BW M X M ASME B16.9 ASTM A 234 Gr WPB

TEES RED TR 0.50" - 1.50" SW 3000# ASME B16.11 ASTM A105

2" - 16" BW M X M ASME B16.9 ASTM A 234 Gr WPB

SOCKOLET S SW 3000#

MSS-SP 75 ASTM A105

WELDOLETS W 2" - 16" BW - ASME B16-25 M X M MSS-SP 75 ASTM A105

CAPS C 2" - 16" BW M ASME B16-9 ASTM A 234 Gr WPB

NIPPLES NA 0.50" - 1.50" PBE, SEAMLESS M ASME B36-10 ASTM A 106 Gr.B

FULL FC 0.50" - 1.50" SW 3000#

ASME B16-11 ASTM A105

COUPLINGS

HALF HC 0.50" - 1.50" SW 3000#

ASME B16-11 ASTM A105

COUPLINGS

NOTE: M=THICKNESS TO MATCH PIPE WALL THICKNESS

Rev.

0

PIPING SPECIFICATION

3A1

PIPING MATERIAL SPECIFICATION

TEMPERATURE ( 0 TO 60 C)

PRESSURE (49 bar g)

GSPC GAS COMPANY LIMITED

Sheet 11 of 18

Document No.

RATING 300#

CODE ANSI B 31.8

BASIC MATERIAL

CORROSION ALLOWANCE 0.5 mm

0.50" - 1.50"

4"-6" :Seamless

8" :Electric Welded

Electric Welded

11-0299-02-08-02-001

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL REMARKS

CODE FROM- AND/OR STANDARD

THRU SCHED.

WN FLANGES FW 2"-16" RF, 125 AARH 300# ASME B16-5

FLG SW FS 0.50 - 1.50 RF, 125 AARH 300# ASME B16-5

BLIND FB 0.50"-16" RF, 125 AARH 300# ASME B16-5

FLANGE

FLANGES FF 0.5" - 16" FF, 125 AARH 300# ASME B16-48

FIG 8

SPCR & FSB 16" FF, 125 AARH 300# ASMEB16-48

BLND

STUD BOLTS B 0.50" - 16'' ASME B18-2 Bolt: A193 B7

Nut: A194 Gr.2H

GASKETS G 0.5" - 16" SPIRAL, 300# B-16.20 - SP. WND

SPIRAL ASME B16.5

metallic with

Graphite Filler

WOUND (5 mm thick)

GATE VG 0.50 - 1.50 SW 800# API 602 ASTM A105

VALVE B16.11

2" - 16" FLGD, B-16.5, 300# API 600 ASTM A 216 Gr WCB

RF/125 AARH

PLUG VP 0.50" - 1.50"

SW, BS -5353

800#

ASME B16-10

ASTM A105

VALVE 2" - 16"

FLG/ BW, API 6D

300#

ASME B16-10

ASTM A 216 Gr WCB

Rev.

0

NOTE: M=THICKNESS TO MATCH PIPE WALL THICKNESS

PIPING MATERIAL SPECIFICATION

Document No.

11-0299-02-08-02-001

Sheet 12 of 18

PRESSURE (49 bar g)

GSPC GAS COMPANY LIMITED

PIPING SPECIFICATION

3A1

TEMPERATURE ( 0 TO 60 C)

RATING 300#

CODE ANSI B 31.8

BASIC MATERIAL

CORROSION ALLOWANCE 0.5 mm

ASTM A105

ASTM A105

ASTM A105

ASTM A105

ASTM A105

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL REMARKS

CODE FROM- AND/OR STANDARD

THRU SCHED.

BALL VBA 0.50 - 1.50 SW, ASME B16-11 300# ASME B16-10 BODY: FULL BORE

VALVES BS 5351 ASTM A105 FIRE SAFE

BALL:SS 316 WRENCH OPERATED.

BODY SEAT: RPTFE

2" FLGD RF:ASME B16-5 300# ASME B16-10 BODY: FULL BORE, FIRE SAFE, WRENCH OPERATED

or BW :ASME B16-5 BS 5351 ASTM A216 Gr. WCB

BALL:

(A 216 Gr. WCB)

+ 0.003" ENP

BODY SEAT: RPTFE

3" - 4" FLGD RF:ASME B16-5 300# ASME B16-10 BODY: DOUBLE BLOCK AND BLEED

or BW :ASME B16-5 BS 5351 ASTM A216 Gr. WCB FULL BORE

(A 216 Gr. WCB)

+ 0.003" ENP FIRE SAFE

BODY SEAT: RPTFE WRENCH OPERATED.

6"-16'' FLGD RF:ASME B16-5 300# ASME B16-10 BODY: DOUBLE BLOCK AND BLEED

or BW :ASME B16-5 BS 5351 ASTM A216 Gr. WCB FULL BORE

(A 216 Gr. WCB)

+ 0.003" ENP FIRE SAFE

BODY SEAT: RPTFE GEAR OPERATED.

GLOBE VGL 0.50 - 1.50 SW, ASME B16-11 300# ASME B16-10 BODY: HANDWHEEL

VALVES BS 5352 ASTM A 216 Gr. WCB FIRE SAFE

TRIM:

ASTM A182 F6

2" - 4" FLGD RF:ASME B16-5 300# ASMEB16-10 BODY: HANDWHEEL

BS 1873 ASTM A 216 Gr. WCB FIRE SAFE

TRIM:

ASTM A182 F6

6" - 16" FLGD RF:ASME B16-5 300# ASME B16-10 BODY: GEAR OPERATED

BS 1873 ASTM A 216 Gr. WCB FIRE SAFE

TRIM:

ASTM A182 F6

LIFT CHECK 0.50 - 1.50 SW, ASME B16-11 300# ASME B16-10 BODY: HORIZONTAL INSTALLATION

VALVES BS 5352 ASTM A 105

TRIM:

ASTM A182 F6

2"-16'' FLGD RF:ASME B16-5 300# ASME B16-10 BODY: HORIZONTAL INSTALLATION

BS 1868 ASTM A 216 Gr. WCB VERTICAL INSTALLATION FLOW UPWARDS

TRIM:

ASTM A182 F6

Document No. Rev.

11-0299-02-08-02-001 0

TEMPERATURE ( 0 TO 60 C)

VCH

SWING

CHECK

VALVE

PIPING MATERIAL SPECIFICATION

Sheet 13 of 18

NOTE: M=THICKNESS TO MATCH PIPE WALL THICKNESS

RATING 300#

CODE ANSI B 31.8

BASIC MATERIAL

CORROSION ALLOWANCE 0.5 mm

PRESSURE (49 bar g)

GSPC GAS COMPANY LIMITED

PIPING SPECIFICATION

3A1

B R A N C H S I Z E

1/2" 3/4" 1" 1.1/2" 2" 3" 4" 6" 8" 10" 12" 14" 16"

H 1/2" T

E 3/4" T T

A 1" T T T

D 1.1/2" T T T T

E 2" S T T T T

R 3" S S S S T T

4" S S S S T T T

S 6" S S S S W T T T

I 8" S S S S W W T T T

Z 10" S S S S W W T T T T

E 12" S S S S W W W T T T T

14" S S S S W W W T T T T T

16" S S S S W W W T T T T T T

LEGEND

T : TEE

S: SOCKOLET -SW

W : WELDOLET- BW

Rev.

0

PIPING SPECIFICATION

GSPC GAS COMPANY LIMITED

RATING 300#

3A1

CODE ANSI B 31.8

TEMPERATURE ( 0 TO 60 C)

BASIC MATERIAL

PRESSURE (49 bar g)

CORROSION ALW 0.5 mm

Document No.

11-0299-02-08-02-001

BRANCH TABLE

PIPING MATERIAL SPECIFICATION

Sheet 14 of 18

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL REMARKS

CODE FROM- AND/OR STANDARD

THRU SCHED.

PIPELINE PL 4"-8" BE 6.4 mm API 5L

API 5L Gr. X42

10" BE 6.4 mm API 5L

API 5L Gr. X52

PIPES P 0.50" - 1.5" PE, SEAMLESS S160 ASME B36-10 ASTM A 106 Gr.B

2"-10" BE, SEAMLESS S80 ASME B36-10 ASTM A 106 Gr.B

12" - 16" BE, SEAMLESS S60 ASME B36-10 ASTM A 106 Gr.B

ELBOWS 90 LR E 0.50" - 1.50" SW 6000# ASME B16.11 ASTM A105

2" - 16" BW, 1.5D, 3D M ASME B16.9 ASTM A 234 Gr WPB

ELBOWS 45 LR E45 0.50" - 1.50" SW 6000# ASME B16.11 ASTM A105

2" - 16" BW, 1.5D, 3D M ASME B16.9 ASTM A 234 Gr WPB

LR Bends 90 LR B 4-16" BW, 3D M ASME B16.9 ASTM A 234 Gr WPB

LR Bends 45 LR B 45 4-16" BW, 3D M ASME B16.9 ASTM A 234 Gr WPB

REDUCERS RC 2" - 16" BW - ASME B16-25 M X M ASME B16-9 ASTM A 234 Gr WPB

CONCENTRIC

REDUCERS RE 2" - 16" BW - ASME B16-25 M X M ASME B16-9 ASTM A 234 Gr WPB

ECCENTRIC

TEES EQUAL T 0.50" - 1.50" SW 6000# ASME B16.11 ASTM A105

2" - 16" BW M X M ASME B16.9 ASTM A 234 Gr WPB

TEES RED TR 0.50" - 1.50" SW 6000# ASME B16.11 ASTM A105

2" - 16" BW M X M ASME B16.9 ASTM A 234 Gr WPB

SOCKOLET S SW 6000#

MSS-SP 97 ASTM A105

WELDOLETS W 2" - 16" BW - ASME B16-25 M X M MSS-SP 97 ASTM A105

CAPS C 2" - 16" BW M ASME B16-9 ASTM A 234 Gr WPB

NIPPLES NA 0.50" - 1.50" PBE, SEAMLESS M ASME B36-10 ASTM A 106 Gr.B

FULL FC 0.50" - 1.50" SW 6000#

ASME B16-11 ASTM A105

COUPLINGS

HALF HC 0.50" - 1.50" SW 6000#

ASME B16-11 ASTM A105

COUPLINGS

NOTE: M=THICKNESS TO MATCH PIPE WALL THICKNESS

Rev.

0

4"-6" :Seamless

8" :Electric Welded

Electric Welded

11-0299-02-08-02-001

0.50" - 1.50"

RATING 600#

CODE ANSI B 31.8

BASIC MATERIAL

CORROSION ALLOWANCE 0.5 mm

PIPING SPECIFICATION

6A1

PIPING MATERIAL SPECIFICATION

TEMPERATURE ( 0 TO 60 C)

PRESSURE (98 bar g)

GSPC GAS COMPANY LIMITED

Sheet 15 of 18

Document No.

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL REMARKS

CODE FROM- AND/OR STANDARD

THRU SCHED.

WN FLANGES FW 2"-16" RF, 125 AARH 600# ASME B16-5

FLG SW FS 0.50 - 1.50 RF, 125 AARH 600# ASME B16-5

BLIND FB 0.50"-16" RF, 125 AARH 600# ASME B16-5

FLANGE

FLANGES FF 0.5" - 16" FF, 125 AARH 600# ASME B16-48

FIG 8

SPCR & FSB 16" FF, 125 AARH 600# ASMEB16-48

BLND

STUD BOLTS B 0.50" - 16'' ASME B18-2 Bolt: A193 B7

Nut: A194 Gr.2H

GASKETS G 0.5" - 16" SPIRAL, 600# B-16.20 - SP. WND

SPIRAL ASME B16.5

metallic with

Graphite Filler

WOUND (5 mm thick)

GATE VG 0.50 - 1.50 SW 800# API 602 ASTM A105

VALVE B16.11

2" - 16" FLGD, B-16.5, 600# API 600 ASTM A 216 Gr WCB

RF/125 AARH

PLUG VP 0.50" - 1.50"

SW, BS -5353

800#

ASME B16-10

ASTM A105

VALVE 2" - 16"

FLG/ BW, API 6D

600#

ASME B16-10

ASTM A 216 Gr WCB

Rev.

0

ASTM A105

ASTM A105

ASTM A105

ASTM A105

ASTM A105

RATING 600#

CODE ANSI B 31.8

BASIC MATERIAL

CORROSION ALLOWANCE 0.5 mm

PRESSURE (98 bar g)

GSPC GAS COMPANY LIMITED

PIPING SPECIFICATION

6A1

TEMPERATURE ( 0 TO 60 C)

NOTE: M=THICKNESS TO MATCH PIPE WALL THICKNESS

PIPING MATERIAL SPECIFICATION

Document No.

11-0299-02-08-02-001

Sheet 16 of 18

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL REMARKS

CODE FROM- AND/OR STANDARD

THRU SCHED.

BALL VBA 0.50 - 1.50 SW, ASME B16-11 600# ASME B16-10 BODY: FULL BORE

VALVES BS 5351 ASTM A105 FIRE SAFE

BALL:SS 316 WRENCH OPERATED.

BODY SEAT: RPTFE

2" FLGD RF:ASME B16-5 600# ASME B16-10 BODY: FULL BORE, FIRE SAFE, WRENCH OPERATED

or BW :ASME B16-5 BS 5351 ASTM A216 Gr. WCB

BALL:

(A 216 Gr. WCB)

+ 0.003" ENP

BODY SEAT: RPTFE

3" - 4" FLGD RF:ASME B16-5 600# ASME B16-10 BODY: DOUBLE BLOCK AND BLEED

or BW :ASME B16-5 BS 5351 ASTM A216 Gr. WCB FULL BORE

(A 216 Gr. WCB)

+ 0.003" ENP FIRE SAFE

BODY SEAT: RPTFE WRENCH OPERATED.

6"-16'' FLGD RF:ASME B16-5 600# ASME B16-10 BODY: DOUBLE BLOCK AND BLEED

or BW :ASME B16-5 BS 5351 ASTM A216 Gr. WCB FULL BORE

(A 216 Gr. WCB)

+ 0.003" ENP FIRE SAFE

BODY SEAT: RPTFE GEAR OPERATED.

GLOBE VGL 0.50 - 1.50 SW, ASME B16-11 600# ASME B16-10 BODY: HANDWHEEL

VALVES BS 5352 ASTM A 216 Gr. WCB FIRE SAFE

TRIM:

ASTM A182 F6

2" - 4" FLGD RF:ASME B16-5 600# ASMEB16-10 BODY: HANDWHEEL

BS 1873 ASTM A 216 Gr. WCB FIRE SAFE

TRIM:

ASTM A182 F6

6" - 16" FLGD RF:ASME B16-5 600# ASME B16-10 BODY: GEAR OPERATED

BS 1873 ASTM A 216 Gr. WCB FIRE SAFE

TRIM:

ASTM A182 F6

LIFT CHECK 0.50 - 1.50 SW, ASME B16-11 600# ASME B16-10 BODY: HORIZONTAL INSTALLATION

VALVES BS 5352 ASTM A 105

TRIM:

ASTM A182 F6

2"-16'' FLGD RF:ASME B16-5 600# ASME B16-10 BODY: HORIZONTAL INSTALLATION

BS 1868 ASTM A 216 Gr. WCB VERTICAL INSTALLATION FLOW UPWARDS

TRIM:

ASTM A182 F6

Document No. Rev.

11-0299-02-08-02-001 0

Sheet 17 of 18

NOTE: M=THICKNESS TO MATCH PIPE WALL THICKNESS

RATING 600#

CODE ANSI B 31.8

BASIC MATERIAL

CORROSION ALLOWANCE 0.5 mm

PRESSURE (98 bar g)

GSPC GAS COMPANY LIMITED

PIPING SPECIFICATION

6A1

TEMPERATURE ( 0 TO 60 C)

VCH

SWING

CHECK

VALVE

PIPING MATERIAL SPECIFICATION

B R A N C H S I Z E

1/2" 3/4" 1" 1.1/2" 2" 3" 4" 6" 8" 10" 12" 14" 16"

H 1/2" T

E 3/4" T T

A 1" T T T

D 1.1/2" T T T T

E 2" S T T T T

R 3" S S S S T T

4" S S S S T T T

S 6" S S S S W T T T

I 8" S S S S W W T T T

Z 10" S S S S W W T T T T

E 12" S S S S W W W T T T T

14" S S S S W W W T T T T T

16" S S S S W W W T T T T T T

LEGEND

T : TEE

S: SOCKOLET -SW

W : WELDOLET- BW

Rev.

0

Document No.

11-0299-02-08-02-001

BRANCH TABLE

PIPING MATERIAL SPECIFICATION

Sheet 18 of 18

PIPING SPECIFICATION

GSPC GAS COMPANY LIMITED

RATING 600#

6A1

CODE ANSI B 31.8

TEMPERATURE ( 0 TO 60 C)

BASIC MATERIAL

PRESSURE (98 bar g)

CORROSION ALW 0.5 mm

GSPC GAS LIMITED

CITY GAS DISTRIBUTION PROJECT

CLIENT JOB NO. -

PIPING MATERIAL SPECIFICATION

TOTAL SHEETS 18

DOCUMENT NO 11 0299 02 08 02 002

0 06/02/10 ISSUED FOR TENDER AS DDS PKS

A 04/02/10 ISSUED FOR IDC AS DDS PKS

REV DATE DESCRIPTION PREP CHK APPR

Document No. Rev

11-0299-02-08-02-002 0 PIPING MATERIAL SPECIFICATION

SHEET 2 of 18

TABLE OF CONTENT

CONTENT PAGE No.

GENERAL NOTES 3

DEFINITIONS 3

CODES AND STANDARDS 3

ABBREVIATIONS 4

PIPING CLASS DESCRIPTION 6

PIPING CLASS 1A1 7

PIPING CLASS 3A1 11

PIPING CLASS 6A1 15

Document No. Rev

11-0299-02-08-02-002 0 PIPING MATERIAL SPECIFICATION

SHEET 3 of 18

1.0 GENERAL NOTES

This specification describes the minimum requirements for the design, furnishing of materials,

fabrication, inspection and testing of pipes, fittings and valves.

All material shall confirm to ASTM, API or BS standards. Design and fabrication shall confirm to ANSI

/ ASME for pressure piping, ANSI B 31.3 Chemical Plant and petroleum Refinery Piping, and ANSI

B 31.8 Gas transmission and Distribution piping system.

2.0 DEFINITIONS

Shall : This verbal form indicates requirements strictly to be followed in order

to confirm to the standards and from which no deviation is permitted.

Should : This verbal form indicates that among several possibilities one is

particularly suitable without mentioning or excluding others or that a

certain course of action is preferred but not necessarily required.

May : This verbal form indicates a course of action permissible within the

limits of this standard.

Can : This verbal form is used for statements of possibility & capability,

whether material, physical or casual.

3.0 CODES AND STANDARDS

The latest revision of the following shall be considered as part of this specification.

ASME B 16.5 Steel Pipe Flanges and Flanged Fittings

ASME B 16.9 Factory made Wrought Steel Butt welding Fittings

ASME B 16.11 Forged Steel Fittings, Socket Welding and Threaded

ASME B 16.20 Metallic Gaskets for Pipe Flanges.

ASME B 16.21 Non-Metallic Flat Gasket for Pipe Flanges

ASME B 16.47 Large Diameter Steel Flanges (26 throu 60)

ASME B 31.3 Process Piping

ASME B 31.4 Pipeline Transportation system for Liquid hydrocarbons & other Liquids

ASME B 31.8 Gas Transmissions and Distribution Piping System

ASME B 36.10 Welded and Seamless Wrought Steel Pipe

ASME B 46.1 Surface Texture

API 5L Line Pipe

API 6D Pipeline Valves

API 590 Steel Line Blank

Document No. Rev

11-0299-02-08-02-002 0 PIPING MATERIAL SPECIFICATION

SHEET 4 of 18

API 600 Steel Gate Valves Flanges and Butt welding Ends

API 602 Compact Steel Gate Valves

MSS SP 44 Steel Pipe line Flanges

MSS SP 75 Specification for High Test Wrought Butt Welding Fittings

MSS SP 97 Integrally Reinforced Forged Branch Outlet Fitting Socket Welding,

Threaded and Butt welding Ends

ASTM A 105 Forging, Carbon Steel for Piping Components

ASTM A 193 Alloy Steel and Stainless Steel bolting Materials for High temp Service.

ASTM A 194 Carbon and Alloy Steel Nuts for Bolts for High Pressure and High

Temperature Service

ASTM A 320 Standard Specification for Alloy Steel and Stainless Steel Bolting

Materials

ASTM A 216 Steel Casting, Carbon, Suitable for Fusion Welding, for High

Temperature Service.

ASTM A 234 Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate

and Elevated Temperature

ASTM A 285 Pressure Vessel Plates, Carbon Steel, Low and Intermediate Tensile

Strength.

ASTM A 694 Forging, Carbon and Alloy Steel, for Pipe Flanges, Fitting, Valves and

Parts for High Pressure Transmission Service.

ASTM A 333 Low temperature service seamless pipe.

ASTM A 350 Forged Carbon and Low Alloy Steel requiring Notch Toughness Testing

for Piping Components

ASTM A 420 Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low

Temperature Service.

ASTM A 860 Standard Specification for Wrought High Strength Low Alloy Steel Butt

Welding Fittings

4.0 ABBREVIATIONS

4.1 Flange Facing

RTJ - Ring Type Joint

FF - Flat Face

RF - Raised Face

Document No. Rev

11-0299-02-08-02-002 0 PIPING MATERIAL SPECIFICATION

SHEET 5 of 18

4.2 Fittings

PE - Plain End

BE - Bevel End

BW - Butt Weld

PBE - Plain Both End

POE - Plain One End

TBE - Threaded Both End

TOE - Threaded One End

LR - Long Radius

SR - Short Radius

4.3 Connections

BW - Butt-Weld

FLGD - Flanged

SCRD - Screwed

SO - Slip-On

SW - Socket Weld

THRD - Threaded

WN - Weld Neck

4.4 Wall Thickness

SCH - Schedule in accordance with ANSI B 36.10 or B 36.19

STD - Standard Weight Wall Thickness

XS - Extra Strong Wall Thickness

XXS - Double Extra Strong Wall Thickness

4.5 Valve Description

BC - Bolted Cap

BB - Bolted Bonnet

ES - Extension Stem

FB - Full Bore

MO - Motor Operated

GO - Gear Operated

NRS - Non-Rising Stem (with inside screw)

OS&Y - Outside Screw and Yoke

RB - Reducer Bore

RS - Rising Stem

SC - Screwed Cap

UB - Union Bonnet

UC - Union Cap

WB - Welded Bonnet

4.6 Pipes Description

BE - Beveled End

CS - Carbon Steel

ERW - Electric Resistance Welded

EFW - Electric Fusion Welded

FS - Forged Steel

HFI - High Frequency Induction

KCS - Killed Carbon Steel

KFS - Killed Forged Steel

OH - Open Hearth

SAW - Submerged Arc Welded

SMLS - Seamless

Document No. Rev

11-0299-02-08-02-002 0 PIPING MATERIAL SPECIFICATION

SHEET 6 of 18

5.0 PIPING CLASSES DESCRIPTION

Piping Classes assigned for the project are based on the following 2-digit system.

First Digit

Numerical, denoting the basic system rating or flange class

i.e. 1 = ASME Class 150

3 = ASME Class 300

6 = ASME Class 600

9 = ASME Class 900

Second Digit

Letter, denoting the material

A - Carbon Steel

C - Stainless Steel

F - Fiberglass Reinforced plastic/epoxy (FRP)

G - Galvanized

P - Plastic (PEHD)

S - Stainless Steel

V - PVC

Third Digit

Sequential number to differentiate two or more piping classes of the same rating and same

material but presenting some difference related to the handled fluid.

Fourth Digit

Letter, denoting the aboveground and underground

U = Underground

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL

CODE FROM- AND/OR STANDARD

THRU SCHED.

PIPES P 0.50" - 0.75" PE, SEAMLESS S160 ANSI B36-10 ASTM A333 GR 6

1" -1.50" PE, SEAMLESS S160 ANSI B36-10 ASTM A333 GR 6

2" BE, SEAMLESS S160 ANSI B36-10 ASTM A333 GR 6

3" - 14" BE, SEAMLESS STD ANSI B36-10 ASTM A333 GR 6

ELBOWS 90 LR E 0.50" - 1.50" SW

3000#

ANSI B16.11 ASTM A350 Gr. LF2

2" - 14" BW, 1.5D M ANSI B16.9 ASTM A420 WPL 6

ELBOWS 45 LR E45 0.50" - 1.50" SW

3000#

ANSI B16.11 ASTM A350 Gr. LF2

2" - 14" BW, 1.5D M ANSI B16.9 ASTM A420 WPL 6

REDUCERS RC 2" - 14" BW - ANSI B16-25 M,M ANSI B16-9 ASTM A420 WPL 6

CONCENTRIC

REDUCERS RE 2" - 14" BW - ANSI B16-25 M,M ANSI B16-9 ASTM A420 WPL 6

ECCENTRIC

TEES EQUAL T 0.50" - 1.50" SW

3000#

ANSI B16.11 ASTM A350 Gr. LF2

2" - 14" BW M ANSI B16.9 ASTM A420 WPL 6

TEES RED TR 0.50" - 1.50" SW

3000#

ANSI B16.11 ASTM A350 Gr. LF2

2" - 14" BW M,M ANSI B16.9 ASTM A420 WPL 6

SOCKOLET S 0.50" - 1.50" SW

3000#

MSS-SP 97 ASTM A 350 LF 2

WELDOLETS W 2" - 10" BW - ANSI B16-25 M,XXS MSS-SP 97 ASTM A 350 LF 2

CAPS C 0.50" - 1.50" SCRF

3000#

ANSI B16.11 ASTM A350 Gr. LF2

2" - 14" BW M ANSI B16-9 ASTM A420 WPL 6

NIPPLES NA 0.50" - 0.75" PBE, SEAMLESS M ANSI B36-10 ASTM A333 GR 6

NB 1" -1.50" PBE, SEAMLESS M ANSI B36-10 ASTM A333 GR 6

FULL FC 0.50" - 1.50" SW 3000#

COUPLINGS

HALF HC 0.50" - 1.50" SW 3000#

COUPLINGS

Rev

0

ANSI B16-11 ASTM A 350 LF 2

ANSI B16-11 ASTM A 350 LF 2

NOTE: X-RAYS 100%

Sheet 7 of 18

Document No.

11-0299-02-08-02-002

PIPING MATERIAL SPECIFICATION

REMARKS

PIPING SPECIFICATION

GSPC GAS COMPANY LIMITED

1A1

TEMPERATURE (-29 TO 65 C)

PRESSURE (18.75 bar g)

RATING 150#

CODE ANSI B 31.8

BASIC MATERIAL LTCS

CORROSION ALL. 1.5 mm

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL

CODE FROM- AND/OR STANDARD

THRU SCHED.

WN FLANGES FW 0.50"-14" 150# RF M ANSI B16-5 ASTM A350 LF 2

125 AARH

BLIND FB 0.50"-14" 150# RF ANSI B16-5 ASTM A350 LF 2

FLANGE 125 AARH

FLANGES FF 0.5" - 8" 150# RF ANSI B16-48 ASTM A350 LF 2

FIG 8 125 AARH

SPCR & FSB 10" - 14" 150# RF ANSI B16-48 ASTM A350 LF 2

BLND 125 AARH

GATE VG 0.50 - 1.50 SW 800# API 602 ASTM A 350 Gr LF2

VALVE B16.11

STUD BOLTS B 0.5" - 14" ANSI B18-2 Bolt: A320 L7

Nut: A194 Gr.4

GASKETS G 0.5" - 14" 150#, SPIRAL B-16.20 - SP. WND

SPIRAL ANSI B16.5 SS316+CAF

WOUND

Rev.

0

REMARKS

RATING 150#

CODE ANSI B 31.8

BASIC MATERIAL LTCS

CORROSION ALLOWANCE 1.5 mm

GSPC GAS COMPANY LIMITED

PIPING SPECIFICATION

1A1

TEMPERATURE(-29 TO 65 C

PRESSURE (18.75 bar g)

NOTE: X-RAYS 100%

Sheet 8 of 18

PIPING MATERIAL SPECIFICATION

Document No.

11-0299-02-08-02-002

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL

CODE FROM- AND/OR STANDARD

THRU SCHED.

BALL VBA 0.50 - 1.50 SW:ANSI B16-5 800# ANSI B16-10 BODY:

VALVES ASTM A350 LF 2

BALL:

SS 316

2"-3" BW:ANSI B16-5 150# ANSI B16-10 BODY:

ASTM A352 LCB

BALL:

SS 316

4"-10" BW:ANSI B16-5 150 # ANSI B16-10 BODY:

ASTM A352 LCB

BALL:

A350LF2 WITH ENP or equal

12" BW:ANSI B16-5 150# ANSI B16-10 BODY:

ASTM A352 LCB

BALL:

A350LF2 WITH ENP or equal

GLOBE VGL 0.50 - 1.50 SW 800# ANSI B16-10 BODY:

VALVES ANSI B16-5 ASTM A350 LF 2

TRIM:

ASTM A182 F6

2" - 12" FLGD RF 150# ANSI B16-10 BODY:

ANSI B16-5 ASTM A352 LCB

TRIM:

ASTM A182 F6

SWING CHECK VCH 0.50 - 1.50 SW 800# ANSI B16-10 BODY:

VALVES ANSI B16-5 ASTM A350 LF 2

TRIM:

ASTM A182 F6

2"-12" FLGD RF 150# ANSI B16-10 BODY:

ANSI B16-5 ASTM A352 LCB

TRIM:

ASTM A182 F6

Document No. Rev.

PRESSURE (18.75 bar g)

GSPC GAS COMPANY LIMITED

BASIC MATERIAL LTCS

CORROSION ALLOWANCE 1.5 mm

PIPING SPECIFICATION

1A1

TEMPERATURE (-29 TO 65 C)

RATING 150#

CODE ANSI B 31.8

REMARKS

FULL BORE

FIRE SAFE

WRENCH OPERATED.

FULL BORE

FIRE SAFE

WRENCH OPERATED.

FULL BORE

FIRE SAFE

GEAR OPERATED.

DOUBLE BLOCK AND BLEED

FULL BORE

FIRE SAFE

GEAR OPERATED.

HANDWHEEL

FIRE SAFE

HANDWHEEL

FIRE SAFE

HORIZONTAL INSTALLATION

PIPING MATERIAL SPECIFICATION

11-0299-02-08-02-002 0

VERTICAL INSTALLATION FLOW

UPWARDS

Sheet 9 of 18

NOTE: X-RAYS 100%

HORIZONTAL INSTALLATION

VERTICAL INSTALLATION FLOW

UPWARDS

B R A N C H S I Z E

1/2" 3/4" 1" 1.1/2" 2" 3" 4" 6" 8" 10" 12" 14" 16" 18" 20" 24" 28" 30" 32" 36"

1/2" T

3/4" T T

1" T T T

1.1/2" T T T T

2" S S S T T

3" S S S S T T

4" S S S S T T T

H 6" S S S S W T T T

E 8" S S S S W W T T T

A 10" S S S S W W T T T T

D 12" S S S S W W W T T T T

E 14" S S S S W W W T T T T T

R 16" S S S S W W W W T T T T T

18" S S S S W W W W T T T T T T

S 20" S S S S W W W W W T T T T T T

I 24"

Z 28"

E 30"

32"

36"

LEGEND

T : TEE - BW

S: SOCKOLET - BW

W : WELDOLET - BW

Rev.

0

RATING 150#

CORROSION ALW 1.5 mm

CODE ANSI B 31.8

BRANCH TABLE

BASIC MATERIAL LTCS

GSPC GAS COMPANY LIMITED

PIPING SPECIFICATION

1A1

TEMPERATURE (-29 TO 65 C)

PRESSURE (18.75 bar g)

PIPING MATERIAL SPECIFICATION

Sheet 10 of 18

Document No.

11-299-02-08-02-002

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL REMARKS

CODE FROM- AND/OR STANDARD

THRU SCHED.

PIPES P 0.50" - 0.75" PE, SEAMLESS S160 ANSI B36-10 ASTM A333 GR 6

1" - 1.50" PE, SEAMLESS S160 ANSI B36-10 ASTM A333 GR 6

2" BE, SEAMLESS S160 ANSI B36-10 ASTM A333 GR 6

3" - 10" BE, SEAMLESS STD ANSI B36-10 ASTM A333 GR 6

12"- 14'' BE, SEAMLESS S40 ANSI B36-10 ASTM A333 GR 6

ELBOWS 90 LR E 0.50" - 1.50" SW 3000# ANSI B16.11 ASTM A350 Gr. LF2

2" - 14" BW, 1.5D M ANSI B16.9 ASTM A420 WPL 6

ELBOWS 45 LR E45 0.50" - 1.50" SW 3000# ANSI B16.11 ASTM A350 Gr. LF2

2" - 14" BW, 1.5D M ANSI B16.9 ASTM A420 WPL 6

REDUCERS RC 2" - 14" BW - ANSI B16-25 M,M ANSI B16-9 ASTM A420 WPL 6

CONCENTRIC

REDUCERS RE 2" - 14" BW - ANSI B16-25 M,M ANSI B16-9 ASTM A420 WPL 6

ECCENTRIC

TEES EQUAL T 0.50" - 1.50" SW 3000# ANSI B16.11 ASTM A350 Gr. LF2

2" - 14" BW M ANSI B16.9 ASTM A420 WPL 6

TEES RED TR 0.50" - 1.50" SW 3000# ANSI B16.11 ASTM A350 Gr. LF2

2" - 14" BW M,M ANSI B16.9 ASTM A420 WPL 6

SOCKOLET S 0.50" - 1.50" SW 3000#

WELDOLETS W 2" - 4" BW - ANSI B16-25 M,XXS MSS-SP 97 ASTM A 350 LF 2

CAPS C 2" - 14" BW M ANSI B16-9 ASTM A420 WPL 6

NIPPLES NA 0.50" - 0.75" PBE, SEAMLESS M ANSI B36-10 ASTM A333 GR 6

NB 1" -1.50" PBE, SEAMLESS M ANSI B36-10 ASTM A333 GR 6

FULL FC 0.50" - 1.50" SW 3000#

COUPLINGS

HALF HC 0.50" - 1.50" SW 3000#

COUPLINGS

Rev.

0

Document No.

11-0299-02-08-02-002

NOTE: X-RAYS 100%

ANSI B16-11 ASTM A 350 LF 2

ANSI B16-11 ASTM A 350 LF 2

PIPING SPECIFICATION

3A1

PIPING MATERIAL SPECIFICATION

TEMPERATURE (-29 TO 65 C)

PRESSURE (49 bar g)

GSPC GAS COMPANY LIMITED

Sheet 11 of 18

RATING 300#

CODE ANSI B 31.8

BASIC MATERIAL LTCS

CORROSION ALLOWANCE 1.5 mm

ASTM A 350 LF 2 MSS-SP 97

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL REMARKS

CODE FROM- AND/OR STANDARD

THRU SCHED.

WN FLANGES FW 2"-14" RF, 125 AARH 300#, M ANSI B16-5 ASTM A350 LF 2

FLG SW FS 0.50 - 1.50 RF, 125 AARH 300#, M ANSI B16-5 ASTM A 350 Gr LF2

BLIND FB 0.50"-14" RF, 125 AARH 300# ANSI B16-5 ASTM A350 LF 2

FLANGE

FLANGES FF 0.5" - 8" FF, 125 AARH 300#, M ANSI B16-48 ASTM A350 LF 2

FIG 8

SPCR & FSB 10" - 14" FF, 125 AARH 300# ANSI B16-48 ASTM A350 LF 2

BLND

GATE VG 0.50 - 1.50 SW 800# API 602 ASTM A 350 Gr LF2

VALVE B16.11

2" - 24" FLGD, B-16.5, 300# API 600 ASTM A 352 Gr. LCB

RF/125 AARH

STUD BOLTS B 0.50" - 14'' ANSI B18-2 Bolt: A320 L7

Nut: A194 Gr.4

PLUG VP 0.50" - 1.50"

SW, BS -5353

800#

ANSI B16-11

ASTM A 350 Gr LF2

VALVE 2" - 12"

FLG/ BW, API 6D

300#

ANSI B16-9

ASTM A 352 Gr LCB

GASKETS G 0.5" - 14" SPIRAL, 300# B-16.20 - SP. WND

SPIRAL ANSI B16.5 SS316+CAF

WOUND

Rev.

0

NOTE: X-RAYS 100%

PIPING MATERIAL SPECIFICATION

Document No.

11-0299-02-08-02-002

Sheet 12 of 18

PRESSURE (49 bar g)

GSPC GAS COMPANY LIMITED

PIPING SPECIFICATION

3A1

TEMPERATURE (-29 TO 65 C)

RATING 300#

CODE ANSI B 31.8

BASIC MATERIAL LTCS

CORROSION ALLOWANCE 1.5 mm

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL REMARKS

CODE FROM- AND/OR STANDARD

THRU SCHED.

BALL VBA 0.50 - 1.50 FLGD RF:ANSI B16-5 300# ANSI B16-10 BODY: FULL BORE

VALVES 125 AARH BS 5351 ASTM A350 LF 2/ A 352 LCB FIRE SAFE

BALL:SS 316 WRENCH OPERATED.

BODY SEAT: RPTFE

2" FLGD RF:ANSI B16-5 300# ANSI B16-10 BODY: FULL BORE, FIRE SAFE, WRENCH OPERATED

or BW :ANSI B16-5 BS 5351 ASTM A350 LF 2/ A 352 LCB

BALL:SS 316

BODY SEAT: RPTFE

3" - 4" FLGD RF:ANSI B16-5 300# ANSI B16-10 BODY: DOUBLE BLOCK AND BLEED

or BW :ANSI B16-5 BS 5351 ASTM A350 LF 2/ A 352 LCB FULL BORE

BALL:SS 316 FIRE SAFE

BODY SEAT: RPTFE WRENCH OPERATED.

6"-36'' FLGD RF:ANSI B16-5 300# ANSI B16-10 BODY: ASTM A350 LF 2/ DOUBLE BLOCK AND BLEED

or BW :ANSI B16-5 BS 5351 ASTM A 352 LCB FULL BORE

BALL:A350LF2 with ENP or equa FIRE SAFE

BODY SEAT: RPTFE GEAR OPERATED.

GLOBE VGL 0.50 - 1.50 FLGD RF:ANSI B16-5 300# ANSI B16-10 BODY: HANDWHEEL

VALVES BS 5352 ASTM A350 LF 2/ A 352 LCB FIRE SAFE

TRIM:

ASTM A182 F6

2" - 4" FLGD RF:ANSI B16-5 300# ANSI B16-10 BODY: HANDWHEEL

BS 1873 ASTM A352 LCB or A350 LF2 FIRE SAFE

TRIM:

ASTM A182 F6

6" - 12" FLGD RF:ANSI B16-5 300# ANSI B16-10 BODY: GEAR OPERATED

BS 1873 ASTM A352 LCB FIRE SAFE

TRIM:

ASTM A182 F6

SWING CHECK VCH 0.50 - 1.50 FLGD RF:ANSI B16-5 300# ANSI B16-10 BODY: HORIZONTAL INSTALLATION

VALVES BS 5352 ASTM A350 LF 2 VERTICAL INSTALLATION FLOW UPWARDS

TRIM:

ASTM A182 F6

2"-30'' FLGD RF:ANSI B16-5 300# ANSI B16-10 BODY: HORIZONTAL INSTALLATION

BS 1868 ASTM A352 LCB VERTICAL INSTALLATION FLOW UPWARDS

TRIM:

ASTM A182 F6

Document No. Rev.

PIPING MATERIAL SPECIFICATION

Sheet 13 of 18

NOTE: X-RAYS 100%

11-0299-02-08-02-002 0

RATING 300#

CODE ANSI B 31.8

BASIC MATERIAL LTCS

CORROSION ALLOWANCE 1.5 mm

PRESSURE (49 bar g)

GSPC GAS COMPANY LIMITED

PIPING SPECIFICATION

3A1

TEMPERATURE (-29 TO 65 C)

B R A N C H S I Z E

1/2" 3/4" 1" 1.1/2" 2" 3" 4" 6" 8" 10" 12" 14" 16" 18" 20" 24" 28" 30" 32" 36"

1/2" T

3/4" T T

1" T T T

1.1/2" T T T T

2" S T T T T

3" S S S S T T

4" S S S S T T T

H 6" S S S S W T T T

E 8" S S S S W W T T T

A 10" S S S S W W T T T T

D 12" S S S S W W W T T T T

E 14" S S S S W W W T T T T T

R 16" S S S S W W W T T T T T T

18" S S S S W W W T T T T T T T

S 20" S S S S W W W T T T T T T T T

I 24" S S S S W W W T T T T T T T T T

Z 28" S S S S W W W T T T T T T T T T T

E 30" S S S S W W W T T T T T T T T T T T

32"

36"

LEGEND

T : TEE -BW

S: SOCKOLET - BW

W : WELDOLET- BW

Rev.

0

PIPING SPECIFICATION

GSPC GAS COMPANY LIMITED

RATING 300#

3A1

CODE ANSI B 31.8

TEMPERATURE (-29 TO 65 C)

BASIC MATERIAL LTCS

PRESSURE (49 bar g)

CORROSION ALW 1.5 mm

Document No.

11-0299-02-08-02-002

BRANCH TABLE

PIPING MATERIAL SPECIFICATION

Sheet 14 of 18

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL REMARKS

CODE FROM- AND/OR STANDARD

THRU SCHED.

PIPES P 0.50" - 0.75" PE, SEAMLESS S160 ANSI B36-10

1" - 1.50" PE, SEAMLESS S160 ANSI B36-10

2" BE, SEAMLESS S160 ANSI B36-10

3" BE, SEAMLESS STD ANSI B36-10

4" - 10" BE, SEAMLESS 80 ANSI B36-10

12" - 14" BE, SEAMLESS

16" - 18" BE, SEAMLESS

20" - 24" BE, SEAMLESS

ELBOWS 90 LR E 0.50" - 1.50" SW

6000# ANSI B16-11

2" - 14"

ASTM A420 WPL 6

16" - 18"

ASTM A420 WPL 6 - W

ELBOWS 45 LR E45 0.50" - 1.50" SW

6000# ANSI B16-11

2" - 14"

ASTM A420 WPL 6

16" - 18"

ASTM A420 WPL 6 - W

TEES EQUAL T 0.50" - 1.50" SW

6000#

2" - 14"

ASTM A420 WPL 6

16" - 18"

ASTM A420 WPL 6 - W

TEES RED TR 0.50" - 1.50" SW

6000#

2" - 14"

ASTM A420 WPL 6

16" - 18"

ASTM A420 WPL 6 - W

SOCKOLET S 0.50" - 1.50" SW 6000# MSS-SP 97 ASTM A 350 LF 2

WELDOLETS W 2" - 6" BW - ANSI B16-25 S 160 MSS-SP97 ASTM A 350 LF 2

CAPS C 0.50" - 1.50" SCRF 6000# ASME B16-11

2" - 18" BW M ASME B16-9 ASTM A 420 Gr. WPL6

PLUG P 0.50" - 1.50" SCRM 6000# ASME B16-11

NIPPLES NA 0.50" - 0.75" PBE, SEAMLESS M ANSI B36-10 ASTM A333 GR 6

NB 1" -1.50" PBE, SEAMLESS M ANSI B36-10 ASTM A333 GR 6

FULL CF 0.50" - 1.50" SW 6000#

COUPLINGS

HALF HC 0.50" - 1.50" SW 6000#

COUPLINGS

Rev.

0

CODE ANSI B 31.8

BASIC MATERIAL LTCS

CORROSION ALLOWANCE 1.5 mm

ANSI B16-11 ASTM A 350 LF 2

ASTM A 350 Gr. LF2

ASTM A 350 Gr. LF2

ANSI B16-11 ASTM A 350 LF 2

ANSI B16-11

PIPING MATERIAL SPECIFICATION

Document No.

11-0299-02-08-02-002

Sheet 15 of 18

NOTE: X-RAYS 100%

GSPC GAS COMPANY LIMITED

PIPING SPECIFICATION

6A1

TEMPERATURE (-29 TO 65 C)

DESIGN PRESSURE (98 bar g)

ANSI B16-9 BW, 1.5D

ASTM A333 GR 6

RATING 600#

BW - ANSI B16-25 M ANSI B16-9

BW, 1.5D M ANSI B16-9

ASTM A 350 Gr. LF2

BW - ANSI B16-25 M ANSI B16-9

Sch 60 ASTM A333 GR 6 ANSI B36-10

ANSI B16-11

M

ASTM A 350 Gr. LF2

ASTM A 350 Gr. LF2

ASTM A 350 Gr. LF2

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL REMARKS

CODE FROM- AND/OR STANDARD

THRU SCHED.

WN FLANGES FW 2" - 18" RF, 125 AARH 600# ANSI B16-5 ASTM A350 LF 2

26" & Above RF, 125 AARH 600# ANSI B 16.47 B ASTM A350 LF 2

FLG SW FS 0.50 - 1.50 RF, 125 AARH 600# ANSI B16-5 ASTM A 350 Gr LF2

BLIND FB 0.50"-18" RF, 125 AARH 600# ANSI B16-5 ASTM A350 LF 2

FLANGES

FLANGES FF 0.5" - 8" FF, 125 AARH 600# ANSI B16-48 ASTM A350 LF 2

FIG 8

SPCR & FSB 10" - 18" FF, 125 AARH 600# ANSI B16-48 ASTM A350 LF 2

BLND

GATE VG 0.50 - 1.50 SW 800# API 602 ASTM A 350 Gr LF2

VALVE B16.11

PLUG VP 0.50" - 1.50" SCRM, 800#

ANSI B16-11

ASTM A 350 Gr LF2

VALVE

2" - 12" 600#

ANSI B16-9

ASTM A 352 Gr LCB

STUD BOLTS B 0.50" - 18'' ANSI B18-2 Bolt: A320 L7

Nut: A194 Gr.4

GASKETS G 0.5" - 18" SPIRAL, 600# B-16.20 - SP. WND

SPIRAL ANSI B16.5 SS316+CAF

WOUND

Rev.

0

SW

BS -5353

FLG/ BW

API 6D

PIPING MATERIAL SPECIFICATION

Document No.

11-0299-02-08-02-002

Sheet 16 of 18

NOTE: X-RAYS 100%

PIPING SPECIFICATION

GSPC GAS COMPANY LIMITED

6A1

TEMPERATURE (-29 TO 65 C)

DESIGN PRESSURE (98 bar g)

RATING 600#

CODE ANSI B 31.8

BASIC MATERIAL LTCS

CORROSION ALLOWANCE 1.5 mm

ITEM SHORT SIZE DESCRIPTION RATING DIMENSION MATERIAL REMARKS

CODE FROM- AND/OR STANDARD

THRU SCHED.

BALL VBA 0.50 - 1.50 FLGD RF:ANSI B16-5 600# ANSI B16-10 BODY: FULL BORE

VALVES ASTM A350 LF 2 FIRE SAFE

BALL: WRENCH OPERATED.

SS 316

2" BW :ANSI B16-5 600# ANSI B16-10 BODY: FULL BORE, FIRE SAFE, WRENCH OPERATED

ASTM A350 LF 2/ A 352 LCB

BALL:

SS 316

3" - 4" FLGD RF:ANSI B16-5 600 # ANSI B16-10 BODY: DOUBLE BLOCK AND BLEED

ASTM A350 LF 2/ A 352 LCB FULL BORE

BALL: FIRE SAFE

SS 316 WRENCH OPERATED.

6"-36'' FLGD RF:ANSI B16-5 600# ANSI B16-10 BODY: DOUBLE BLOCK AND BLEED

or BW :ANSI B16-5 ASTM A350 LF 2/ A 352 LCB FULL BORE

BALL: FIRE SAFE

A350LF2 WITH ENP or equal GEAR OPERATED.

GLOBE VGL 0.50 - 1.50 FLGD RF:ANSI B16-5 600# ANSI B16-10 BODY: HANDWHEEL

VALVES ASTM A350 LF 2 FIRE SAFE

TRIM:

ASTM A182 F6

2" - 4" FLGD RF:ANSI B16-5 600# ANSI B16-10 BODY: HANDWHEEL

ASTM A352 LCB or A350 LF2 FIRE SAFE

TRIM:

ASTM A182 F6

6" - 12" FLGD RF:ANSI B16-5 600# ANSI B16-10 BODY: GEAR OPERATED

ASTM A352 LCB FIRE SAFE

TRIM:

ASTM A182 F6

SWING CHECK VCH 0.50 - 1.50 FLGD RF:ANSI B16-5 600# ANSI B16-10 BODY: HORIZONTAL INSTALLATION

VALVES ASTM A350 LF 2 VERTICAL INSTALLATION FLOW UPWARDS

TRIM:

ASTM A182 F6

2"-30'' FLGD RF:ANSI B16-5 600# ANSI B16-10 BODY: HORIZONTAL INSTALLATION

ASTM A352 LCB VERTICAL INSTALLATION FLOW UPWARDS

TRIM:

ASTM A182 F6

Document No. Rev.

11-0299-02-08-02-002 0

RATING 600#

CODE ANSI B 31.8

BASIC MATERIAL LTCS

TEMPERATURE (-29 TO 65 C)

GSPC GAS COMPANY LIMITED

PIPING SPECIFICATION

6A1

PIPING MATERIAL SPECIFICATION

Sheet 17 of 18

CORROSION ALLOWANCE 1.5 mm

NOTE: X-RAYS 100%

DESIGN PRESSURE (98 bar g)

B R A N C H S I Z E

1/2" 3/4" 1" 1.1/2" 2" 3" 4" 6" 8" 10" 12" 14" 16" 18" 20" 24" 28" 30" 32" 36"

1/2" T

3/4" T T

1" T T T

1.1/2" T T T T

2" S T T T T

3" S S S S T T

4" S S S S T T T

H 6" S S S S W T T T

E 8" S S S S W W T T T

A 10" S S S S W W T T T T

D 12" S S S S W W W T T T T

E 14" S S S S W W W T T T T T

R 16" S S S S W W W T T T T T T

18" S S S S W W W W T T T T T T

S 20" S S S S W W W W T T T T T T T

I 24" S S S S W W W W T T T T T T T T

Z 28" S S S S W W W W T T T T T T T T T

E 30" S S S S W W W W T T T T T T T T T T

32" S S S S W W W W T T T T T T T T T T T

36" S S S S W W W W T T T T T T T T T T T T

LEGEND

T : TEE -BW

S: SOCKOLET - BW

W : WELDOLET- BW

Rev.

0

PIPING MATERIAL SPECIFICATION

Sheet 18 of 18

Document No.

11-0299-02-08-02-002

RATING 600#

CORROSION ALL. 1.5 mm

CODE ANSI B 31.8

BRANCH TABLE

BASIC MATERIAL LTCS

GSPC GAS COMPANY LIMITED

PIPING SPECIFICATION

6A1

TEMPERATURE (-29 TO 65 C)

DESIGN PRESSURE (98 bar g)

Potrebbero piacerti anche

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDa EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNessuna valutazione finora

- Pipe FittingsDocumento40 paginePipe FittingsLucky Jaswal100% (1)

- 13.date Sheet For Gate ValveDocumento2 pagine13.date Sheet For Gate ValveMrinal Kanti BhaduriNessuna valutazione finora

- Piping Design CriteriaDocumento15 paginePiping Design CriteriaSubash Chandrabose0% (1)

- Pipin Standard Drawing 6423mp214!00!0010000 - Rev01 - 01Documento120 paginePipin Standard Drawing 6423mp214!00!0010000 - Rev01 - 01mister pogi100% (1)

- Piping SpecificationsDocumento67 paginePiping SpecificationsVedran Kosanovic100% (3)

- Part 2 - Roy A. Parisher, Robert A. Rhea - Pipe Drafting and Design-Gulf Professional Publishing (2022)Documento240 paginePart 2 - Roy A. Parisher, Robert A. Rhea - Pipe Drafting and Design-Gulf Professional Publishing (2022)Numan KashifNessuna valutazione finora

- Large Bore DetailsDocumento85 pagineLarge Bore DetailsAmreusit SaschimbnumeleNessuna valutazione finora

- Ewp000 P30 J00 501 - 1H PDFDocumento61 pagineEwp000 P30 J00 501 - 1H PDFOk Oh100% (2)

- Piping and Valve Specifications Rev. A PDFDocumento28 paginePiping and Valve Specifications Rev. A PDFYessine RebaiNessuna valutazione finora

- Piping Specifications HarrisDocumento27 paginePiping Specifications Harrisrensieovi100% (2)

- SAMSUNG SEM 3074E Piping Design Manual Pump PipingDocumento21 pagineSAMSUNG SEM 3074E Piping Design Manual Pump PipingSlobodan AnticNessuna valutazione finora

- ES - Piping Material SpecificationDocumento14 pagineES - Piping Material SpecificationJegan Cheng100% (2)

- Element Standard Manufacturing Method: Piping CommoditiesDocumento8 pagineElement Standard Manufacturing Method: Piping CommoditiesKamalakannan AyyaduraiNessuna valutazione finora

- Piping QTDocumento51 paginePiping QTSaif Ul Haq Mohammed100% (1)

- Butt Weld Stainless Steel FittingsDocumento16 pagineButt Weld Stainless Steel Fittingsbayu susiloNessuna valutazione finora

- Standards in The Valve IndustryDocumento2 pagineStandards in The Valve IndustryessnelsonNessuna valutazione finora

- Thumb RuleDocumento42 pagineThumb RuleShabeer KiblaalamNessuna valutazione finora

- Reducing-Tee Mechanical Piping PDFDocumento4 pagineReducing-Tee Mechanical Piping PDFanjargoklithNessuna valutazione finora

- KIL3012 - WEEK 3 - 24.9.19 (Student Copy)Documento84 pagineKIL3012 - WEEK 3 - 24.9.19 (Student Copy)EdNessuna valutazione finora

- P&Id Related: Sr. No. Check Points DoneDocumento5 pagineP&Id Related: Sr. No. Check Points DoneSwapna Priya VattemNessuna valutazione finora

- Data Sheet-Ball ValveDocumento2 pagineData Sheet-Ball ValveJatin Vadhera VCSP100% (1)

- Ejemplo Piping Class PDFDocumento5 pagineEjemplo Piping Class PDFDagoberto CerrudNessuna valutazione finora

- Piping DesignDocumento9 paginePiping Designjmclaug502Nessuna valutazione finora

- ASTM GradesDocumento1 paginaASTM GradesBill GuNessuna valutazione finora

- VDS (Valve Data Sheet)Documento1 paginaVDS (Valve Data Sheet)Shandi Hasnul Farizal0% (1)

- Valve Material ApplicationDocumento16 pagineValve Material ApplicationMuhammadShabbirNessuna valutazione finora

- Buttweld Fittings Accesorios SoldadosDocumento5 pagineButtweld Fittings Accesorios SoldadosJuan CadenaNessuna valutazione finora

- 1722 Piping Drafting Instruc GuideDocumento26 pagine1722 Piping Drafting Instruc GuideRizwan Ashraf100% (2)

- Specs Chart PDFDocumento1 paginaSpecs Chart PDFsojeckNessuna valutazione finora

- Selection and Application of FlangesDocumento11 pagineSelection and Application of FlangesbandithaguruNessuna valutazione finora

- Piping Arrangement ChecklistDocumento1 paginaPiping Arrangement ChecklistAbhishek SharmaNessuna valutazione finora

- Piping Specification SheetDocumento63 paginePiping Specification SheetNilesh Gohel100% (1)

- 500 SP PIP 018 Rev C (Check Valve)Documento13 pagine500 SP PIP 018 Rev C (Check Valve)anwar01Nessuna valutazione finora

- Function of Piping Component: Steam Trap and Drain TrapDocumento23 pagineFunction of Piping Component: Steam Trap and Drain TrapMallela Sampath KumarNessuna valutazione finora

- Piping Material SpecificationsDocumento26 paginePiping Material SpecificationsWahidfunNessuna valutazione finora

- Common Materilas For CS PipingDocumento2 pagineCommon Materilas For CS PipingValiullah SarpanchNessuna valutazione finora

- Ac 036630 001Documento1 paginaAc 036630 001navaronefraNessuna valutazione finora

- Ball Valves: Sharma MVSRK 15 October 2013Documento49 pagineBall Valves: Sharma MVSRK 15 October 2013Jay Ganta100% (2)

- Stainless Steel 304 FlangesDocumento6 pagineStainless Steel 304 FlangesiSteelindiaNessuna valutazione finora

- How To Create Pipe ClassDocumento6 pagineHow To Create Pipe ClassShyam Prasad K SNessuna valutazione finora

- PmsDocumento94 paginePmssdk1978100% (1)

- Universal Y StrainerDocumento2 pagineUniversal Y Strainerabdi zakiNessuna valutazione finora

- Piping MaterialsDocumento1 paginaPiping MaterialsKalaiYarasanNessuna valutazione finora

- VMS PaliDocumento61 pagineVMS Palichintan100% (2)

- PFD Vs PIDDocumento65 paginePFD Vs PIDashirNessuna valutazione finora

- Datasheets For Bucket Type StrainerDocumento2 pagineDatasheets For Bucket Type StrainerbecpavanNessuna valutazione finora

- Steel Member SizesDocumento265 pagineSteel Member SizesMubashar HassanNessuna valutazione finora

- Piping Quiz AnsDocumento13 paginePiping Quiz Anssairam2234100% (1)

- 1) P&Id Latest Revision. 2) Vendor Drawings of Equipments and In-Line Instruments. 3) Line List. 4) Piping Material Specification. 5) Updated ModelDocumento3 pagine1) P&Id Latest Revision. 2) Vendor Drawings of Equipments and In-Line Instruments. 3) Line List. 4) Piping Material Specification. 5) Updated ModelNavaneeth PurushothamanNessuna valutazione finora

- Overview Part 1 PDFDocumento65 pagineOverview Part 1 PDFKim NamjoonNessuna valutazione finora

- ENGINEERING STANDARD - Standard Piping Material SpecificationDocumento33 pagineENGINEERING STANDARD - Standard Piping Material SpecificationGanesh Eshwar100% (2)

- Volime II of II Mechanical Piping-GAILDocumento245 pagineVolime II of II Mechanical Piping-GAILBathi Hari PrasadNessuna valutazione finora

- 5026-PS-001 - 0 Supply of Piping MaterialsDocumento17 pagine5026-PS-001 - 0 Supply of Piping MaterialsCARLOS OLIVEROSNessuna valutazione finora

- Documents Plc150Documento7 pagineDocuments Plc150Anonymous cuOIjrLINessuna valutazione finora

- Volime II of II Mechanical Piping PDFDocumento245 pagineVolime II of II Mechanical Piping PDFkamleshyadavmoneyNessuna valutazione finora

- Laying Tender PDFDocumento199 pagineLaying Tender PDFankeshkatochNessuna valutazione finora

- Astm f1155 1998Documento25 pagineAstm f1155 1998ttplan800Nessuna valutazione finora

- Norsok L001Documento2 pagineNorsok L001Walid Labidi50% (2)

- Piping Material Classes: NotesDocumento16 paginePiping Material Classes: NotesVedran KosanovicNessuna valutazione finora

- 2014 PLTB Present Guide PDFDocumento125 pagine2014 PLTB Present Guide PDFPato Patiño MuñozNessuna valutazione finora

- B16 47+book PDFDocumento18 pagineB16 47+book PDFAnonymous K3FaYFlNessuna valutazione finora

- HRSG Manufacturing: Doosan Heavy Industries VietnamDocumento10 pagineHRSG Manufacturing: Doosan Heavy Industries VietnamMai DangNessuna valutazione finora

- Dewrance Parallel Slide Gate Val - Copy 1Documento12 pagineDewrance Parallel Slide Gate Val - Copy 1Sapto Hardi YunantoNessuna valutazione finora

- Development of A Multi-Pump Test Rig: Background of The StudyDocumento58 pagineDevelopment of A Multi-Pump Test Rig: Background of The StudyMarc Danielle G Josue IINessuna valutazione finora

- Turgo Final ReportDocumento29 pagineTurgo Final ReportFouzi FûpĩNessuna valutazione finora

- DRF Hydraulic Scale DRF450Documento109 pagineDRF Hydraulic Scale DRF450ANH LÊ100% (4)

- BSP Vs NPT Thread - Knowledge - Yuyao Jiayuan Hydraulic Fitting FactoryDocumento5 pagineBSP Vs NPT Thread - Knowledge - Yuyao Jiayuan Hydraulic Fitting FactorySalahiddin AbuselmiyaNessuna valutazione finora

- Tabela de Óleos LubrificantesDocumento2 pagineTabela de Óleos LubrificantesAlbert MesquitaNessuna valutazione finora

- Chemcad Sizing ToolsDocumento48 pagineChemcad Sizing Toolsparedanil100% (1)

- SP en Esquema Hidraulico 1Documento21 pagineSP en Esquema Hidraulico 1SANTANDER GARCIANessuna valutazione finora

- 0002 - 102 Pressure Testing SafelyDocumento18 pagine0002 - 102 Pressure Testing SafelyFaris WahedNessuna valutazione finora

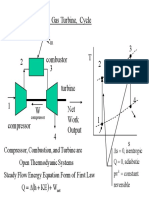

- Simple Brayton, Gas Turbine, Cycle 3: Systems Ic Thermodyan Open Are Turbine And, Combustion, CompressorDocumento9 pagineSimple Brayton, Gas Turbine, Cycle 3: Systems Ic Thermodyan Open Are Turbine And, Combustion, CompressorsuperaluddinNessuna valutazione finora

- CV H.Imran AliDocumento3 pagineCV H.Imran Alimoj mastiNessuna valutazione finora

- Valvula Serguridad Chao ChaoDocumento1 paginaValvula Serguridad Chao ChaoFherNessuna valutazione finora

- LEA HEINZMANN Gas Mixers For MAN Engines eDocumento8 pagineLEA HEINZMANN Gas Mixers For MAN Engines eOmar JenbachNessuna valutazione finora

- Air Service Unit, Simplified RepresentationDocumento1 paginaAir Service Unit, Simplified RepresentationelumalaipcNessuna valutazione finora

- Hvac PDFDocumento1 paginaHvac PDFKoteswara RaoNessuna valutazione finora

- To Commissioning Manual: Appendix No. 1Documento7 pagineTo Commissioning Manual: Appendix No. 1Bassem BalghouthiNessuna valutazione finora

- Belimo Model Number Change Dec 2014Documento3 pagineBelimo Model Number Change Dec 2014Huỳnh VũNessuna valutazione finora

- SAIC-D-2012 Rev 2Documento4 pagineSAIC-D-2012 Rev 2ரமேஷ் பாலக்காடுNessuna valutazione finora

- Turbofan Engine Database As A Preliminary Design ToolDocumento15 pagineTurbofan Engine Database As A Preliminary Design Toolcramerps2084Nessuna valutazione finora

- Oska8581 KDocumento16 pagineOska8581 KGökay DalNessuna valutazione finora

- Drytec CatalogDocumento72 pagineDrytec CatalogLogist ChinaNessuna valutazione finora

- Home Water Supply SystemDocumento49 pagineHome Water Supply Systemragani ramadasNessuna valutazione finora

- Basic Rule For Calculating Pressure DropDocumento8 pagineBasic Rule For Calculating Pressure DropAnonymous DJrec2Nessuna valutazione finora

- Topic 1 ACMVDocumento21 pagineTopic 1 ACMVEmi ArisNessuna valutazione finora

- Steering Gear in ShipsDocumento19 pagineSteering Gear in ShipsJulius PampolaNessuna valutazione finora

- Aparatos y Metodos para Mantener La Circulación Constante Durante La Perforación.Documento9 pagineAparatos y Metodos para Mantener La Circulación Constante Durante La Perforación.Raul BlancoNessuna valutazione finora

- SonnaxDocumento1 paginaSonnaxJhony Fui100% (1)