Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pipe Wall Thickness Under External Pressure

Caricato da

Anonymous DJrec2Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pipe Wall Thickness Under External Pressure

Caricato da

Anonymous DJrec2Copyright:

Formati disponibili

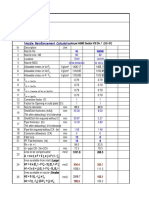

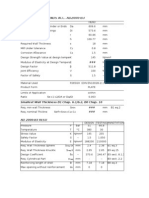

Thickness calculation of cylindrical shell and tube

Code Design data Symbols Pi Pe Temp Ci Ce E Di Tnom Tol L Descriptions Internal design pressure ,Bar External design pressure ,Bar Design temperature ,Degree C Corrosion allowance at inside surface,mm Corrosion allowance at outside surface,mm Joint efficiency Shell inside diameter in uncorroded condition ,mm Shell nominal thickness ,mm Permissible variation under specified thickness ,mm Design length of shell ,mm Calculations Under internal pressure Maximum allowable stress value ,S Required thickness ,Treq Design thickness ,Tdes Under external pressure Required thickness ,Treq Shell outside diameter in corroded ,Doc L/Doc Doc/Treq Factor determined from Fig.G ,A Factor determined from Fig.CS-2 ,B If Doc/Treq >= 10 Maximum allowable external pressure If Doc/Treq < 10 Yield strength ,Y Se Pa1 Pa2 Maximum allowable external pressure = = = = =

[

ASME Section VIII Division 1; UG-27,UG-28

Item No. Part Material SA-516-70 Shape Cylindrical shell

Values 12 1 100 1.5 1.5 0.85 1900 16 0.25 2500

= = =

120.66 0.05*Pi*(Di+2*Ci) S*E-0.06*Pi Treq+Ci+Ce

MPa = = 11.21 14.21 mm mm < Tnom

= = = = = =

13.00 Di+2*(Tnom-Ce) 1.30 148.38 0.0005611 56.131

mm = 1929.00 mm

>=

10

MPa

40*B 3*(Doc/Treq)

5.04

Bar > Pe

MIN(2*S,0.9*Y)

2. 167 0. 0833 ]* 10 * B Doc / Treq

= = = =

Satisfactory

20 * Se 1 *[1 ] Doc / Treq Doc / Treq

MIN(Pa1,Pa2)

Potrebbero piacerti anche

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocumento1 paginaK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjNessuna valutazione finora

- Pressure Vessel Assessment SpreadsheetDocumento3 paginePressure Vessel Assessment SpreadsheetrawirabbatNessuna valutazione finora

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Documento35 pagineDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainNessuna valutazione finora

- ASME VIII Calc - Shell - HeadsDocumento4 pagineASME VIII Calc - Shell - HeadsMuh Safaat100% (1)

- Vessel Nozzle Load DefinitionsDocumento2 pagineVessel Nozzle Load DefinitionsrsubramaniNessuna valutazione finora

- Pressure Drop Calculation - 6 Inch Permeate and Reject PumpDocumento2 paginePressure Drop Calculation - 6 Inch Permeate and Reject Pumpalmandhari33Nessuna valutazione finora

- Sample FLG CalcDocumento6 pagineSample FLG CalcameyyammaiNessuna valutazione finora

- Pipe cap thickness and coupling rating calculationsDocumento2 paginePipe cap thickness and coupling rating calculationsmasaminathanNessuna valutazione finora

- Process Industry Basket StrainersDocumento27 pagineProcess Industry Basket StrainersmartinnovelNessuna valutazione finora

- Orifice SizingDocumento2 pagineOrifice SizingAvinav Kumar100% (1)

- Nozzle Reinforcement Calculation Excel SheetDocumento3 pagineNozzle Reinforcement Calculation Excel Sheetramesh punjabiNessuna valutazione finora

- A11Documento1 paginaA11liviu_dovaNessuna valutazione finora

- Cylindrical & Spherical Shell CalculationsDocumento24 pagineCylindrical & Spherical Shell CalculationsTinBáoNessuna valutazione finora

- Pipe Wall Thickness Calculation According ASME B31 3Documento93 paginePipe Wall Thickness Calculation According ASME B31 3linhcdt3100% (1)

- Selection of TEMA Class of Heat ExchangerDocumento10 pagineSelection of TEMA Class of Heat ExchangerBalkundeNessuna valutazione finora

- API 650 STORAGE TANK DESIGN CALCULATIONDocumento14 pagineAPI 650 STORAGE TANK DESIGN CALCULATIONhgagselim2012Nessuna valutazione finora

- ISO 13623 pipe wall thickness calculation for Mahani-2 projectDocumento6 pagineISO 13623 pipe wall thickness calculation for Mahani-2 projectRanjan KumarNessuna valutazione finora

- Stress RelievingDocumento1 paginaStress RelievingCruz Gabriel Rosetti100% (1)

- Friction Loss in Pipe LineDocumento3 pagineFriction Loss in Pipe LineAvinash VasudeoNessuna valutazione finora

- Pressure Design Straight Pipe (Run Pipe)Documento6 paginePressure Design Straight Pipe (Run Pipe)gembirasekaliNessuna valutazione finora

- External Pressure - Pressure Vessel EngineeringDocumento15 pagineExternal Pressure - Pressure Vessel Engineeringarjun100% (1)

- Steam tracing simulation determines Process Fluid TemperatureDocumento74 pagineSteam tracing simulation determines Process Fluid TemperaturecybermineNessuna valutazione finora

- Horizontal Pressure Vessel Calculation (Eng)Documento59 pagineHorizontal Pressure Vessel Calculation (Eng)Chamseddine MerdasNessuna valutazione finora

- GRP Piping - Stress AnalysisDocumento5 pagineGRP Piping - Stress Analysisghkashyap1Nessuna valutazione finora

- Basket StrainersDocumento19 pagineBasket StrainersDiana CalderónNessuna valutazione finora

- Pipe Thickness CalculationDocumento1 paginaPipe Thickness Calculationananyo_senguptaNessuna valutazione finora

- Engineering Example CalculationDocumento78 pagineEngineering Example Calculationkae kaeNessuna valutazione finora

- Project of Pressure VesselDocumento25 pagineProject of Pressure VesselKalkidan DanielNessuna valutazione finora

- PSV Sizing (Steam)Documento2 paginePSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- Piping Related FormulasDocumento16 paginePiping Related Formulasnike_y2kNessuna valutazione finora

- Hydrostatic Test Pressure Calculation: Pipe DataDocumento2 pagineHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNessuna valutazione finora

- Calculation For Reinforced PadDocumento4 pagineCalculation For Reinforced Padjsridhar_34750% (2)

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocumento8 pagine8 AS4041 ASME B31 3 Pipe Wall ThicknessĐinh Thiện SỹNessuna valutazione finora

- Calculate Steam Pipe Sizing and CapacityDocumento2 pagineCalculate Steam Pipe Sizing and CapacityjoeljdiazNessuna valutazione finora

- DESIGN COLUMN WALL THICKNESS AND VESSEL SUPPORTDocumento12 pagineDESIGN COLUMN WALL THICKNESS AND VESSEL SUPPORTfarahanisiliasNessuna valutazione finora

- Branch Reinforcement Per Asme B31.4 PipelineDocumento1 paginaBranch Reinforcement Per Asme B31.4 PipelinegateauxboyNessuna valutazione finora

- Equipment SizingDocumento9 pagineEquipment SizingAnonymous Hy5Ir9QXNessuna valutazione finora

- Design of Large Opening Nozzle by Bulletin WRC-107Documento12 pagineDesign of Large Opening Nozzle by Bulletin WRC-107ALONSO GOMEZNessuna valutazione finora

- Sizing Pressure Regulators & Control ValvesDocumento16 pagineSizing Pressure Regulators & Control ValvesCH1253Nessuna valutazione finora

- Piping Stress Critical Lines - Basis For Piping Critical Line ListDocumento4 paginePiping Stress Critical Lines - Basis For Piping Critical Line Listashish.mathur1Nessuna valutazione finora

- 7 PDFDocumento26 pagine7 PDFargaNessuna valutazione finora

- Thin Walled Pressure Vessel Design Calculation TutorialDocumento9 pagineThin Walled Pressure Vessel Design Calculation TutorialGeorge SamsonNessuna valutazione finora

- Branch RF CalcDocumento6 pagineBranch RF CalcHarish Harish0% (1)

- ASME VIII-1 Calculations for Sample Pressure VesselDocumento21 pagineASME VIII-1 Calculations for Sample Pressure VesselTrishul Nath Pallay100% (1)

- Nozzle Design CalculationDocumento1 paginaNozzle Design CalculationSachin5586Nessuna valutazione finora

- GAS PIPELINE CALCULATIONDocumento37 pagineGAS PIPELINE CALCULATIONrasnowmah2012Nessuna valutazione finora

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocumento49 pagineDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Nessuna valutazione finora

- Pipe Branch Calculations ExampleDocumento3 paginePipe Branch Calculations ExampleAhmed Yusuf0% (1)

- Design Calculations For Pressure VesselsDocumento73 pagineDesign Calculations For Pressure Vesselsshani5573Nessuna valutazione finora

- Design Calculations For Pressure VesselsDocumento24 pagineDesign Calculations For Pressure VesselsMichael Lageman93% (15)

- Pressure vessel design element thickness calculatorDocumento30 paginePressure vessel design element thickness calculatorPeña Eepesa100% (2)

- Design Calculations For Pressure VesselsDocumento32 pagineDesign Calculations For Pressure VesselsGeorge Georgian100% (3)

- Design Calculations For Pressure VesselsDocumento30 pagineDesign Calculations For Pressure VesselsVinoth Rajendra100% (3)

- Design Calculations For Pressure VesselsDocumento28 pagineDesign Calculations For Pressure VesselsUmair AwanNessuna valutazione finora

- Type of Element Connected To The Shell: Nozzle: The Pressure Design Option Was Design Pressure + Static HeadDocumento1 paginaType of Element Connected To The Shell: Nozzle: The Pressure Design Option Was Design Pressure + Static HeadwhngomjNessuna valutazione finora

- AD2000 (31barg) CalculationDocumento10 pagineAD2000 (31barg) CalculationMagdaline Matabang100% (1)

- Internal CoilDocumento2 pagineInternal CoilwhngomjNessuna valutazione finora

- ASME Air Tank DesignDocumento2 pagineASME Air Tank Designchethan100% (1)

- Weight Estimation of Vessels AppsDocumento39 pagineWeight Estimation of Vessels Appsmacwan23Nessuna valutazione finora

- Design Calculations For Pressure ShellDocumento33 pagineDesign Calculations For Pressure ShellGeorge GeorgianNessuna valutazione finora

- 117 Excerpts 2004Documento7 pagine117 Excerpts 2004Anonymous DJrec2Nessuna valutazione finora

- The Business Model CanvasDocumento1 paginaThe Business Model CanvasAnonymous DJrec2Nessuna valutazione finora

- Factor of Safety On The Geotechnical Information WebsiteDocumento2 pagineFactor of Safety On The Geotechnical Information WebsiteAnonymous DJrec2Nessuna valutazione finora

- Development and Future of Circulating Fluidized Bed Boilers in ChinaDocumento4 pagineDevelopment and Future of Circulating Fluidized Bed Boilers in ChinaAnonymous DJrec2Nessuna valutazione finora

- Evolution of Management ThoughtDocumento17 pagineEvolution of Management ThoughtAnonymous DJrec2Nessuna valutazione finora

- Bearing Capacity Factors On The Geotechnical Information WebsiteDocumento2 pagineBearing Capacity Factors On The Geotechnical Information WebsiteAnonymous DJrec2Nessuna valutazione finora

- Cohesion On The Geotechnical Information WebsiteDocumento2 pagineCohesion On The Geotechnical Information WebsiteAnonymous DJrec2Nessuna valutazione finora

- Foundation Code 2004Documento64 pagineFoundation Code 2004Patie Zheng100% (2)

- External Friction Angle On The Geotechnical Information WebsiteDocumento2 pagineExternal Friction Angle On The Geotechnical Information WebsiteAnonymous DJrec2100% (1)

- 4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - ParadeepDocumento48 pagine4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - Paradeepvignesh_freeboterNessuna valutazione finora

- Foundation Code 2004Documento64 pagineFoundation Code 2004Patie Zheng100% (2)

- CFD Simulation On CFBC BoilerDocumento6 pagineCFD Simulation On CFBC BoilerAnonymous DJrec2Nessuna valutazione finora

- BEM Code of Ethics - Ir. Yim Hon WaDocumento53 pagineBEM Code of Ethics - Ir. Yim Hon WaAnonymous DJrec2Nessuna valutazione finora

- Managing A Safe Work PlaceDocumento3 pagineManaging A Safe Work PlaceAnonymous DJrec2Nessuna valutazione finora

- 0217 PresentationDocumento73 pagine0217 PresentationHector RodriguezNessuna valutazione finora

- Malaysia Kia Sportage Price List 2012Documento1 paginaMalaysia Kia Sportage Price List 2012Anonymous DJrec2Nessuna valutazione finora

- The Nature and Purpose of Accounting ExplainedDocumento16 pagineThe Nature and Purpose of Accounting ExplainedSubashiиy PяabakaяaиNessuna valutazione finora

- Understanding MarketingDocumento5 pagineUnderstanding MarketingAnonymous DJrec2Nessuna valutazione finora

- Power Amps Efficiency PFDocumento5 paginePower Amps Efficiency PFAnonymous DJrec2Nessuna valutazione finora

- Engineers in Construction Industry - Ir. Choo Kok BengDocumento22 pagineEngineers in Construction Industry - Ir. Choo Kok BengAnonymous DJrec2Nessuna valutazione finora

- BEM Code of EthicsDocumento11 pagineBEM Code of EthicsAbdul Hakim AbdullahNessuna valutazione finora

- The Nature and Purpose of Accounting ExplainedDocumento16 pagineThe Nature and Purpose of Accounting ExplainedSubashiиy PяabakaяaиNessuna valutazione finora

- Industrial LowbayDocumento8 pagineIndustrial LowbayAnonymous DJrec2Nessuna valutazione finora

- Dry-Type Transformers: Codes and Standards Enhancement (CASE) StudyDocumento22 pagineDry-Type Transformers: Codes and Standards Enhancement (CASE) StudyAnonymous DJrec2Nessuna valutazione finora

- HarmonicsDocumento7 pagineHarmonicsAnonymous DJrec2Nessuna valutazione finora

- Motor Load and Efficiency PDFDocumento16 pagineMotor Load and Efficiency PDFwfjerrNessuna valutazione finora

- Basics of Power CableDocumento7 pagineBasics of Power CableAnonymous DJrec2Nessuna valutazione finora

- Third Quarter 2016 Investment Outlook: Asset Class SectorDocumento6 pagineThird Quarter 2016 Investment Outlook: Asset Class SectorAnonymous DJrec2Nessuna valutazione finora

- CiMB Research Report On REITDocumento6 pagineCiMB Research Report On REITAnonymous DJrec2Nessuna valutazione finora

- Information: Hardware Fitting AccessoriesDocumento17 pagineInformation: Hardware Fitting AccessoriesAmrish TyagiNessuna valutazione finora

- Cypress Landing Housing For VeteransDocumento24 pagineCypress Landing Housing For VeteransEmmanuel BrayNessuna valutazione finora

- Critical Buckling Load of Pile in Liquefied SoilDocumento8 pagineCritical Buckling Load of Pile in Liquefied SoilKefas JanuarNessuna valutazione finora

- PerfectPleat SC M8 - Prod - Mark - SHT - AFP 1 202C NewDocumento2 paginePerfectPleat SC M8 - Prod - Mark - SHT - AFP 1 202C NewRonald SalasNessuna valutazione finora

- US8480802 VetrazzoDocumento11 pagineUS8480802 VetrazzoPavle SpasojevicNessuna valutazione finora

- RF Joints Manual enDocumento75 pagineRF Joints Manual enVladimir Jerson Alferez VargasNessuna valutazione finora

- Concrete swimming pool designDocumento14 pagineConcrete swimming pool designCristian BarbulescuNessuna valutazione finora

- Invitation To Bid - Proposed Soil TestingDocumento3 pagineInvitation To Bid - Proposed Soil TestingMac GonzalesNessuna valutazione finora

- Sample MOADocumento8 pagineSample MOAStewart Paul TorreNessuna valutazione finora

- (4C X 6mm) NYYHYDocumento3 pagine(4C X 6mm) NYYHYRahmawan fiberhomeNessuna valutazione finora

- Sustainable Design PrinciplesDocumento15 pagineSustainable Design PrinciplesyaraNessuna valutazione finora

- List of Activities To Be Carried Out Before The Kiln Light UpDocumento3 pagineList of Activities To Be Carried Out Before The Kiln Light UpVijay BhanNessuna valutazione finora

- CABLE-STAYED BRIDGE ConstructionDocumento6 pagineCABLE-STAYED BRIDGE ConstructionbifefumiNessuna valutazione finora

- MD AssignmentsDocumento2 pagineMD Assignmentsvikramsingh1011Nessuna valutazione finora

- Alternative materials and waste-derived fuels for cement industryDocumento4 pagineAlternative materials and waste-derived fuels for cement industryalbertbunguriNessuna valutazione finora

- Design - Calcs - Coupling Beams 4-7Documento4 pagineDesign - Calcs - Coupling Beams 4-7Krishna AnishNessuna valutazione finora

- 2011 NEC Code Changes HandbookDocumento33 pagine2011 NEC Code Changes HandbookBlackie KnightNessuna valutazione finora

- Method Statement For Installation of Steel Supports For Gratings at TR A...Documento9 pagineMethod Statement For Installation of Steel Supports For Gratings at TR A...Faraaz MohammedNessuna valutazione finora

- Willamette Ball Cone Valves Sales 2200 2600Documento28 pagineWillamette Ball Cone Valves Sales 2200 2600chandrasingh4564Nessuna valutazione finora

- Bolt Anchor FAZ II07302015 173728Documento9 pagineBolt Anchor FAZ II07302015 173728Kliment RistevskiNessuna valutazione finora

- Pay#4 EditedDocumento114 paginePay#4 EditedARSENessuna valutazione finora

- Management of Construction Projects A Constructor's Perspective 438 PDFDocumento438 pagineManagement of Construction Projects A Constructor's Perspective 438 PDFbakbak60% (5)

- Shear Wall Design PDFDocumento9 pagineShear Wall Design PDFjk.dasgupta100% (2)

- Project Phases: Planning PhaseDocumento4 pagineProject Phases: Planning PhaseWissam NumanNessuna valutazione finora

- Sor 16-17 PDFDocumento524 pagineSor 16-17 PDFRamuCivilNessuna valutazione finora

- Analysis and Design of Elevated Intze Watertank and Its Comparative Study in Different Wind Zones - Using SAP2000Documento12 pagineAnalysis and Design of Elevated Intze Watertank and Its Comparative Study in Different Wind Zones - Using SAP2000IJSTENessuna valutazione finora

- Hydraulic Cyl Calculation FormulasDocumento3 pagineHydraulic Cyl Calculation Formulasknsaravana100% (1)

- Water and Sewerage AuthorityDocumento43 pagineWater and Sewerage AuthorityCarl Crow100% (1)

- Op Exam 6-ADocumento4 pagineOp Exam 6-AHOFFERNessuna valutazione finora

- PMC Scope of WorkDocumento21 paginePMC Scope of WorkVijaita Vikas Gandhi100% (2)