Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ASME Div 1

Caricato da

Sudhanshu67Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ASME Div 1

Caricato da

Sudhanshu67Copyright:

Formati disponibili

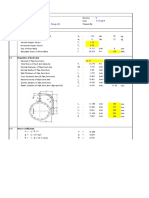

PRESSURE VESSEL DESIGN CALCULATIONS

DATE:05/03/2014

CYLINDRICAL SHELL THICKNESS

under Internal Pressure Ref.: DESIGN DATA DESIGN PRESSURE DESIGN TEMPERATURE SHELL INSIDE DIA. CORROSION ALLOWANCE JOINT EFFICIENCY SHELL MATERIAL ALL. STRESSES @ DESIGN TEMP. ALL. STRESSES @ AMP.TEMP. MIN. REQUIRED THICKNESS AS PER UG - 16 ( cor) PROVIDED SHELL THICKNESS kg / mm kg / mm mm mm S Sa tmin Tp kg / mm C mm mm P Tc D C E 0.038067 120 3600 3.2 1 51660 12.02261 12.02261 1.6 10 ASME Sec. VIII - Div. 1 UG - 27

COR. INSIDE RADIUS REQUIRED SHELL THICKNESS

mm mm

1803.2

T = P R / [ S E - 0.6 P ] + C

8.9

MIN.REQUIRED SHELL THICKNESS PROVIDED SHELL THICKNESS

mm mm

Tmin Tp

8.9 10

MAXIMUM ALLOWABLE WORKING PRESSURE ( M.A.W.P - HOT & COR.) P = S.E ( Tp - C ) / [ R + 0.6 ( Tp - C ) ] kg /mm 0.0452

MAXIMUM ALLOWABLE WORKING PRESSURE ( M.A.W.P - COLD & UNCOR.) P = Sa.E . Tp / [ (R -C) + 0.6 Tp ] kg /mm 0.0666

ELONGATION 50 . Tp / ( D / 2 + Tp / 2 ) % 0.28

MIN REQD. THICKNESS AS PER UG - 16 : 3/32" + C for Steam , Water & Compressed Air Services 1/16" + C for Other Services

D:\Sudhanshu\Calculation sheets\[ASME Div 1.xls]DATA

PRESSURE VESSEL DESIGN CALCULATIONS

DATE:05/03/2014

CYLINDRICAL SHELL THICKNESS

under Internal Pressure Ref.: DESIGN DATA M.A.W.P DESIGN TEMPERATURE SHELL INSIDE DIA. CORROSION ALLOWANCE JOINT EFFICIENCY SHELL MATERIAL ALL. STRESSES @ DESIGN TEMP. ALL. STRESSES @ AMP.TEMP. MIN. REQUIRED THICKNESS AS PER UG - 16 ( cor) PROVIDED SHELL THICKNESS kg / mm kg / mm mm mm S Sa tmin Tp kg / mm C mm mm P Tc D C E 0.0452 120 3600 3.2 1 51660 12.02261 12.02261 1.6 10 ASME Sec. VIII - Div. 1 UG - 27

COR. INSIDE RADIUS REQUIRED SHELL THICKNESS

mm mm

1803.2

T = P R / [ S E - 0.6 P ] + C

10.0

MIN.REQUIRED SHELL THICKNESS PROVIDED SHELL THICKNESS

mm mm

Tmin Tp

10.0 10

MAXIMUM ALLOWABLE WORKING PRESSURE ( M.A.W.P - HOT & COR.) P = S.E ( Tp - C ) / [ R + 0.6 ( Tp - C ) ] kg /mm 0.0452

MAXIMUM ALLOWABLE WORKING PRESSURE ( M.A.W.P - COLD & UNCOR.) P = Sa.E . Tp / [ (R -C) + 0.6 Tp ] kg /mm 0.0666

ELONGATION 50 . Tp / ( D / 2 + Tp / 2 ) % 0.28

MIN REQD. THICKNESS AS PER UG - 16 : 3/32" + C for Steam , Water & Compressed Air Services 1/16" + C for Other Services

D:\Sudhanshu\Calculation sheets\[ASME Div 1.xls]DATA

PRESSURE VESSEL DESIGN CALCULATIONS

DATE:05/03/2014

ELLIPSOIDAL HEAD THICKNESS

under Internal Pressure Ref.: DESIGN DATA DESIGN PRESSURE DESIGN TEMPERATURE HEAD INSIDE DIA. CORROSION ALLOWANCE JOINT EFFICIENCY HEAD MATERIAL ALL. STRESSES @ DESIGN TEMP. ALL. STRESSES @ AMP.TEMP. MIN. REQUIRED THICKNESS AS PER UG - 16 PROVIDED HEAD THICKNESS kg / mm kg / mm mm mm S Sa tmin. Tp kg / mm C mm mm P Tc D C E 0.038067 120 3600 3.2 1 51660 12.02261 12.02261 1.6 12 ASME Sec. VIII - Div. 1 UG - 32

COR. INSIDE CROWN RADIUS COR. INSIDE KNUCKLE RADIUS REQUIRED HEAD THICKNESS

mm mm mm

R r

3243.2 615.2

T = [P (D+2C)] / [2 S E - 0.2 P ] + C

8.91

MIN. REQUIRED HEAD THICKNESS PROVIDED HEAD THICKNESS

mm mm

Tmin Tp

8.9 12 10.7 MIN

MAXIMUM ALLOWABLE WORKING PRESSURE ( M.A.W.P - HOT & COR. ) P = 2S.E ( Tp - C ) / [(D+2C) + 0.2 ( Tp - C ) kg /mm 0.0501

MAXIMUM ALLOWABLE WORKING PRESSURE ( M.A.W.P - COLD & UNCOR. ) P = 2Sa.E. Tp / [D + 0.2 Tp ] kg /mm 0.0715

ELONGATION 75 . Tp / ( r + Tp / 2 ) % 1.29

MIN REQD. THICKNESS AS PER UG - 16 : 3/32" + C for Steam , Water & Compressed Air Services 1/16" + C for Other Services

D:\Sudhanshu\Calculation sheets\[ASME Div 1.xls]DATA

PRESSURE VESSEL DESIGN CALCULATIONS

DATE:05/03/2014

ELLIPSOIDAL HEAD THICKNESS

under Internal Pressure Ref.: DESIGN DATA M.A.W.P DESIGN TEMPERATURE HEAD INSIDE DIA. CORROSION ALLOWANCE JOINT EFFICIENCY HEAD MATERIAL ALL. STRESSES @ DESIGN TEMP. ALL. STRESSES @ AMP.TEMP. MIN. REQUIRED THICKNESS AS PER UG - 16 PROVIDED HEAD THICKNESS kg / mm kg / mm mm mm S Sa tmin. Tp kg / mm C mm mm P Tc D C E 0.0452 120 3600 3.2 1 51660 12.02261 12.02261 1.6 12 ASME Sec. VIII - Div. 1 UG - 32

COR. INSIDE CROWN RADIUS COR. INSIDE KNUCKLE RADIUS REQUIRED HEAD THICKNESS

mm mm mm

R r

3243.2 615.2

T = [P (D+2C)] / [2 S E - 0.2 P ] + C

9.99

MIN. REQUIRED HEAD THICKNESS PROVIDED HEAD THICKNESS

mm mm

Tmin Tp

10.0 12 12.0 MIN

MAXIMUM ALLOWABLE WORKING PRESSURE ( M.A.W.P - HOT & COR. ) P = 2S.E ( Tp - C ) / [(D+2C) + 0.2 ( Tp - C ) kg /mm 0.0586

MAXIMUM ALLOWABLE WORKING PRESSURE ( M.A.W.P - COLD & UNCOR. ) P = 2Sa.E. Tp / [D + 0.2 Tp ] kg /mm 0.0801

ELONGATION 75 . Tp / ( r + Tp / 2 ) % 1.45

MIN REQD. THICKNESS AS PER UG - 16 : 3/32" + C for Steam , Water & Compressed Air Services 1/16" + C for Other Services

D:\Sudhanshu\Calculation sheets\[ASME Div 1.xls]DATA

Potrebbero piacerti anche

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocumento1 paginaK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjNessuna valutazione finora

- Hemispherical EndsDocumento3 pagineHemispherical EndsEng-CalculationsNessuna valutazione finora

- Flat End With A Full-Face GasketDocumento3 pagineFlat End With A Full-Face GasketEng-CalculationsNessuna valutazione finora

- If Any Data - Please Entry This Data: Equipment: Pressure VesselDocumento19 pagineIf Any Data - Please Entry This Data: Equipment: Pressure VesselES RouzaNessuna valutazione finora

- AD 2000 Head Under Intenal PressureDocumento3 pagineAD 2000 Head Under Intenal Pressuremechengg01Nessuna valutazione finora

- MD PV ASME v0.1Documento35 pagineMD PV ASME v0.1rizalramaNessuna valutazione finora

- Flat Ends Welded Directly To The ShellDocumento9 pagineFlat Ends Welded Directly To The ShellEng-CalculationsNessuna valutazione finora

- Spherical ShellsDocumento3 pagineSpherical ShellsEng-CalculationsNessuna valutazione finora

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Documento32 paginePV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNessuna valutazione finora

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDocumento1 paginaRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutNessuna valutazione finora

- Flat End With A Full-Face Gasket For Single Isolated OpeningDocumento3 pagineFlat End With A Full-Face Gasket For Single Isolated OpeningEng-CalculationsNessuna valutazione finora

- Shell Thickness CalculationsDocumento2 pagineShell Thickness CalculationsskocogluNessuna valutazione finora

- Flat Ends With A Relief GrooveDocumento11 pagineFlat Ends With A Relief GrooveEng-CalculationsNessuna valutazione finora

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design ToolSudjono BroNessuna valutazione finora

- Flat Ends With A Hub For Uniform Thickness ShellDocumento5 pagineFlat Ends With A Hub For Uniform Thickness ShellEng-CalculationsNessuna valutazione finora

- Design by AnalysisDocumento22 pagineDesign by AnalysisJEELE77Nessuna valutazione finora

- Welding Calculation ModulDocumento5 pagineWelding Calculation ModulricardoNessuna valutazione finora

- 809-WS-ASME VIII Div 2 - Ellipsoidal Head Design - Rev0Documento2 pagine809-WS-ASME VIII Div 2 - Ellipsoidal Head Design - Rev0Sebastiano OrofinoNessuna valutazione finora

- .Documento7 pagine.Darshan Panchal100% (1)

- Narrow Face Flange - Slip On Hub TypeDocumento17 pagineNarrow Face Flange - Slip On Hub TypeEng-CalculationsNessuna valutazione finora

- Tailing LugDocumento2 pagineTailing Lugjagannadha varmaNessuna valutazione finora

- PV Elite Vessel Analysis Program HorizontalDocumento55 paginePV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriNessuna valutazione finora

- Mozzle Repad Design ToolDocumento2 pagineMozzle Repad Design ToolSiddiqui Muhammad AshfaqueNessuna valutazione finora

- Pressure Vessel Design 2018 VER BDocumento61 paginePressure Vessel Design 2018 VER BBob FitcherNessuna valutazione finora

- Design Calculation Fuel Gas ScrubberDocumento239 pagineDesign Calculation Fuel Gas ScrubberPeja JusohNessuna valutazione finora

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Documento4 pagineFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNessuna valutazione finora

- Design Calculations For Pressure VesselsDocumento43 pagineDesign Calculations For Pressure VesselsMoises Alvarez LeandroNessuna valutazione finora

- Design Calculations for Pressure VesselDocumento37 pagineDesign Calculations for Pressure VesselfnyaclsNessuna valutazione finora

- Section VIII CalDocumento22 pagineSection VIII CalthodathersNessuna valutazione finora

- Product Form Table 1A: Maximum Allowable Stress Values for Ferrous Materials at Design TemperatureDocumento10 pagineProduct Form Table 1A: Maximum Allowable Stress Values for Ferrous Materials at Design TemperatureSalvador MalagoNessuna valutazione finora

- 16 Preiss Study en 13445 Asme ViiiDocumento26 pagine16 Preiss Study en 13445 Asme ViiiDubaiHMARNessuna valutazione finora

- Compress EvaluateDocumento23 pagineCompress EvaluateVishalDhiman100% (1)

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design Toolnaveen_86Nessuna valutazione finora

- Cylindrical ShellsDocumento3 pagineCylindrical ShellsEng-CalculationsNessuna valutazione finora

- Asme Sec 8 Div 1 - App 1-10Documento11 pagineAsme Sec 8 Div 1 - App 1-10BibinBabuNessuna valutazione finora

- HE Header E535Documento91 pagineHE Header E535rizal mubarokNessuna valutazione finora

- Spherical Shells (7.4.3) EN 13445-3Documento3 pagineSpherical Shells (7.4.3) EN 13445-3met-calcNessuna valutazione finora

- N11 Nozzle CalDocumento9 pagineN11 Nozzle Calגרבר פליקסNessuna valutazione finora

- Spherical Shells en 13445-3 - 7.4.3Documento3 pagineSpherical Shells en 13445-3 - 7.4.3met-calc100% (1)

- Calcu Nozzle NeckDocumento15 pagineCalcu Nozzle Necksachmaya0% (1)

- Pressure Test Requirements for Unfired Pressure Vessels According to EN 13445Documento14 paginePressure Test Requirements for Unfired Pressure Vessels According to EN 13445Nanang PhNessuna valutazione finora

- Weld stress check for FAVID clips and demister clipsDocumento3 pagineWeld stress check for FAVID clips and demister clipsrsubramaniNessuna valutazione finora

- PRESSURE VESSEL STRENGTH CALCULATIONDocumento52 paginePRESSURE VESSEL STRENGTH CALCULATIONClaudia BonocoreNessuna valutazione finora

- Final Weld Strength CalnsDocumento5 pagineFinal Weld Strength CalnsamachmouchiNessuna valutazione finora

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Documento21 pagineCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Elliptical Head Design ToolDocumento1 paginaElliptical Head Design ToolssierroNessuna valutazione finora

- Deaera DesignDocumento13 pagineDeaera DesignBhanu K PrakashNessuna valutazione finora

- Structural stress calculation methods for welded jointsDocumento11 pagineStructural stress calculation methods for welded jointsBob LoblawNessuna valutazione finora

- Asme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoDocumento72 pagineAsme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoSivateja NallamothuNessuna valutazione finora

- MDMT Calculations For A Pressure Vessel - Abdel Halim GalalaDocumento12 pagineMDMT Calculations For A Pressure Vessel - Abdel Halim Galalabego00Nessuna valutazione finora

- Nozzle Calcs Rev ADocumento6 pagineNozzle Calcs Rev AbolivarNessuna valutazione finora

- Saddle design calculationsDocumento9 pagineSaddle design calculationsduf fuNessuna valutazione finora

- Flange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gDocumento10 pagineFlange Calculation As Per JIS B 8243 Appendix 2: Internal Pressure, Integral Flange R (C-B) /2-gAsep MulyadiNessuna valutazione finora

- Design of base plate for columnDocumento6 pagineDesign of base plate for columnsoumyaNessuna valutazione finora

- 8KL FERMENTER DESIGN CALCULATIONSDocumento3 pagine8KL FERMENTER DESIGN CALCULATIONSkirandas_mullasseryNessuna valutazione finora

- Design Calculations For Pressure VesselsDocumento32 pagineDesign Calculations For Pressure VesselsGeorge Georgian100% (3)

- UEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPPDocumento8 pagineUEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPPmkchy12100% (1)

- Design Calculations For Pressure VesselsDocumento24 pagineDesign Calculations For Pressure VesselsMichael Lageman93% (15)

- 31barg CalculationDocumento10 pagine31barg Calculationshani5573Nessuna valutazione finora

- API 650-RF Pad CalculationDocumento1 paginaAPI 650-RF Pad CalculationSudhanshu67100% (2)

- AES Type Heat ExchangerDocumento8 pagineAES Type Heat ExchangerSudhanshu67100% (1)

- Api 610Documento1 paginaApi 610Sudhanshu67Nessuna valutazione finora

- AdapterDocumento16 pagineAdapterSudhanshu67Nessuna valutazione finora

- Is 6533 Part-2 Design of Construction of Steel Chimney-CodDocumento23 pagineIs 6533 Part-2 Design of Construction of Steel Chimney-CodRiaz M IbrahimNessuna valutazione finora

- Material EquivalentDocumento3 pagineMaterial EquivalentSudhanshu670% (1)

- Chapter 2. Estimation of Wind Load EffectsDocumento23 pagineChapter 2. Estimation of Wind Load EffectsSudhanshu67Nessuna valutazione finora

- API Code Master List - 2005Documento11 pagineAPI Code Master List - 2005Sudhanshu67Nessuna valutazione finora

- Grundfos LiteratureDocumento16 pagineGrundfos LiteratureMajdi NeouiNessuna valutazione finora

- Centrifugal Pump Design - Rev 2Documento11 pagineCentrifugal Pump Design - Rev 2jehadyam100% (1)

- Dimensions, Sizes and Specification of DIN Flange & DIN Standard Flanges of Slip On Flanges, Blind Flanges, Welding FlangesDocumento7 pagineDimensions, Sizes and Specification of DIN Flange & DIN Standard Flanges of Slip On Flanges, Blind Flanges, Welding FlangesSudhanshu67Nessuna valutazione finora

- PV Elite Heat Exchanger CalculationsDocumento99 paginePV Elite Heat Exchanger CalculationscbousmuNessuna valutazione finora

- Saddle AnalysisDocumento17 pagineSaddle AnalysisAntonio Perez ZornozaNessuna valutazione finora

- Full Paper RECPDocumento5 pagineFull Paper RECPSudhanshu67Nessuna valutazione finora

- Sample13 SpreadsheetDocumento100 pagineSample13 SpreadsheetSourav HaitNessuna valutazione finora

- Full Paper RECPDocumento5 pagineFull Paper RECPSudhanshu67Nessuna valutazione finora

- Brookes Bell-Carriage of SulphurDocumento4 pagineBrookes Bell-Carriage of SulphurAntonio Perez100% (1)

- Powder Coating Recycling: Reducing Waste & Your Environmental FootprintDocumento3 paginePowder Coating Recycling: Reducing Waste & Your Environmental FootprintAn TrNessuna valutazione finora

- Imsbc Palm Kernel Shell (PKS)Documento6 pagineImsbc Palm Kernel Shell (PKS)majiex77100% (2)

- Green Catalogue PDFDocumento12 pagineGreen Catalogue PDFSumita JaiswalNessuna valutazione finora

- Fibre Rope - Terminology and Good PracticesDocumento19 pagineFibre Rope - Terminology and Good PracticesLe Quyen NguyenNessuna valutazione finora

- Rollinson & Pease 2021 - Geochemical BookDocumento285 pagineRollinson & Pease 2021 - Geochemical BookLuciano SilvaNessuna valutazione finora

- Preliminary Technical Program HMnS2016Documento33 paginePreliminary Technical Program HMnS2016manjumv27Nessuna valutazione finora

- Renu Yarn List: Type Quality Brightness Country of Origin MOQDocumento4 pagineRenu Yarn List: Type Quality Brightness Country of Origin MOQSharif0721Nessuna valutazione finora

- Lesson Plan ME-220 Engineering MaterialsDocumento2 pagineLesson Plan ME-220 Engineering MaterialsHajiasifAliNessuna valutazione finora

- M&MSDocumento2 pagineM&MSASIST MechNessuna valutazione finora

- NG Candle Wax Guide: Paraffin, Soy, Beeswax & MoreDocumento8 pagineNG Candle Wax Guide: Paraffin, Soy, Beeswax & MoreNancyHendryNessuna valutazione finora

- Coil WindingDocumento17 pagineCoil WindingSourav Das0% (1)

- 3 - SWCC Specification M02 Polyethylene Coating Rev0Documento30 pagine3 - SWCC Specification M02 Polyethylene Coating Rev0EngineerSajidAlam100% (1)

- Improving Garbage Collection in Brgy. GatbucaDocumento9 pagineImproving Garbage Collection in Brgy. GatbucaKaren AsaharNessuna valutazione finora

- To Measure The Head Loss (HL) in A Pipe of Uniform Diameter (D)Documento6 pagineTo Measure The Head Loss (HL) in A Pipe of Uniform Diameter (D)Syed Ali Hasnain NaqviNessuna valutazione finora

- SoapDocumento4 pagineSoapSi OneilNessuna valutazione finora

- Dictionar Tehnic General / General Technical Dictionary: Romana/RomanianDocumento62 pagineDictionar Tehnic General / General Technical Dictionary: Romana/RomanianAma81100% (17)

- Discharge Plasma and Ion - Surface InteractionsDocumento50 pagineDischarge Plasma and Ion - Surface InteractionsIriantoNessuna valutazione finora

- 05 - Boat Building MaterialsDocumento8 pagine05 - Boat Building MaterialsPhong TuanNessuna valutazione finora

- Popping Magnesium RibbonDocumento2 paginePopping Magnesium RibbonChristian ConolNessuna valutazione finora

- SSC Resistance of QT-900 and QT-1000 Coiled TubingDocumento11 pagineSSC Resistance of QT-900 and QT-1000 Coiled TubingSeçkin ÖztelNessuna valutazione finora

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocumento12 pagineSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingKamil AYDINNessuna valutazione finora

- MOL Transol 220 Industrial Gear OilDocumento2 pagineMOL Transol 220 Industrial Gear OilMaDa GeoNessuna valutazione finora

- 3) Dynamic Properties and Influence of Clay Mineralogy Types On The Cyclic Strength of Mine Tailings PDFDocumento13 pagine3) Dynamic Properties and Influence of Clay Mineralogy Types On The Cyclic Strength of Mine Tailings PDFVgkBharadwajNessuna valutazione finora

- Handbook of Biopolymers Advances and Multifaceted Applications (Ahmed, Shakeel Kanchi, Suvardhan Kumar Etc.)Documento323 pagineHandbook of Biopolymers Advances and Multifaceted Applications (Ahmed, Shakeel Kanchi, Suvardhan Kumar Etc.)Tecuitlatl100% (3)

- CSA GasTrade-Ed7 Quiz U10-Ch3Documento2 pagineCSA GasTrade-Ed7 Quiz U10-Ch3diegoNessuna valutazione finora

- Et 0000 0 000 04 750Documento83 pagineEt 0000 0 000 04 750RenatoNessuna valutazione finora

- ConsolidationDocumento42 pagineConsolidationalishagarcia01Nessuna valutazione finora

- Arkema - Polymer Selection Guide For Liquid ResinsDocumento28 pagineArkema - Polymer Selection Guide For Liquid ResinsYoNessuna valutazione finora

- Tle 6 (Industrial Arts) Week 8 Day 2Documento3 pagineTle 6 (Industrial Arts) Week 8 Day 2Krisna HundosNessuna valutazione finora