Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

JHA 27 For Online Weld Repair of Shell Butt Joint

Caricato da

mujahid1137Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

JHA 27 For Online Weld Repair of Shell Butt Joint

Caricato da

mujahid1137Copyright:

Formati disponibili

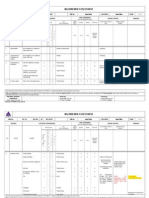

JOB HAZARD ANALYSIS FORM

Page No. 1 of 13

PETROSERV LTD

JSA Number:

27( METHOD STATEMENT No. PT/4648/MS/M/12)

Job being analyzed:

Procedure for online weld repair of shell butt joint

Department / Section

Projects

JHA Members

Project Manager , Project Engineer

Area / Location:

Halul

Job Performer

Petroserv limited

Signature

Date

APPOVALS

Name

Project Engineer

Anand

Safety Representative

Eldho Koloth

Project Manager

Ganesh

Any Other

Emergency Situation /

Evacuation

Note

Format No .PT-IMSP-10-F-03

Hazardous Gases, Fire

REV No.

DATE

17/09/2012

General job requirements

/Common PPE

-Coveralls

-Safety Helmet

-Safety Shoes (Shoes must not

be smooth)

-Safety Glasses (Clear)

-Safety Gloves

-Barricade / Sign the Area.

-Pre-Start Safety Toolbox Talk

JOB HAZARD ANALYSIS FORM

Page No. 2 of 13

PETROSERV LTD

Sequence of Basic Job Steps

OIL TRANSFERING

Potential Hazards

PRESENCE OF FLAMMABLE /

TOXIC VAPOR OR LIQUID

Hazard Control

ENSURE THE WORKSITE IS FREE FROM TOXIC / FLAMMABLE

VAPOR.

CARRY OUT GAS TEST FOR SAFE WORKING AREA

PROVIDE RESPIRATORY PROTECTIVE EQUIPMENT

FIRE & EXPLOSION

ENSURE THE AVAILABILITY OF SPARK / FLAME ARRESTER

MOUNTED IS BEING USED ON THE EXHAUST OF EQUIPMENT &

SHALL BE 50 FEET AWAY FROM THE TANK

CONFIRM THE AVAILABILITY OF EARTHING ON THE EQUIPMENT

TO DISSIPATE THE ELECTROSTATIC CHARGES.

ENSURE THE AVAILABILITY OF SUITABLE & APPROVED FIRE

EXTINGUISHERS AT SITE.

NEVER BRING A NAKED FLAME OR SPARK GENERATING TOOL

NEAR TO WHILE COLLECTING A FLAMMABLE LIQUID.

DEFECTIVE EQUIPMENT &

ACCESSORIES

COLLAPSE OF HOSE / SPLASH

OF HAZARDOUS FLUID

ENSURE THE PUMP, ISOLATION VALVE AND HOSES ARE FREE

FROM DEFECT.

DO NOT OVERLOAD THE PIPE/ HOSE WHILE OIL TRANSFERRING

THROUGH THE PIPE / HOSE.

USE SAFETY GOGGLES

Format No .PT-IMSP-10-F-03

JOB HAZARD ANALYSIS FORM

Page No. 3 of 13

PETROSERV LTD

Sequence of Basic Job Steps

Potential Hazards

Hazard Control

USE CORRECT TYPE OF TOOLS TO OPEN & HOLD THE FLANGE

USE HOSE OF SUITABLE PRESSURE RATING.

HOSE LEAK OR RUPTURE

STOP THE PUMPING IMMEDIATELY IN CASE OF LEAK.

SPILLAGE

IMMEDIATELY ALERT OTHERS IN THE AREA AND THE QP

SUPERVISOR, AND EVACUATE THE AREA IF NECESSARY.

EVACUATE ALL PERSONNEL, SEAL OFF ACCESS FROM DANGER

AREA (IF SAFE TO DO SO WITHOUT PERSONAL RISK)

ISOLATE ANY IGNITION SOURCE.

FOR EXTERNAL SPILLS, COVER DRAINS TO PREVENT THE

MATERIAL GOING INTO DRAINS AND OR WATER COURSES. DO

NOT WASH SPILLAGE INTO DRAINS

ENSURE SAFE DISPOSAL OF THE SPILLED SUBSTANCES AND

ANY ABSORBENT MATERIAL USED.

ACQUIRE RECOMMENDED PERSONAL PROTECTIVE EQUIPMENT

AND TRAINING IN ITS PROPER USE. SAFETY PERSONAL

PROVIDES SHALL TRAINING TO WORKERS IN THE PROPER USE

OF

PERSONAL

PROTECTIVE

EQUIPMENT,

INCLUDING

RESPIRATORS, GLOVES, AND EYE AND FACE PROTECTION

Format No .PT-IMSP-10-F-03

JOB HAZARD ANALYSIS FORM

Page No. 4 of 13

PETROSERV LTD

Sequence of Basic Job Steps

WORKING AT HEIGHT

Potential Hazards

FALL OF MATERIAL FROM

HEIGHT

Hazard Control

TOOLS AND OTHER ARTICLES AND MATERIALS SHALL BE

PROPERLY LOWERED AND SHALL NOT BE THROWN DOWN

FROM HEIGHT. THEY SHALL BE LOWERED / RAISED BY ROPE.

PPES HARD HATS & SAFETY SHOES SHALL BE USED BY THE

WORKERS WORKING BELOW

TOOLS SHALL BE CARRIED IN BAGS & SECURED

FALL OF PERSON FROM

HEIGHT

EXPERIENCED WORKERS SHALL BE USED.

PERSONNEL SHALL BE INFORMED OF THE HAZARDS AND

PRECAUTIONS OF WORKING AT HEIGHT.

FULL BODY SAFETY HARNESS MUST BE USED.

PPES SHALL BE USED.

MANUAL TOOLS

TOOLS SHALL BE INSPECTED BEFORE USE.

CORRECT TOOLS SHALL BE USED.

PPE SHALL BE USED.

INSTALLATION OF SCAFFOLDING

(RIGGING UP/DOWN SCAFFOLDING

MATERIALS FROM GROUND LEVEL

TO THE DESIRED HEIGHT)

INJURY / DAMAGE AS A

USE APPROPRIATE BARRICADES TO PROTECT PERSONNEL.

RESULT OF DROPPING TOOLS

AND SCAFFOLD COMPONENTS KEEP TOOLS IN TOOL BAG OR BASKETS SECURED PROPERLY.

LOOSE MATERIAL SHALL NOT BE KEPT ON

PLATFORM

A SUITABLE CAPACITY CRANE SHALL BE USED TO

Format No .PT-IMSP-10-F-03

SHIFT

JOB HAZARD ANALYSIS FORM

Page No. 5 of 13

PETROSERV LTD

Sequence of Basic Job Steps

Potential Hazards

Hazard Control

THE SCAFFOLDING MATERIALS FROM TANK

TO THE RESPECTIVE LEVEL.

GROUND LEVEL

ALL COMPONENTS TO BE CHECKED PRIOR TO INSTALLATION.

INJURY / DAMAGE DUE TO

AVOID BROKEN, BENT AND EXCESSIVELY RUSTED OR

COLLAPSE OF SCAFFOLD OR

DAMAGED FRAMES / ACCESSORIES.

BY

PERSONNEL

FALLING

FROM SCAFFOLD.

ERECT AND DISMANTLE ALL SCAFFOLD TO COMPLY TO

REQUIREMENTS.

SCAFFOLD MUST BE ERECTED/DISMANTLED BY TRAINED /

EXPERIENCED PERSONNEL UNDER THE DIRECTION OF

COMPETENT SUPERVISOR.

SCAFFOLD SHALL BE ERECTED ON A PLAIN LEVEL SURFACE

AND SECURED TO PERMANANET STRUCTURES. ADDITIONAL

PLATES SHALL BE PROVIDED TO SCAFFOLDING BASE WHEN

ERECTING ON SOFT GROUND.

SCAFFOLD SHALL BE INSPECTED BY A COMPETENT PERSON

AND SCAFF TAG SYSTEM SHALL BE FOLLOWED.

SUFFICIENT ACCESS / EGRESS SHALL

CONSIDERING EMERGENCY SITUATION.

BE

PROVIDED

CHECK SPECIFIED LIMITS OF SCAFFOLD BEFORE UTILIZATION.

USE SAFETY HARNESS AND LANYARD ANCHORED TO SECURE

POINT WHEN WORKING ABOVE 2.0 METERS HEIGHT.

ACCESS / LADDERS, GUARD RAIL SYSTEM AND TOE BOARD

Format No .PT-IMSP-10-F-03

JOB HAZARD ANALYSIS FORM

Page No. 6 of 13

PETROSERV LTD

Sequence of Basic Job Steps

Potential Hazards

Hazard Control

SHALL BE PROVIDE & SECURELY FIXED.

GRINDING

UNAUTHORIZED WORK

OBTAIN HOT WORK PERMIT BEFORE STARTING THE JOB.

INVALID PERMIT

GET THE PERMIT VALIDATED FOR THE DAY

COMPETENCY OF PERSONNEL

SUPERVISOR MUST ENSURE THAT ALL WORK ACTIVITIES ARE

CARRIED OUT BY EXPEREINCE AND COMPETENT PERSONNEL.

LACK OF POOR

COMMUNICATION

TOOLBOX TALK SHALL BE CONDUCTED BY THE SUPERVISOR.

HASTE OR SHORTCUT

FIRE HAZARD BURNS

SAFETY OFFICER SHALL CONDUCT INSPECTION, MONITOR

WORK ACTIVITIES AND SHALL ENSURE SAFETY STANDARDS

AND PROCEDURES ARE STRICTLY ADHERED TO.

GAS TESTING SHALL BE CARRIED OUT BY CERTIFIED AND

AUTHORIZED GAS TESTER (QP PERSONNEL).

HOT WORK SHALL HAVE APPROPRIATE HABITAT OR

ENCLOSURE TO PREVENT SPARKS AND NAKED FLAME

EXPOSURE.

NO COMBUSTIBLE / FLAMMABLE

AVAILABLE NEAR THE WORK.

MATERIAL

SHALL

BE

TRAINED FIRE WATCH SHALL BE POSTED AND STAND- BY FIRE

WATCHER SHALL BE AVAILABLE DURING GRINDING.

CORRECT FIRE EXTINGUISHERS SHALL BE MAINTAINED

CABLES SHALL BE LAID PROPERLY.

Format No .PT-IMSP-10-F-03

JOB HAZARD ANALYSIS FORM

Page No. 7 of 13

PETROSERV LTD

Sequence of Basic Job Steps

Potential Hazards

Hazard Control

CONDITION OF CABLES SHALL BE MONITORED REGULARLY

FIRE BLANKET SHALL BE MAINTAINED NEAR THE WORK.

INJURY WHILE GRINDING &

GRINDING SPARKS

PPES SHALL BE USED FOR THE SPECIFIC JOB

MAKE SURE THAT EQUIPMENT IS PROVIDED WITH GUARDS

UNAUTHORIZED PERSONNELSHALL BE KEPT AWAY FROM THE

AREA

ELECTROCUTION / INJURY

DUE TO ELECTRIC SHOCK

DYE-PENETRATING TEST

ENSURE ALL EQUIPMENTS HAVE BEEN CONNECTED

EARTHING / GROUNDING TO PREVENT ELECTROCUTION.

TO

AVOID LONG AND REPEATED CONTACTS WITH DYE PENETRANT

IRRITATION OF SKIN, EYES,

MATERIAL. IT CAN CAUSE IRRITATION.

DIZZINESS & NAUSEA

SAFETY GOGGLES AND COVERALL SHALL BE USED DURING THE

TEST.

IF DYE, DEVELOPER AND CLEANER CANISTER ARE USED, THEY

SHALL BE STORED AND DISPOSED OFF PROPERLY AFTER USE.

AT NO TIME SHALL THE CANISTER BE DISPOSED OF IN FIRE.

ALL WASTE MATERIALS SHALL BE DISPOSED OFF PROPERLY.

WELDING

Format No .PT-IMSP-10-F-03

UNAUTHORIZED WORK

OBTAIN HOT WORK PERMIT BEFORE STARTING THE JOB.

INVALID PERMIT

GET THE PERMIT VALIDATED FOR THE DAY

COMPETENCY OF PERSONNEL

SUPERVISOR SHALL ENSURE THAT ALL WORK ACTIVITIES ARE

JOB HAZARD ANALYSIS FORM

Page No. 8 of 13

PETROSERV LTD

Sequence of Basic Job Steps

Potential Hazards

Hazard Control

CARRIED OUT BY EXPEREINCE AND COMPETENT PERSONNEL.

LACK

OF

KNOWLEDGE

HAZARD

HASTE OR SHORTCUT

FIRE

HAZARD

EXPLOSION

TOOLBOX TALK SHALL BE CONDUCTED BY THE SUPERVISOR.

SAFETY OFFICER SHALL CONDUCT INSPECTION, MONITOR

WORK ACTIVITIES AND SHALL ENSURE SAFETY STANDARDS

AND PROCEDURES ARE STRICTLY ADHERED TO.

BURNS,

GAS TESTING SHALL BE CARRIED OUT BY CERTIFIED AND

AUTHORIZED GAS TESTER (QP PERSONNEL).

HOT WORK SHALL HAVE APPROPRIATE HABITAT OR

ENCLOSURE TO PREVENT SPARKS AND NAKED FLAME

EXPOSURE.

BEFORE STARTING WELDING MAKE SURE THAT THE AREA IS

CLEAR OF ALL TYPES OF COMBUSTIBLE MATERIALS.

ENSURE FIRE EXTINGUISHERS ARE AVAILABLE ON SITE.

TRAINED FIRE WATCH SHALL BE POSTED AND STAND-BY FIRE

WATCHER SHALL ALSO BE AVAILABLE DURING HOT WORK.

HOUSE KEEPING SHALL BE MAITAINED.

CORDONING OF THE AREA.

Format No .PT-IMSP-10-F-03

ELECTROCUTION

ENSURE ALL EQUIPMENTS / GENERATORS HAVE BEEN

CONNECTED TO EARTHING / GROUNDING TO PREVENT

ELECTROCUTION.

DAMAGE CABLE

ENSURE CABLES ARE IN GOOD CONDITION

JOB HAZARD ANALYSIS FORM

Page No. 9 of 13

PETROSERV LTD

Sequence of Basic Job Steps

Potential Hazards

HOT TABS END PIECES OF

WELDING RODS.

Hazard Control

ENSURE THE ROD HOLDER ARE IN GOOD CONDITION.

HOT TABS SHALL NOT BE THROWN BUT COLLECTED IN TIN

CANS.

SPARKING

USE PROPER CABLE CONNECTOR FOR EXTENSION.

WHERE CABLES ARE CROSSING THE WALKING AREA THEN

ENSURE PROPER PROTECTION.

UV RAYS

WELDER & HELPERS SHALL WEAR WELDING GOGGLES

TOXIC FUMES

USE OF EQUIPMENTS, WELDING M/C,

GENERATORS ETC

FIRE

HAZARD

REFUELING

USE APPROPRIATE RPE & PPE

DURING

SWITCH OFF EQUIPMENT BEFORE STARTING REFUELING

ENSURE SAFE ACCESS TO THE EQUIPMENT TO BE REFULED

STAY NEAR THE EQUIPMENT FUELING POINT WHEN FUELING.

NEVER OVERFILL THE FUEL TANK

REFULLING TO BE DONE AT SLOW RATE TO REDUCE THE

POTENTIAL FOR SPILLAGE AND STATIC IGNITION.

FIRE EXTINGUSHER SHALL BE MAINTAINED.

NO IGNITION SOURCE SHOULD BE AVAILABLE DURING & NEAR

REFUELING.

USE PROPER PPE

Format No .PT-IMSP-10-F-03

JOB HAZARD ANALYSIS FORM

Page No. 10 of 13

PETROSERV LTD

Sequence of Basic Job Steps

WORK IN OPEN AREA

Potential Hazards

HEAT STRESS & INJURY

Hazard Control

SUMMER WORKING TIME SHALL BE FOLLOWED.

ADEQUATE SHADE OR REST AREA SHALL BE PROVIDED

BREAKS SHALL BE TAKEN AND JOB ROTATION MAY BE

FOLLOWED.

USE PROPER PPE

VEHICLE MOVEMENT

ACCIDENTS INJURY

DAMAGE TO PROPERTY

& LICENSED DRIVERS SHALL ONLY OPERATE VEHICLES.

VEHICLES SHALL BE MAINTAINED PROPERLY AND NOT

OVERLOADED.

SPEED LIMITS & TRAFFIC RULES SHALL BE ADHERED.

PAINTING

WORK PERMIT SHALL BE OBTAINED BEFORE COMMENCING OF

WORK.

STORAGE FOR PAINT, THINNERS ETC. SHALL BE AWAY FROM

THE WORK AREA.

FIRE AND EXPLOSION

CAUSED BY FLAMMABLE

MATERIALS. E.G. PAINT,

THINNERS, TOXIC VAPORS.

SIGN BOARD FLAMMABLE MATERIAL; AND 'NO SMOKING; 'NO

NAKED LIGHT' ETC. DISPLAYED.

ONLY WORKING CREW PERSONS ENTER THE PAINTING AREA,

UNAUTHORIZED SHALL NOT BE ALLOWED.

FLAMMABLE MATERIAL SHALL BE ISOLATED AND KEPT AWAY

Format No .PT-IMSP-10-F-03

JOB HAZARD ANALYSIS FORM

Page No. 11 of 13

PETROSERV LTD

Sequence of Basic Job Steps

Potential Hazards

Hazard Control

FROM OTHER SUBSTANCES / MATERIALS.

REMOVE COMBUSTIBLE SUBSTANCE FROM THE WORK AREA

AND MAINTAIN TIDY HOUSEKEEPING.

CONTROL THE IGNITION SOURCES I.E. NO SMOKING, NO NAKED

LIGHTS.

ADEQUATE FIRE EXITS TO BE PROVIDED. SUCH EXITS SHALL

NOT BE OBSTRUCTED (INSIDE AND OUTSIDE).

FIRE EXTINGUISHERS TO BE KEPT ON STANDBY IN THE

WORKING AREAS.

WEAR PERSONAL PROTECTIVE EQUIPMENT: SAFETY HELMET,

SAFETY SHOE, SAFETY FULL BODY HARNESS, FOR ELEVATION

WORK, EYE PROTECTION, AND HAND PROTECTION AND AS

REQUIRED RESPIRATORY PROTECTION.

ALL PAINTS AND THINNERS ETC. TO BE USED IN ACCORDANCE

WITH THE MSDS SHEETS SPECIFYING THE HAZARDS

ASSOCIATED IN USING THE SUBSTANCES.

HOUSE KEEPING

SLIP, TRIP, FALL HAZARD

WORK LOCATION, EQUIPMENT AND BUILDINGS ARE TO BE KEPT

CLEAN AND ORDERLY AT ALL TIMES.

ALL WORK AREAS ARE TO BE FREE OF DANGEROUS

PROJECTIONS OR OBSTRUCTIONS, AND ARE TO BE MAINTAINED

Format No .PT-IMSP-10-F-03

JOB HAZARD ANALYSIS FORM

Page No. 12 of 13

PETROSERV LTD

Sequence of Basic Job Steps

Potential Hazards

Hazard Control

FREE OF RUBBISH, OIL, GREASE AND WATER.

ALL TOILET FACILITIES, INCLUDING HAND BASINS MUST BE

MAINTAINED IN A CLEAN AND HYGIENIC CONDITION.

ALL SCRAP AND REFUSE BINS MUST BE CLEARLY MARKED AS

TO THE TYPE OF THE SCRAP OR REFUSE THAT MUST BE

DEPOSITED IN THEM.

SCRAP AND GARBAGE BINS MUST BE EMPTIED & CLEANED ON A

DAILY BASIS.

FLAMMABLE WASTE MUST BE STORED IN METAL CONTAINERS

LOCATED AT A SAFE DISTANCE FROM ANY POSSIBLE IGNITION

SOURCE.

SPILLAGES OF OIL, GREASE ETC. MUST BE CLEANED UP AS

SOON AS IS PRACTICABLE.

ALL STACKING OF MATERIAL MUST BE MADE ON GROUND

THAT IS LEVEL AND ALL STACKS MUST BE NEAT AND STABLE.

ALL CIRCULAR OBJECTS MUST BE SUITABLY CHOCKED TO

PREVENT THEM FROM ROLLING.

ALL EMPTY PAINT/OIL DRUMS, PACKING MATERIAL SHALL NOT

BE STORED FOR MORE THAN A WEEK AT THE SITE.

COVER / SECURE CABLE / CORDS, WIRES / ROPES AWAY FROM

WALKWAYS AND OTHER PATHWAYS.

Format No .PT-IMSP-10-F-03

JOB HAZARD ANALYSIS FORM

Page No. 13 of 13

PETROSERV LTD

Sequence of Basic Job Steps

Potential Hazards

Hazard Control

KEEP WALK WAYS, AISLE, AND STAIRCASES CLEAR OF

MATERIALS, EQUIPMENTS AND OTHER ITEMS.

Format No .PT-IMSP-10-F-03

Potrebbero piacerti anche

- The IEE Wiring Regulations Explained and IllustratedDa EverandThe IEE Wiring Regulations Explained and IllustratedValutazione: 4 su 5 stelle4/5 (14)

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsDa EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsValutazione: 3.5 su 5 stelle3.5/5 (14)

- SWMS Unloading Containers GeneratorsDocumento15 pagineSWMS Unloading Containers GeneratorsSampath AhNessuna valutazione finora

- Petrofac Steel Erection Risk AssessmentDocumento4 paginePetrofac Steel Erection Risk AssessmentVivek Naik100% (2)

- Risk Assessment For Tightness TestDocumento8 pagineRisk Assessment For Tightness TestAriel Dela Cruz100% (1)

- 3.jsa - Arc Welding-NDocumento5 pagine3.jsa - Arc Welding-NVivek NaikNessuna valutazione finora

- Method Statement FormatDocumento11 pagineMethod Statement FormatPrem Preetham Dsouza100% (1)

- Risk Assessment For Air BlowingDocumento8 pagineRisk Assessment For Air BlowingAriel Dela Cruz100% (5)

- Risk Assessment for LPSG Steam Pipe Hot Work in ERDocumento6 pagineRisk Assessment for LPSG Steam Pipe Hot Work in ERdassi99Nessuna valutazione finora

- Guernsey Water Safe Work Procedures ManualDocumento142 pagineGuernsey Water Safe Work Procedures Manualrizonico0% (1)

- RA For High Pressure Cleaning Using HPCE 520-330Documento3 pagineRA For High Pressure Cleaning Using HPCE 520-330George CristianNessuna valutazione finora

- Method Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSDocumento11 pagineMethod Statement Format (CDRIHBIBSG and Silo DC Pipe Line Cleaning by Hydrojetting MOSPrem Preetham Dsouza100% (1)

- JSA - Cable Trench ExcavationDocumento9 pagineJSA - Cable Trench Excavationfrancis_e_tan75% (4)

- AHA Application of ISOLA N-S GroutDocumento2 pagineAHA Application of ISOLA N-S Groutmitimas2003100% (1)

- HAZARD IDENTIFICATION PLAN FOR PIPELINE DEMOLITIONDocumento20 pagineHAZARD IDENTIFICATION PLAN FOR PIPELINE DEMOLITIONprince100% (1)

- Line Breaking Procedure - Sp#15: 5/20/2010 Tim Vodopivec Kathy KiestlerDocumento6 pagineLine Breaking Procedure - Sp#15: 5/20/2010 Tim Vodopivec Kathy Kiestlerabdelkader benabdallahNessuna valutazione finora

- Craftsman Air Compressor Manual - 919.165190Documento27 pagineCraftsman Air Compressor Manual - 919.165190Dan CarsonNessuna valutazione finora

- Mep 831a Operator Unit and Direct Support Maintenance Manual Including Repair Parts and Special Tools List TM 9 6115 639 13pDocumento516 pagineMep 831a Operator Unit and Direct Support Maintenance Manual Including Repair Parts and Special Tools List TM 9 6115 639 13pomoigeNessuna valutazione finora

- TM 9-2330-334-13P M1147 FMTV-LHST Trailer Part 1Documento136 pagineTM 9-2330-334-13P M1147 FMTV-LHST Trailer Part 1AdvocateNessuna valutazione finora

- Risk Assessment for Vessel Approaching InstallationDocumento2 pagineRisk Assessment for Vessel Approaching InstallationDevi Ratna PratiwiNessuna valutazione finora

- Risk Assessment - In-Situ Lamination in Manhole SystemsDocumento12 pagineRisk Assessment - In-Situ Lamination in Manhole Systemsloveson709100% (5)

- JSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardDocumento23 pagineJSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardSHAH NAWAZ SAEEDNessuna valutazione finora

- JSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardDocumento23 pagineJSA For Hydrojetting (Gun With Rigid Lance) at Jetting YardSHAH NAWAZ SAEEDNessuna valutazione finora

- S788 ManualDocumento248 pagineS788 ManualPerry BettertonNessuna valutazione finora

- TM-9-6115-664-13-P Power UnitDocumento426 pagineTM-9-6115-664-13-P Power UnitThoukididis ThoukididouNessuna valutazione finora

- Manual Compresors Ingersoll Rand 250cfm - TM 5 4310 452 14Documento405 pagineManual Compresors Ingersoll Rand 250cfm - TM 5 4310 452 14Jose Lin MontenegroNessuna valutazione finora

- Job Safety Analysis Worksheet for Tank CleaningDocumento16 pagineJob Safety Analysis Worksheet for Tank Cleaningjiks_i4uNessuna valutazione finora

- TM 10-5411-247-13PDocumento408 pagineTM 10-5411-247-13PAdvocate100% (1)

- 1300 MaxtrakDocumento409 pagine1300 MaxtrakNatan83% (6)

- JSA Pipe Installation 2012Documento2 pagineJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- Job Safety Analysis for Oxy-cutting WorkDocumento2 pagineJob Safety Analysis for Oxy-cutting WorkAbdul Hakam Mohamed YusofNessuna valutazione finora

- 0 - Complete Blasters GuideDocumento217 pagine0 - Complete Blasters GuideTao XiaoNessuna valutazione finora

- 0 - Complete Blasters GuideDocumento215 pagine0 - Complete Blasters Guideflo696869Nessuna valutazione finora

- Risk Assessment For Mobilization Works DCP 3Documento4 pagineRisk Assessment For Mobilization Works DCP 3thomas_196382% (11)

- Safety in The Process Industry Occupational Health and SafetyDocumento11 pagineSafety in The Process Industry Occupational Health and SafetyMae GustoNessuna valutazione finora

- Rams For Repair of Leakage On Sludge Aeration Tank in Owerri EtpDocumento12 pagineRams For Repair of Leakage On Sludge Aeration Tank in Owerri EtpBrendan I.KanwanyeNessuna valutazione finora

- Spirax Sarco Steam TrapDocumento12 pagineSpirax Sarco Steam TrapRowelMacocoNessuna valutazione finora

- Near Miss Report NM SIN 025Documento15 pagineNear Miss Report NM SIN 025za8319712Nessuna valutazione finora

- Air Compressor ManualDocumento52 pagineAir Compressor ManualccbilNessuna valutazione finora

- Chapter 7 Safety PolicyDocumento29 pagineChapter 7 Safety Policyมิตร อันมาNessuna valutazione finora

- TM 10-4310-503-13P Emergency Breathing Air Compressor NSN 4310-01-541-4359Documento240 pagineTM 10-4310-503-13P Emergency Breathing Air Compressor NSN 4310-01-541-4359AdvocateNessuna valutazione finora

- 001d Airside SafetyDocumento12 pagine001d Airside SafetyAslamNessuna valutazione finora

- PT. SWIBER BERJAYA CHECK PPE & CONTROLS REQUIREDDocumento1 paginaPT. SWIBER BERJAYA CHECK PPE & CONTROLS REQUIREDDevi Ratna Pratiwi0% (1)

- Crane Mobile SpecificationDocumento13 pagineCrane Mobile Specificationsancakemre100% (2)

- MIP17 - HSE - PP - 011 PPE Needs Analysis REV 1Documento20 pagineMIP17 - HSE - PP - 011 PPE Needs Analysis REV 1AmeerHamzaWarraichNessuna valutazione finora

- RA1 - NG PembrokeDocumento2 pagineRA1 - NG PembrokeanthonyconnorNessuna valutazione finora

- Bird StrikeDocumento47 pagineBird StrikeMarcelo Kenji DoiNessuna valutazione finora

- TM 55 1520 228 23 1Documento1.115 pagineTM 55 1520 228 23 1Evert ̶C̶a̶r̶l̶o̶s̶100% (1)

- JSA Welding Confined SpaceDocumento2 pagineJSA Welding Confined Spacegkmlal100% (4)

- Running Air Compressor MachineDocumento2 pagineRunning Air Compressor MachineAbdul Hakam Mohamed Yusof100% (2)

- RA 002 - Engine Casing Exhaust Funnel - Hot WorkDocumento6 pagineRA 002 - Engine Casing Exhaust Funnel - Hot Workdassi99Nessuna valutazione finora

- Safety Critical ElementsDocumento2 pagineSafety Critical Elementsdtr17Nessuna valutazione finora

- TM 1 1520 237 23 1Documento569 pagineTM 1 1520 237 23 1Anonymous Kn5uYJ50% (2)

- Site Safety InstructionDocumento6 pagineSite Safety InstructionSathish Kumar TRNessuna valutazione finora

- TM 55-1520-228-BD PDFDocumento312 pagineTM 55-1520-228-BD PDFAnselmo Alvarez Gonzalez100% (1)

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocumento1 paginaJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNessuna valutazione finora

- 001 JSA Site CompoundDocumento15 pagine001 JSA Site CompoundRui Ribeiro100% (1)

- Corrosion and Fouling Control in Desalination IndustryDa EverandCorrosion and Fouling Control in Desalination IndustryNessuna valutazione finora

- AIR CRASH INVESTIGATIONS – THE CRASH OF VIRGIN GALACTIC SPACESHIP 2Da EverandAIR CRASH INVESTIGATIONS – THE CRASH OF VIRGIN GALACTIC SPACESHIP 2Nessuna valutazione finora

- Underwater Technology: Offshore PetroleumDa EverandUnderwater Technology: Offshore PetroleumL. AtteraasNessuna valutazione finora

- Msihc 1989Documento24 pagineMsihc 1989mujahid1137Nessuna valutazione finora

- Mohd Parvez Khan Updated CVDocumento5 pagineMohd Parvez Khan Updated CVmujahid1137Nessuna valutazione finora

- New Rules From Mol-2Documento4 pagineNew Rules From Mol-2Anonymous ZvDNOmNessuna valutazione finora

- HSE Requirements Form Sub-ContractorsDocumento2 pagineHSE Requirements Form Sub-Contractorsmujahid1137Nessuna valutazione finora

- Health and Safety Objectives 2009Documento4 pagineHealth and Safety Objectives 2009mujahid1137100% (1)

- PFS-ACAF-20 and 30 FFDocumento2 paginePFS-ACAF-20 and 30 FFmujahid1137Nessuna valutazione finora

- HAZOPDocumento8 pagineHAZOPMandar PhadkeNessuna valutazione finora

- Gen SafetyDocumento2 pagineGen Safetymujahid1137Nessuna valutazione finora

- CAF Fixed Piping Systems Design ManualDocumento29 pagineCAF Fixed Piping Systems Design Manualmujahid1137100% (1)

- Record Keeping with Excel and AccessDocumento16 pagineRecord Keeping with Excel and Accessmujahid1137100% (1)

- Asphalt HazardDocumento1 paginaAsphalt Hazardmujahid1137Nessuna valutazione finora

- Recycle Used Cartridges & BatteriesDocumento1 paginaRecycle Used Cartridges & Batteriesmujahid1137Nessuna valutazione finora

- PT Imsp 10 F 02 Hra Rev 00 HoDocumento3 paginePT Imsp 10 F 02 Hra Rev 00 Homujahid1137Nessuna valutazione finora

- Trial Pit During ExcavationDocumento3 pagineTrial Pit During Excavationmujahid1137Nessuna valutazione finora

- Trial PitsDocumento1 paginaTrial Pitsmujahid1137Nessuna valutazione finora

- JHA 14 For Removal of Top Shell Courses and Wind Girder and Other Structural (PT-4648-MS-M-002)Documento12 pagineJHA 14 For Removal of Top Shell Courses and Wind Girder and Other Structural (PT-4648-MS-M-002)mujahid1137Nessuna valutazione finora

- Jha For - TransformerDocumento7 pagineJha For - Transformermujahid1137Nessuna valutazione finora

- Confined SpaceDocumento23 pagineConfined Spacemujahid11370% (1)

- Safety ManualDocumento24 pagineSafety ManualTu Pham MinhNessuna valutazione finora

- Nfpa 4-7Documento2 pagineNfpa 4-7mujahid1137Nessuna valutazione finora

- HEALTH & SAFETY RISK ASSESSMENTDocumento52 pagineHEALTH & SAFETY RISK ASSESSMENTmujahid113794% (36)

- L6H 6C9HDCANL :CK H 7ANHD A:9DI :GL H:!JH: 6C9GJ7: Duration of The Entire ProcedureDocumento1 paginaL6H 6C9HDCANL :CK H 7ANHD A:9DI :GL H:!JH: 6C9GJ7: Duration of The Entire Proceduremujahid1137Nessuna valutazione finora

- 14.electrical SafetyDocumento30 pagine14.electrical SafetyZulkarnaenUchihaNessuna valutazione finora

- Jha For - TransformerDocumento7 pagineJha For - Transformermujahid1137Nessuna valutazione finora

- Basic Safety ManualDocumento21 pagineBasic Safety Manualmujahid1137Nessuna valutazione finora

- Safty PlanDocumento91 pagineSafty Planmujahid1137100% (1)

- Chemical Safety Handbook: 1.0 General Laboratory ProtocolDocumento12 pagineChemical Safety Handbook: 1.0 General Laboratory Protocolmujahid1137Nessuna valutazione finora

- Fire Extinguisher (2) 4Documento1 paginaFire Extinguisher (2) 4mujahid1137Nessuna valutazione finora

- Construction Safety Training MaterialsDocumento1 paginaConstruction Safety Training Materialsmujahid1137Nessuna valutazione finora

- Lecture Euler EquationDocumento33 pagineLecture Euler EquationYash RajNessuna valutazione finora

- Pick Pack Ship Public APIDocumento19 paginePick Pack Ship Public APIgauravpuri198050% (2)

- UnitTest D10 Feb 2024Documento26 pagineUnitTest D10 Feb 2024dev.shah8038Nessuna valutazione finora

- Creating Literacy Instruction For All Students ResourceDocumento25 pagineCreating Literacy Instruction For All Students ResourceNicole RickettsNessuna valutazione finora

- Villanueva Poetry Analysis Template BSEE 35Documento7 pagineVillanueva Poetry Analysis Template BSEE 35CHRISTIAN MAHINAYNessuna valutazione finora

- A Rail-To-Rail Constant Gain Buffered Op-Amp For Real Time Video ApplicationsDocumento8 pagineA Rail-To-Rail Constant Gain Buffered Op-Amp For Real Time Video Applicationskvpk_vlsiNessuna valutazione finora

- Atomic Structure QuestionsDocumento1 paginaAtomic Structure QuestionsJames MungallNessuna valutazione finora

- SolidWorks2018 PDFDocumento1 paginaSolidWorks2018 PDFAwan D'almightyNessuna valutazione finora

- IBM TS2900 Tape Autoloader RBDocumento11 pagineIBM TS2900 Tape Autoloader RBLeonNessuna valutazione finora

- Amazon Invoice Books 4Documento1 paginaAmazon Invoice Books 4raghuveer9303Nessuna valutazione finora

- 9284 - Technical Instruction Addenum 3 Corrigendum 2Documento5 pagine9284 - Technical Instruction Addenum 3 Corrigendum 2Bambang HerimantoNessuna valutazione finora

- From Memphis To KingstonDocumento19 pagineFrom Memphis To KingstonCarlos QuirogaNessuna valutazione finora

- LESSON 9 Steam Generators 2Documento12 pagineLESSON 9 Steam Generators 2Salt PapiNessuna valutazione finora

- 2023 Catalog Score SummerDocumento65 pagine2023 Catalog Score Summermadhudasa0% (2)

- Management Theory and Practice: Methods of Performance AppraisalDocumento3 pagineManagement Theory and Practice: Methods of Performance AppraisalRadha maiNessuna valutazione finora

- DSC analysis of hair denaturationDocumento2 pagineDSC analysis of hair denaturationDiosel Rezia PrazaNessuna valutazione finora

- 1.1 Enterprise AssessmentDocumento1 pagina1.1 Enterprise AssessmentGermanRobertoFongNessuna valutazione finora

- Top-Down DesignDocumento18 pagineTop-Down DesignNguyễn Duy ThôngNessuna valutazione finora

- F FS1 Activity 3 EditedDocumento15 pagineF FS1 Activity 3 EditedRayshane Estrada100% (1)

- 6 An Indian American Woman in Space 2Documento11 pagine6 An Indian American Woman in Space 2Manju YadavNessuna valutazione finora

- Armv8-A Instruction Set ArchitectureDocumento39 pagineArmv8-A Instruction Set ArchitectureraygarnerNessuna valutazione finora

- WISECO 2011 Complete CatalogDocumento131 pagineWISECO 2011 Complete CatalogfishuenntNessuna valutazione finora

- M.Com Second Semester – Advanced Cost Accounting MCQDocumento11 pagineM.Com Second Semester – Advanced Cost Accounting MCQSagar BangreNessuna valutazione finora

- Password ManagementDocumento7 paginePassword ManagementNeerav KrishnaNessuna valutazione finora

- Engr2227 Apr03Documento10 pagineEngr2227 Apr03Mohamed AlqaisiNessuna valutazione finora

- DTS-00750 Mast Maintenance ManualDocumento12 pagineDTS-00750 Mast Maintenance Manualsertecs polNessuna valutazione finora

- Inner Unit EstimateDocumento35 pagineInner Unit EstimateMir MoNessuna valutazione finora

- A Generation of Contradictions-Unlocking Gen Z 2022 China FocusDocumento25 pagineA Generation of Contradictions-Unlocking Gen Z 2022 China FocusCindy Xidan XiaoNessuna valutazione finora

- Public OpinionDocumento7 paginePublic OpinionSona Grewal100% (1)

- Thesis Hakonen Petri - Detecting Insider ThreatsDocumento72 pagineThesis Hakonen Petri - Detecting Insider ThreatsalexandreppinheiroNessuna valutazione finora