Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mesh-Intro 14.5 L08 Mesh Quality

Caricato da

anmol6237Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mesh-Intro 14.5 L08 Mesh Quality

Caricato da

anmol6237Copyright:

Formati disponibili

2012 ANSYS, Inc. November 20, 2012 1 Release 14.

5

14. 5 Release

Introduction to ANSYS

Meshing

Lecture 8

Mesh Quality

2012 ANSYS, Inc. November 20, 2012 2 Release 14.5

What you will learn from this presentation

Impact of the Mesh Quality on the Solution

Quality criteria

Methods for checking the mesh quality

Tools to improve quality in Meshing

Pinch

Virtual topology

Mesh Quality

2012 ANSYS, Inc. November 20, 2012 3 Release 14.5

Check Mesh

Quality

Preprocessing Workflow

Sketches and

Planes

Geometry Import

Options

3D Operations

Direct CAD/Bi-

Directional CAD

Geometry

Cleanup and

Repair

Automatic

Cleanup

Merge, Connect,

Projection, Flow

Volume

Extraction, etc

Extrude, Revolve,

Sweep, etc

3D Operations

Boolean, Body

Operations, Split,

etc

Meshing

Methods

Hybrid Mesh: Tet,

Prisms, Pyramids

Hexa Dominant,

Sweep meshing

Global Mesh

Settings

Local Mesh

Settings

Sizing,

Body/Sphere of

Influence, Match

Control, etc

Geometry Creation

OR

Geometry Import

Geometry

Operations

Meshing Solver

Assembly

Meshing

2012 ANSYS, Inc. November 20, 2012 4 Release 14.5

Meshing Process in ANSYS Meshing

2012 ANSYS, Inc. November 20, 2012 5 Release 14.5

Impact of the Mesh Quality

Good quality mesh means that

Mesh quality criteria are within correct range

Orthogonal quality

Mesh is valid for studied physics

Boundary layer

Solution is grid independent

Important geometric details are well captured

Bad quality mesh can cause;

Convergence difficulties

Bad physic description

Diffuse solution

User must

Check quality criteria and improve grid if needed

Think about model and solver settings before generating the grid

Perform mesh parametric study, mesh adaption

2012 ANSYS, Inc. November 20, 2012 6 Release 14.5

Example showing

difference between a

mesh with cells

failing the quality

criteria and a good

mesh

Unphysical values in

vicinity of poor

quality cells

Impact of the Mesh Quality on the

Solution

2012 ANSYS, Inc. November 20, 2012 7 Release 14.5

(max,avg)

CSKEW

=(0.912,0.291)

(max,avg)

CAR

=(62.731,7.402)

(max,avg)

CSKEW

=(0.801,0.287)

(max,avg)

CAR

=(8.153,1.298)

Vz

MIN

-100ft/min

Vz

MAX

400ft/min

Vz

MIN

-90ft/min

Vz

MAX

600ft/min

Impact of the Mesh Quality on the Solution

Large cell size

change

M

e

s

h

2

M

e

s

h

1

Diffusion example

2012 ANSYS, Inc. November 20, 2012 8 Release 14.5

Solution run with

multiple meshes

Note : For all runs the

computed Y+ is valid

for wall function (first

cell not in laminar

zone)

Grid Dependency

DP 0 DP 1 DP 2 DP 3 DP 4

Nb Cells 500 3 000 24 000 190 000 1.5 M

DP 0

DP 3

2%

x8

2012 ANSYS, Inc. November 20, 2012 9 Release 14.5

Hexa cells can be stretched in

stream direction to reduce

number of cells

Bias defined on inlet and

outlet walls

Bias defined on inlet edges

16 000 cells (~DP2)

Delta P = 310 Pa (~DP3)

Grid Dependency

2012 ANSYS, Inc. November 20, 2012 10 Release 14.5

Hexa: Concentration in one direction

Angles unchanged

Tetra: Concentration in one direction

Angles change

Prism: Concentration in one direction

Angles unchanged

Solution for boundary layer

resolution

Hybrid prism/tetra meshes

Prism in near-wall region, tetra in

volume

Automated

Reduced CPU-time for good

boundary layer resolution

Hexa vs. Tetra

Hexa

Tetra

Prism

Prisms (near wall)

Tetra (in volume)

2012 ANSYS, Inc. November 20, 2012 11 Release 14.5

Displays mesh information for Nodes and Elements

List of quality criteria for the Mesh Metric

Select the required criteria to get details for quality

It shows minimum, maximum, average and standard deviation

Different physics and different solvers have different requirements for

mesh quality

Mesh metrics available in ANSYS Meshing include:

Element Quality

Aspect Ratio

Jacobean Ration

Warping Factor

Parallel Deviation

Maximum Corner Angle

Skewness

Orthogonal Quality

Mesh Statistics and Mesh Metrics

For Multi-Body Parts, go to corresponding body in Tree Outline

to get its separate mesh statistics per part/body

2012 ANSYS, Inc. November 20, 2012 12 Release 14.5

Orthogonal Quality (OQ)

Derived directly from

Fluent solver discretization

For a cell it is the minimum of:

computed for each face i

For the face it is computed as the minimum of computed for each edge I

Where Ai is the face normal vector and fi is a vector from the centroid of the cell to the centroid

of that face, and ci is a vector from the centroid of the cell to the centroid of the adjacent cell,

where ei is the vector from the centroid of the face to the centroid of the edge

At boundaries and internal walls

ci is ignored in the computations of OQ

Mesh Quality Metrics

A

1

A

2

A

3

f

1

f

2

f

3

c

2

c

1

c

3

A

1

A

2

A

3

e

1

e

2

e

3

On cell

| || | i i

i i

f A

f A

| || | i i

i i

c A

c A

| || | i i

i i

e A

e A

On face

0 1

Worst Perfect

2012 ANSYS, Inc. November 20, 2012 13 Release 14.5

Skewness

Two methods for determining skewness:

1. Equilateral Volume deviation:

Skewness =

Applies only for triangles and tetrahedrons

2. Normalized Angle deviation:

Skewness =

Where is the equiangular face/cell (60 for

tets and tris, and 90 for quads and hexas)

Applies to all cell and face shapes

Used for hexa, prisms and pyramids

(

e

min

e

e

e max

,

180

max

u

u u

u

u u

min u

max u

optimal cell size cell size

optimal cell size

Optimal (equilateral) cell

Actual cell

Circumsphere

Mesh Quality Metrics

e

u

0 1

Perfect Worst

2012 ANSYS, Inc. November 20, 2012 14 Release 14.5

Mesh Quality

Mesh quality recommendations

Low Orthogonal Quality or high skewness values are not recommended

Generally try to keep minimum orthogonal quality > 0.1, or maximum skewness < 0.95.

However these values may be different depending on the physics and the location

of the cell

Fluent reports negative cell volumes if the mesh contains degenerate cells

Skewness mesh metrics spectrum

Orthogonal Quality mesh metrics spectrum

Excellent Very good Good Acceptable Bad Unacceptable

0-0.25 0.25-0.50 0.50-0.80 0.80-0.94 0.95-0.97 0.98-1.00

Unacceptable Bad Acceptable Good Very good Excellent

0-0.001 0.001-0.14 0.15-0.20 0.20-0.69 0.70-0.95 0.95-1.00

2012 ANSYS, Inc. November 20, 2012 15 Release 14.5

Aspect Ratio

2-D:

Length / height ratio: x/y

3-D

Area ratio

Radius ratio of circumscribed / inscribed

circle

Limitation for some iterative solvers

A < 10 100

(CFX: < 1000)

Large aspect ratio are accepted where

there is no strong transverse

gradient (boundary layer ...)

y

x

2012 ANSYS, Inc. November 20, 2012 16 Release 14.5

Smoothness

Checked in solver

Volume Change in Fluent

Available in Adapt/Volume

3D :

i

= V

i

/ V

nb

Expansion Factor in CFX

Checked during mesh import

Ratio of largest to smallest element volumes

surrounding a node

Recommendation:

Good: 1.0 < < 1.5

Fair: 1.5 < < 2.5

Poor: > 5 20

2012 ANSYS, Inc. November 20, 2012 17 Release 14.5

Displays Mesh Metrics graph for the

element quality distribution

Different element types are plotted

with different color bars

Can be accessed through menu bar

using Metric Graph button

Axis range can be adjusted using

controls button (details next slide)

Click on bars to view corresponding

elements in the graphics window

Use to help locate poor quality

elements

Mesh Metric Graph

2012 ANSYS, Inc. November 20, 2012 18 Release 14.5

Elements on Y-Axis can be plotted

with two methods;

Number of Elements

Percentage of Volume/Area

Options to change the range on

either axis

Specify which element types to

include in graph

Tet4 = 4 Node Linear Tetrahedron

Hex8 = 8 Node Linear Hexahedron

Wed6 = 6 Node Linear Wedge (Prism)

Pyr5 = 5 Node Linear Pyramid

Quad4 = 4 Node Linear Quadrilateral

Tri3 = 3 Node Linear Triangle

Te10, Hex20, Wed15, Pyr13, Quad8 &

Tri6 non-linear elements

Mesh Metric Graph Controls

2012 ANSYS, Inc. November 20, 2012 19 Release 14.5

Section Planes

Displays internal elements of the mesh

Elements on either side of plane can be displayed

Toggle between cut or whole elements display

Elements on the plane

Edit Section Plane button can be used to drag section plane to new location

Clicking on Edit Section Plane button will make section planes anchor to appear

Multiple section planes are allowed

For large meshes, it is advisable to switch to geometry mode (click on geometry in the Tree Outline),

create the section plane and then go back to mesh model

2012 ANSYS, Inc. November 20, 2012 20 Release 14.5

The CFX solver calculates 3 important measures of mesh

quality at the start of a run and updates them each time the

mesh is deformed

Mesh Orthogonality

Aspect Ratio

Expansion Factor

Mesh Quality Check for CFX

+--------------------------------------------------------------------+

| Mesh Statistics |

+--------------------------------------------------------------------+

Domain Name: Air Duct

Minimum Orthogonality Angle [degrees] = 20.4 ok

Maximum Aspect Ratio = 13.5 OK

Maximum Mesh Expansion Factor = 700.4 !

Domain Name: Water Pipe

Minimum Orthogonality Angle [degrees] = 32.8 ok

Maximum Aspect Ratio = 6.4 OK

Maximum Mesh Expansion Factor = 73.5 !

Global Mesh Quality Statistics :

Minimum Orthogonality Angle [degrees] = 20.4 ok

Maximum Aspect Ratio = 13.5 OK

Maximum Mesh Expansion Factor = 700.4 !

Good

(OK)

Acceptable

(ok)

Questionable

(!)

2012 ANSYS, Inc. November 20, 2012 21 Release 14.5

Mesh Quality Check for Fluent

Grid check tools available

Check : Perform various mesh consistency

checks

Report Quality : lists worse values of

orthogonal quality and aspect ratio

TUI command mesh/check-verbosity sets

the level of details in the report

2012 ANSYS, Inc. November 20, 2012 22 Release 14.5

Factors Affecting Quality

Geometry problems

Small edge

Gaps

Sharp angle

Meshing parameters

Sizing Function On / Off

Min size too large

Inflation parameters

Total height

Maximum angle

Hard sizing

Meshing methods

Patch conformal or patch independent tetra

Sweep or Multizone

Cutcell

Geometry cleanup in Design Modeler

or

Virtual topology & pinch in Meshing

Mesh setting change

Mesh setting change

2012 ANSYS, Inc. November 20, 2012 23 Release 14.5

When to use?

To merge together a number of small

(connected) faces/edges

To simplify small features in the model

To simplify load abstraction for

mechanical analysis

To create edge splits for better control of

the surface mesh control

Virtual cells modify topology

Original CAD model remains unchanged

New faceted geometry is created with

virtual topology

Restrictions

Limited to developable surfaces

Virtual Faces cannot form a closed region

Virtual Topology

Without VT With VT

2012 ANSYS, Inc. November 20, 2012 24 Release 14.5

Creating Virtual Topology

Creates VT automatically

Creates VT manually

To acces VT menu, click on Model and then

on Virtual Topology

Right click on VT menu to access automated

and manual VT tools

2012 ANSYS, Inc. November 20, 2012 25 Release 14.5

Automatic Virtual Topology

Automatically creating Virtual Faces

Left Click Virtual Topology in Model Tree

Set Behaviour in Details

Controls aggressiveness of automatic VT algorithm

Low: merges only the worst faces (and edges)

Medium & High: try to merge more faces

Select if Face Edges shall be merged

Right Click Virtual Topology and click Generate Virtual

Cells

Manually creating a Virtual Face

RMB on Model tree and select Insert Virtual Topology

Select Virtual Topology from the Tree Outline

Pick faces or edges, RMB and Insert Virtual Cell

All VT entities created can be seen in different colors if Virtual

Topology is selected in Tree Outline

2012 ANSYS, Inc. November 20, 2012 26 Release 14.5

Virtual Topology : Example

With Virtual cells:

Small faces are merged to

form a single virtual face

and edges of the original

set of faces are no longer

respected for meshing

Without Virtual cells:

Edges are respected while

creating surface mesh

2012 ANSYS, Inc. November 20, 2012 27 Release 14.5

Project to underlying Geometry

Virtual topologies are a faceted

representation of the original geometry.

By default mesh is projected to the facets

Improved projection can be obtained by

projecting back to the underlying

geometry

2012 ANSYS, Inc. November 20, 2012 28 Release 14.5

Virtual Topology : Example

Creating edge split

Select Virtual Topology from the Tree Outline

Pick the edge(s)

RMB and select Virtual Split Edge at + or Virtual Split

Edge to split the edge at the location specified by the

selection, or to enter the split ratio in the Details

window, respectively

With edge splits:

We can add edge constrains to improve the mesh

Edge splits can be moved interactively. Pick the virtual edge, hold the F4 key

and move the red node along the edge with the mouse

2012 ANSYS, Inc. November 20, 2012 29 Release 14.5

Pinch

Pinch control removes small features at the mesh level

Slivers

Short Edges

Sharp Angles

The Pinch feature works on vertices and edges only

The Pinch feature is supported for the following mesh methods:

Patch Conforming Tetrahedrons

Thin Solid Sweeps

Hex Dominant meshing

Quad Dominant Surface Meshing

Triangles Surface meshing

Not supported for

CutCell

Patch Independent

Multizone

General Sweep

2012 ANSYS, Inc. November 20, 2012 30 Release 14.5

Pinch Control

Pinch features can be defined 2 ways

Automatically : pinches created based on global pinch tolerance in Mesh Detail

Manually : pinch created one by one by user with local tolerance

All pinches are listed in Model Tree under Mesh menu with methods and

local controls

Manual

Automated

2012 ANSYS, Inc. November 20, 2012 31 Release 14.5

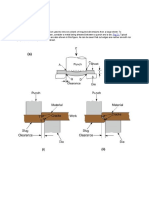

Vertex-vertex Pinch controls will be created on an edge with length less

than the specified tolerance

Will pinch out the slave

geometry into the master

geometry

Pinch: Vertex-Vertex

Mesh without Pinch

Control

Mesh with Pinch

Control

2012 ANSYS, Inc. November 20, 2012 32 Release 14.5

Edge-Edge Pinch controls will be created on any face for which two edges

are within the proximity of specified tolerance

Will pinch out the entire or a

portion of the slave geometry into

the master

Pinch: Edge-Edge

Mesh without Pinch

Control

Mesh with Pinch

Control

2012 ANSYS, Inc. November 20, 2012 33 Release 14.5

Workshops 5 (Applications Choice)

5a Mixing

Tank*

*DM

Required

5c

Combustion

Chamber

(2d)

5b

Automotive

Aero

5e

Manifold*

*DM

Required

5d

Assembly

Meshing

Potrebbero piacerti anche

- Mesh-Intro 14.5 L07 Assembly MeshingDocumento32 pagineMesh-Intro 14.5 L07 Assembly Meshinganmol6237Nessuna valutazione finora

- Fluent-Intro 14.5 WS04 AirfoilDocumento37 pagineFluent-Intro 14.5 WS04 AirfoilalfredozegarraNessuna valutazione finora

- Mesh-Intro 15.0 L07 Mesh Quality and Advanced TopicsDocumento34 pagineMesh-Intro 15.0 L07 Mesh Quality and Advanced TopicsMuralidharan ShanmugamNessuna valutazione finora

- Ask-The-experts ANSYS Advanced MeshingDocumento47 pagineAsk-The-experts ANSYS Advanced MeshingShaheen S. RatnaniNessuna valutazione finora

- Fluent-Intro 16.0 L07 TurbulenceDocumento50 pagineFluent-Intro 16.0 L07 TurbulenceDaniel CastroNessuna valutazione finora

- Fluent-Intro 17.0 Module07 TurbulenceDocumento50 pagineFluent-Intro 17.0 Module07 TurbulenceSadullah TaşkınNessuna valutazione finora

- Fluent-Intro 15.0 L03 BoundaryConditionsDocumento48 pagineFluent-Intro 15.0 L03 BoundaryConditionsravi456comp100% (1)

- DM-Intro 16.0 L04 Geometry ModelingDocumento32 pagineDM-Intro 16.0 L04 Geometry ModelingNitin B maskeNessuna valutazione finora

- Fluent-Intro 16.0 L05 PostProcessing PDFDocumento68 pagineFluent-Intro 16.0 L05 PostProcessing PDFAnonymous 8209ZTNessuna valutazione finora

- Fluent-Intro 16.0 L06 SolverSettings PDFDocumento49 pagineFluent-Intro 16.0 L06 SolverSettings PDFAnonymous 8209ZTNessuna valutazione finora

- Fluent-Adv Turbulence 15.0 L02 Rans ModelsDocumento46 pagineFluent-Adv Turbulence 15.0 L02 Rans Modelsbecool_bcn75Nessuna valutazione finora

- The Most Accurate and Advanced Turbulence CapabilitiesDocumento47 pagineThe Most Accurate and Advanced Turbulence CapabilitiesaddafrrNessuna valutazione finora

- Fluent 13.0 Lecture05 Solver SettingsDocumento32 pagineFluent 13.0 Lecture05 Solver Settingsshraveen1991Nessuna valutazione finora

- Fluent-Intro 16.0 L09 BestPractices PDFDocumento43 pagineFluent-Intro 16.0 L09 BestPractices PDFAnonymous 8209ZTNessuna valutazione finora

- Fluent-Adv-rm 14.5 L05 MRFDocumento37 pagineFluent-Adv-rm 14.5 L05 MRFMohamed SelwenNessuna valutazione finora

- Fluent-Intro 14.5 L05 SolverSettingsDocumento45 pagineFluent-Intro 14.5 L05 SolverSettingsJesús Castillo González0% (1)

- CFX-FSI 14.5 Lect-05 Two Way Solving PostDocumento42 pagineCFX-FSI 14.5 Lect-05 Two Way Solving PostShaheen S. RatnaniNessuna valutazione finora

- Transition ModelsDocumento36 pagineTransition ModelsSadullah TaşkınNessuna valutazione finora

- Turbulence Modeling - BetaDocumento88 pagineTurbulence Modeling - BetaMayra ZezattiNessuna valutazione finora

- Fluent12 Lecture08 UdfDocumento25 pagineFluent12 Lecture08 UdfAli ettehadiNessuna valutazione finora

- 2020R1 FluentDocumento65 pagine2020R1 Fluentagrbovic100% (1)

- Acoustics AACTx R150 L06 AppendixDocumento26 pagineAcoustics AACTx R150 L06 AppendixPercy Romero MurilloNessuna valutazione finora

- Fluent HeatTransfer L04 NaturalConvectionDocumento51 pagineFluent HeatTransfer L04 NaturalConvectionsingourNessuna valutazione finora

- 6 SolarLoadDocumento22 pagine6 SolarLoadali100% (1)

- ANSYS FSI For Thermal Management and Aeroelasticity 11th May 2011 PDFDocumento52 pagineANSYS FSI For Thermal Management and Aeroelasticity 11th May 2011 PDFdharmeswarNessuna valutazione finora

- Modeling and Simulation of Mutiphase Flows (CFD Tips) : Pouriya NiknamDocumento33 pagineModeling and Simulation of Mutiphase Flows (CFD Tips) : Pouriya Niknambrian sanmbranoNessuna valutazione finora

- Curious About Making User Defined Functions in ANSYS Fluent?Documento23 pagineCurious About Making User Defined Functions in ANSYS Fluent?bajank agus739Nessuna valutazione finora

- Fluent-Intro 14.5 WS06 Sliding MeshDocumento35 pagineFluent-Intro 14.5 WS06 Sliding MeshalfredozegarraNessuna valutazione finora

- Fluent 13.0 Lecture03 Solver BasicsDocumento15 pagineFluent 13.0 Lecture03 Solver BasicsGhazlani Mohamed AliNessuna valutazione finora

- CFX FSI 14.5 2011 L1 Overview of FSI in Workbench 37Documento37 pagineCFX FSI 14.5 2011 L1 Overview of FSI in Workbench 37Moh SenNessuna valutazione finora

- Fluent-Intro 17.0 Module05 Solving PDFDocumento49 pagineFluent-Intro 17.0 Module05 Solving PDFHennry Anderson Zumaran SanchezNessuna valutazione finora

- Fluent HeatTransfer L02 ConductionDocumento40 pagineFluent HeatTransfer L02 ConductionsingourNessuna valutazione finora

- Modeling 2D Fluidized BedDocumento10 pagineModeling 2D Fluidized BedAshwini SwamiNessuna valutazione finora

- CFX Intro 13.0 WS02 AirfoilDocumento27 pagineCFX Intro 13.0 WS02 Airfoilvicky3000Nessuna valutazione finora

- Fluent HeatTransfer L01 Introduction PDFDocumento50 pagineFluent HeatTransfer L01 Introduction PDFHoNessuna valutazione finora

- Combustion Modeling Strategies FLUENTDocumento7 pagineCombustion Modeling Strategies FLUENTKrozeNessuna valutazione finora

- 04 TurbulenceDocumento37 pagine04 TurbulenceYaroslavBerezhkoNessuna valutazione finora

- 8 PorousMedia PDFDocumento24 pagine8 PorousMedia PDFaliNessuna valutazione finora

- Fluent-Adv-rm 14.5 L06 MPMDocumento50 pagineFluent-Adv-rm 14.5 L06 MPMMohamed SelwenNessuna valutazione finora

- Discrete Phase Modelling - CombustionDocumento63 pagineDiscrete Phase Modelling - CombustionFabian Andrey DiazNessuna valutazione finora

- Mechanical Intro 17.0 M03 Structural Analysis PDFDocumento49 pagineMechanical Intro 17.0 M03 Structural Analysis PDFFedericaNessuna valutazione finora

- CFX FSI 14.5 CFX FSI - Two - Way - Convergence Two-Way FSI Simulations 39Documento39 pagineCFX FSI 14.5 CFX FSI - Two - Way - Convergence Two-Way FSI Simulations 39Moh SenNessuna valutazione finora

- Fluent12 Lecture11 PostDocumento49 pagineFluent12 Lecture11 PostAlex__182Nessuna valutazione finora

- Fluent-Adv Turbulence 15.0 L03 Wall ModelingDocumento38 pagineFluent-Adv Turbulence 15.0 L03 Wall Modelingbecool_bcn75Nessuna valutazione finora

- Fluent-Adv Turbulence 15.0 L05 Case StudiesDocumento51 pagineFluent-Adv Turbulence 15.0 L05 Case StudiesEnrique FloresNessuna valutazione finora

- Ansys Ls-Dyna Mapdl 14.5 Ws01 Fan Blade ContainmentDocumento5 pagineAnsys Ls-Dyna Mapdl 14.5 Ws01 Fan Blade ContainmentPercy Romero MurilloNessuna valutazione finora

- Fluent-Intro 14.5 L03 Turbulence&HeatTransfer&Transient PDFDocumento72 pagineFluent-Intro 14.5 L03 Turbulence&HeatTransfer&Transient PDFWedye BagonkNessuna valutazione finora

- Fluent-Intro 16.0 L08 HeatTransfer PDFDocumento45 pagineFluent-Intro 16.0 L08 HeatTransfer PDFAnonymous 8209ZTNessuna valutazione finora

- Tutorial 5 FluentDocumento56 pagineTutorial 5 FluentCrisner ToicenNessuna valutazione finora

- Fluid Structure Interaction in COMSOLDocumento33 pagineFluid Structure Interaction in COMSOLVoona RanganadhanNessuna valutazione finora

- Fluent Combustion 15.0 L01-IntroductionDocumento17 pagineFluent Combustion 15.0 L01-IntroductionrafsebeNessuna valutazione finora

- Fluent BcsDocumento28 pagineFluent BcsJoonhongNessuna valutazione finora

- AM 12 Appendix ADocumento66 pagineAM 12 Appendix AMohamad Poortoosi100% (1)

- Computational Methods - CFD Lecture 1Documento31 pagineComputational Methods - CFD Lecture 1Morteza KhashehchiNessuna valutazione finora

- SNECMA 14.5 L06 Local Mesh ControlsDocumento35 pagineSNECMA 14.5 L06 Local Mesh ControlsAnaNessuna valutazione finora

- Mesh Quality and Advenced VNDocumento37 pagineMesh Quality and Advenced VNRE ACNessuna valutazione finora

- Open Foam-MeshingDocumento122 pagineOpen Foam-Meshingsuresh_501100% (1)

- StarCCM - AeroAcousticsDocumento40 pagineStarCCM - AeroAcousticsFeiD.HolaNessuna valutazione finora

- Fluent Meshing 14.5 L03 Boundary FixDocumento77 pagineFluent Meshing 14.5 L03 Boundary FixShaheen S. RatnaniNessuna valutazione finora

- Mesh-Intro 19R2 M05 Lecture Slides Mesh Quality and Advanced TopicsDocumento60 pagineMesh-Intro 19R2 M05 Lecture Slides Mesh Quality and Advanced TopicsSahil Jawa100% (1)

- Industrial EnclosuresDocumento56 pagineIndustrial Enclosuresanmol6237Nessuna valutazione finora

- Design and Fabrication of Automated Manual Gear Transmission in Motor BikesDocumento57 pagineDesign and Fabrication of Automated Manual Gear Transmission in Motor Bikesanmol6237Nessuna valutazione finora

- Damping Calculations for Race Vehicle SuspensionDocumento99 pagineDamping Calculations for Race Vehicle SuspensionManu PantNessuna valutazione finora

- Sri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet NoDocumento2 pagineSri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet Noanmol6237Nessuna valutazione finora

- ME 443/643: Introduction to HyperMeshDocumento37 pagineME 443/643: Introduction to HyperMeshanmol6237Nessuna valutazione finora

- HW Starter Manual March HresolutionDocumento23 pagineHW Starter Manual March HresolutionCharan KumarNessuna valutazione finora

- List of over 150 Solidworks clientsDocumento4 pagineList of over 150 Solidworks clientsanmol6237Nessuna valutazione finora

- RGB Color TableDocumento5 pagineRGB Color Tableanmol6237Nessuna valutazione finora

- Creo2 Adv PrimerDocumento174 pagineCreo2 Adv PrimerAmit JhaNessuna valutazione finora

- Nissan Walkin ChennaiDocumento2 pagineNissan Walkin Chennaianmol6237Nessuna valutazione finora

- Nissan Walkin ChennaiDocumento2 pagineNissan Walkin Chennaianmol6237Nessuna valutazione finora

- Nissan Walkin ChennaiDocumento2 pagineNissan Walkin Chennaianmol6237Nessuna valutazione finora

- Nissan Walkin Chennai 1Documento2 pagineNissan Walkin Chennai 1anmol6237Nessuna valutazione finora

- Sri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet NoDocumento1 paginaSri Ganapathi Industries Kushaiguda Title: Scale Size DRWG No: Sheet Noanmol6237Nessuna valutazione finora

- Press Tool Cutting ForceDocumento1 paginaPress Tool Cutting Forceanmol6237Nessuna valutazione finora

- Tool Design TerminologyDocumento5 pagineTool Design Terminologyanmol6237Nessuna valutazione finora

- Gate Syllabus For Mech EnggDocumento4 pagineGate Syllabus For Mech Engganmol6237Nessuna valutazione finora

- Ceed Model Question PaperDocumento21 pagineCeed Model Question PaperSatvender SinghNessuna valutazione finora

- Parametric Modeling With Creo ParametricDocumento41 pagineParametric Modeling With Creo Parametricfrancesca050168Nessuna valutazione finora

- GD AdvantagesDocumento1 paginaGD Advantagesanmol6237Nessuna valutazione finora

- More Than 100 Keyboard Shortcuts Must ReadDocumento3 pagineMore Than 100 Keyboard Shortcuts Must ReadChenna Keshav100% (1)

- Train Schedule: From Bhopal To Indore JN BG (INBD) BPL - INBD PassengerDocumento1 paginaTrain Schedule: From Bhopal To Indore JN BG (INBD) BPL - INBD Passengeranmol6237Nessuna valutazione finora

- SHEARINGDocumento6 pagineSHEARINGanmol6237Nessuna valutazione finora

- M Tech Project List 2015 NewDocumento5 pagineM Tech Project List 2015 Newanmol6237Nessuna valutazione finora

- GDDocumento2 pagineGDanmol6237Nessuna valutazione finora

- Term - 1 - Class - X Communicative English - 2010Documento27 pagineTerm - 1 - Class - X Communicative English - 2010Nitin GargNessuna valutazione finora

- Intro To CFD ProblemDocumento1 paginaIntro To CFD ProblemlinoNessuna valutazione finora

- Ansys Training Book.Documento15 pagineAnsys Training Book.Sarath Babu SNessuna valutazione finora

- Train Schedule: From Bhopal To Indore JN BG (INBD) BPL - INBD PassengerDocumento1 paginaTrain Schedule: From Bhopal To Indore JN BG (INBD) BPL - INBD Passengeranmol6237Nessuna valutazione finora

- E2SEM1MT2TD06102012Documento3 pagineE2SEM1MT2TD06102012anmol6237Nessuna valutazione finora

- Plan and dispatch efficiently with IVU.railDocumento32 paginePlan and dispatch efficiently with IVU.railmakbadrusNessuna valutazione finora

- Nexus TroubleshootingDocumento127 pagineNexus TroubleshootingTylorKytasaariNessuna valutazione finora

- Andrew Joseph L. RamosDocumento80 pagineAndrew Joseph L. Ramoslee.macalisangNessuna valutazione finora

- Installation StepsDocumento16 pagineInstallation StepsFawzyNessuna valutazione finora

- PPCL User GuideDocumento152 paginePPCL User GuideGuilherme RozaNessuna valutazione finora

- Sy0 601 13Documento26 pagineSy0 601 13MEN'S ARENANessuna valutazione finora

- Job Description - Product Delivery ManagerDocumento1 paginaJob Description - Product Delivery ManagerYoshua GaloenkNessuna valutazione finora

- SAS With Style: Creating Your Own ODS Style Template For RTF OutputDocumento20 pagineSAS With Style: Creating Your Own ODS Style Template For RTF Outputnishu_aminNessuna valutazione finora

- ETAP Power System Engineering Workshop 7 - 9 May 2013 - SingaporeDocumento4 pagineETAP Power System Engineering Workshop 7 - 9 May 2013 - SingaporeSeanChanNessuna valutazione finora

- University of Cagliari: Blynk PlatformDocumento34 pagineUniversity of Cagliari: Blynk PlatformSmart ClasseNessuna valutazione finora

- HikCentral Web Client ManualDocumento961 pagineHikCentral Web Client ManualArmel SimoNessuna valutazione finora

- TCL TK and SkillDocumento16 pagineTCL TK and SkillGeoff LabuacNessuna valutazione finora

- HW6 SolutionDocumento7 pagineHW6 SolutionfarhanNessuna valutazione finora

- HSBCnet How To Create A Restricted TemplateDocumento2 pagineHSBCnet How To Create A Restricted TemplateAfrica SolutionsNessuna valutazione finora

- Inmos - Transputer Databook 3eDocumento515 pagineInmos - Transputer Databook 3ejuggle333Nessuna valutazione finora

- El Impacto de La Inteligencia Artificial Sobre La GovernanzaDocumento272 pagineEl Impacto de La Inteligencia Artificial Sobre La GovernanzadarioNessuna valutazione finora

- Terms of Service: A. Software License. As Long As User Complies With The Terms ofDocumento8 pagineTerms of Service: A. Software License. As Long As User Complies With The Terms ofhyugNessuna valutazione finora

- R-PLS Path Modeling ExampleDocumento8 pagineR-PLS Path Modeling ExamplemagargieNessuna valutazione finora

- UG496 BT122 Project Configuration Users GuideDocumento22 pagineUG496 BT122 Project Configuration Users Guidemar_barudjNessuna valutazione finora

- FYDP RubricsDocumento2 pagineFYDP RubricsHey MarkoNessuna valutazione finora

- Login - Ufone Technical Department - Login Creation - Access - Form - HammadDocumento1 paginaLogin - Ufone Technical Department - Login Creation - Access - Form - HammadhammadNessuna valutazione finora

- Microsoft CAN Riyas RupeshDocumento3 pagineMicrosoft CAN Riyas RupeshRupesh PatericalNessuna valutazione finora

- Starting A Call Center BusinessDocumento1 paginaStarting A Call Center Businessnivedita patilNessuna valutazione finora

- BS-400 Installation Guide (v1.0) PDFDocumento28 pagineBS-400 Installation Guide (v1.0) PDFDENessuna valutazione finora

- 2023 CQT Agenda V6 2 - 13 PDFDocumento41 pagine2023 CQT Agenda V6 2 - 13 PDFJohn LajoieNessuna valutazione finora

- BlackBerry 10 OS 10.3.2.2474-10.3.2.2836-Release Notes-EnDocumento7 pagineBlackBerry 10 OS 10.3.2.2474-10.3.2.2836-Release Notes-EnAtish Kumar ChouhanNessuna valutazione finora

- Pinnacle Studio 26 User GuideDocumento249 paginePinnacle Studio 26 User GuideVinicius Alves100% (2)

- DSA456 Midterm Dilli PDFDocumento8 pagineDSA456 Midterm Dilli PDFnavneetkaur12482Nessuna valutazione finora

- Security Awareness Training AgendaDocumento95 pagineSecurity Awareness Training AgendaChandra RaoNessuna valutazione finora

- SQL Tutorial PDFDocumento43 pagineSQL Tutorial PDFAkki ash100% (1)