Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Effects of Shear Box Size On The Strength For Different Type of Silty Sands in Direct Shear Tests

Caricato da

Javier MtDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Effects of Shear Box Size On The Strength For Different Type of Silty Sands in Direct Shear Tests

Caricato da

Javier MtCopyright:

Formati disponibili

Unsaturated Soils: Theory and Practice 2011 Jotisankasa, Sawangsuriya, Soralump and Mairaing (Editors) Kasetsart University, Thailand,

ISBN 978-616-7522-77-7

Effects of shear box size on the strength for different type of silty sands in directof shear tests Effects shear box size on the strength for different type of silty sands in direct shear tests Reza Ziaie Moayed

Assistant Professor, Department of Civil Engineering, International University of Imam Khomeini, Qazvin, Iran, reza_ziaie_moayed@yahoo.com R.Z. Moayed

Amir Alizadeh Iran, reza_ziaie_moayed@yahoo.com

Assistant Professor, Department of Civil Engineering, International University of Imam Khomeini, Qazvin,

M.Sc. Candidate of Geotechnical Engineering, International University of Imam Khomeini, Qazvin, Iran, A. Alizadeh Amir_Aliizadeh@yahoo.com M.Sc. Candidate of Geotechnical Engineering, International University of Imam Khomeini, Qazvin, Iran, Amir_Aliizadeh@yahoo.com ABSTRACT: Previous researches were done on clean granular soils in order to observe the effects of scale factor on shear strength. In present paper the effect of shear box size on the strength of silty sand soils is studied using direct shear test results. To accomplish this purpose, Firuzkuh standard sand was used which contains angular particle shape. Three different silt percentages (10 %, 20% and 30%) were added into the pure Firuzkuh sand and tests performed on specimens in maximum compaction density and with optimum moisture content. Direct shear tests were performed with two shear box sizes (100 x 100 mm and 60 x 60 mm), in which the normal pressure and displacement rates were constant. Results indicate that the peak shear strength decreases as shear box size increases. Also increasing the silt percentages will cause decrease in the peak shear strength. KEYWORDS: direct shear box; scale factor; angular particle shape; silty sand; peak Shear Strength 1 INTRODUCTION The direct shear tests are widely used in geotechnical engineering in order to evaluate the shear strength characteristics of geomaterials. The popularity of using this simple apparatus is due to soils shear failure modes that relatively represent the condition where the soil in field has. The results adopted from direct shear tests considered to be straightforward. Despite there are some insignificant errors caused by apparatus inherent errors while measuring the applied normal stress and errors made by rigidity condition of top loading platen , or the peak frictional angle mobilized in horizontal shear plane that leads to smaller values than the frictional angle in the plane which contains minor and major principal stresses. The stress and strain conditions become more nonuniform by improper boundary mechanical conditions of the shear boxes, which can have significant effects on the measured strength and dilatancy characteristic (Mikasa, 1960; Jewell and Worth, 1987; Shibuya et al., 1997). Po-kai Wu et al. (2007) showed that specimen size and specimen shape has some effects on the shear zone and shear bands development in the dense Toyoura sand and sandy gravel so that affects properties such as deformation properties, dilatancy, peak shear strength and peak frictional angle. They also suggested using rectangular cross section specimens to more accurately evaluate the direct shear behavior of granular material. Previous studies (Parsons 1936 and Palmeira and Milligan 1989) on few sands in shear boxes with different sizes showed different results. Parsons (1936) tested Ottawa and crushed quartz showed a slight decrease in frictional angle with increasing shear box sizes, but Palmeira and Milligan (1989) tested Leighton Buzzard Sand and results showed no difference in frictional angle with increasing shear box size. Cerato and Lutenegger (2006) tested a range of sands varying densities and angularities, using different size shear boxes to determine the scale effects. They analyzed sand using digital image analysis techniques that treated particles as two-dimensional objects and evaluated the angularity ratio. The test results showed that the friction angles of well-graded angular natural sands and the angular poorly graded manufactured gravel pack, were most affected by specimen size and they suggested to do more testing to confirm the ASTM Standard 3080-90 minimum H/Dmax ratio of 6, because it should revised to increase to ensure the specimen size will not affect friction angle results. In this study with regard to angularity effect factor and in continuation of Ceratos (2006) study , Firuzkuh standard sand with three different silt percentages were tested to determine the effect of silt percentag-

265

es and specimen size on the shear strength of silty sands. 2 PREVIOUS WORKS 2.1 Specimen size effects in direct shear test results Specimen size or scale effects were studied as early as 1936. Parsons (1936) presented test results for crushed quartz and Ottawa uniform sand which showed that larger shear boxes produced lower values of friction angle. Tests were done with very small normal stresses to obtain the failure envelopes (0.015 to 0.1 kg/cm2 or 1.5 to 9.8 kPa) that such low normal stresses in conventional direct shear machines would be unlikely. Results showed that friction angles obtained for the crushed quartz varied from 30.7 to 31.5 (Figure 1) and the uniform sand varied slightly more from 28.5 to 31.0 . Results presented in Table 1.

Table 1. Scale effect of crushed quartz and Ottawa sand (after Parsons 1936) Shear Box Crushed Quartz Ottawa Sand Dimensions Friction Angle Friction Angle L(mm) W Degree Degree (mm) 6060 31.5 31.0 120100 31.1 29.6 120200 30.7 28.5

Table 2. Shear box size effect of dense Leighton Buzzard sand (from Palmeira and Milligan 1989) Dimensions t* Shear (deL (mm) W (mm) H (mm) (mm) Box gree) Small 606032 92 50.1 Medium 252152152 182 50.2 Large 100010001000 10010 49.4 * t = Shear Zone Thickness at Mid-Height

Figure 2. Scale effect on shear zone thickness (after Palmeira and Milligan 1989).

2.2 Specimen size effect on shear zone thickness

Figure 1. Specimen size effect on friction angle of crushed quartz (after Parsons 1936).

Palmeira and Milligans (1989) results of dense Leighton Buzzard Sand tested using three different size shear boxes showed that there was no significant influence of box size on the resulting friction angles (Table 2). They also find that shear zone thickness at the mid-height of sample was significantly affected by the scale factor (Figure2).

The term shear zone means the small layer of sand that is involved in the shearing process and the area where mechanism of localization occurs and this zone consists of many shear bands propagate from the edges of the shear box. Shear zone has been shown that significantly affected by the scale factor of the direct shear test (Palmeira and Milligan 1989). Palmeira and Milligan (1989) used a technique to obtain the shear zone thickness by observing visually through the Perspex wall of shear boxes and by placing thin wires vertically inside the sample. The test results for Leighton Buzzard sand presented in Figure 2 which showed that the shear zone thickness in relation to sample height decreased with increase in the sample size in relation to mean soil particle diameter. Many researchers defined shear zone as a sole function of mean grain size, d50 (Roscoe 1970;

266

Bridgwater 1980; Scarpelli and Wood 1982; Hartley 1982; Mhlhaus and Vardoulakis 1987; DeJong et al. 2003). If this were true, then theoretically, the same sands in different size shear boxes would have the same size shear zone thickness. Roscoe (1970) reported the shear zone thickness in simple shear tests observed about 10d50 and Bridgwater (1980) confirmed it theoretically using a statistical mechanics approach. Scarpelli and Wood (1982) observed using radiographs that the shear zone thickness was not constant along the length of sample and reached the value of 10d50 where the dilation had ceased. Hartley (1982) showed that shear zone thickness is 5 to 10 times the average grain diameter when boundary condition of the test allows the shear zone to develop. Mhlhaus and Vardoulakis (1987) using a Cosserat theorys plasticity analysis determined that shear zone thickness was about sixteen particle diameters. The shear zone thickness increases with increasing angularity and grain size, and it correlates with the strain necessary to obtain the failure (DeJaeger 1994; Kita and Okamura 2000). The mentioned studies on shear zone thickness used similar size shear boxes, which may cause similar values. Palmeira and Milligan (1989) used larger shear boxes and results showed much more values of shear zone thickness. Hight and Leroueil (2003) performed tests on dense Leighton Buzzard Sand in square shear box with different specimen heights in each test. They showed that increase in the specimen height relative to the width, increased the ratio of shear stress to the normal stress. The reason why different values of friction angle obtained in this study may be the height of the specimen that influences the normal stress distribution of the specimen shear plane, caused by the moment of shear force applied to the upper half of the box which is transferred to the specimen. Previous studies showed that it is important to take height of specimen into account to let shear zone form , and it is also important for shear boxes to have adequate length so that shear zone can fully propagate. 3 TEST MATERIALS AND EXPERIMENTAL PROGRAM The sand used in this study is Firuzkuh #161 crushed silica sand. This type of sand has a golden yellow color and has a uniform aggregation, which henceforth briefly named Firuzkuh Sand. Firuzkuh sand has recently been used in studies in laboratory stress-strain tests and studies on cyclic loading and liquefaction behavior in the University of Tehran

and Amirkabir University of Technology (e.g., Ghahremani, M., 2006, Effect of Plastic Fines on Cyclic Resistance of Saturated Sands; Ghalandarzadeh, A., Bahadori, H., 2010, Study of the Cyclic Behavior of Saturated Sand Considering the Effect of Induced Anisotropy) and defined as a standard sand in Iran. Toyoura and Sengenyama standard sands that their characteristics are described in this paper were compared to Firuzkuh sand. Grain size distribution curves of the last two mentioned sands are presented in Figure 3. The curves show that grain size distribution of Firuzkuh sand is more close to Sengenyamas. Physical characteristics of Firuzkuh Sand and the two mentioned standard sands are presented in Table 3.

Figure 3. Grain size distribution curve of Firuzkuh sand compared with the curves of Toyoura and Sengenyama sands.

In order to observe the most effects of specimen size on shear strength properties, it is needed to perform tests on dense and angular sands. For this purpose Firuzkuh Sand with angular particle shape was used. Three different Silt percentages (10%, 20%, and 30%) were added into the pure Firuzkuh sand to observe how the finer percent of silty sands affects the important factor of angularity and its influence on specimen size effects. Specific gravity tests were performed in general accordance with ASTM D 854-92 standard test method for specific gravity of soils. Maximum and minimum index density tests were performed in general accordance with ASTM D 4253-93, standard test method for maximum index density and unit weight of soils using a vibratory table and ASTM D 4254-93, standard test method for Minimum index density and unit weight of soils and calculation of relative density, respectively. Laboratory compaction tests using Modified Proctor test method performed in general accordance with ASTM D 155709, standard

267

Table 3. Firuzkuh Sand physical characteristics and comparing with Toyoura and Sengenyama Sands Sand Type Firuzkuh #161 Toyoura Sengenyama Gs 2.685 2.65 2.72 emax 0.943 0.977 0.911 emin 0.603 0.597 0.55 D50 (mm) 0.27 0.17 0.27 Cu 1.87 Cc 0.88 -

suggested normal stresses for larger shear boxes , therefore it is possible to compare test results of different size shear boxes with similar normal stresses. There are three different shear box types, showed in Figure 4. In this study, the type A was used.

test method for laboratory compaction characteristics of soil using modified effort. Grain-size analyses were performed in general accordance with ASTM D 422-63 Standard Test Method for particle size analysis of soils. Specimens with maximum density and optimum moisture content were prepared by manual tamping using a small hammer. 4 DIRECT SHEAR TESTS Direct shear box tests were performed on each soil in general accordance with ASTM D 3080-90, standard test method for direct shear tests of soils under consolidated drained conditions for three different relative densities. According to ASTM D 3080-90, the direct shear box test has several particle-size to box size requirements when preparing specimens for testing. It is recommended that the minimum specimen width should not be less than ten times the maximum particle-size diameter and the minimum initial spec men thickness should not be less than six times the maximum particle diameter. The minimum specimen width to thickness ratio should be 2 to 1. Jewell and Wroth (1987) suggest a ratio of shear box length to average particle size in the range of 50 to 300. Three different shear box sizes were used in this study (300 x 300 mm, 100 x 100 mm and 60 x 60 mm). The first square shear box had a width of 60 mm and a depth of 24.5 mm (aspect ratio, H/L=0.408). The samples were sheared at a constant rate of 0.9 mm/min, which is consistent with the standard rate for undrained tests on sands. The second square shear box had a width of 100 mm and a depth of 35 mm (aspect ratio, H/L=0.583). In the two first size shear boxes ( 60mm x 60mm , 100mm x 100mm) five tests were performed for each density with five increasing normal stresses (108.9, 163.4, 217.9, 326.85, and 435.8 kPa) using a dead weight system. These applied normal stresses are slightly more than suggested range in the literature due to observe the most scale effects and also provide the

Figure 4. Three types of direct shear boxes currently in use (modified from Figure 4 of Shibuya et al., 1997).

5 TEST RESULTS The peak friction angles for each type of soil at maximum dry density in different size shear boxes were presented in Table 4. In some tests, the failure envelope didnt go through zero because tests were done under unsaturated conditions, so that little amounts of apparent cohesion might occur. This Phenomenon happens in some cohesionless soils, in unsaturated condition that particles bound together by capillary attractive forces. These forces in the water molecules hold wetted soil particles together to form a weak cohesion. Apparent cohesion can also be the result of particle cementation caused by mineralogy or thixotrapic action. Thixotrapy action is the result of previous high stress history. Accordingly the friction angles were computed from peak shear strength. Friction angles may show curvature dependence with relative density over a large range of normal stresses, as is noted is some triaxial compression tests (Baker 2004). In order to use medium to high range of normal stresses, the failure envelope consisted of a curve part in higher stresses. The friction angles were computed by considering the linearity of failure envelopes. There is another method for more accurately computing the friction angles. In this method, the average of hypothetical slope values between each consecutive points of failure envelope is determined as the friction angle.

268

Table 4. Direct shear box test results using the peak shear strength Soil Type Shear Box Sizes (mm) 60 x 60 (deg) 42.46 39.18 35.35 33.27 100 x100 (deg) 38.88 36.06 34.51 32.76 Figure 6. Shear stress versus shear strain for each applied normal stress in silty sand I (tests using 60 x 60 mm shear box).

Pure Sand Silty Sand I (10% Silt) Silty Sand II (20% Silt) Silty Sand III (30% Silt)

The results showed that the friction angles reduced with increasing the shear box size. It is recognized from results that the scale effects on friction angles and these values decreased with increasing shear box size. The reduction rate of friction angle decreased with increasing the silt percentage. Increasing the silt percentages in silty sands can influences the role of angularity as a scale effect factor. The added finer percent of silt may also affect the shear zone propagation. These two effects that mentioned above can decrease the scale effects and specimen size effects. The shear stress data versus shear strain for each applied normal stress , for pure Firuzkuh sand and silty sand I , using 6 x 6 mm shear box , were plotted in Figure 5 and Figure 6 relatively. Similar figures for tests using 100 x 100 mm shear box is also presented in Figure7 and Figure 8. It is observed from these two figures that the peak shear strength was increased with increasing the normal stress.

Figure 7. Shear stress versus shear strain for each applied normal stress in pure Firuzkuh sand (tests using 100 x 100 mm shear box).

Figure 8. Shear stress versus shear strain for each applied normal stress in silty sand I (tests using 100 x 100 mm shear box). Figure 5. Shear stress versus shear strain for each applied normal stress in pure Firuzkuh sand (tests using 60 x 60 mm shear box).

Peak shear strengths for each normal stresses were obtained from direct shear tests using different shear box sizes and results were plotted versus normal stresses values , in Figure 9 and Figure 10 for pure firuzkuh sand and silty sand I , respectively. These

269

two last figures indicated that slope of approximated failure envelope as a linear envelope , was harder for the 6 x 6 mm shear box , In fact the figures showed that the friction angle was affected by scale effect or specimen size effect , and reduced as the shear box size increased for dense pure sands and dense silty sands. The failure envelopes also represents that internal errors , like apparent cohesion, are less in larger shear boxes. It is obvious from Figure 9 and Figure 10 that shear box size had a significant effect on the peak shear strength in silty sands with different silt percentages. The ratios of reduction in the friction angle to the friction angle obtained from 60 x 60 mm shear box tests 60x60 , were plotted versus silt percentages in Figure 11. The Figure 11 showed that the scale effects were observed in both dense pure sands and silty sands , and these effects on the friction angle deacreased with increasing the silt percentage in dense silty sands.

Figure 11. Ratio of reduction in friction angle to the friction angle obtained from 60 x 60 mm shear box tests 60x60, versus silt percentages.

6 CONCLUSION Firuzkuh sand with different silt percentages were tested using different direct shear box sizes to determine the rates of the scale effect in silty sands with different silt percentages. For this purpose and in order to observe the scale effects or specimen size effects on shear strength properties Firuzkuh sand was chosen as the base sand for silty sands with angular particles , and also all specimens prepared in the maximum densities and applied stresses were in the medium to high ranges. From the tests results and their analysis presented above, the following conclusions were derived: Scale effects were observed in the pure Firuzkuh sand and three types of silty sand with different silt percentages. The results showed that peak shear strength decreased as the shear box size increased. The results showed that the friction angles decreased with increasing the shear box size and the reduction rate were reduced by increasing the silt percentages. So the tests indicated that the scale effect can be seen in silty sands but the rate of its effect reduces with increasing the silt percentages. It can also be seen from the test data that larger shear boxes can more accurately determine the shear strength properties of granular soils or cohesionless soils under unsaturated condition. REFERENCES

Figure 9. Failure envelopes for pure Firuzkuh sand with different shear box sizes.

Figure 10. Failure envelopes for silty sand type I with different shear box sizes.

ASTM D3080-98, 1998. Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM International,West Conshochocken, PA. Baker, R. (2004). Nonlinear Mohr Envelopes Based on Triaxial Data, Journal of Geotechnical and Geoenvironmental Engineering, ASCE, Vol. 130, No. 5, pp. 498506. Bridgwater, J. (1980). On the Width of Failure Zones, Geotechnique, Vol. 30, No. 4, pp. 533536. Cerato, A.B. and Lutenegger, A.J. 2006. Specimen Size and Scale Effects of Direct Shear Box Tests of Sands, Geotechnical Testing Journal, Vol. 29, No. 6.

270

DeJaeger, J. (1978). Epaisseur De La Zone Pertubee Par Le Cisaillement. Colloque International RILEM sur les Materiaux Granulaires, Budapest, October, 6-12. pp. 185-196. DeJaeger, J. (1991). Influence de la Morphologie des Sables Sur leur Comportement Mecanique. Ph.D. thesis, Universit Catholique de Louvain, Louvain-la-Neuve. DeJaeger, J. (1994). Influence of Grain Size and Shape on the Dry Sand Shear Behaviour. Proceedings of the 13th International Conference on Soil Mechanics and Foundation Engineering, Vol. 1, pp. 1316. Hartley, S. (1982). Shear Bands in Sand. Part II. Project Report, Department of Engineering, University of Cambridge. Hight, D. W. and Leroueil, S. 2003. Characterisation of Soils for Engineering Purposes. In Proceedings of the International Workshop on Characterisation and Engineering Properties of Natural Soils, Natural Soils 2002, Singapore, 24 December 2002, Vol. 1, pp. 255362. Jewell, R. A. and Wroth, C. P. 1987. Direct Shear Tests on Reinforced Sand, Geotechnique, Vol. 37, No. 1, pp. 5368. Kato, Y., Nakata, Y., Hyodo, M., and Murata, H. 2003. Effect of Particle Characteristics on Drained Shear Properties of Sand. Deformation Characteristics of Geomaterials, Di Benedetto et al., Eds., pp. 707713. Kuo, C. Y. and Freeman, R. B. 2000. Imaging Indices for Quantification of Shape, Angularity, and Surface Texture of Aggregates. Transportation Research Record, Vol. 1721, pp. 5765. Mikasa, M. (1960). New direct shear test apparatus, Proceedings 15th Annual Convention of Japan Society of Civil Engineering, Japanese Geotechnical Society, Tokyo, pp. 45 48 (in Japanese). Mhlhaus, H. B. and Vardoulakis, I. 1987. The thickness of Shear Bands in Granular Materials, Geotechnique, Vol. 37, No. 3, pp.271283. Palmeira, E. M. and Milligan, G. W. E. 1989. Scale Effects in Direct Shear Tests on Sand. Proceedings of the 12th International Conference on Soil Mechanics and Foundation Engineering, Vol. 1, No. 1. pp. 739742. Parsons, J. D. (1936). Progress Report on an Investigation of the Shearing Resistance of Cohesionless Soils. Proceedings of the 1st International Conference on Soil Mechanics and Foundation Engineering, Vol. 2, pp. 133138. Po-Kai Wu, Matsushima, k., and Tatsuoka, F. 2007. Effects of Specimen Size and Some Other Factors on the Strength and Deformation of Granular Soil in Direct Shear Tests, Geotechnical Testing Journal, Vol. 31, No. 1. Roscoe, K. H. (1970). The Influence of Strains in Soil Mechanics - The Tenth Rankine Lecture, Geotechnique, Vol. 20, No. 2, pp.129170. Shibuya, S., Mitachi, T., and Tamate, S. 1997. Interpretations of direct shear box testing of sands as quasi-simple shear, Geotechnique, Vol. 47, No. 4, pp. 769790.

271

Potrebbero piacerti anche

- The Direct Shear Strength and Dilatancyof Sand-Gravel MixturesDocumento27 pagineThe Direct Shear Strength and Dilatancyof Sand-Gravel MixturesPipatpong NookhaoNessuna valutazione finora

- Swelling TestDocumento5 pagineSwelling TestwoimonyetNessuna valutazione finora

- Triaxial Testing of Granular Soil (Colliat-Dangus, 1988)Documento21 pagineTriaxial Testing of Granular Soil (Colliat-Dangus, 1988)Abraham FIgueroa ARevaloNessuna valutazione finora

- SPT-Field Permeability TestDocumento7 pagineSPT-Field Permeability TestkhemankarNessuna valutazione finora

- Column Supported Embankments - AsceDocumento24 pagineColumn Supported Embankments - AsceAnonymous D5s00DdUNessuna valutazione finora

- Roberson 2012 PDFDocumento22 pagineRoberson 2012 PDFAdy NugrahaNessuna valutazione finora

- Hardening SoilDocumento24 pagineHardening SoildiegofernandodiazsepNessuna valutazione finora

- Predicting The Saturated Hydraulic ConductivityDocumento34 paginePredicting The Saturated Hydraulic Conductivitysantiag987100% (2)

- ISRM Point Load IndexDocumento10 pagineISRM Point Load IndexkatherineNessuna valutazione finora

- Duncan Friction Angle of Sand Stone11Documento13 pagineDuncan Friction Angle of Sand Stone11asder02Nessuna valutazione finora

- Coefficient of Consolidation and Its CorDocumento6 pagineCoefficient of Consolidation and Its CorMD Anan MorshedNessuna valutazione finora

- ASTM Code For CU Triaxial Test PDFDocumento13 pagineASTM Code For CU Triaxial Test PDFAhmedHossainNessuna valutazione finora

- Pindan Sand Properties StudyDocumento15 paginePindan Sand Properties Studyganguly147147Nessuna valutazione finora

- Engineering Properties of Soil and RockDocumento87 pagineEngineering Properties of Soil and RockJavier Francisco Gómez Bernal100% (2)

- BS ConsolidationDocumento25 pagineBS ConsolidationKamukwema johnNessuna valutazione finora

- Friction Capacity of SoilDocumento8 pagineFriction Capacity of SoilkushaljpNessuna valutazione finora

- Cavity Expansion Analysis For Interpretation of CPT Data in Layered SoilsDocumento8 pagineCavity Expansion Analysis For Interpretation of CPT Data in Layered SoilsMarcus ViniciusNessuna valutazione finora

- Evaluation of SHANSEP Parameters For Soft Bonneville ClaysDocumento67 pagineEvaluation of SHANSEP Parameters For Soft Bonneville ClaysAmanda Cervantes100% (1)

- Jamiolkowski Et Al (1988)Documento18 pagineJamiolkowski Et Al (1988)Dariusz GuzikNessuna valutazione finora

- Direct Shear TestDocumento2 pagineDirect Shear TestUtkarsh KumarNessuna valutazione finora

- 01 HBSN Pullout Test ProgramDocumento59 pagine01 HBSN Pullout Test ProgramsiavashsaeediNessuna valutazione finora

- 08 - Footings On SandDocumento16 pagine08 - Footings On SandHoshear Bakr100% (1)

- Shear Strength Reduction at Soil Structure InterfaceDocumento10 pagineShear Strength Reduction at Soil Structure InterfaceKasim BaručijaNessuna valutazione finora

- Bearing Capacity and Settlement of Deep Foundations VFinalDocumento57 pagineBearing Capacity and Settlement of Deep Foundations VFinalNazmulNessuna valutazione finora

- Assessment of Empirical Equations For The Compression Index of Fine Grained Soils in MissouriDocumento12 pagineAssessment of Empirical Equations For The Compression Index of Fine Grained Soils in Missouritayour007Nessuna valutazione finora

- Foundation Design and Construction in Hong KongDocumento20 pagineFoundation Design and Construction in Hong KongXet Fat100% (1)

- AttD6 - 225 Roy Geotech ReportDocumento128 pagineAttD6 - 225 Roy Geotech ReportEmerson SilvaNessuna valutazione finora

- BBA Certificate 14-H218 Securegrid HS Geogrid For Basal Reinforcement (BBA, First Issue, Oct 2018)Documento14 pagineBBA Certificate 14-H218 Securegrid HS Geogrid For Basal Reinforcement (BBA, First Issue, Oct 2018)sandycastleNessuna valutazione finora

- Equivalence DPSH (B) and SPT - 2007Documento4 pagineEquivalence DPSH (B) and SPT - 2007eduardomanar1224100% (1)

- Load Transfer Settlement and Stability of Embankments Founded On Columns Installed by Deep Mixing MethodsDocumento35 pagineLoad Transfer Settlement and Stability of Embankments Founded On Columns Installed by Deep Mixing MethodsBeer PhermphornNessuna valutazione finora

- California Bearing Ratio TestDocumento7 pagineCalifornia Bearing Ratio TestBhaskara Rao KatragaddaNessuna valutazione finora

- Pull Out TestDocumento20 paginePull Out TestTareq Al ShyoukhyNessuna valutazione finora

- Coefficient of Compressibility Correlations of Soil and Rock Properties in Geotechnical EngineeringDocumento1 paginaCoefficient of Compressibility Correlations of Soil and Rock Properties in Geotechnical EngineeringTomasz Cz100% (1)

- Mayne 2006 OverView InSitu Singapore ColourDocumento57 pagineMayne 2006 OverView InSitu Singapore ColoursenhuNessuna valutazione finora

- Rock-Engineering Tutorials Solutions BBDDocumento7 pagineRock-Engineering Tutorials Solutions BBDSandip PaudelNessuna valutazione finora

- An Approximate Analysis Procedure For Piled Raft FoundationsDocumento21 pagineAn Approximate Analysis Procedure For Piled Raft FoundationsNicky198100% (1)

- CBR-Index Soil PropertiesDocumento5 pagineCBR-Index Soil PropertiesJagathChandraNessuna valutazione finora

- The New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsDocumento10 pagineThe New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsabualamalNessuna valutazione finora

- Thewes2016 - Clogging EvaluationDocumento7 pagineThewes2016 - Clogging EvaluationMoez SelmiNessuna valutazione finora

- Types of Grouting PDFDocumento24 pagineTypes of Grouting PDFSurender Singh83% (6)

- Method B12 - The Determination of The Effect of Soluble Deleterious Material in Fine Aggregate For Concrete.Documento5 pagineMethod B12 - The Determination of The Effect of Soluble Deleterious Material in Fine Aggregate For Concrete.GUO LEINessuna valutazione finora

- State of Florida Soils Foundations HandbkDocumento180 pagineState of Florida Soils Foundations HandbkPaulCShihNessuna valutazione finora

- Geostatistics in Geotechnical EngineeringDocumento9 pagineGeostatistics in Geotechnical EngineeringParag Jyoti DuttaNessuna valutazione finora

- Foundations On Soft Soils For Khulna MedicalDocumento6 pagineFoundations On Soft Soils For Khulna MedicalJahid Jahidul Islam KhanNessuna valutazione finora

- The Effect of Overconsolidation On The Behaviour of Clays During Shear-HenkelDocumento12 pagineThe Effect of Overconsolidation On The Behaviour of Clays During Shear-HenkelAnonymous GnfGTwNessuna valutazione finora

- Contact PressureDocumento2 pagineContact PressurePrantik Adhar Samanta100% (1)

- 2 - Load Testing of Deep FoundationsDocumento119 pagine2 - Load Testing of Deep FoundationsTalis BattleNessuna valutazione finora

- Cegb3014 Module 3 Slope StabilityDocumento76 pagineCegb3014 Module 3 Slope StabilityMAAbuBakar100% (1)

- Shear Strength of Silt and Clay EmbankmentDocumento319 pagineShear Strength of Silt and Clay EmbankmenttonaalaniNessuna valutazione finora

- Hydrogeology of Bukit Timah GraniteDocumento19 pagineHydrogeology of Bukit Timah Graniteadf500100% (1)

- HS Model PresentationDocumento58 pagineHS Model Presentationgeologist84100% (2)

- Measurement of Hydraulic Conductivity of Saturated Porous Materials Using A Flexible Wall PermeameterDocumento24 pagineMeasurement of Hydraulic Conductivity of Saturated Porous Materials Using A Flexible Wall PermeameterManolo AtarihuanaNessuna valutazione finora

- Moment Load in WallapDocumento3 pagineMoment Load in WallapSajjad AnwarNessuna valutazione finora

- PreviewpdfDocumento51 paginePreviewpdfIrfan WiranataNessuna valutazione finora

- Earth WorkDocumento4 pagineEarth WorkNurali MamenNessuna valutazione finora

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980Da EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980Nessuna valutazione finora

- (2019) Verdugo, R. Seismic Site ClassificationDocumento13 pagine(2019) Verdugo, R. Seismic Site ClassificationJavier MtNessuna valutazione finora

- (1969) Lacoss Et Al. Estimation of Seismic Noise Structure Using ArraysDocumento18 pagine(1969) Lacoss Et Al. Estimation of Seismic Noise Structure Using ArraysJavier MtNessuna valutazione finora

- Surface Wave Benchmarking Exercise: Methodologies, Results and UncertaintiesDocumento8 pagineSurface Wave Benchmarking Exercise: Methodologies, Results and UncertaintiesJavier MtNessuna valutazione finora

- Space and Time Spectra of Stationary Stochastic Waves, With Special Reference To MicrotremorsDocumento42 pagineSpace and Time Spectra of Stationary Stochastic Waves, With Special Reference To MicrotremorsJavier MtNessuna valutazione finora

- Surface-Wave Method For Near-Surface Characterization: A TutorialDocumento21 pagineSurface-Wave Method For Near-Surface Characterization: A TutorialJavier MtNessuna valutazione finora

- Site Effect Evaluation Using Spectral Ratios With Only One StationDocumento15 pagineSite Effect Evaluation Using Spectral Ratios With Only One StationJavier MtNessuna valutazione finora

- Surface Waves FotiDocumento58 pagineSurface Waves FotiJavier MtNessuna valutazione finora

- SPT Analyzer SpecificationsDocumento1 paginaSPT Analyzer SpecificationsJavier MtNessuna valutazione finora

- (2005) Chavez-Garcia F. An Alternative Approach To The SPAC Analysis of Microtremors, Exploiting Stationarity of NoiseDocumento17 pagine(2005) Chavez-Garcia F. An Alternative Approach To The SPAC Analysis of Microtremors, Exploiting Stationarity of NoiseJavier MtNessuna valutazione finora

- (2009) Foti Et Al. Notes On FK Analysis of Surface WavesDocumento12 pagine(2009) Foti Et Al. Notes On FK Analysis of Surface WavesJavier MtNessuna valutazione finora

- Engineering Properties of Expansive Clays PDFDocumento60 pagineEngineering Properties of Expansive Clays PDFJavier MtNessuna valutazione finora

- Eng003 Oral ProjectDocumento1 paginaEng003 Oral ProjectJavier MtNessuna valutazione finora

- Hangers and Supports For Hvac Piping and EquipmentDocumento10 pagineHangers and Supports For Hvac Piping and EquipmentAmeen Mohamed Ali SanadNessuna valutazione finora

- Nonlinear Analysis of RC Beams Based On Moment-Curvature RelationDocumento14 pagineNonlinear Analysis of RC Beams Based On Moment-Curvature RelationSamia ChowdhuryNessuna valutazione finora

- Flange Dimensions PDFDocumento4 pagineFlange Dimensions PDFSRINIVASNessuna valutazione finora

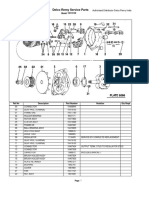

- Delco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaDocumento2 pagineDelco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaWilson AcostaNessuna valutazione finora

- G10 Ch03 Test 2024 01 AnsDocumento2 pagineG10 Ch03 Test 2024 01 AnsmethaethkNessuna valutazione finora

- Company Overview: Leading Global Manufacturer of Pushing, Pulling, Lifting, and Rotating SolutionsDocumento8 pagineCompany Overview: Leading Global Manufacturer of Pushing, Pulling, Lifting, and Rotating Solutionsj24maybe5963Nessuna valutazione finora

- MS008 Steel Tank MSDocumento9 pagineMS008 Steel Tank MSMhando IgnasNessuna valutazione finora

- Old Oil Barrel GeneratorDocumento15 pagineOld Oil Barrel GeneratorAlbert NewhearthNessuna valutazione finora

- PHY Acceleration ProblemsDocumento4 paginePHY Acceleration Problemsminna1208Nessuna valutazione finora

- 10 ASME B31.3 Final Exam ClosedDocumento3 pagine10 ASME B31.3 Final Exam ClosedMichael Albuquerque100% (1)

- Physics FormulasDocumento108 paginePhysics FormulasArsalan Ahmed Usmani100% (3)

- A Review of Flow and Heat TransferDocumento28 pagineA Review of Flow and Heat TransferOssama Bohamd100% (1)

- Tensile Fabric Details 3Documento1 paginaTensile Fabric Details 3FRANKLYN SPENCERNessuna valutazione finora

- 9A03302 ThermodynamicsDocumento4 pagine9A03302 ThermodynamicssivabharathamurthyNessuna valutazione finora

- 77 3001 TypeDDocumento8 pagine77 3001 TypeDSasan AbbasiNessuna valutazione finora

- Metric Outside Diameter Polyethylene (PE) Plastic Pipe (DR-PN)Documento11 pagineMetric Outside Diameter Polyethylene (PE) Plastic Pipe (DR-PN)astewayb_964354182Nessuna valutazione finora

- Fisher GX Globe Valve d103171x012Documento30 pagineFisher GX Globe Valve d103171x012arun_tulsianeyNessuna valutazione finora

- Valvula DesaireadoraDocumento4 pagineValvula DesaireadoracccNessuna valutazione finora

- Hydraulic Circuits Tutorial PDFDocumento40 pagineHydraulic Circuits Tutorial PDFShaheen S. Ratnani69% (13)

- PVT (Hydrocarbon Phase Behaviour)Documento18 paginePVT (Hydrocarbon Phase Behaviour)Oscar Mauricio TellezNessuna valutazione finora

- Nouvelle Brochure BTTDocumento28 pagineNouvelle Brochure BTTskirubananthNessuna valutazione finora

- Cross-Section Properties: GeometryDocumento2 pagineCross-Section Properties: GeometryBENJAMIN AHMETSPAHIĆNessuna valutazione finora

- Boosted Master Cylinder: Service InstructionsDocumento4 pagineBoosted Master Cylinder: Service InstructionsesesNessuna valutazione finora

- Service Bulletin - Water - Pressure - Valve - AssemblyDocumento3 pagineService Bulletin - Water - Pressure - Valve - AssemblylicavitosNessuna valutazione finora

- Scale Up of HSM GranulatorsDocumento15 pagineScale Up of HSM Granulatorshicham1963Nessuna valutazione finora

- Oxygen: 3-Bottle & 4-Bottle Service CartsDocumento52 pagineOxygen: 3-Bottle & 4-Bottle Service CartsJUAN BAEZA PAREDES100% (1)

- OPENSEESDocumento41 pagineOPENSEESJUAN URGILESNessuna valutazione finora

- Fire Sprinkler System GuideDocumento2 pagineFire Sprinkler System GuideMike LojoNessuna valutazione finora

- Astm A139Documento6 pagineAstm A139banglvhNessuna valutazione finora